Deep sea extreme environment simulation system

An extreme environment, simulation system technology, applied in the field of comprehensive research, can solve problems such as poor detection of weak Raman active substances, attenuation of Raman signals, etc., to achieve the effect of improving sensitivity, weakening attenuation, and improving signal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

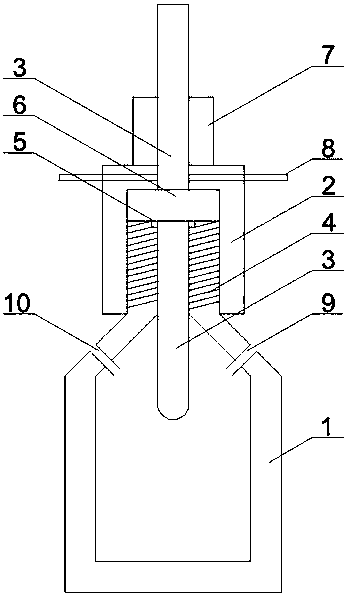

[0040] Such as figure 1 As shown, a Raman reaction chamber includes a cabin body 1, a hatch cover 2 and an immersion Raman probe 3. The cabin body 1 is provided with a sample injection pressurization channel, and the hatch cover 2 is movably connected to the top 4 of the cabin body. The submerged Raman probe 3 is fixed on the top 4 of the cabin by the hatch cover 2, and the front end of the submerged Raman probe 3 goes deep into the cabin 1.

[0041] During the experiment, firstly, the front end of the submerged Raman probe 3 is deep into the cabin body 1, and then the hatch cover 2 is connected to the top 4 of the cabin body, and the submerged Raman probe 3 is fixed on the top 4 of the cabin body by the hatch cover 2 , inject the required liquid sample and gas sample into the cabin body 1 through the sample injection pressurization channel, control the pressure in the cabin body 1 by controlling the amount of the liquid sample and gas sample, complete the simulation of the hi...

Embodiment 2

[0043] Such as figure 1 As shown, a kind of Raman reaction cabin, the same part as embodiment one will not be repeated, the difference is that the hatch cover 2 is screwed to the cabin top 4, and the hatch cover 2 and the cabin top 4 are fixed on the top of the cabin by this structure. Together, the submerged Raman probe 3 is provided with a blocking part 6. In this embodiment, the blocking part 6 is a flange, and the blocking part 6 is arranged between the hatch cover 2 and the top 4 of the cabin body. The submerged Raman probe 3 moves up and down, so that the submerged Raman probe 3 is fixed on the top 4 of the cabin by the hatch cover 2 . Preferably in this embodiment, the top of the hatch cover 2 is provided with a polygonal prism 6 in section, the hatch cover 2 is screwed to the cabin body 1, and the hatch cover 2 and the cabin body 1 can be screwed tighter by the prism 7 when tightening.

Embodiment 3

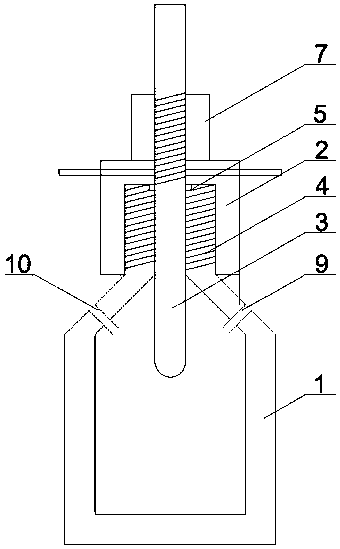

[0045] Such as figure 2 As shown, a kind of Raman reaction cabin, the same part as embodiment one will not be repeated, the difference is that the hatch cover 2 is screwed to the cabin top 4, and the hatch cover 2 and the cabin top 4 are fixed on the top of the cabin by this structure. Together, the immersion Raman probe 3 is screwed to the hatch 2 , so that the immersion Raman probe 3 is fixed on the top 4 of the cabin by the hatch 2 . Preferably in this embodiment, the top of the hatch cover 2 is provided with a polygonal prism 6 in section, the hatch cover 2 is screwed to the cabin body 1, and the hatch cover 2 and the cabin body 1 can be screwed tighter by the prism 7 when tightening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com