Preparation method of halloysite-carbon composite adsorbent for removing NO

A technology of carbon composite and adsorbent, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., to achieve the effects of enriching alkaline sites, reducing specific surface area, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

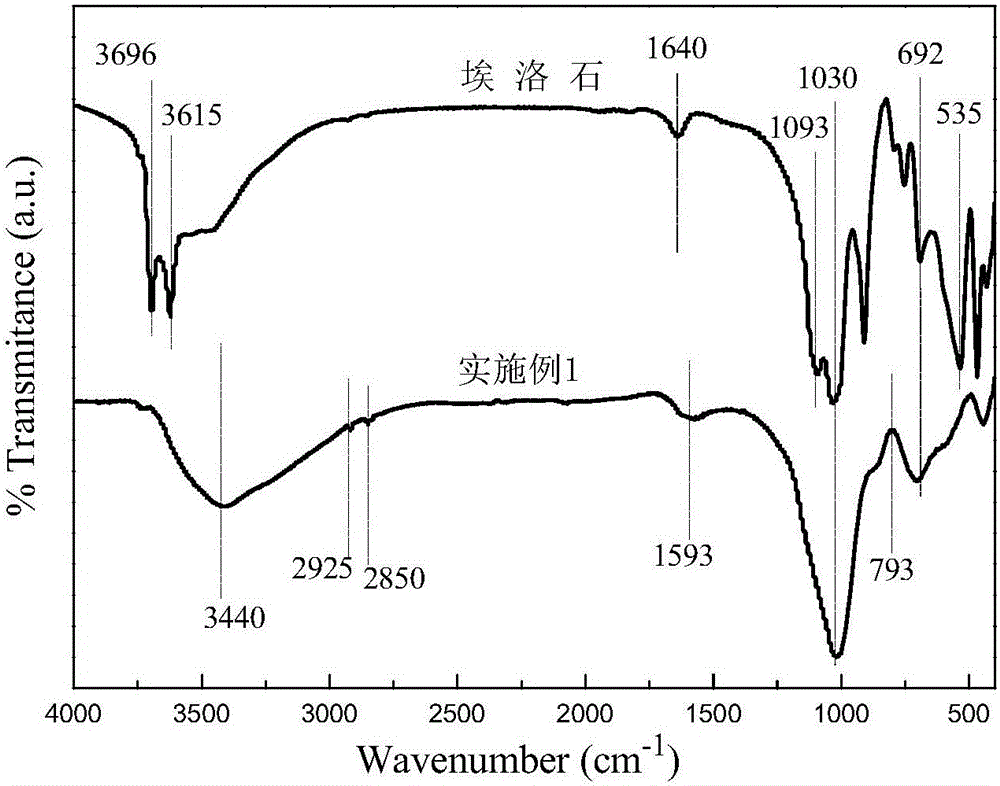

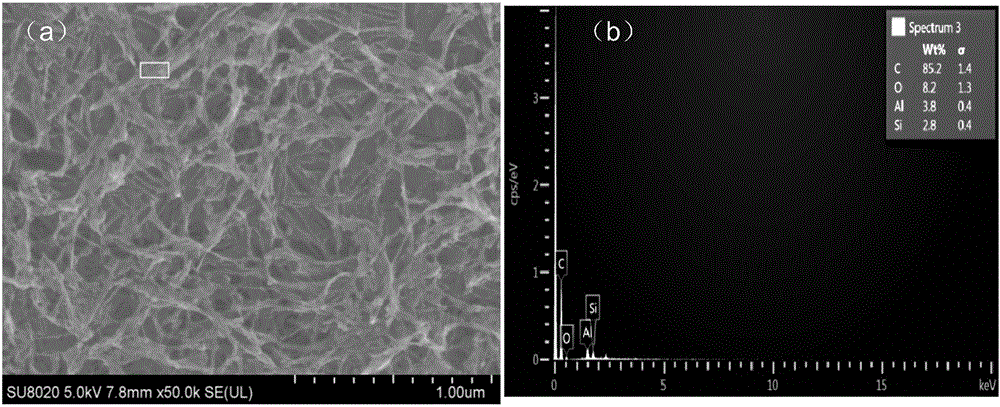

[0022] In this example, the halloysite / charcoal composite adsorbent was prepared as follows:

[0023] (1) Crush the original halloysite ore and pass through a 300-mesh sieve to obtain halloysite powder;

[0024] (2) Weigh 8g of potassium carbonate powder and dissolve in 60mL of deionized water to obtain a potassium carbonate solution; respectively weigh 2g of halloysite powder and 4g of chitosan, add to the potassium carbonate solution, immerse and stir for 4h, and dry at 105°C After obtaining the mixture material.

[0025] (3) Put the mixture in a horizontal tube sintering furnace, N 2 In the atmosphere, the temperature is increased to 800°C at a rate of 5°C / min, and the temperature is kept and activated for 90 minutes. After cooling to room temperature, a black product is obtained;

[0026] (4) Wash the black product with 0.1 mol / L hydrochloric acid solution to remove the residual activator, and then wash the sample with 60° C. deionized water to neutrality. The washed sample is d...

Embodiment 2

[0037] In this example, the halloysite / charcoal composite adsorbent was prepared as follows:

[0038] (1) Crush the original halloysite ore and pass through a 300-mesh sieve to obtain halloysite powder;

[0039] (2) Weigh 8g of potassium carbonate powder and dissolve in 60mL of deionized water to obtain a potassium carbonate solution; respectively weigh 2g of halloysite powder and 4g of chitosan, add to the potassium carbonate solution, immerse and stir for 4h, and dry at 105°C After obtaining the mixture material.

[0040] (3) Put the mixture in a horizontal tube sintering furnace, N 2 In the atmosphere, the temperature is increased to 800°C at a rate of 5°C / min, and the temperature is kept for 120min. After cooling to room temperature, a black product is obtained;

[0041] (4) Wash the black product with 0.1 mol / L hydrochloric acid solution to remove the residual activator, and then wash the sample with 60° C. deionized water to neutrality. The washed sample is dried at 105°C and ...

Embodiment 3

[0045] In this example, the halloysite / charcoal composite adsorbent was prepared as follows:

[0046] (1) Crush the original halloysite ore and pass through a 300-mesh sieve to obtain halloysite powder;

[0047] (2) Weigh 8g of potassium carbonate powder and dissolve it in 60mL of deionized water to obtain a potassium carbonate solution; respectively weigh 2g of halloysite powder and 4g of chitosan, add to the potassium carbonate solution, immerse and stir for 4h, and dry at 105°C After obtaining the mixture material.

[0048] (3) Put the mixture in a horizontal tube sintering furnace, N 2 Under the atmosphere, the temperature is increased to 800°C at a rate of 5°C / min, and the temperature is kept and activated for 150 minutes. After cooling to room temperature, a black product is obtained;

[0049] (4) Wash the black product with 0.1 mol / L hydrochloric acid solution to remove the residual activator, and then wash the sample with 60° C. deionized water to neutrality. The washed samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com