Technique for producing zinc stearate by dry method and device

A zinc stearate and production process technology, which is applied in carboxylate preparation, chemical/physical/physical chemical fixed reactors, organic chemistry, etc., can solve the problems of yellowish product color and high reaction temperature, and achieve drying energy Large consumption, high degree of dispersion and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Reaction raw materials: 67 kilograms of zinc carbonate, 330 kilograms of stearic acid, 20 kilograms of deionized water.

[0032] First put stearic acid into the reaction vessel 4 through the feeding port 6, heat and stir for about 10 minutes, and after the temperature rises to 50°C, put zinc carbonate into it, and after fully stirring, pour 20kg of deionized water from the feeding port, and pass The gas inlet and outlet pipe port 7 is continuously fed with nitrogen, and the air in the reaction vessel 4 is discharged from the top feeding port 6. After gradually replacing the air in the reaction container 4 with nitrogen, the feeding port 6 is closed tightly. While stirring, gradually heat the reaction mass to between 80°C and 110°C. Open the gas inlet and outlet pipeline port 7 valves, the CO generated in the reaction process 2 , deionized water vapor and the water vapor generated by the reaction are discharged from the reaction vessel 4. After reacting f...

Embodiment 2

[0033] Embodiment 2: Reaction raw materials: 30 kilograms of zinc oxide, 200 kilograms of stearic acid, 10 kilograms of deionized water.

[0034] First, zinc oxide is put into the reaction vessel 4 through the feeding port 6, stirred and added with deionized water, after the reaction between the zinc oxide and the water is completed, stearic acid is put in, and nitrogen gas is constantly introduced through the gas inlet and outlet pipe port 7, and the reaction vessel 4 The air is discharged from the top feeding port 6, and after gradually replacing the air in the reaction vessel 4 with nitrogen, close the feeding port 6 and the gas inlet and outlet pipe port 7 valves. While stirring, gradually heat the reaction mass to between 80°C and 110°C. Keep the vapor pressure formed by the deionized water and the reaction water in the reactor 4 between 0-0.1 MPa. After reacting for about two hours, open the valve of the gas inlet and outlet pipeline 7, and discharge the nitrogen, deion...

