Automotive functionalized graphene damping slurry and preparation method thereof

A technology of damping slurry and function, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., to achieve the effects of strong surface adsorption, large specific surface area, and high chemical purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further explained below in conjunction with specific examples.

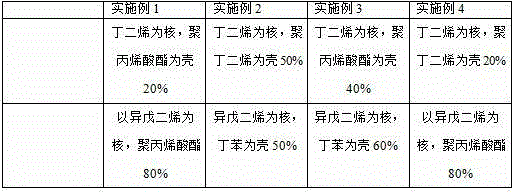

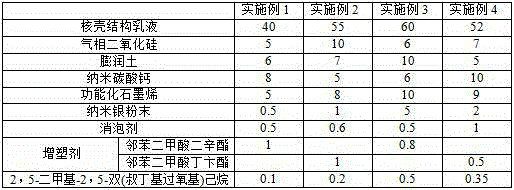

[0042] According to the formula described in Table 1,

[0043] Sieve bentonite, fumed silica, nano-calcium carbonate, functionalized graphene, and nano-silver powder, and use a 100-200 mesh sieve to blend the core-shell emulsion, defoamer, plasticizer, and cross-linking agent, and stir Evenly, add the powder sieved in the above steps into the blended emulsion, use mechanical stirring to mix, room temperature, stirring speed 100~200r / min, add deionized water, adjust the consistency to 8~10.

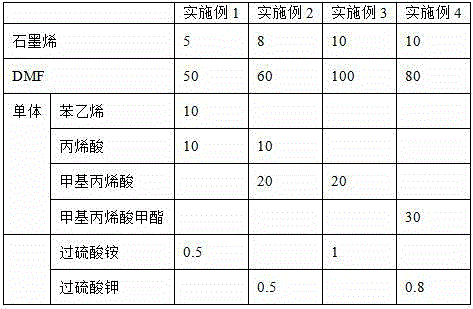

[0044] Prepare functionalized graphene according to table three formulations:

[0045] Functional graphene treatment method: Weigh a certain amount of graphene, dissolve it in DMF, disperse it ultrasonically, slowly add the purified monomer dropwise under magnetic stirring, add the initiator, continue to react for 3~4h after the dropwise addition, filter, and dry Preparation of functionali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com