Colloid power battery internal formation electrolyte and preparation method thereof

A power battery and electrolyte technology, which is applied in the field of colloidal power battery internalization into electrolyte and its preparation, can solve the problems of increased electrode corrosion speed, small electrochemical reaction area, and low battery life, and can slow down the short circuit of sulfate crystals, The effect of improving charge acceptance and strong charge acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

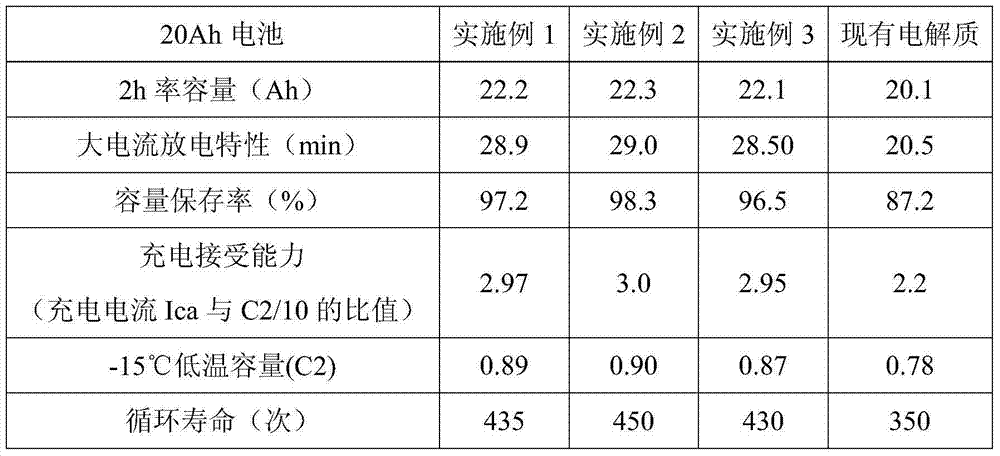

Embodiment 1

[0020] According to the mass fraction of nano-silica with a particle size of 7-40nm per ton of colloidal electrolyte, polypropylene with a molecular weight of 80,000-150,000, a concentration of 40% dilute sulfuric acid, deionized water, stannous sulfate and sodium sulfate are 2.9% in sequence , 0.1%, 42%, 53%, 1%, and 1% were sampled, and added to a 100L container after sampling, and stirred for 0.5h at a temperature of 15°C, a pressure of 0.35Kpa, and a stirring speed of 80rpm to obtain the colloidal electrolyte of the present invention . Example 2:

Embodiment 2

[0021] According to the mass fraction of nano-silica with a particle size of 7 to 40nm, polypropylene with a molecular weight of 80,000 to 150,000, a concentration of 44%, deionized water, stannous sulfate and sodium sulfate in each ton of colloidal electrolyte, they are 1% in order , 1%, 44%, 50%, 3% and 1% were sampled and added to a 100L container, and stirred for 1 hour at a temperature of 35°C, a pressure of 0.4Kpa, and a stirring speed of 100rpm to obtain the colloidal electrolyte of the present invention.

Embodiment 3

[0023] According to the mass fraction of nano-silica with a particle size of 7-40nm per ton of colloidal electrolyte, polypropylene with a molecular weight of 80,000-150,000, a concentration of 48%, dilute sulfuric acid, deionized water, stannous sulfate and sodium sulfate are 5.5% in sequence , 0.5%, 42%, 50%, 1% and 1% were sampled and added to a 100L container, and stirred for 1h at a temperature of 50°C, a pressure of 0.45Kpa, and a stirring speed of 120rpm to obtain the colloidal electrolyte of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com