Patents

Literature

144results about How to "Strong surface adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

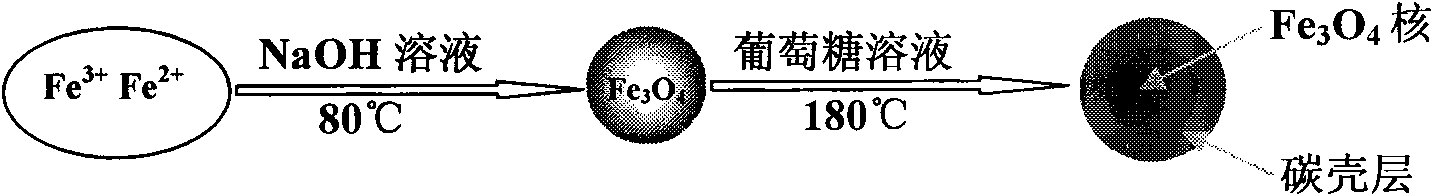

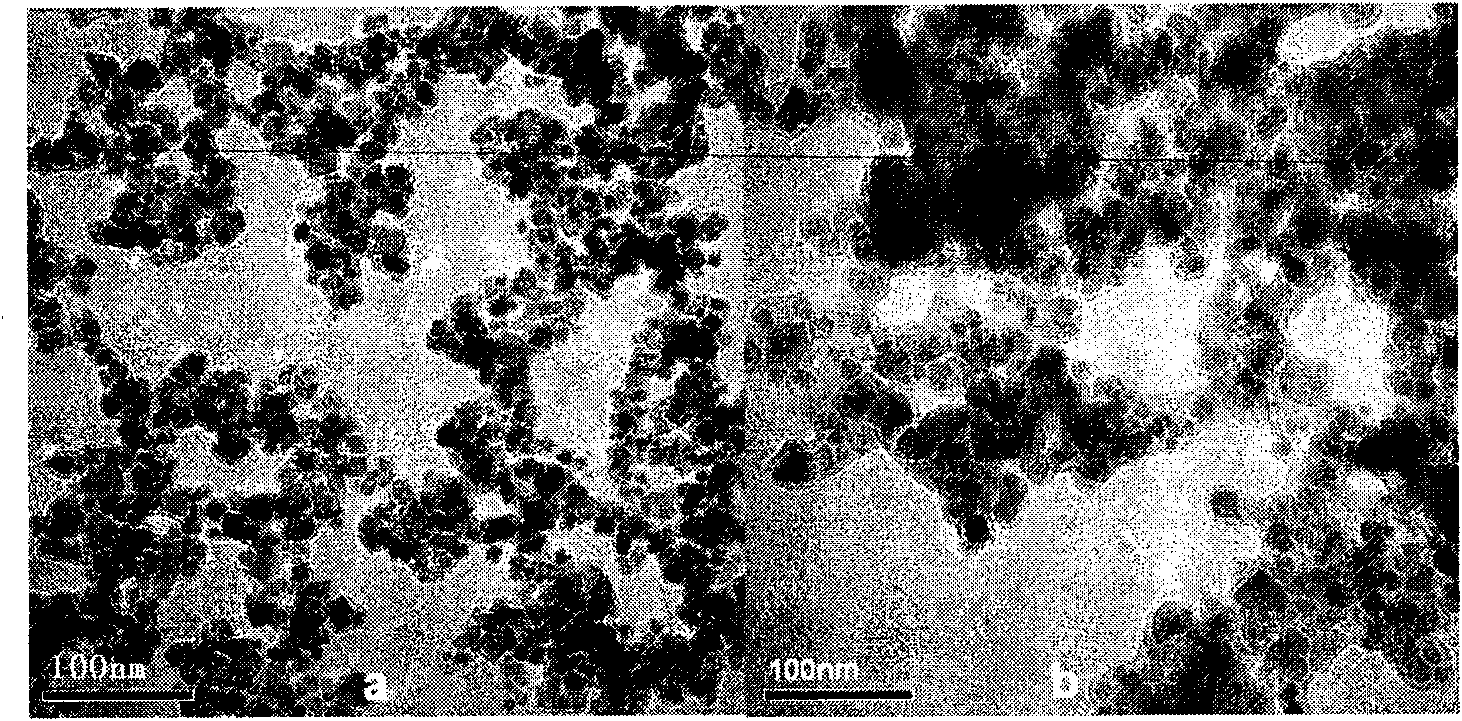

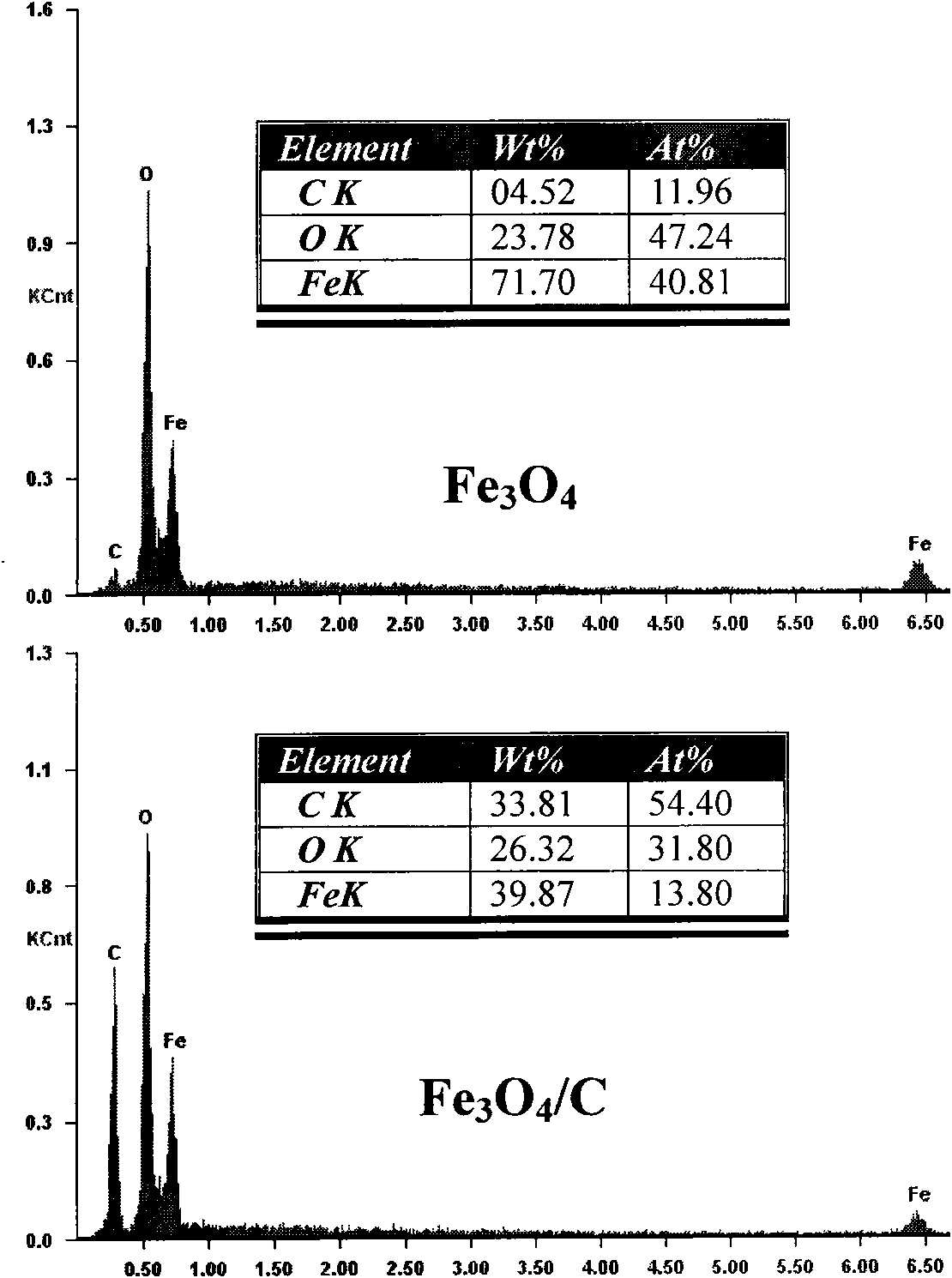

Preparation method and application of core-shell type Fe3O4/C magnetic nano solid extracting agent

InactiveCN101664668AStrong extraction abilityFast processingOther chemical processesInorganic material magnetismSolid phase extractionSorbent

The invention relates to a Fe3O4 / C magnetic nano solid extracting agent coated with a novel carbon material, belonging to the field of chemical analysis and test instruments and equipment. The extracting agent simultaneously has large special surface area of nano material, short disperse path, magnetic separation capacity of magnetic material and strong adsorption capacity of carbon material, thereby being very suitable for pretreating large-scale and large-size water samples in batch. In addition, the solid extracting agent is simple to prepare, low in raw material cost, rapid and convenientto extract and friendly to the environment and only needs using a small amount of organic solvent in the whole process.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Organic silicon lubricating grease and preparation method thereof

ActiveCN101870905AImprove the lubrication effectNo dielectric constantThickenersAdditivesBase oilThermal stability

The invention relates to the technical field of lubricating grease, in particular to organic silicon lubricating grease and a preparation method thereof. The organic silicon lubricating grease comprises the following components in percentage by mass: 10 to 80 percent of base oil, 1 to 30 percent of modifier and 5 to 25 percent of thickening agent. The organic silicon lubricating grease has the advantages of wide application range, excellent dielectric property, insulating property, sealing property, thermal stability, shockproof property and lubricating property, and obvious improvement on lubricating property and thermal stability particularly.

