Environment-friendly waterproof coating and preparation method thereof

A waterproof and environmentally friendly technology, applied in the field of coatings, can solve the problems of loss of mechanical resistance, easy to touch damage, etc., to achieve the effect of easy operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

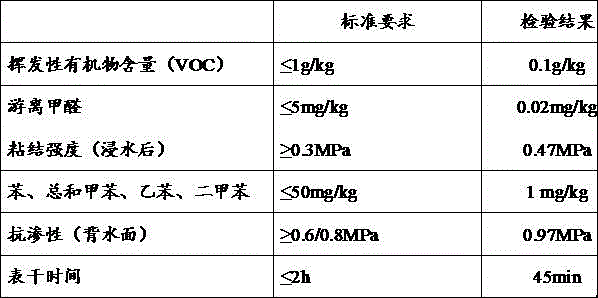

Image

Examples

Embodiment 1

[0048] A waterproof coating and a preparation method thereof. The coating comprises a component A superhydrophobic material and a component B polymeric emulsion, and the components of the raw materials are composed as follows according to the ratio of parts by mass:

[0049] Component A superhydrophobic material: 20 parts of graphene, 3 parts of polydimethyldiallyl ammonium chloride, 55 parts of sodium silicate solution, 10 parts of 10% NaOH, 25 parts of methacryloxysilane and deionized 8 parts of water;

[0050] Component B coating composition: 20 parts of lignin, 30 parts of sweet potato cationic etherified starch, 18 parts of diatom mud, 10 parts of ash calcium (calcium hydroxide content is 90%, whiteness is 90%, particle size is 1200 mesh) 11 parts of heavy calcium (calcium carbonate content is 97%, whiteness is 90%, particle size is 1200 mesh), 0.5 parts of polyoxypropylene oxide glyceryl ether, 0.8 parts of polyacrylamide and 20 parts of deionized water;

[0051] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com