Method and device for quickly recycling heavy metal wastewater

A heavy metal and resource-based technology, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of low recycling value, harsh operating environment, low treatment efficiency, etc. Value, wide treatment range, high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

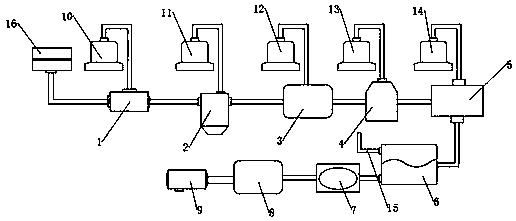

[0030] The method for rapidly reusing heavy metal wastewater comprises the following steps:

[0031] S1: The heavy metal-containing waste water is passed through the grid well 16 to remove the internal and suspended impurities, and is introduced into the pipeline mixer 1 through the pipeline;

[0032] S2: Use vulcanization technology to mix the heavy metal-containing wastewater and the pH regulator in the pipeline mixer 1, adjust the pH to 6, and then enter the mixing reaction tank 2 and add Na at the same time 2 S carries out mixing reaction, and the reaction time is 0.5 hour, obtains vulcanization solution, and pH adjusting agent can be acid or alkali; The solution after adjusting in the described S2 step and Na 2 When S carries out mixing reaction, adopt stirrer to stir and mix, and its rotating speed is 30r / min, and stirring level is 7 grades, and reaction time 15min; Said Na 2 The concentration of S preparation is 10%; the metering pump of the mixed reaction tank is adde...

Embodiment 2

[0038] The method for rapidly reusing heavy metal wastewater comprises the following steps:

[0039] S1: The heavy metal-containing waste water is passed through the grid well 16 to remove the internal and suspended impurities, and is introduced into the pipeline mixer 1 through the pipeline;

[0040] S2: Use vulcanization technology to mix the heavy metal-containing wastewater and the pH regulator in the pipeline mixer 1, adjust the pH to 7, and then enter the mixing reaction tank 2 and add Na at the same time 2 S carries out mixing reaction, and the reaction time is 1 hour, obtains vulcanization solution, and pH adjusting agent can be acid or alkali; The solution after adjusting in the described S2 step and Na 2 When S is mixed and reacted, a stirrer is used to stir and mix, its rotating speed is 80r / min, the stirring grade is 7.5 grades, and the reaction time is 25min; the Na 2 The concentration of S preparation is 15%; the metering pump of the mixed reaction tank is added...

Embodiment 3

[0046] The method for rapidly reusing heavy metal wastewater comprises the following steps:

[0047] S1: The heavy metal-containing waste water is passed through the grid well 16 to remove the internal and suspended impurities, and is introduced into the pipeline mixer 1 through the pipeline;

[0048] S2: Use vulcanization technology to mix the heavy metal-containing wastewater and the pH regulator in the pipeline mixer 1, adjust the pH to 8, and then enter the mixing reaction tank 2 and add Na at the same time 2 S carries out mixing reaction, and the reaction time is 2 hours, obtains vulcanization solution, and pH adjusting agent can be acid or alkali; The solution after adjusting in the described S2 step and Na 2 When S is mixed and reacted, a stirrer is used to stir and mix, its rotating speed is 120r / min, the stirring grade is 8 grades, and the reaction time is 30min; the Na 2 The concentration of S preparation is 20%; the metering pump in the mixing reaction tank is adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com