Owner:东莞太平洋博高润滑油有限公司

Multipurpose polyester film and preparation method thereof

The invention relates to a multipurpose polyester film and a preparation method thereof. The preparation method adopts a biaxial orientation technique and comprises the following steps: 1. preparation of functional assistants; 2. precrystallization and drying; 3. melt extrusion: the precrystallized and dried PET (polyethylene terephthalate) slices and the functional assistants are heated and molten by an extruder, and the melt is uniformly delivered to a die head for slab casting under the push of extrusion pressure; 4. slab casting: the uniform and stable melt from the extrusion system runs on rotating quenching rollers through the die head to form an amorphous slab; 5. longitudinal stretching and lateral stretching: the cast slab is subjected to longitudinal stretching after entering a longitudinal stretching machine, and subjected to lateral stretching after entering a lateral stretching machine; and 7. pulling, slicing, corona treatment, rolling and inspection. The method has wide application range, such as environment-friendly films, twist wrap films, high-brightness films, insulation films, capacitive films, car protecting films, bronzing films, aluminizing films and composite packaging films.

Owner:福建百宏高新材料实业有限公司

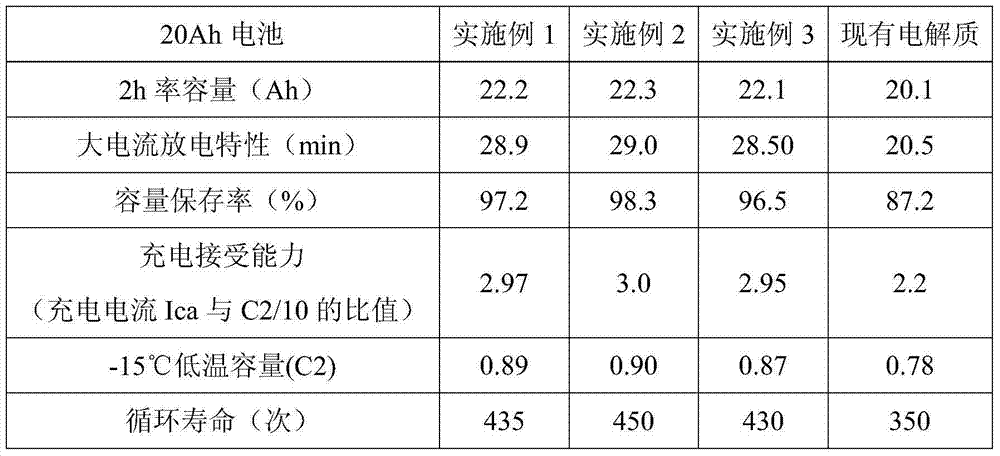

Colloid power battery internal formation electrolyte and preparation method thereof

InactiveCN103500846AImprove stabilityGood thickening effectSecondary cellsPower batteryInternal resistance

The invention discloses colloid power battery internal formation electrolyte which belongs to the field of batteries. The electrolyte consists of the following components in parts by weight: 1-20 parts of nano silicon dioxide, 0.1-5 parts of polypropylene, 40-50 parts of dilute sulphuric acid, 40-55 parts of deionized water, 1-5 parts of stannous mono-sulphate and 1-5 parts of sodium sulfate. The electrolyte solves the problems of low thixotropy, high heat resistance and high electrical resistance of colloid electrolyte made from general silica sol. A storage battery filled with the electrolyte disclosed by the invention is high in stability and thixotropy, low in internal resistance, low in self-discharge, high in charging acceptance capacity and high in low-temperature tolerance; the capacity of the battery is improved, and the cycle life of the battery is prolonged.

Owner:无锡华燕新电源有限公司

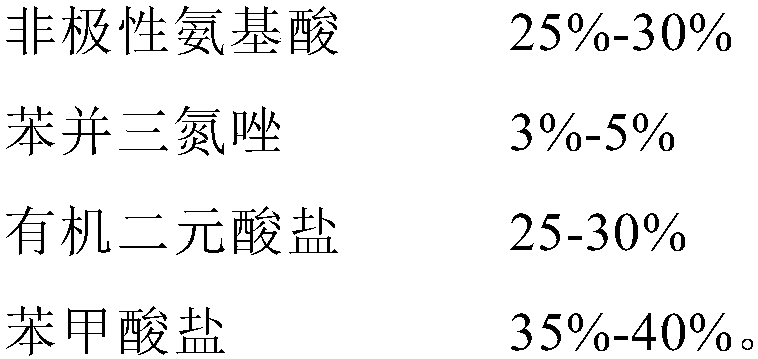

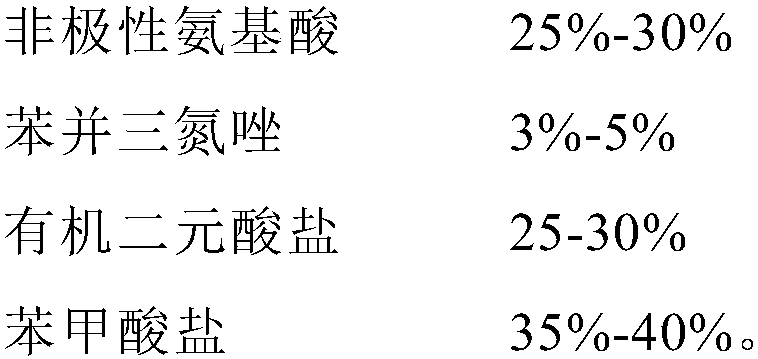

Compound gaseous-phase rust inhibitor as well as preparation method and application thereof

The invention relates to a compound gaseous-phase rust inhibitor as well as a preparation method and application thereof. The compound gaseous-phase rust inhibitor comprises the following components in percentage by mass: 25%-30% of nonpolar amino acid, 3%-5% of benzotriazole, 25%-30% of organic diacid salt and 35%-40% of benzoate. A plastic masterbatch containing the compound gaseous-phase rust inhibitor comprises the following components in percentage by mass: 30-40% of compound rust inhibitor, 50-60% of carrier plastics and 10-20% of adjuvant. Compared with the prior art, the compound gaseous-phase rust inhibitor has the advantages that nonpolar amino acid is selected by regulating and controlling the polarity of an amino acid molecule, and the compatibility of an amino acid rust inhibitor and a plastic film is improved by utilizing the good corrosion resistance of an amino acid compound, taking fumed silica as a dispersion carrier and utilizing the characteristics of the large specific surface area, strong surface adsorbability and good dispersibility of fumed silica, so that the rust inhibiting capacity of a volatile rust-inhibiting plastic film is improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Preparation method of rice starch nano-sized crystals

The invention relates to a preparation method of rice starch nano-sized crystals. The preparation method includes: using rice as the raw material, grinding the rice into powder, compositely treating with alkali and alkaline protease to prepare rice starch, and combining super-high-pressure homogenizing and sulfuric digestion to prepare the rich starch into the rice starch nano-sized crystals. The rice starch nano-sized crystals prepared by the method have the advantages that the average particle size of the rice starch nano-sized crystals is smaller than 150 nanometers, and the rice starch nano-sized crystals can be easily biodegraded and are environmental friendly; the rice starch nano-sized crystals are high in surface absorption force and good in dispersity, solubility and enzymolysis performance; the rice starch nano-sized crystals are cream-like soft and smooth in texture, quite easy to digest and absorb, fine and smooth in taste, low in calorie and the like, and the rice starch nano-sized crystals can be used as fat substitutes, food seasoning, the sugar coating of candy and the excipient of tablets. The preparation method is simple in in process and low in cost. The rice starch nano-sized crystals can also be used as nano medicine carriers through biological modification and are quite wide in application range.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

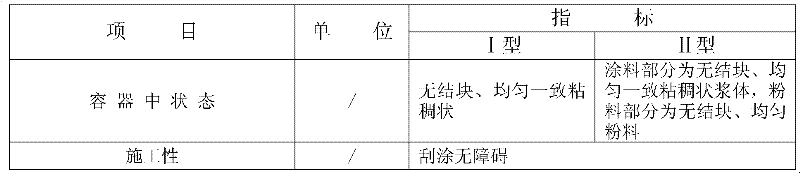

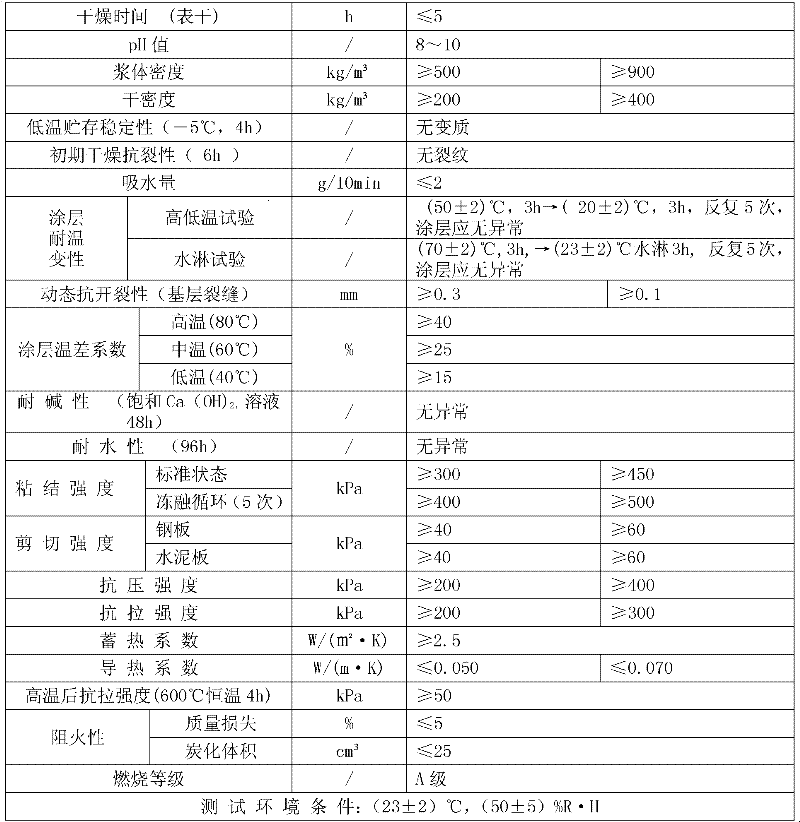

High-performance microscopic microfiber building heat insulation and heat preservation slurry and using method thereof

ActiveCN102531465AReduce volumeLow thermal conductivityClimate change adaptationHeat proofingSlurrySilicon dioxide

The invention provides high-performance microscopic microfiber building heat insulation and heat preservation slurry with high tensile strength, compressive strength, heat insulation performance and tear resistance, and a using method thereof. The slurry comprises the following components of crylic synthetic resin, fluorinated silicone synthetic resin, a water retention thickening agent solution,a sepiolite fiber, a vermiculite fiber, a mullite fiber, powdered silicon dioxide, pearlife, a rock wool fiber, hollow ceramic microballs, a defoaming agent, a mildewproof bacteriacide and water; andfurthermore, white portland cement, a reinforcing agent and water which is 20 to 30 weight percent of a component A can be added.

