Activated coal gangue powder nano-composite modified asphalt mixture and preparation method thereof

A nano-composite and modified asphalt technology, applied in the field of road engineering materials, can solve the problems of environmental pollution, occupation of large land and farmland, etc., and achieve the effect of improving road performance, less surface energy defects, and strong surface adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

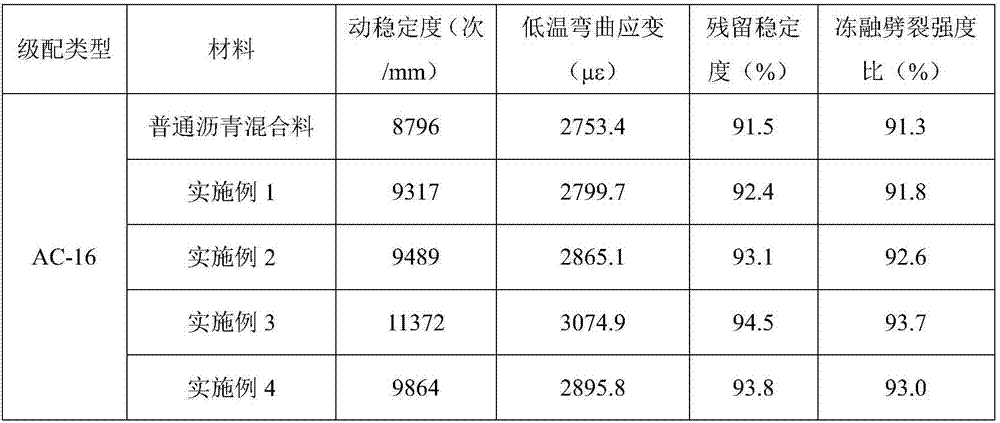

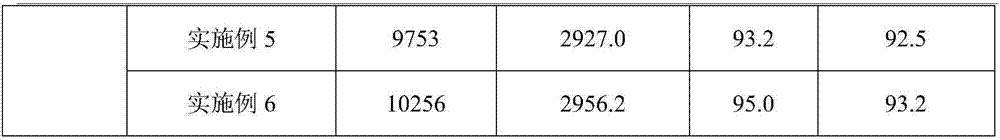

Embodiment 1

[0027] Embodiment 1: A nano-composite modified asphalt mixture of activated coal gangue powder is made of the following raw materials in parts by weight: 3 parts of asphalt, 0.09 parts of nano-composite modifier, and 100 parts of ore materials. The nanocomposite modifier contains 0.06 parts of nano-silica and 0.03 part of nano-alumina, and the mineral material contains 14 parts of ore powder and 3.5 parts of activated coal gangue powder; the mineral material used in this embodiment is AC-16 type Mineral material, the asphalt used is road petroleum asphalt.

Embodiment 2

[0028] Example 2: A nano-composite modified asphalt mixture of activated coal gangue powder, made of the following raw materials in parts by weight: 4 parts of asphalt, 0.12 parts of nano-composite modifier, and 100 parts of mineral materials, wherein, the The nanocomposite modifier contains 0.08 parts of nano-silica and 0.04 parts of nano-alumina, and the mineral material contains 12.25 parts of mineral powder and 5.25 parts of activated coal gangue powder; the mineral material used in this embodiment is AC-16 type Mineral materials, the bitumen used is coal tar pitch.

Embodiment 3

[0029] Embodiment 3: A nano-composite modified asphalt mixture of activated coal gangue powder, made of the following raw materials in parts by weight: 4.5 parts of asphalt, 0.135 parts of nano-composite modifier, and 100 parts of mineral materials, wherein, the The nanocomposite modifier contains 0.09 parts of nano-silica and 0.045 parts of nano-alumina, and the mineral material contains 10.5 parts of mineral powder and 7 parts of activated coal gangue powder; the mineral material used in this embodiment is AC-16 type Mineral material, the asphalt used is road petroleum asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com