Graphene antiseptic coating and preparation method thereof

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problem of poor film strength and impact resistance, uneven dispersion of graphene powder, uneven pores on the surface of the coating film and other problems, to achieve the effects of good anti-corrosion performance, improved uneven dispersion, and strong surface adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of graphene anticorrosion coating, comprises the steps:

[0027] S1: Preparation of graphene oxide powder: the graphene oxide solid was prepared by the Hummer method, and the graphene oxide solid was ground and sieved to obtain graphene oxide powder with a particle size of 50-300 nm;

[0028] S2: Preparation of graphene-modified carbon fiber powder: Mix the graphene oxide powder and N,N-dimethylformamide in step S1, sonicate for 30 minutes until the suspension is uniform, add polyacrylonitrile, and reflux at 90°C to obtain the fiber Slurry, the weight ratio of graphene oxide powder to N,N-dimethylformamide is 1:2~4; use a spinning needle with an inner diameter of 1~2mm to draw the fiber slurry to 50cm 3 In the syringe, the polyacrylonitrile fiber was prepared by using an electrospinning device. The power supply voltage of the electrospinning device was 15-18KV, the distance from the needle tip to the collector was 20cm, the speed of the syri...

Embodiment 1

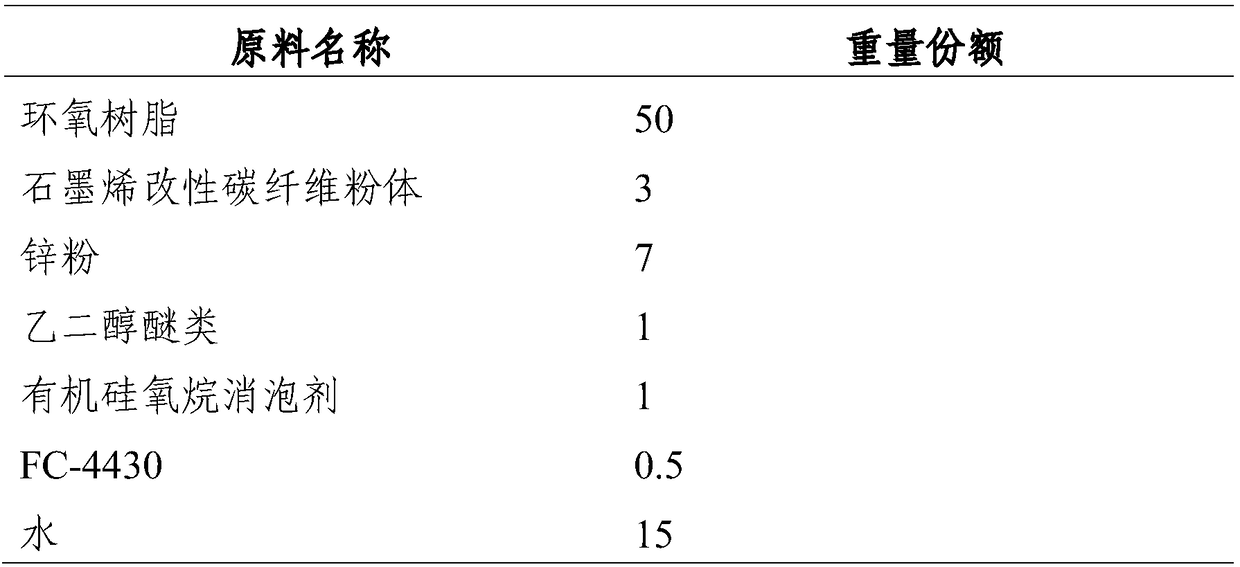

[0033] Proportioning each component by following raw material parts by weight:

[0034]

[0035] According to the ratio of the above-mentioned raw materials by weight, the resin, film-forming accelerator, defoamer, and auxiliary agent are mixed, stirred for 20 minutes under ultrasonic conditions, and the rotating speed is 500 rpm; Slowly add carbon fiber powder into the above mixture at a speed of 1200rpm, and stir ultrasonically for 30 minutes; under the condition of ultrasonic stirring, slowly add commercially available zinc powder into the mixture, the particle size of zinc powder is 2μm, and the speed is 1200-1500rpm , and ultrasonically stirred for 60 minutes to obtain a graphene anti-corrosion coating.

Embodiment 2

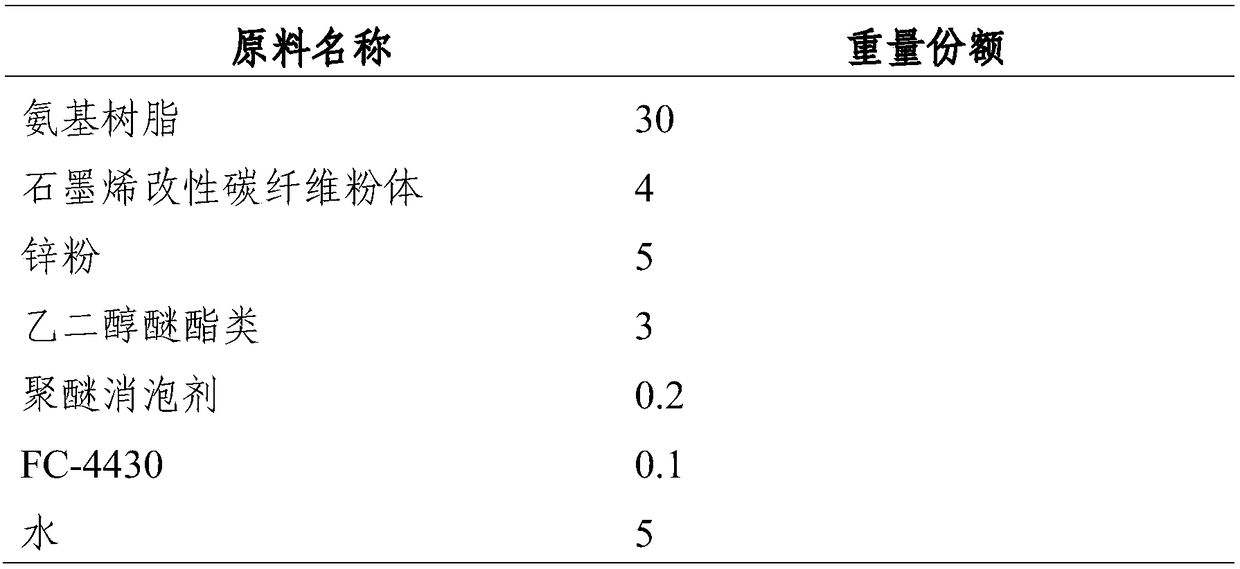

[0037] Proportioning each component by following raw material parts by weight:

[0038]

[0039]According to the ratio of the above-mentioned raw materials by weight, the resin, film-forming accelerator, defoamer, and auxiliary agent are mixed, stirred for 20 minutes under ultrasonic conditions, and the rotating speed is 600 rpm; The carbon fiber powder was slowly added to the above mixture at a speed of 1000rpm, and ultrasonically stirred for 30 minutes; under the condition of ultrasonic stirring, the commercially available zinc powder was slowly added to the mixture. Stir for 60min to obtain a graphene anticorrosion coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com