Owner:FUJIAN OUNUOCHUANGNENG NEW MATERIAL TECH CO LTD

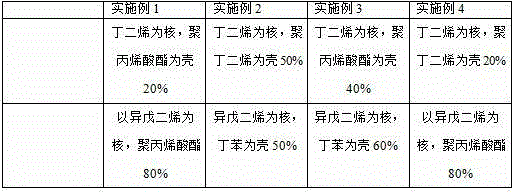

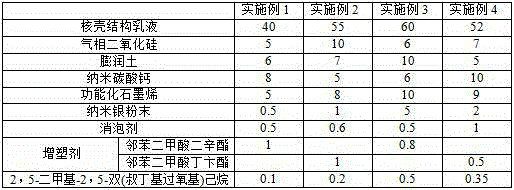

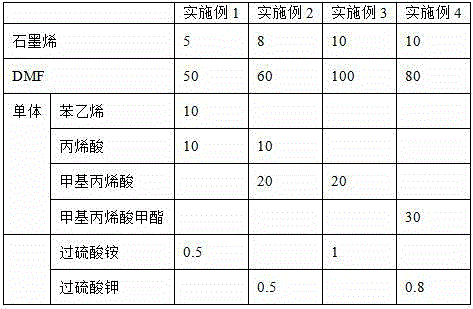

Automotive functionalized graphene damping slurry and preparation method thereof

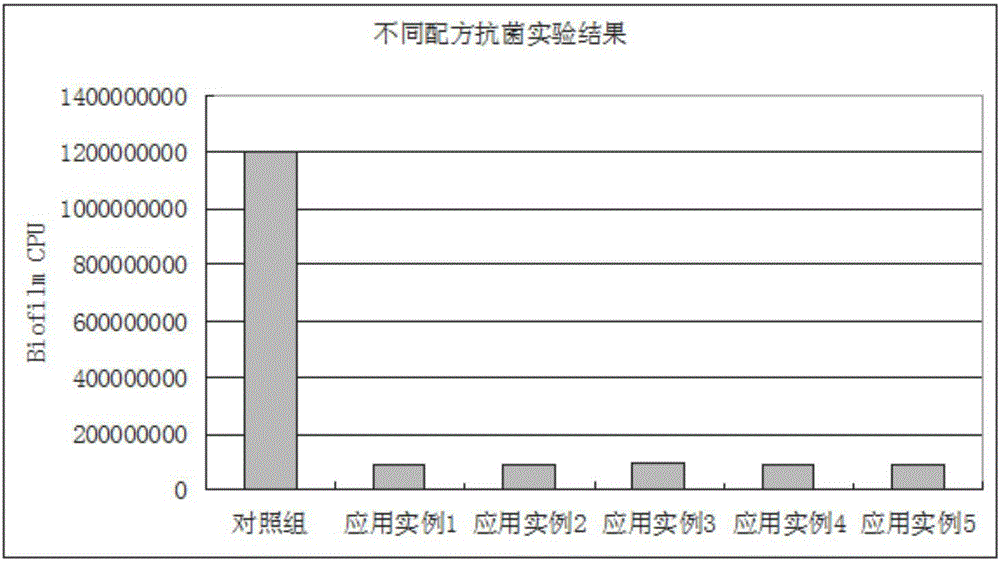

ActiveCN104910748ALarge specific surface areaStrong surface adsorptionAntifouling/underwater paintsPaints with biocidesSolubilityCross-link

The invention relates to a preparation method of an automotive damping material and mainly relates to a high-performance damping slurry filled withe functionalized graphene and a preparation method of the high-performance damping slurry. The preparation method comprises the steps of sieving bentone, fumed silica, nano calcium carbonate, functionalized graphene, nano-silver powder by use of a sieve of 100-200 meshes, blending a core-shell emulsion, a defoamer, a plasticizer and a cross-linking agent, stirring evenly, adding the sieved powder to the blended emulsion, mixing by virtue of mechanical stirring at a normal temperature and a stirring speed within the range of 100-200r / min, and adding deionized water for regulating the thickness to the range of 8-10. The functionalized graphene has excellent solubility with a polymer matrix; due to frictional loss between the functionalized graphene and the polymer matrix due to interfacial slippage, the energy can be effectively dissipated, and the noise pollution in a vehicle can be effectively reduced; meanwhile, the silver nanomaterial is taken as an antimycotic assistant, and has an excellent antimycotic effect.

Owner:常州祥锐碳素科技有限公司 +1

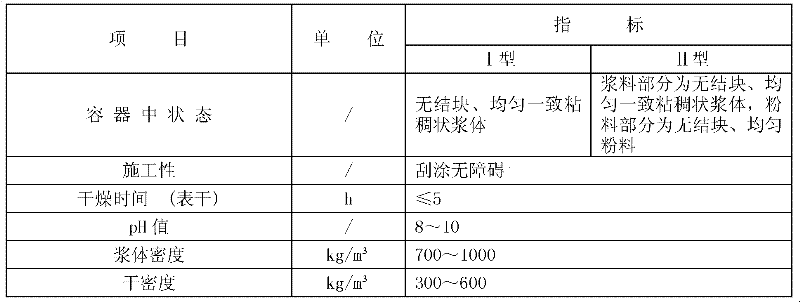

Waterproof cement-based coating and preparation method thereof

InactiveCN106348675ALarge specific surface areaStrong surface adsorptionFunctional monomerWater reducer

The invention discloses a waterproof cement-based coating and a preparation method thereof. The waterproof cement-based coating comprises a component A of super hydrophobic materials, a component B of emulsion and a component C of inorganic powder; the component A of the super hydrophobic materials prepared with a sol-gel method from, by weight, 35-50 parts of graphene, 2.5-6 parts of ethyl silicate, 5-12 parts of a silane coupling agent, 55-75 parts of absolute ethyl alcohol, 0.8-2 parts of ammonium hydroxide and 8-15 parts of deionized water; the component B of the emulsion is prepared from, by weight, 35-55 parts of hard monomers, 35-55 parts of soft monomers, 2-5 parts of functional monomers, 2-10 parts of super hydrophobic materials, 1-5 parts of a coalescing agent, 1-5 parts of plasticizer, 0.8-1.5 parts of emulgator, 0.5-1 part of a dispersing agent, 0.5-1 part of corrosion remover, 0.05-1 part of defoamer and 0.05-1 part of an initiating agent; the component C of the inorganic powder is prepared from, by weight, 25-45 parts of ordinary portland cement, 25-45 parts of portland fly-as cement, 20-30 parts of 200-mesh silica sand, 15-10 parts of a carbon nano tube and 0.-1 part of water reducer. During preparation, the obtained super hydrophobic materials are added in emulsion polymerization, so that stability of better bonding strength, waterproofness, impact resistance and the like of the coating is achieved.

Owner:山东天汇防水股份有限公司

High-performance de-foaming agent and preparation method thereof

ActiveCN103657161AHas defoaming effectSmall particle sizeFoam dispersion/preventionPolyesterCoating system

Owner:张锦碧

Nanometer lubricant for drilling fluid and preparation method of nanometer lubricant

InactiveCN108753269AGood dispersionLarge specific surface areaMaterial nanotechnologyDrilling compositionWater in oil emulsionSURFACTANT BLEND

The invention discloses a nanometer lubricant for a drilling fluid and a preparation method of the nanometer lubricant in the petroleum industry. The lubricant is added to the drilling fluid to improve the lubricity of the drilling fluid, and then the friction and the torque in the drilling process are reduced. The nanometer lubricant for the drilling fluid comprises linear alpha-olefin, nanosilicon dioxide, sulfide fatty acid ester, a surfactant and water, the preparation method comprises putting the linear alpha-olefin into a stirring kettle, controlling the temperature of the kettle to 25-30 DEG C, then proportionally adding the surfactant, stirring for 4 hours, proportionally adding the nanosilicon dioxide, stirring for 2 hours, then proportionally adding the sulfide fatty acid ester,stirring for 2 hours, proportionally adding water, controlling the water addition speed to be lower than or equal to 2 m<3> / h, and continuously stirring for 4 hours until an even water-in-oil emulsionis formed, wherein the water-in-oil emulsion is the nanometer lubricant for the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

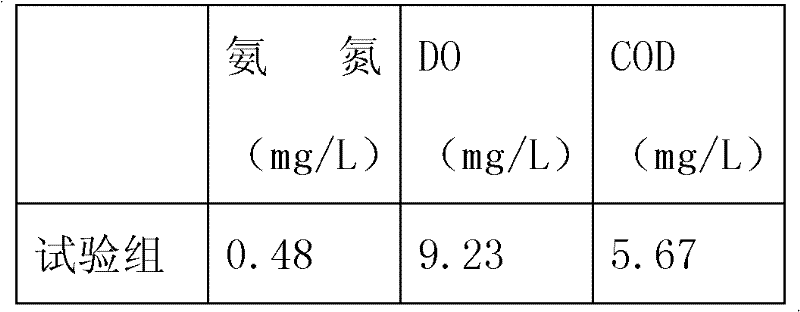

Controlled release microecological preparation for water quality improvement and preparation method thereof

ActiveCN102311935AImprove adsorption capacityImprove protectionFungiBacteriaBiotechnologyWater quality

The invention which discloses a controlled release microecological preparation for water quality improvement and a preparation method thereof belongs to the biotechnological field, and concretely relates to the preparation method of the controlled release microecological preparation for water quality improvement. The microecological preparation treats bacillus subtilis as a main flora and Bacillus cereus, lactics, and microzyme as auxiliary floras. By adopting the composite microbial preparation to process water, organic mud can be effectively degraded, harmful substances of ammonia, nitrites, hydrogen sulfide and the like in water can be absorbed and utilized, the breeding of harmful microbes and harmful algae can be inhibited, the microecological environment of water can be balanced, and the health growth of aquatic organisms can be promoted, so the microecological preparation of the present invention is more economical and is more suitable for popularization than common microecological preparations.

