Compound gaseous-phase rust inhibitor as well as preparation method and application thereof

A gas-phase rust inhibitor and rust inhibitor technology, applied in the field of rust inhibitors, can solve the problems of decreased rust resistance, high molecular polarity, poor appearance of plastic packaging films, etc., to achieve excellent rust resistance and improve interaction. , Improve the effect of anti-rust ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

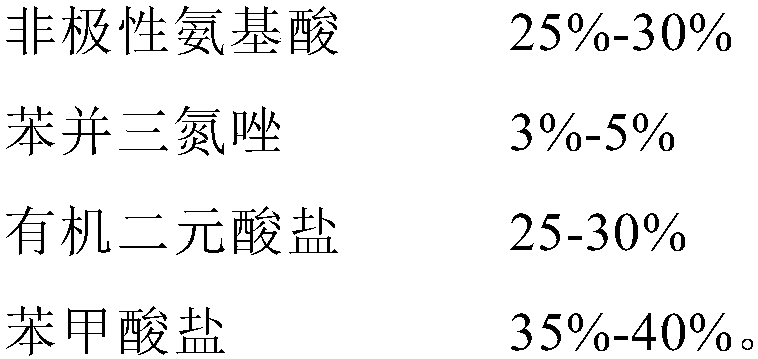

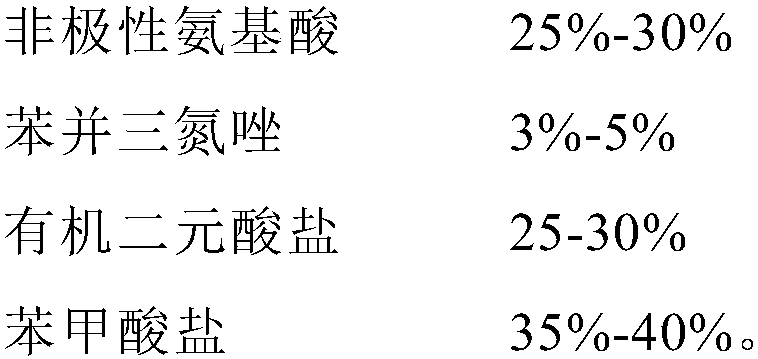

[0025] Weigh 30 g of phenylalanine, 3 g of benzotriazole, 10 g of sodium succinate, 20 g of ammonium sebacate, and 37 g of sodium benzoate, mix them evenly, and perform fine grinding and drying to obtain 100 g of compound vapor phase rust inhibitor 1.

Embodiment 2

[0027] Weigh 25g of leucine, 5g of benzotriazole, 10g of sodium succinate, 20g of sodium sebacate, and 40g of ammonium benzoate, mix them evenly, and perform fine grinding and drying to obtain 100g of compound vapor phase rust inhibitor 2.

Embodiment 3

[0029] Weigh 30 g of tryptophan, 5 g of benzotriazole, 30 g of sodium adipate, and 35 g of morpholine benzoate, mix them uniformly, and carry out fine grinding and drying to obtain 100 g of compound vapor phase rust inhibitor 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com