Preparation method of highly elastic water-based polyurethane synthetic leather

A water-based polyurethane and synthetic leather technology, applied in textiles and papermaking, can solve the problems of water-based polyurethane synthetic leather, such as decreased flatness and poor resilience, and achieve the effects of increasing softening point, improving stability, and strong surface adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

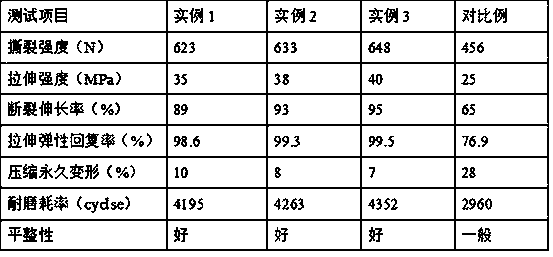

Examples

example 1

[0028] In parts by weight, 35 parts of polybutylene adipate diol, 20 parts of polyoxypropylene diol, 10 parts of stannous octoate, and 20 parts of rosin are placed in a three-necked flask with vent tube and stirrer , connect the three-necked flask to the vacuum pump, turn on the vacuum pump, heat the three-necked flask to 80°C with an electric heating mantle, start the stirrer at the same time, stir at a speed of 100r / min for 20min; continue to heat the above-mentioned three-necked flask to 120°C, and control the vacuum The temperature is 50 Pa, heat preservation and dehydration for 2 hours, and lower the temperature to 80 ° C, and add 30 parts of isophorone diisocyanate, 20 parts of fumed silica, 20 parts of maleic anhydride, and 10 parts of glycerin to the three-necked flask by weight. React for 10 minutes. After the reaction heat release is over, use a heating mantle to heat the three-necked flask to 85°C, and keep it warm for 3 hours to obtain a water-based polyurethane slu...

example 2

[0030] In parts by weight, 38 parts of polybutylene adipate diol, 23 parts of polyoxypropylene diol, 11 parts of stannous octoate, and 21 parts of rosin are placed in a three-necked flask with vent tube and stirrer , connect the three-necked flask to the vacuum pump, turn on the vacuum pump, heat the three-necked flask to 83°C with an electric heating mantle, start the stirrer at the same time, stir at a speed of 110r / min for 25min; continue to heat the above-mentioned three-necked flask to 125°C, and control the vacuum Temperature is 135Pa, heat preservation and dehydration for 2.5h, and lower the temperature to 83°C, add 35 parts of isophorone diisocyanate, 23 parts of fumed silica, 25 parts of maleic anhydride, 13 parts of glycerin to the three-necked flask , reacted for 11 minutes, and after the reaction exotherm was over, heated the three-necked flask with a heating mantle to 86°C, and kept it warm for 3.5 hours to obtain a water-based polyurethane slurry; put the fir wood...

example 3

[0032] In parts by weight, 40 parts of polybutylene adipate diol, 25 parts of polyoxypropylene diol, 12 parts of stannous octoate, and 22 parts of rosin are placed in a three-necked flask with vent tube and stirrer , connect the three-necked flask to the vacuum pump, turn on the vacuum pump, heat the three-necked flask to 85°C with an electric heating mantle, start the stirrer at the same time, stir at a speed of 120r / min for 30min; continue to heat the above-mentioned three-necked flask to 130°C, and control the vacuum The temperature is 200 Pa, heat preservation and dehydration for 3 hours, and lower the temperature to 85 ° C. In parts by weight, add 40 parts of isophorone diisocyanate, 25 parts of fumed silica, 30 parts of maleic anhydride, and 15 parts of glycerin to the three-necked flask. React for 12 minutes. After the reaction heat release is over, use a heating mantle to heat the three-necked flask to 87°C, and keep it warm for 4 hours to obtain a water-based polyureth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com