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

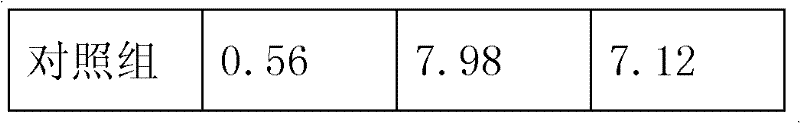

Preparation method of low-temperature-resistant TPU hot melt adhesive membrane

InactiveCN107760246ALarge specific surface areaStrong surface adsorptionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesRosinHot-melt adhesive

The invention relates to the technical field of high molecular adhesives and particularly relates to a preparation method of a low-temperature-resistant TPU hot melt adhesive membrane. The preparationmethod comprises the following steps: modifying rosin to obtain modified rosin; reacting with other raw materials to prepare polyurethane; and adding an additive to react to obtain the low-temperature-resistant TPU hot melt adhesive membrane. According to the preparation method provided by the invention, the surface adsorption capacity of fumed silica is strong, and polyurethane at the low temperature is accumulated on the surface of the fumed silica and is hardly oriented to be orderly arranged and crystallized, so that the low-temperature crystallization of the low-temperature-resistant TPUhot melt adhesive membrane is reduced; low-temperature-resistant TPU hot melt adhesive membrane and rosin react to obtain maleated rosin which has the characteristics of being relatively high in softening point, acid value and the like; the maleated rosin reacts with glycerinum to generate modified rosin resin, so that the softening point thereof is increased, and the stability thereof is improved; at the low temperature, the TPU hot melt adhesive membrane keeps viscoelasticity, so that a purpose of keeping high adhesive property at the low temperature is reduced, and the low-temperature-resistant TPU hot melt adhesive membrane is wide in application prospect.

Owner:徐冬

Glass curtain wall energy-saving paint and preparation method thereof

InactiveCN107099213ALower heat transfer coefficientReduce pollutionAntifouling/underwater paintsPaints with biocidesEpoxyThermal insulation

The invention discloses glass curtain wall energy-saving paint and a preparation method thereof, and relates-the technical field of energy-saving materials, the glass curtain wall energy-saving paint includes the following raw materials: 65-75 parts of modified waterborne epoxy resin, 45-55 parts of a thermal insulation filler, 20-25 parts of antibacterial powder, 20-23 parts of an ultraviolet absorbent, 15-17 parts of nano titanium dioxide, 10-15 parts of an additive and 70-80 parts of water. The glass curtain wall energy-saving paint has the advantages of coating uniformity, strong adhesion, good weatherability and good insulating performance, can effectively reduce the glass heat transfer coefficient, and is heat and ultraviolet radiation-blocking, thereby reducing energy consumption and light pollution to play an indoor and outdoor energy-saving role.

Owner:合肥市旺友门窗有限公司

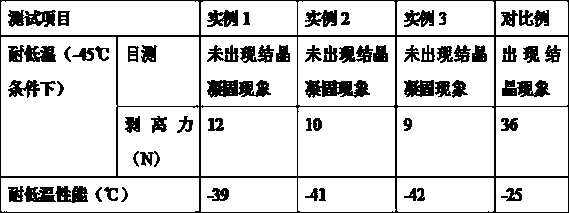

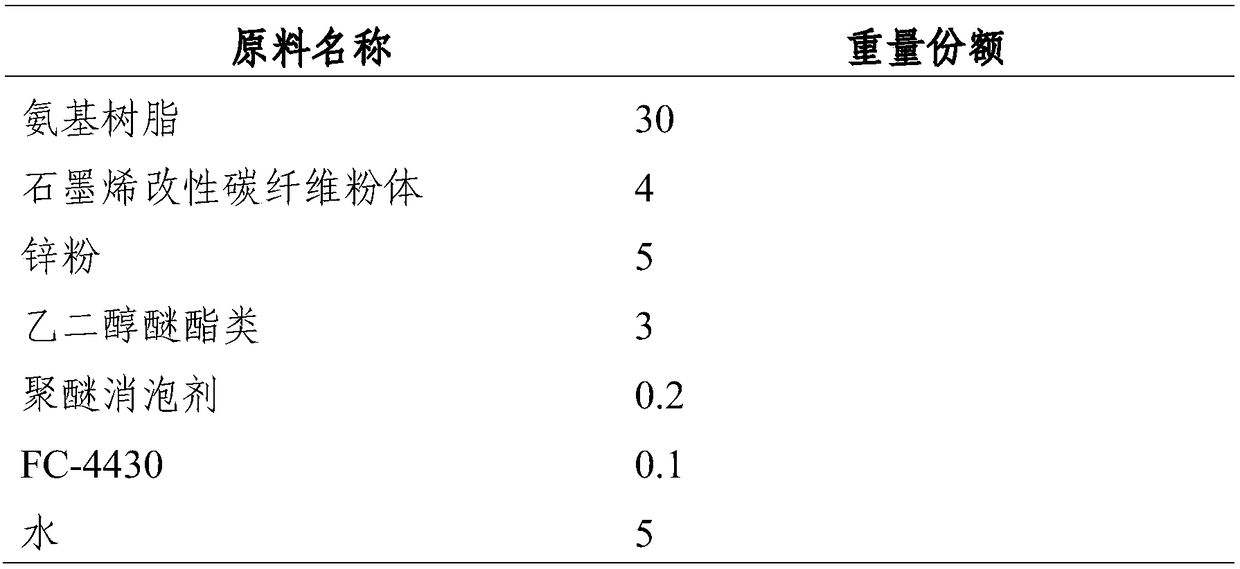

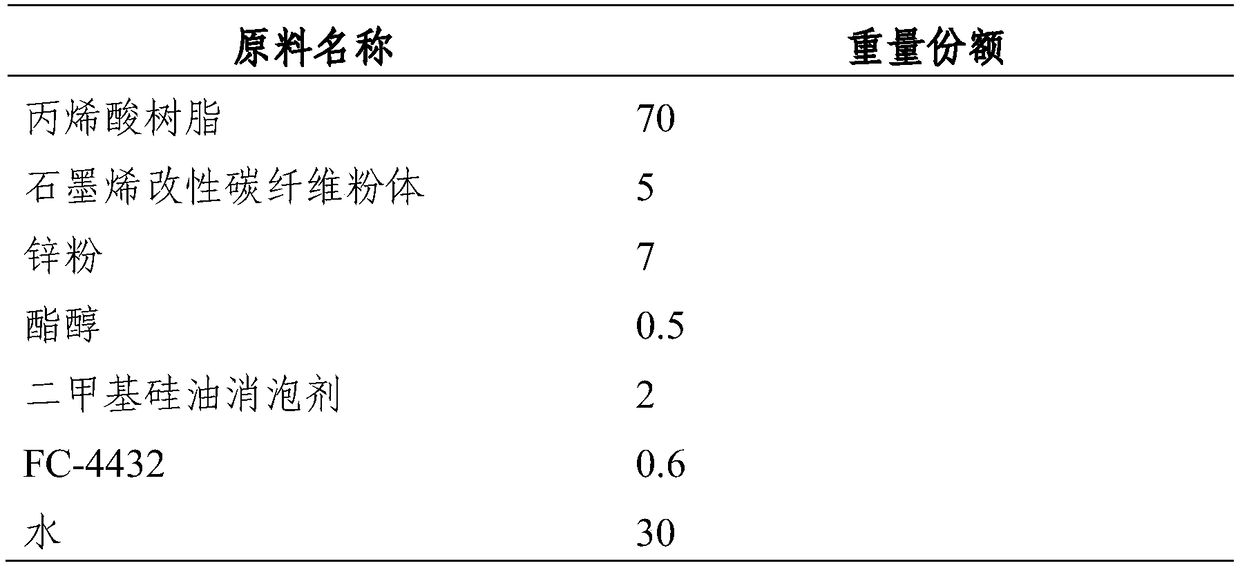

Graphene antiseptic coating and preparation method thereof

InactiveCN109294388AImprove anti-corrosion performanceNo pollution in the processAnti-corrosive paintsEpoxy resin coatingsCarbon fibersModified carbon

The invention discloses a graphene antiseptic coating. Raw materials of the graphene antiseptic coating comprises, in parts by weight, 30-70 parts of resin, 3-5 parts of graphene-modified carbon fiberpowder, 5-10 parts of zinc powder, 0.5-3 parts of a film-forming accelerator, 0.2-2 parts of a defoaming agent, 0.1-1 part of an auxiliary agent and 5-30 parts of water. Through the coating, the phenomenons of easily uneven dispersion and easy agglomeration caused by direct addition of graphene to the coating can be improved effectively, and meanwhile the corrosion resistance of the coating, theadhesion of the coating and the impact resistance and flexibility of the coating can be improved; and a preparation method of the graphene antiseptic coating has simple operation and easy industrialization.

