Circulation utilization technology and equipment for electroplating waste water separated by integrated membrane

A technology that integrates membrane separation and electroplating wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., to solve environmental pollution, effectively remove and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

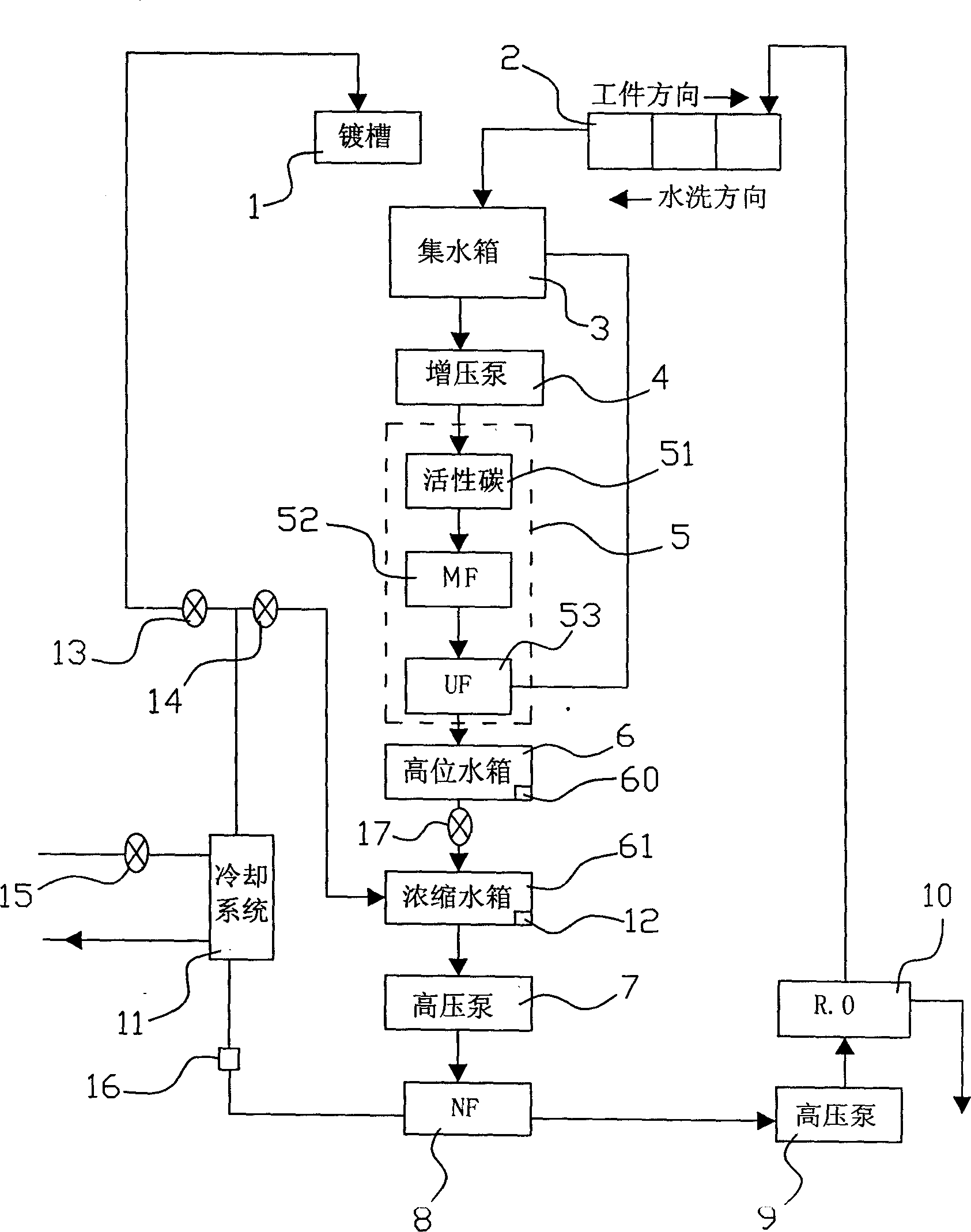

[0018] Refer below figure 1 A specific embodiment of the present invention will be described.

[0019] The electroplating wastewater integrated membrane separation and recycling equipment, its main structure includes a water collection tank 3, a pretreatment module 5 composed of activated carbon filter modules 51, microfiltration membrane modules 52, and ultrafiltration membrane modules 53 connected in series. , nanofiltration membrane module 8 and reverse osmosis membrane module 10. The water collection tank 3 is connected to the electroplating rinse tank 2 through an overflow pipe, and the inlet of the water collection tank 3 and the pretreatment assembly 5 is connected through a pipeline, and a booster pump 4 is installed in the pipeline; the permeate outlet of the ultrafiltration membrane module 53 is connected to a The high-level water tank 6 is connected, and the concentrate outlet water is connected to the water collection tank 3 through a pipeline; the intermediate wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com