Embodiment 3

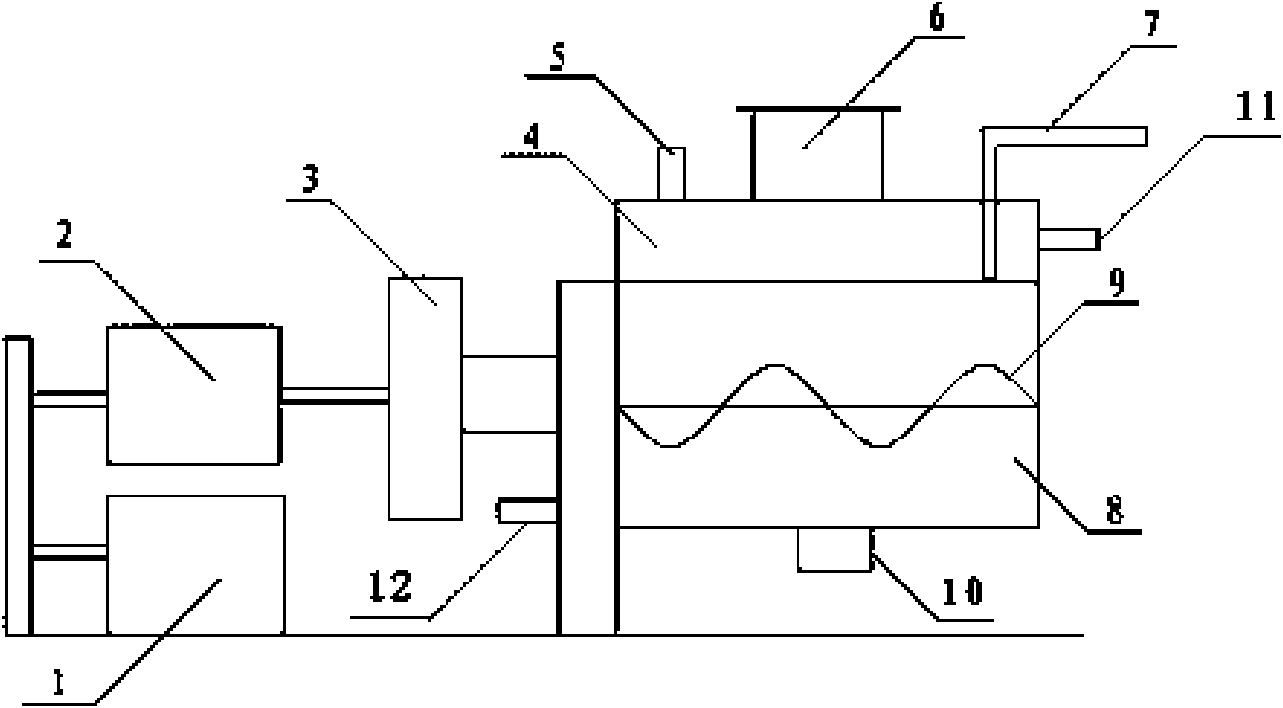

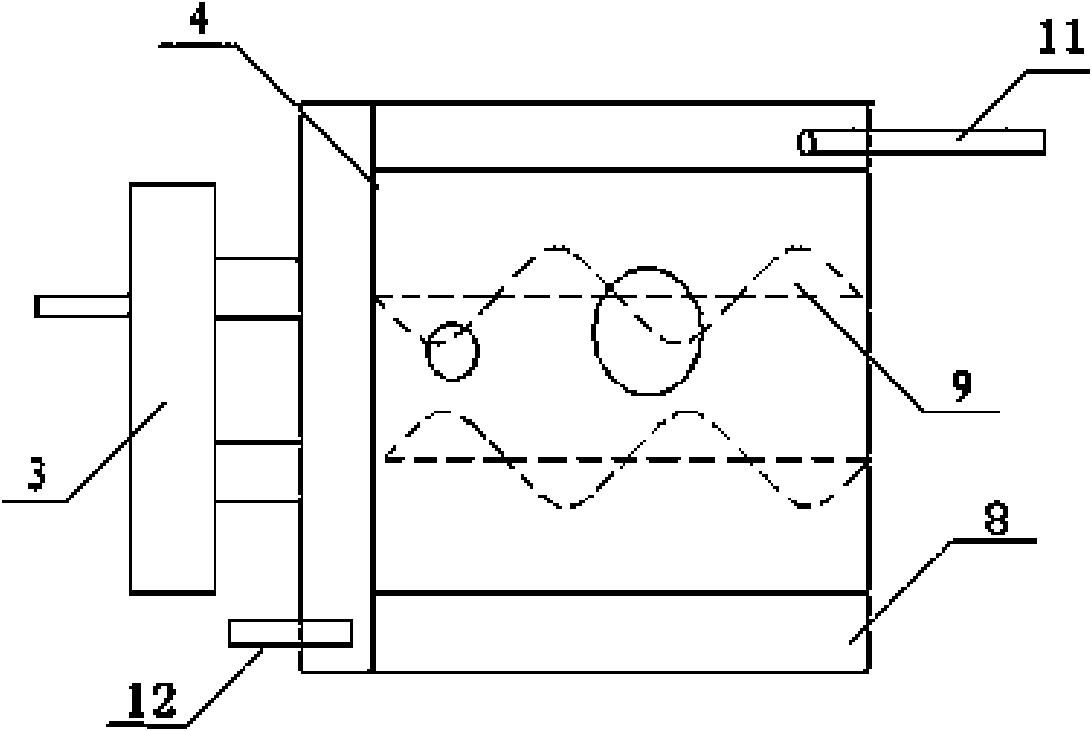

[0038] Embodiment 3: asfigure 1 , 2 As shown, the reaction device includes a reaction vessel 4, a feeding port 6 and a jacket 8, the motor 1 is connected with the speed reducer 2, the speed reducer 2 is connected with the gear transmission 3, and the gear transmission 3 is connected with the agitator 9 installed in the reaction vessel 4 , the agitator 9 is 2, and reverse shear rotation, variable frequency speed regulation; the reaction vessel 4 is a pressure vessel, the top of the reaction vessel 4 is provided with a feeding port 6, a gas inlet and outlet pipe port 7 and a temperature measuring port 5, the reaction vessel A jacket 8 is set outside 4, a discharge port 10 is set under the reaction vessel 4, and a steam and cooling water inlet 11 and a steam and cooling water outlet 12 are set on the side of the jacket 8, which can be heated or cooled by steam or cooling water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com