Owner:无锡泰科纳米新材料有限公司

Autoclaved aerated concrete plate and molding process thereof

The invention discloses an autoclaved aerated concrete plate and a molding process thereof which are applied to the field of building materials and are used for solving the technical problem of use limitation caused by rough surface of a high-strength granite concrete plate in the prior art. The technical scheme has the key points that the autoclaved aerated concrete plate comprises the followingcomponents in parts by weight: 100-110 parts of cement, 125-140 parts of quick lime, 600-610 parts of coal ash, 6-10 parts of aerated aluminum paste, 200-230 parts of expanded perlites and 30-40 partsof powder filler. The expanded perlites and the powder filler are added into the cement, the quick lime, the coal ash and the aerated aluminum paste, and self-gaps of the expanded perlites and gaps between the adjacent expanded perlites can be filled with the powder filler, so that the autoclaved aerated concrete plate which is uniform in texture and smooth in surface can be favorably prepared, and the use range of the plate is remarkably widened.

Owner:南京兴陶预制品有限责任公司

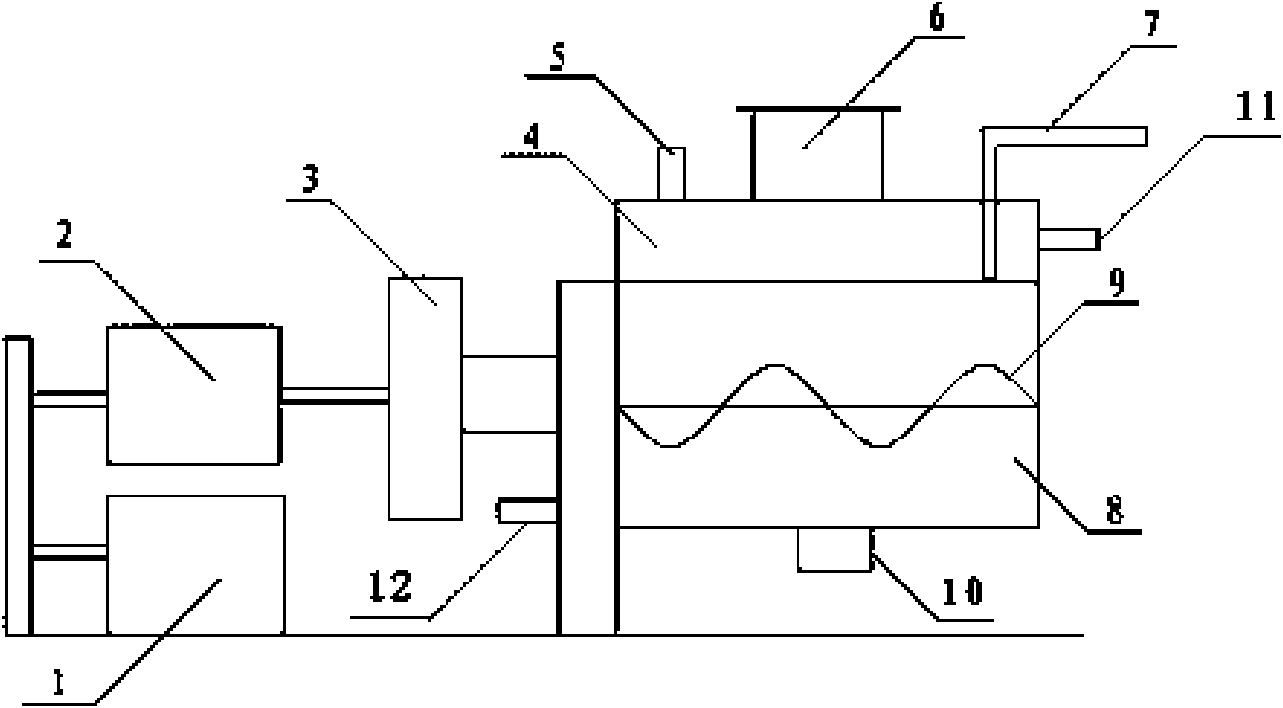

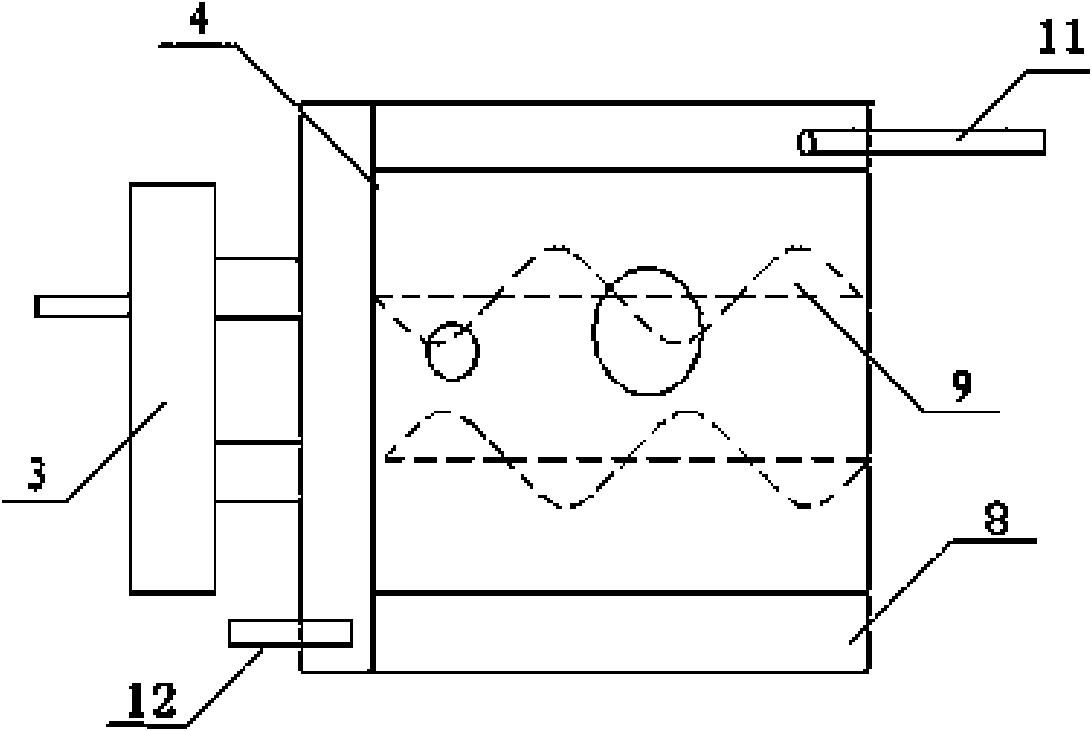

Technique for producing zinc stearate by dry method and device

ActiveCN101607883ASpecial requirements for bactericidal effectPrecipitation particles are smallChemical/physical/physico-chemical stationary reactorsCarboxylic acid salt preparationZinc compoundsWastewater

The invention discloses a technique for producing zinc stearate by a dry method. The technique comprises the following steps of: adding stearate, zinc compound and water in a mass ratio of 82 to 88%:10 to 15%:2 to 5% into a reactor, stirring and reacting for 1 to 5 hours at temperature of 50 to 150 DEG C and pressure of 0 to 0.10 MPa, and then obtaining the zinc stearate. The reaction device is characterized in that a motor (1) is connected with a speed reducer (2) which is connected with a gear transmission (3); the gear transmission (3) is connected with a stirrer (9) arranged in a reaction container (4); and a temperature measuring port (5) and a feeding port (6) are arranged above the reaction container (4) which is externally provided with a clamping sleeve (8), and a discharging port (10) is arranged below the reaction container (4). The invention has simple technique, little equipment investment, short production period, no wastewater discharging, high efficiency and low cost; and compared with a melting method, the technique has lower reaction temperature, low energy consumption and good whiteness and the obtained rough product after the reaction is ended is more loose and easy to be crushed.

Owner:HUZHOU CITY LINGHU XINWANG CHEM CO LTD

Super hydrophobic JS waterproof coating and preparing method thereof

InactiveCN106278041AUniform and good waterproof performanceEvenly distributedFunctional monomerWater reducer

The invention discloses a super hydrophobic JS waterproof coating and a preparing method thereof. The coating is prepared from component A super hydrophobic materials, component B emulsion and component C inorganic powder. The component A super hydrophobic materials are prepared from 15-25 parts of graphene, 2.5-6 parts of a water soluble cationic surfactant, 55-75 parts of a sodium silicate solution, 10-15 parts of NaOH of 10%, 25-45 parts of a silylating reagent and 8-15 parts of deionized water with the electrochemical stratification method; the component B emulsion is prepared from 35-55 parts of hard monomers, 35-55 parts of soft monomers, 2-5 parts of functional monomers, 2-10 parts of super hydrophobic materials, 1-5 parts of a film forming agent, 1-5 parts of a plasticizer, 0.8-1.5 parts of an emulsifying agent, 0.5-1 part of a dispersing agent, 0.5-1 part of a preservative, 0.05-1 part of an antifoaming agent and 0.05-0.1 part of an evocating agent; the component C inorganic powder is prepared from 25-45 parts of ordinary portland cement, 25-45 parts of fly-ash portland cement, 20-30 parts of quartz sand of 200 meshes, 10-15 parts of carbon nano-tubes and 0.5-1 part of a water reducer. When the super hydrophobic JS waterproof coating is prepared, the obtained super hydrophobic materials are added into emulsion polymerization, and the coating has the more excellent stabilities such as bonding strength, water resistance and impact resistance.

