Method for removing heavy metals from electronic waste outer shell PS plastic

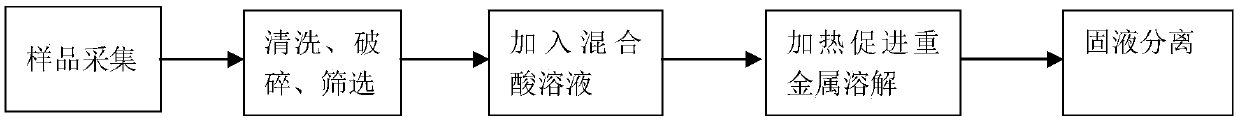

A technology for electronic waste and heavy metals, which is applied in the field of removing heavy metals in PS plastics of electronic waste shells, can solve the problems of high content of harmful substances, waste of land resources, environmental pollution, etc. less time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

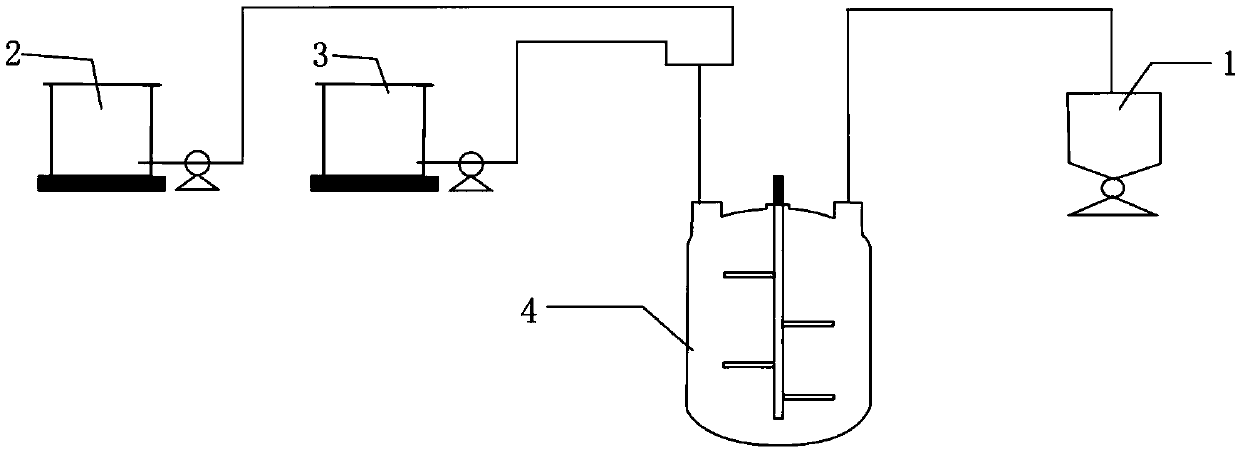

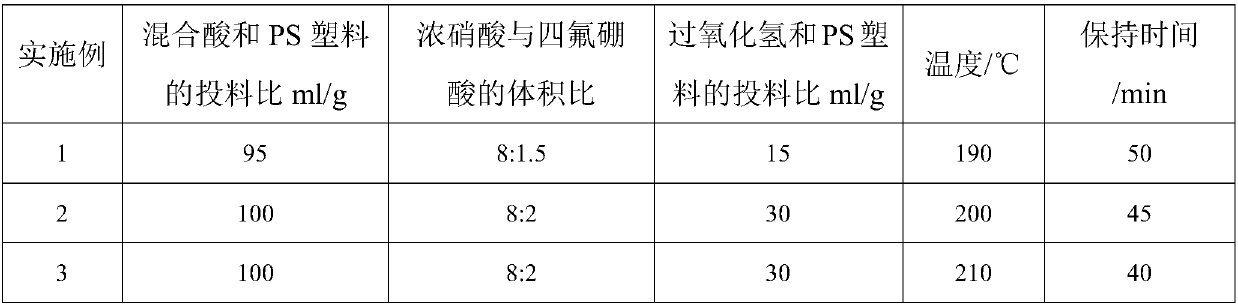

[0029] Put the PS plastic sample into a closed reaction tank 4 after being pulverized, and add the mixed acid formed by mixing concentrated nitric acid and 40wt% tetrafluoroboric acid in volume ratio as shown in Table 2 to obtain solution a; Add 30wt% hydrogen peroxide solution to soak for half an hour, heat to dissolve. After the reaction, the solution is cooled, and the valuable heavy metals in the solution are recovered after solid-liquid separation, and the heavy metal content in the solution and the quality of the separated plastic sample are measured to calculate the recovery rate.

[0030] Table 2. Example Operating Conditions

[0031]

[0032] The detection process of the present embodiment is as follows:

[0033] The solution sample was first washed with aqua regia (HCl:HNO 3 =3:1) Digested in a 100ml long-necked Erlenmeyer flask for 2h, after heating and digesting, add distilled water and slightly heat back to dissolve. Dilute the digestion solution to a consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com