Aluminum profile anode oxidizing electrolyte, preparation method thereof and aluminum profile anode oxidizing process

An anodizing and electrolyte technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of poor electrolyte stability, color change of oxide film, uneven thickness, etc., to enhance corrosion resistance. The effect of improving corrosion resistance and film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

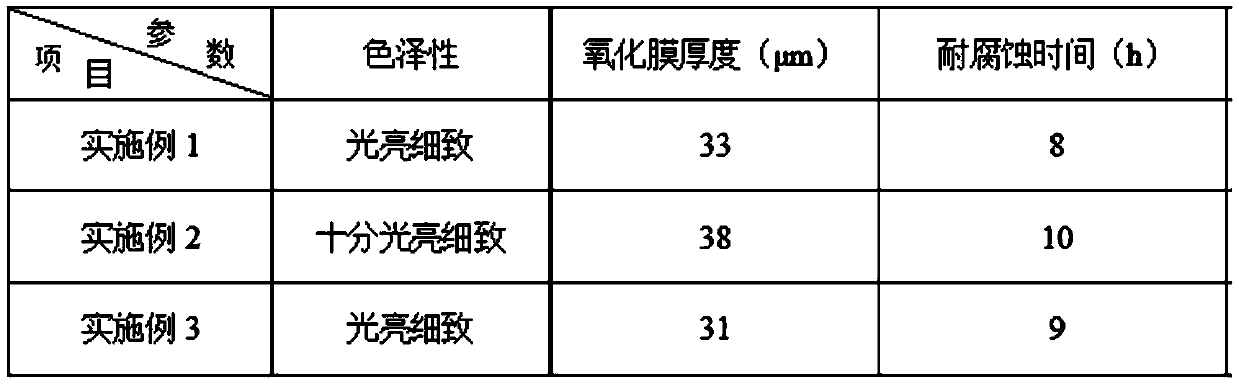

Examples

Embodiment 1

[0035] In this embodiment, the electrolyte is prepared through the following three steps:

[0036] (1) preparing phytic acid solution: dissolving phytic acid in water to obtain a phytic acid solution with a concentration of 225g / L;

[0037] (2) preparation of fulvic acid solution: fulvic acid is dissolved in water to obtain a concentration of fulvic acid solution of 87.5g / L;

[0038] (3) Preparation of electrolyte: the phytic acid solution prepared in step (1) is mixed with the fulvic acid solution prepared in step (2) in equal volumes, and ultrasonically mixed to obtain a mixed solution, which is added to the mixed solution in stirring Add dropwise a sodium hydroxide solution with a concentration of 0.1mol / L until the pH of the mixed solution is 2.5, then add water to the mixed solution to obtain an electrolyte, the concentration of phytic acid in the electrolyte is 90g / L, fulvic acid The concentration in the electrolyte is 35g / L.

[0039] The anodizing process of aluminum ...

Embodiment 2

[0047] In this embodiment, the electrolyte is prepared through the following three steps:

[0048] (1) preparing phytic acid solution: dissolving phytic acid in water to obtain a phytic acid solution with a concentration of 200g / L;

[0049] (2) preparation of fulvic acid solution: fulvic acid is dissolved in water to make a concentration of 102g / L fulvic acid solution;

[0050] (3) Preparation of electrolyte: the phytic acid solution prepared in step (1) is mixed with the fulvic acid solution prepared in step (2) in equal volumes, and ultrasonically mixed to obtain a mixed solution, which is added to the mixed solution in stirring Add dropwise a sodium hydroxide solution with a concentration of 0.1mol / L until the pH value of the mixed solution is 2.8, then add water to the mixed solution to obtain an electrolyte, the concentration of phytic acid in the electrolyte is 80g / L, fulvic acid The concentration in the electrolyte is 40.8g / L.

[0051] The anodizing process of aluminu...

Embodiment 3

[0059] In this embodiment, the electrolyte is prepared through the following three steps:

[0060] (1) preparing phytic acid solution: dissolving phytic acid in water to obtain a phytic acid solution with a concentration of 175g / L;

[0061] (2) preparation of fulvic acid solution: fulvic acid is dissolved in water to make a concentration of 137.5g / L fulvic acid solution;

[0062] (3) Preparation of electrolyte: the phytic acid solution prepared in step (1) is mixed with the fulvic acid solution prepared in step (2) in equal volumes, and ultrasonic dispersion is used to uniformly obtain a mixed solution, which is added to the mixed solution in stirring Add dropwise a sodium hydroxide solution with a concentration of 0.05mol / L until the pH value of the mixed solution is 2.0, then add water to the mixed solution to obtain an electrolyte, the concentration of phytic acid in the electrolyte is 70g / L, fulvic acid The concentration in the electrolyte is 55g / L.

[0063] The anodizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com