Owner:山东天汇防水股份有限公司

Biomass waterproof coating and preparation method thereof

ActiveCN106336761AImprove breathabilityGood flexibilityStarch dervative coatingsLignin material coatingsSilanesDip-coating

The invention discloses a biomass waterproof coating and a preparation method thereof. The coating consists of two parts: a component A super-hydrophobic material and a component B coating composition; the component A super-hydrophobic material comprises, in parts by mass, 2-10 parts of graphene, 15-30 parts of a mixed acid solution, 5-12 parts of an amino ethyoxyl silane-toluene mixed liquid, 5-12 parts of fluoroacrylate, and 20-35 parts of a methanol solution and is prepared by covering the surface of graphene with two layers of waterproof films through a dip coating method; the component B coating composition is prepared from the ingredients in parts by mass: 20-30 parts of lignin, 20-30 parts of starch, 16-18 parts of diatom ooze, 10-12 parts of ash-calcium, 11-15 parts of heavy carbonate calcium, 0.5-1 part of a defoaming agent, 0.8-1 part of a dispersing agent and 15-30 parts of deionized water; the waterproof coating is prepared by mixing the component A super-hydrophobic material and the component B coating composition. The biomass waterproof coating adopts starch, lignin, diatom ooze and other biomass raw materials, and has environmental-protection significance in both production and application; with addition of the super-hydrophobic material, the strength, heat dissipation, thermal conductivity and other properties of the coating are improved while a coating layer is endowed with more uniform and better waterproof performance.

Owner:山东天汇防水股份有限公司

High-solid environmental-protection surface patching paint and production method thereof

The present invention relates to an one package high-solid environment-protecting type surface repairing paint and its production method. Said repairing paint is made up by using nitro-cotton and alkyd resin as film-forming substance, using acetone, ethyl acetate and butyl acetate as solvent, adding filling material and plasticizer, mixing them and using diluting agent to regulate viscosity. Said repairing paint has a certain flowability, specially has good affinity with wood, can be infiltrated into the wood grain or filled into the indentation of wood surface so as to implement the goal of repairing surface defect of wood product and obtaining flat and smooth wood surface.

Owner:CHINA FIRST PENCIL CO LTD

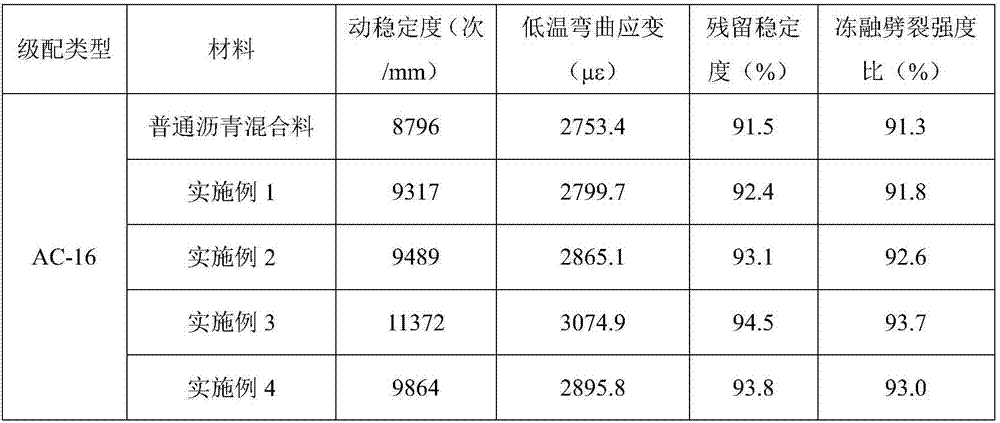

Activated coal gangue powder nano-composite modified asphalt mixture and preparation method thereof

The invention discloses an activated coal gangue powder nano-composite modified asphalt mixture. The activated coal gangue powder nano-composite modified asphalt mixture is prepared from, by weight, 3-7 parts of asphalt, 0.09-0.21 parts of a nano-composite modifier and 100 parts of mineral aggregates, wherein the nano-composite modifier comprises, by weight, 0.06-0.14 parts of nano-silica and 0.03-0.07 parts of nano-alumina; and the mineral aggregates comprise 14-7 parts of mineral powder and 3.5-10.5 parts of activated coal gangue powder. The pavement mixture has the advantage of excellent pavement performances, wide sources of materials, large destroy load resistance, and remarkably improved high-temperature stability, low-temperature stability and water stability. The invention also discloses a preparation method of the asphalt mixture. The preparation method has the advantages of cleanness, no waste pollution, simple preparation process, and high economic and social values.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

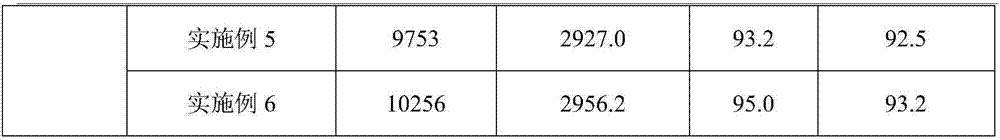

Aluminum profile anode oxidizing electrolyte, preparation method thereof and aluminum profile anode oxidizing process

ActiveCN110306228AStrong complexing abilityStrong surface adsorptionSurface reaction electrolytic coatingAluminum IonElectrolysis

The invention discloses aluminum profile anode oxidizing electrolyte, a preparation method thereof and an aluminum profile anode oxidizing process and belongs to the technical field of electrolysis orelectrophoretic processes. The electrolyte is composed of phytic acid, fulvic acid, a PH conditioning agent and water, the concentration of the phytic acid in the electrolyte is 70-90 g / L, the concentration of the fulvic acid in the electrolyte is 35-55 g / L, and the PH value of the electrolyte is 2.0-2.8. On the one hand, the phytic acid of the electrolyte is mainly sourced from root trunks, stems and seeds of plants, the fulvic acid can be used for a medical purpose, and therefore, the electrolyte mainly composed of the phytic acid and the fulvic acid is completely poisonous and harmless andis environmentally friendly; and on the other hand, aluminum ions dispersed into a solution and a complex formed by the phytic acid and the aluminum ions can be adsorbed to a position nearby an aluminum profile, a complex of phytic acid and Al<3+> is also formed on the surface of aluminum oxide while hole sealing is assisted, a layer of compact hydrophobic protective film is produced, a chemicaldissolution effect of the electrolyte on the oxidation film is retarded, the performance of the film is improved, and the corrosion resistance of the oxidation film is enhanced.

Owner:ANHUI LANT ALUMINUM

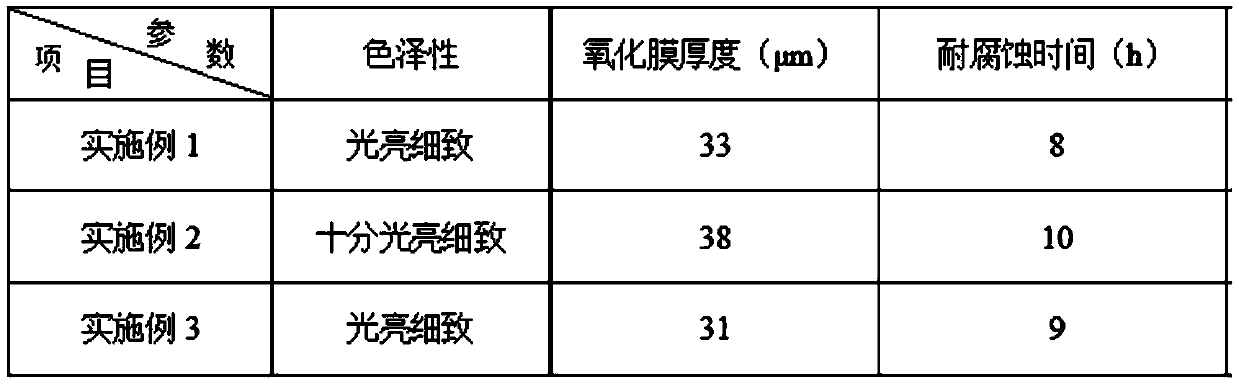

Automotive graphene EVA (ethylene vinyl acetate copolymer) high-foam sound-insulation material and method for preparing same

