Preparation of magnetic biomass charcoal and adsorption of magnetic biomass charcoal to dye

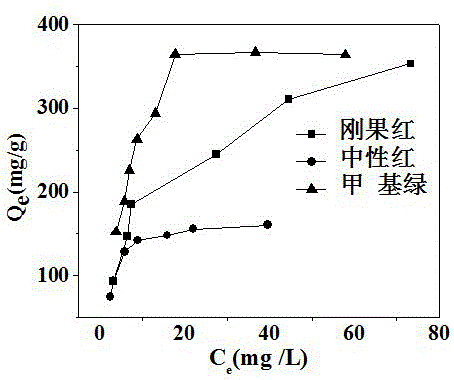

A biomass and magnetic technology, applied in the direction of adsorption of water/sewage treatment, water pollutants, alkali metal compounds, etc., can solve the problems of easy agglomeration of magnetic nanoparticles, and achieve strong surface adsorption, good superparamagnetism, good The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

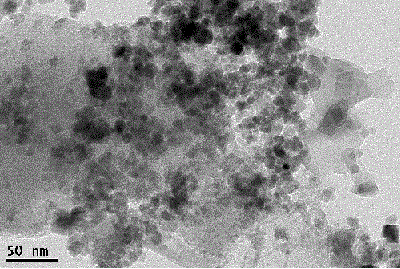

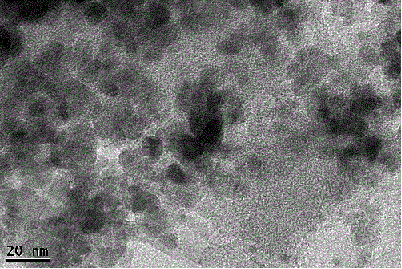

[0018] The preparation method of magnetic biomass charcoal composite material can be divided into two steps in detail: First, the preparation of biomass charcoal. The fallen leaves of Fallon were washed with distilled water and dried at 50°C. The fallen leaves are ground and screened with 60 mesh molecular sieves. Place the leaf powder in an alumina porcelain boat and put it in a tube furnace. Under argon, the temperature is increased to 800°C at a rate of 5°C per minute and kept at this temperature for 5 hours. Finally, it is naturally cooled to room temperature to obtain activated carbon powder. .

[0019] 2. Preparation of magnetic biomass charcoal. Take activated carbon (0.9g), anhydrous FeCl 3 (0.972g) and anhydrous CH 3 COONa (1.5g) in 60mL diethylene glycol, and the mixture was heated under magnetic stirring until completely mixed. Then, the solution was transferred to a polytetrafluoroethylene autoclave and kept at 200°C for 24 hours. After cooling to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com