Rubber belt type vacuum filter discharge device

A technology of vacuum filter and unloading device, which is applied in the directions of filtration and separation, moving filter element filter, separation method, etc., can solve the problems such as easy corrosion of the seal of the cylinder moving parts, large structure of the whole unloading device, and complicated cylinder installation. , to achieve the effect of reliable performance, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

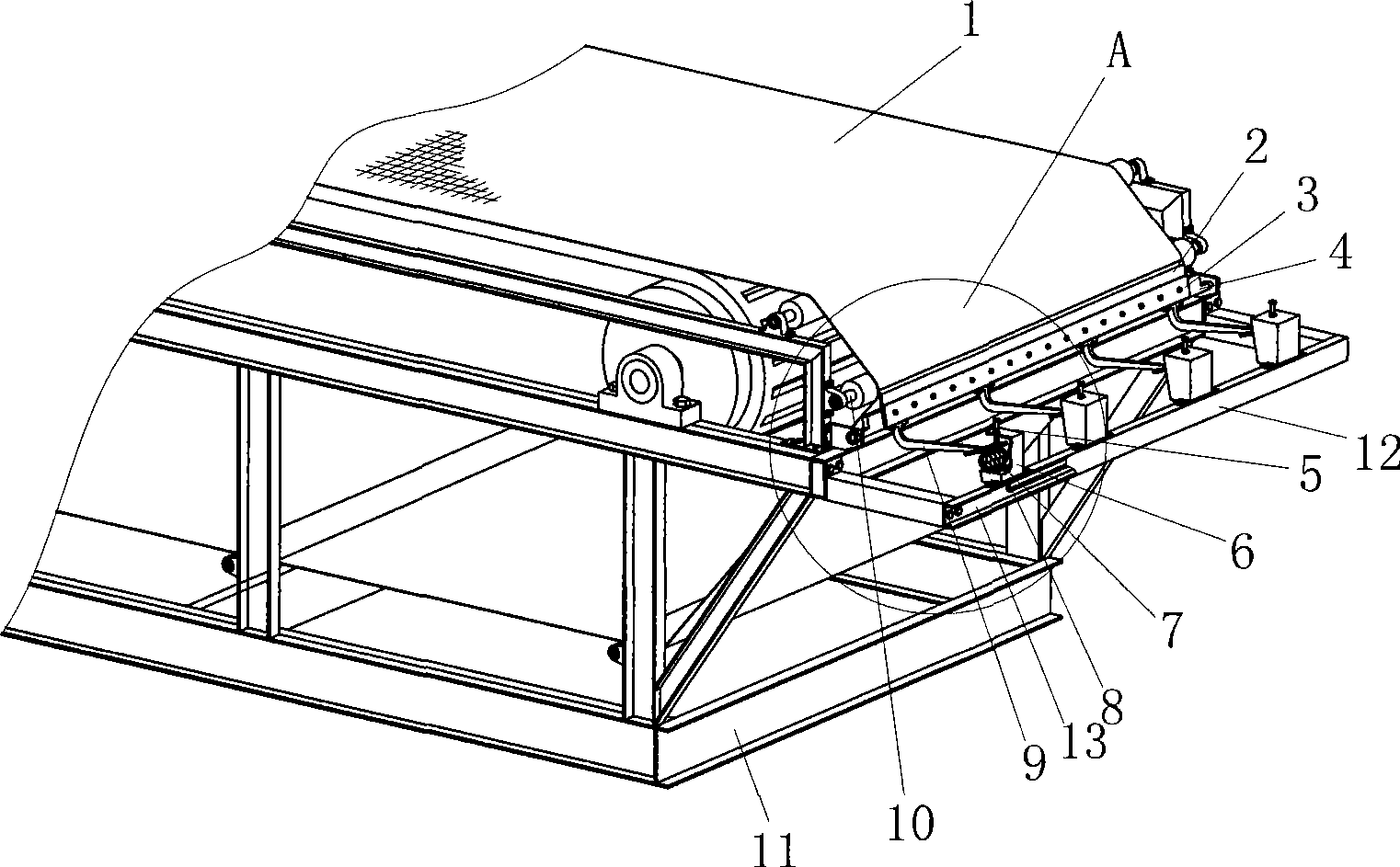

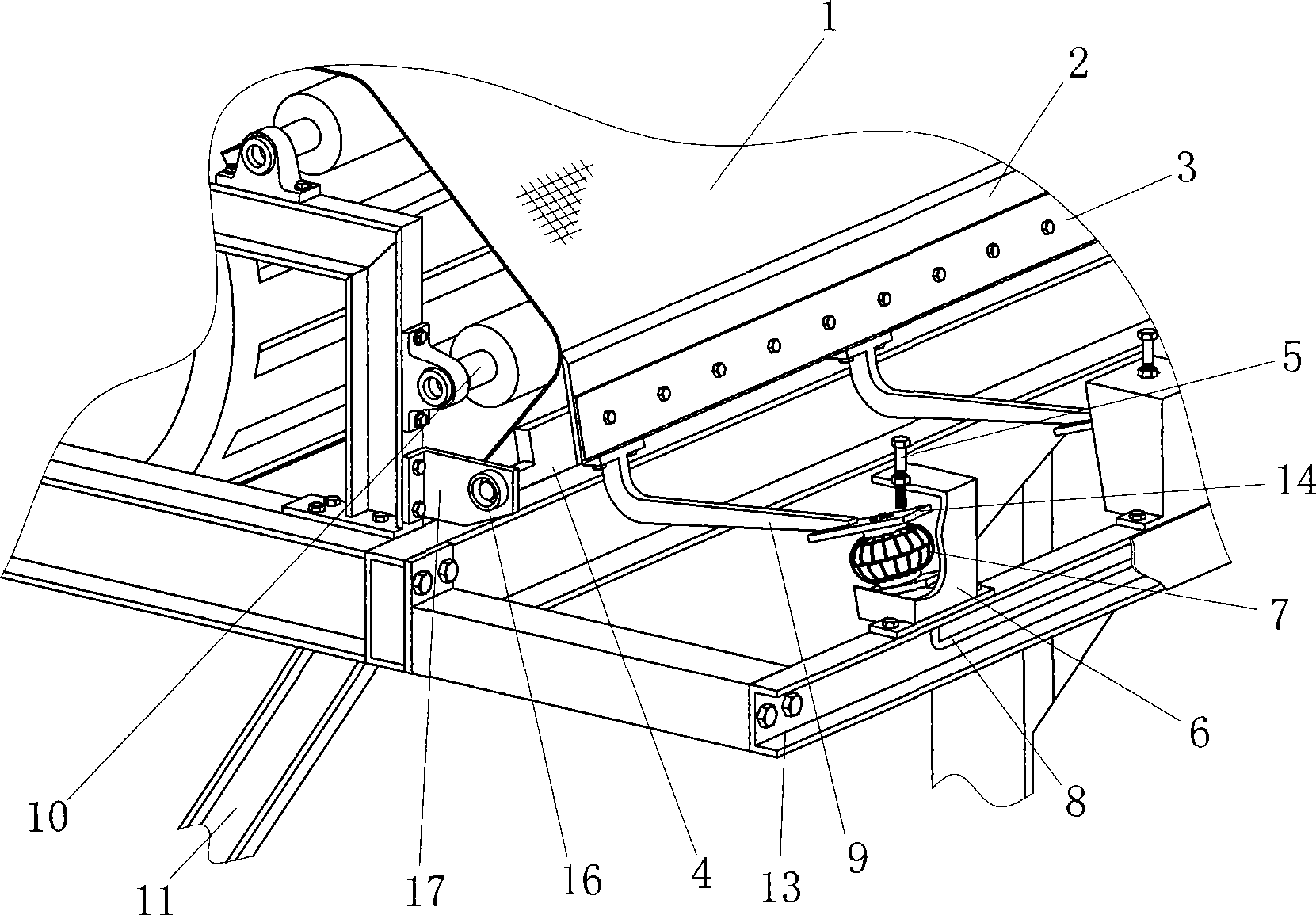

[0036] Embodiment 1: as figure 1, shown in 2, a rubber belt type vacuum filter unloading device, it is used on the filter, the filter includes a filter cloth 1, when the filter cloth 1 passed through the discharge roller 10, the filter cloth 1 became zigzag, For the filter cake folds attached to the filter cloth 1, the rubber belt vacuum filter discharge device of the present invention is correspondingly provided at the discharge roller 10, which includes a scraper support 11 and a The scraper bracket 17 on the scraper support 11, the scraper bracket 17 is pivotally connected with a scraper frame 3 through a bearing 16, a scraper 2 is installed on the scraper frame 3, and one end of four curved rods 9 is fixedly connected At the lower end of the scraper holder 3, the four curved rods 9 are evenly arranged, and the other end of the curved rod 9 is associated with the mounting arm 14 on an air bag 7, the air bag 7 is connected with a trachea 8, and the air bag 7 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com