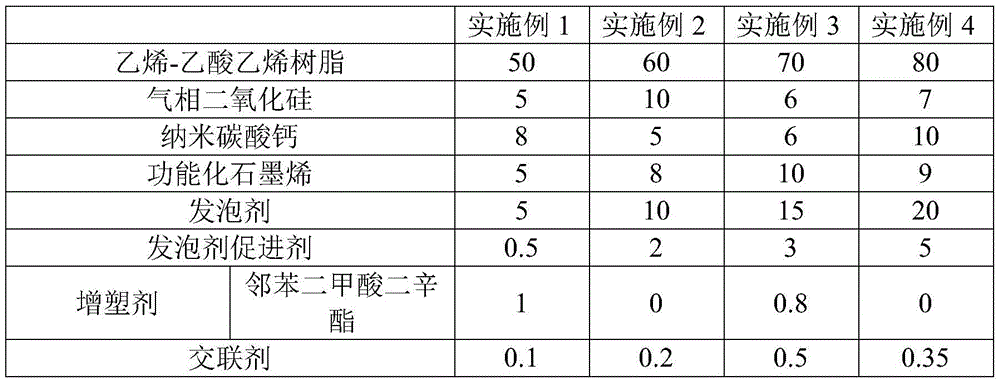

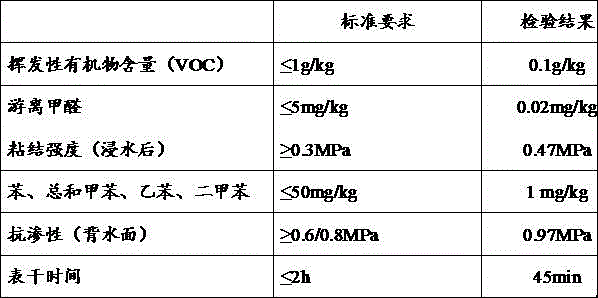

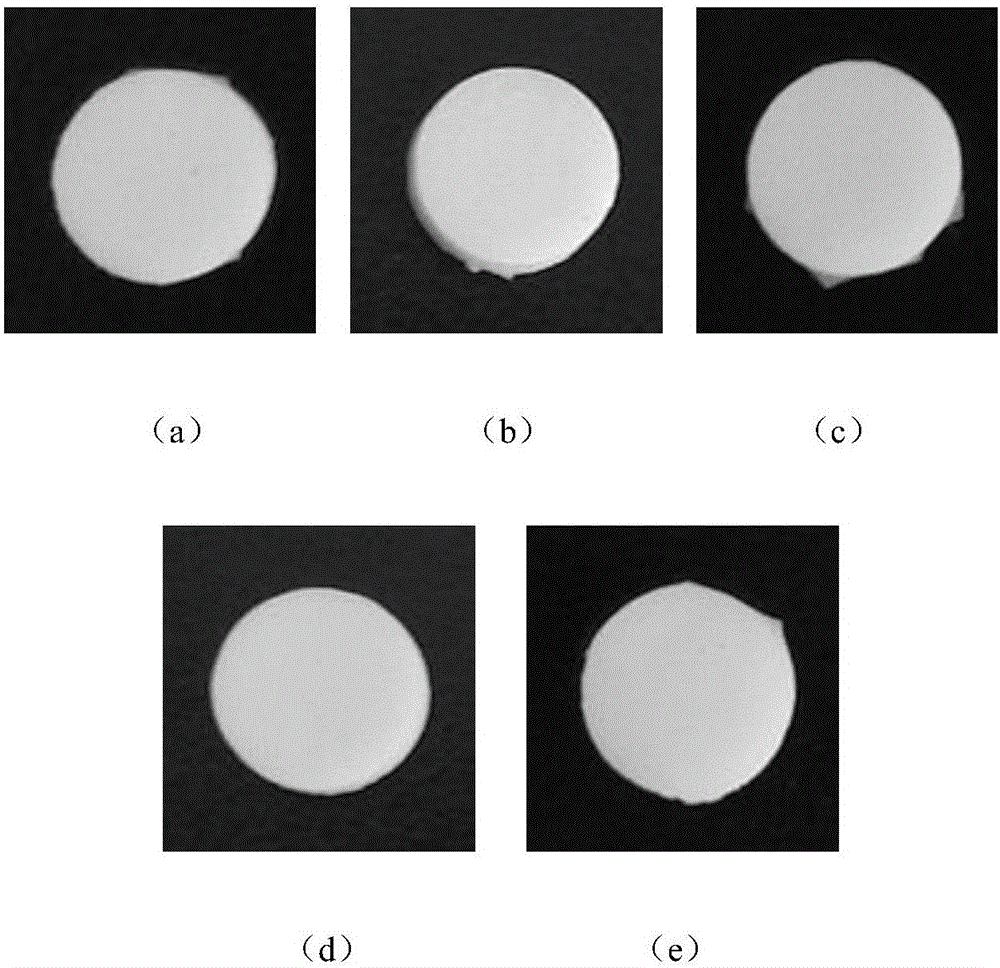

The invention relates to a method for preparing an automotive sound-insulation material, and mainly relates to a high-performance foam damping material and a method for preparing the same. Graphene is used as a filler for the high-performance foam damping material. The method includes preparation procedures of mixing ethylene-vinyl acetate resin, fumed silica, filling agents, the functionalized graphene and plasticizers with one another in an internal mixer at the mixing temperature of 85 DEG C and the rotational speed of 30 revolutions / min for 5-10min to obtain mixed compounds; adding foaming agents, foaming agent accelerators and peroxide cross-linking agents into the mixed compounds to continue mixing at the mixing temperature of 85 DEG C and the rotational speed of 30 revolutions / min for 5-10min; discharging slices of the mixed compounds. The high-performance foam damping material and the method have the main technical advantages that the functionalized graphene and polymer matrixes are excellent in solubility, energy can be effectively dissipated under the effect of friction loss owing to interface slip between the functionalized graphene and the polymer matrixes, and accordingly noise pollution in automobiles can be effectively reduced.

Owner:常州碳润新材料科技有限公司 +1

Fire-retarded oil base wax-resistant agent

The composition of flame retardant oil-base paraffin removing and inhibiting agent for paraffin control and removal in oil field contains light oil 10-20 portions, mixed benzene 70-95 portions, methyl alcohol 0.1-5 portions, water 0.1-1 portion, Peregal 1-5 portions and fluorosurfactant 10 to the minus third-10 to the minus fifth portion. Said paraffin removing and inhibiting agent can be formed into a spread water film on the oil surface, and so that the contact of oil with air can be completely cut off. Said paraffin removing and inhibiting agent can not be burned.

Owner:大庆油田九龙实业公司

Waterproof coating for decoration engineering and preparation method thereof

InactiveCN108822667AHigh bonding strengthImprove waterproof performanceCoatingsEmulsionBonding strength

The invention provides a waterproof coating for decoration engineering and a preparation method thereof. The waterproof coating is prepared from the following components: a modified butyl acrylate emulsion, ethyl silicate, castor oil, talc powder, titanium dioxide, graphene, anhydrous ethanol, dimethylethanolamine, dibutyltin dilaurate, a polymerization inhibitor, a defoamer, a coalescing agent and deionized water. The waterproof coating prepared by the invention has excellent bonding strength, waterproof performance, impact resistance and stability.

Owner:合肥语林装饰工程有限公司

Environment-friendly waterproof coating and preparation method thereof

ActiveCN106189532ASimple and fast operationPracticalStarch dervative coatingsLignin material coatingsMoistureDefoaming Agents

The invention relates to environment-friendly waterproof coating and a preparation method thereof. The coating comprises two parts: a component A, namely a superhydrophobic material, and a component B, namely a coating composition, wherein the component A, namely the superhydrophobic material, is prepared from the following components in parts by mass: 15 to 25 parts of graphene, 2.5 to 6 parts of a water-soluble cationic surfactant, 55 to 75 parts of a sodium silicate solution, 10 to 15 parts of 10% NaOH, 25 to 45 parts of a silanizing reagent and 8 to 15 parts of deionized water; the superhydrophobic material is obtained by performing silanizing treatment on the surface of the graphene by an electrochemical lamination method; the component B, namely coating composition, is prepared from the following components in parts by mass: 20 to 30 parts of lignin, 20 to 30 parts of starch, 16 to 18 parts of diatom ooze, 10 to 12 parts of ash calcium, 11 to 15 parts of ground calcium carbonate, 0.5 to 1 part of a defoaming agent, 0.8 to 1 part of a dispersing agent and 15 to 30 parts of deionized water; and the waterproof coating is prepared by mixing the component A, namely the superhydrophobic material, and the component B, namely coating composition. According to the environment-friendly waterproof coating and the preparation method thereof which are provided by the invention, environment-friendly biomass materials, such as the starch, the lignin, the diatom ooze and the like, are adopted, and the added superhydrophobic material makes up the defect that the diatom ooze and calcium powder absorb moisture easily, so uniform and excellent water resistance of the coating layer is achieved.

Owner:山东天汇防水股份有限公司

Polymerizable quaternary ammonium salt modified anti-microbial pit and fissure sealant and preparation method thereof

InactiveCN106008812AImprove liquidityLong operating timeImpression capsDentistry preparationsFunctional monomerReactive diluent

The invention discloses a polymerizable quaternary ammonium salt modified anti-microbial pit and fissure sealant and a preparation method thereof and belongs to the technical field of medical materials for the oral cavity. The polymerizable quaternary ammonium salt modified anti-microbial pit and fissure sealant is prepared from 40%-80% of resin monomer matrixes, 15%-40% of a reactive diluent, 3%-25% of functional monomers, 0.5%-10% of polymerizable quaternary ammonium salt monomers, 1%-20% of nanoscale filler, 0.5%-3% of NaF, 0.05%-3% of a photosensitive initiation mixture, 0.001%-0.05% of a polymerization inhibitor and 0.3%-5% of pigment. The pit and fissure sealant has good biological safety, is short in curing time at the temperature of the oral cavity and long in operation time and has an effective and lasting antibacterial effect; the preparation method is simple to operate, environment-friendly and suitable for industrial large-scale production.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

