Membrane adsorbent for recycling nitrogen and phosphorus resources from waste water as well as preparation method and application thereof

A technology of membrane adsorption and adsorbent, which is applied in the field of membrane adsorbent and its preparation for the recovery of nitrogen and phosphorus resources in wastewater. It can solve the problems of long reaction time, difficult regeneration, and unqualified effluent quality in biological methods, and achieve adsorption and desorption. Effect of good performance, good mechanical and thermal stability, good filtration and adsorption function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

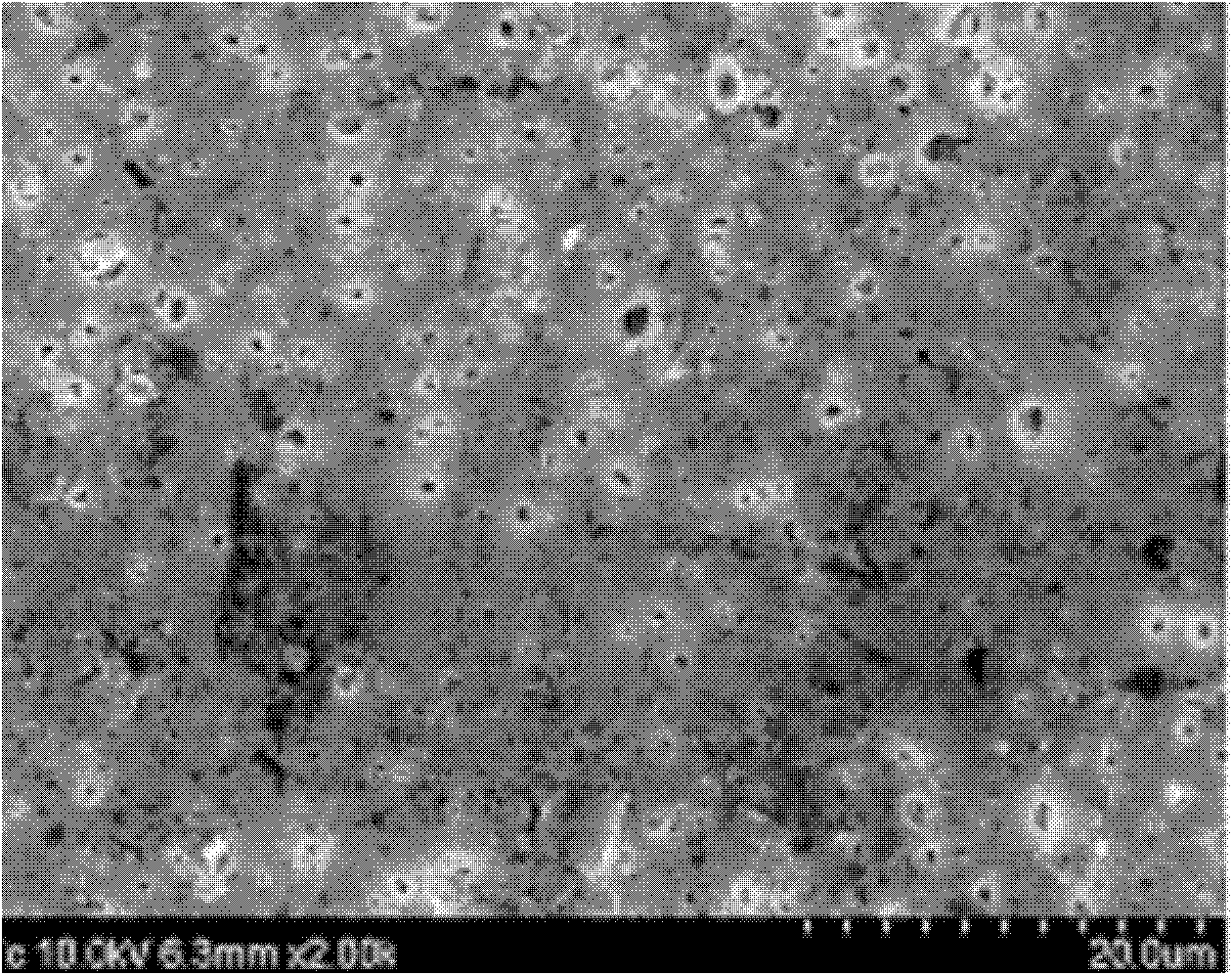

[0031] The formula design of the mass percentage of the membrane adsorbent casting liquid is: 16wt% polyvinylidene fluoride (produced by Sanaifu Company); 11wt% cation exchange resin powder [Polylite Co., Ltd., model MN500] (polyvinylidene fluoride / resin= 59 / 41), the average particle size is 31.78μm; 16wt% polyethylene glycol; 2wt% polyvinylpyrrolidone and 55wt% N,N dimethylacetamide.

[0032] The process of making membrane adsorbent is as follows: first add 5.5g resin to 27.5g DMAc and stir, after the dispersion is uniform, add 8g PEG and 1g PVP, add 8g polyvinylidene fluoride several times after the solid is completely dissolved to ensure that the ion exchange resin is in The polymer is evenly dispersed. After adding PES, the solution is stirred at 40~50℃ for 4~12 hours; after the dissolution and dispersion are complete, let it stand for 24 hours to degas and prepare it into a casting liquid; artificially place the casting liquid on the glass After scraping the plate into a fla...

Embodiment 2

[0034] The formula design of the mass percentage of the membrane adsorbent casting solution is: 16wt% polyethersulfone [produced by BASF]; 16wt% cation exchange resin powder [Polylite Co., Ltd., model MN500] (polyethersulfone / resin=50 / 50), The average particle size is 20μm; 16wt% polyethylene glycol; 2wt% polyvinylpyrrolidone and 50wt% N,N dimethylacetamide.

[0035] The process of making membrane adsorbent is as follows: first add 8g resin into 24gDMAc and stir, after the dispersion is uniform, add 8gPEG and 1gPVP, add 8g PES several times after the solid is completely dissolved to ensure that the ion exchange resin is dispersed in the polymer Evenly, after adding PES, stir the solution at 40~50℃ for 4~12 hours; after dissolving and dispersing completely, let stand and degas for 24 hours to prepare casting liquid; manually scrape the casting liquid on the glass plate to make the thickness After the flat membrane is 0.20~0.30mm, it is solidified and formed at 20~30°C; then the re...

Embodiment 3

[0037] The formula design of the total mass percentage of the membrane adsorbent casting solution is: 16wt% polyethersulfone [produced by BASF]; 24wt% cation exchange resin powder [Polylite Co., Ltd., model MN500] (polyethersulfone / resin=40 / 60) , The average particle size is 31.78μm; 16wt% polyethylene glycol; 2wt% polyvinylpyrrolidone and 42wt% N, N dimethylacetamide.

[0038] The process of making membrane adsorbent is as follows: first add 12g resin into 21gDMAc and stir, after the dispersion is uniform, add 8gPEG and 1gPVP, add 8g PES several times after the solid is completely dissolved, to ensure that the ion exchange resin is dispersed in the polymer Evenly, after adding PES, stir the solution at 40~50℃ for 4~12 hours; after dissolving and dispersing completely, let stand and degas for 24 hours to prepare casting liquid; manually scrape the casting liquid on the glass plate to make it The flat membrane with a thickness of 0.20~0.30mm is cured and formed in a water coagulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com