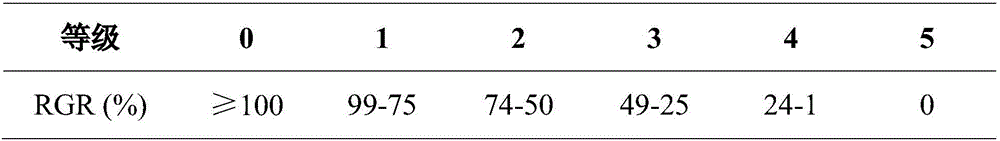

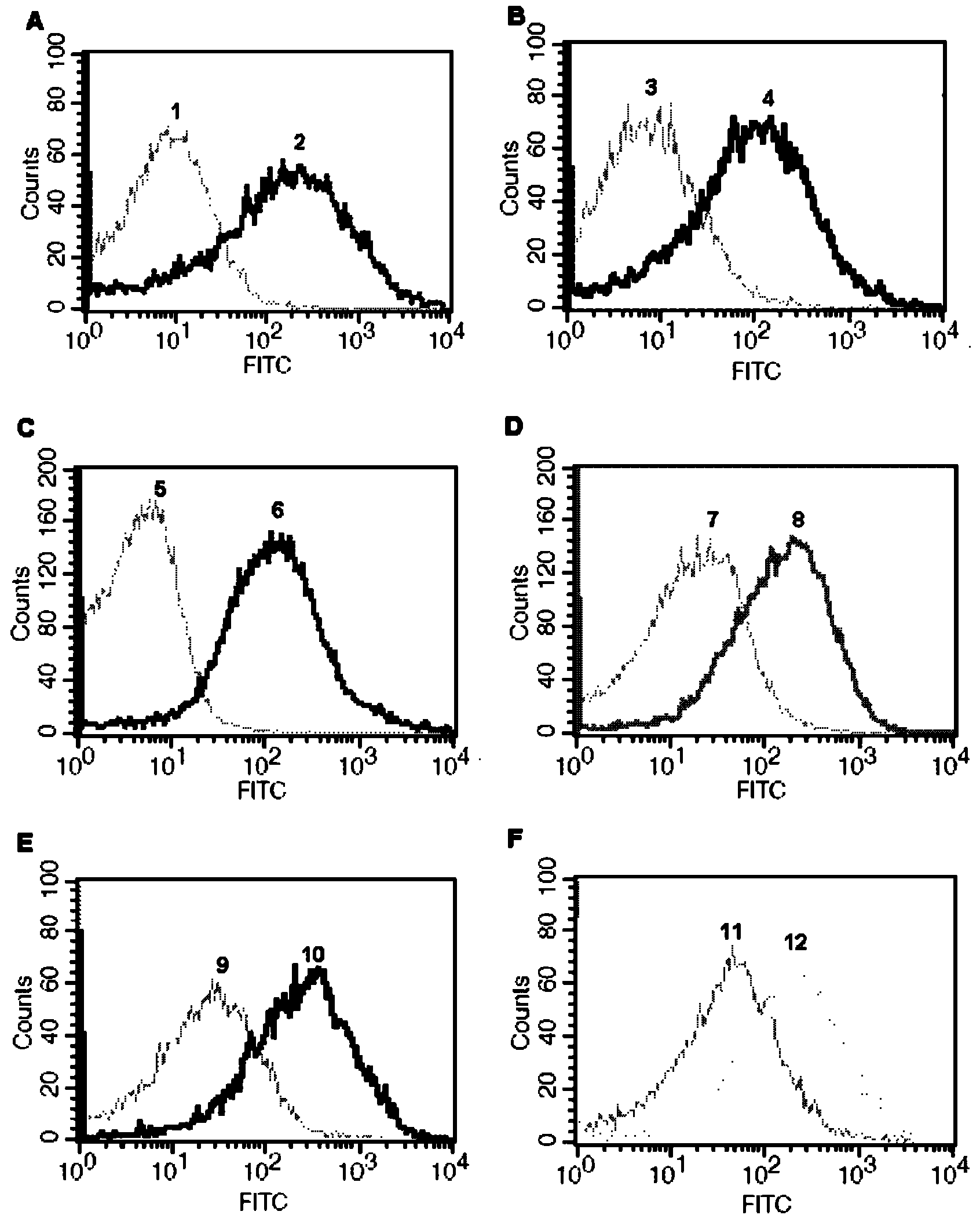

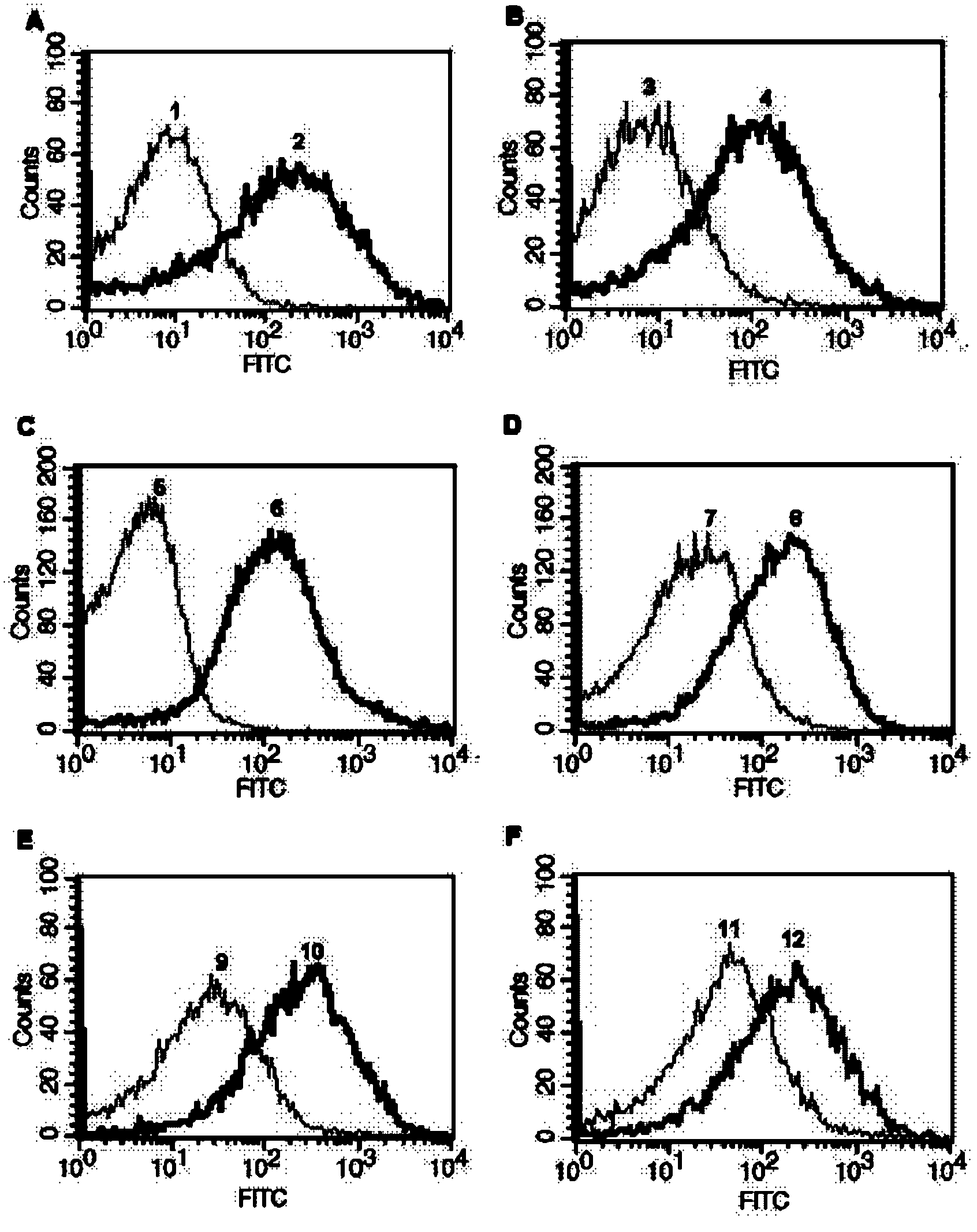

Intracellular protein detection method by flow cytometry

ActiveCN102520188ARealize qualitative detectionEfficient detectionBiological testingSilica nanoparticlesFluorescein

The invention belongs to the field of flow cytometry technology, and specifically relates to an intracellular protein detection method by the use of flow cytometry. The method comprises the following steps of: connecting an amino or carboxy functional group on the surface of 100-120nm silica nanoparticle with an amino group of an antibody against the intracellular protein to be detected by the use of covalent bonds, incubating the silica nanoparticle together with intracellular proteins obtained by ultrasonic and other methods, adding another differently sourced antibody which targeted the same intracellular protein to be detected and carrying out incubating, then incubating with a fluorescein labeled second antibody to form a silica nanoparticle-antibody-intracellular protein-antibody-fluorescein labeled second antibody compound, and finally carrying out qualitative detection on the compound by using flow cytometry. According to the invention, after binding to the antibody against the intracellular protein to be detected, the silica nanoparticle has initiative targeting ability and can target various different intracellular proteins.

Owner:JILIN UNIV

Novel wooden composite board

ActiveCN107253240AImprove surface qualityImprove pass rateLaminationLamination apparatusCarbonizationEngineering

The invention discloses a novel wooden composite board which comprises a central layer. Transition layers are arranged on the upper face and the lower face of the central layer respectively. Impregnated paper layers are arranged on the upper faces and the lower faces of the transition layers respectively. The impregnated paper layers, the transition layers and the central layer are mutually bonded and connected through adhesive layers at high temperature and high pressure. The novel wooden composite board is reasonable in structure and novel in design, good in surface quality, high in pass percent and durable, and overcomes the shortcomings of easy cracking, carbonization and shedding of existing ecological board surface stickers. In addition, a production process is simple, the production efficiency is high, the production cost is greatly reduced, and the shortcomings of complicated process, long production period and high cost of existing ecological boards are overcome.

Owner:临沂市新天力机械有限公司

Preparation method of highly elastic water-based polyurethane synthetic leather

The invention relates to the technical field of polyurethane synthetic leather preparation, in particular to a preparation method of highly elastic water-based polyurethane synthetic leather. The method comprises the steps of taking polybutylene glyool adipate and polypropylene oxide glycol as raw materials, adding additives such as stannous octoate, rosin and maleic anhydride, taking fir wood asa raw material, mixing and extruding water-based polyurethane slurry, talcum powder and linear polyethene masterbatch in an extruder, coating nonwoven base cloth with an extruded material, performingdrying to form a water-based polyurethane synthetic leather base, and treating the water-based polyurethane synthetic leather base to form the water-based polyurethane synthetic leather. According tothe method, a carbonized wood fiber has a strong thickening effect and can improve viscoelasticity of the polyurethane slurry; polyurethane molecules are absorbed and stacked on the surface of fumed silica in a formation process of the polyurethane slurry, so that the crystallinity of the water-based polyurethane synthetic leather is reduced; the maleic rosin reacts with glycerol, so that polyurethane keeps better resilience; and the method has broad application prospects.

Owner:孙祎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com