Hardware universal hinging unit

A technology of structural parts and hinges, which is applied in the direction of elastic couplings, mechanical equipment, couplings, etc., and can solve the problems that the nodes of the beam end support have not been used, and there are not many nodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

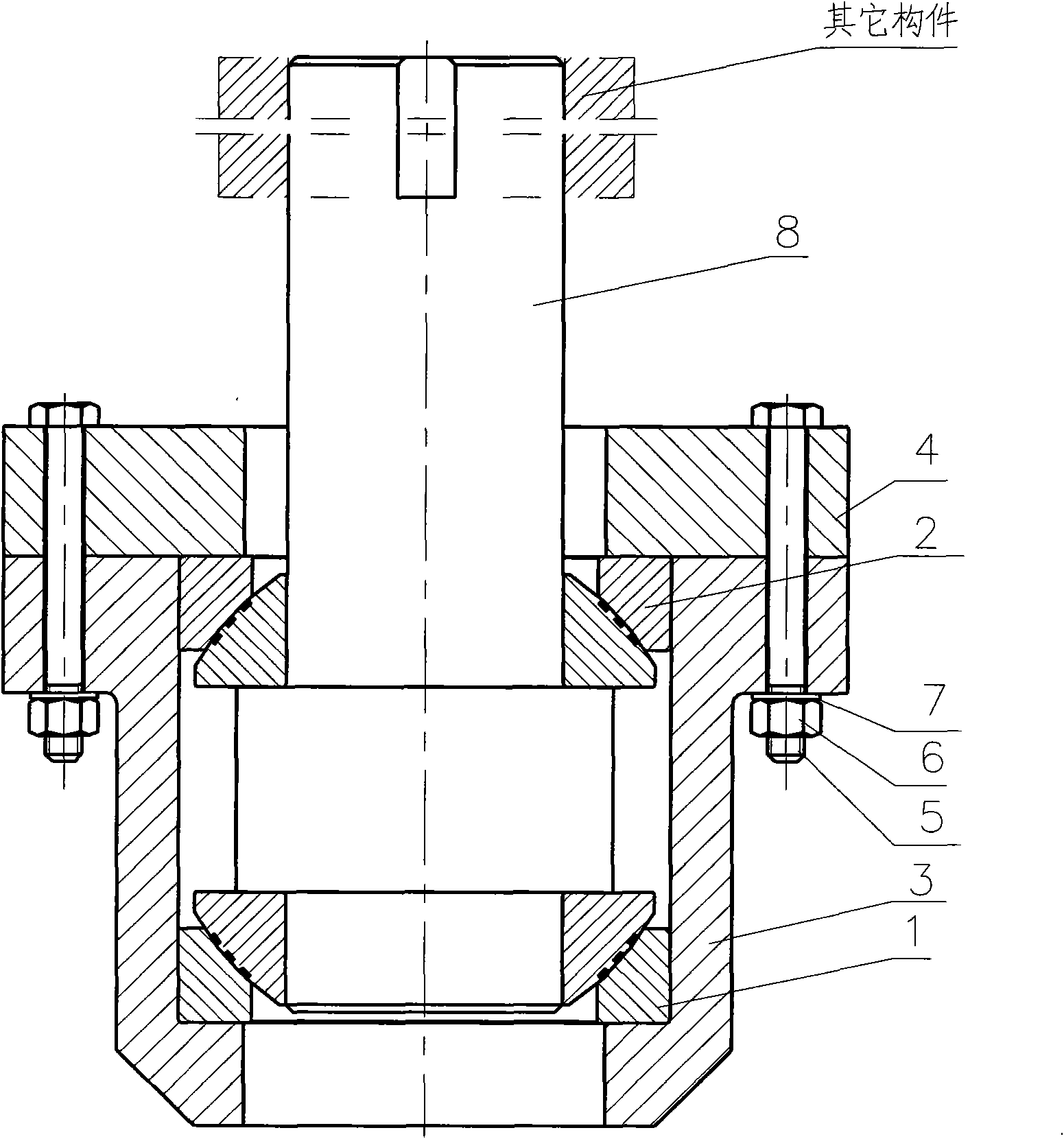

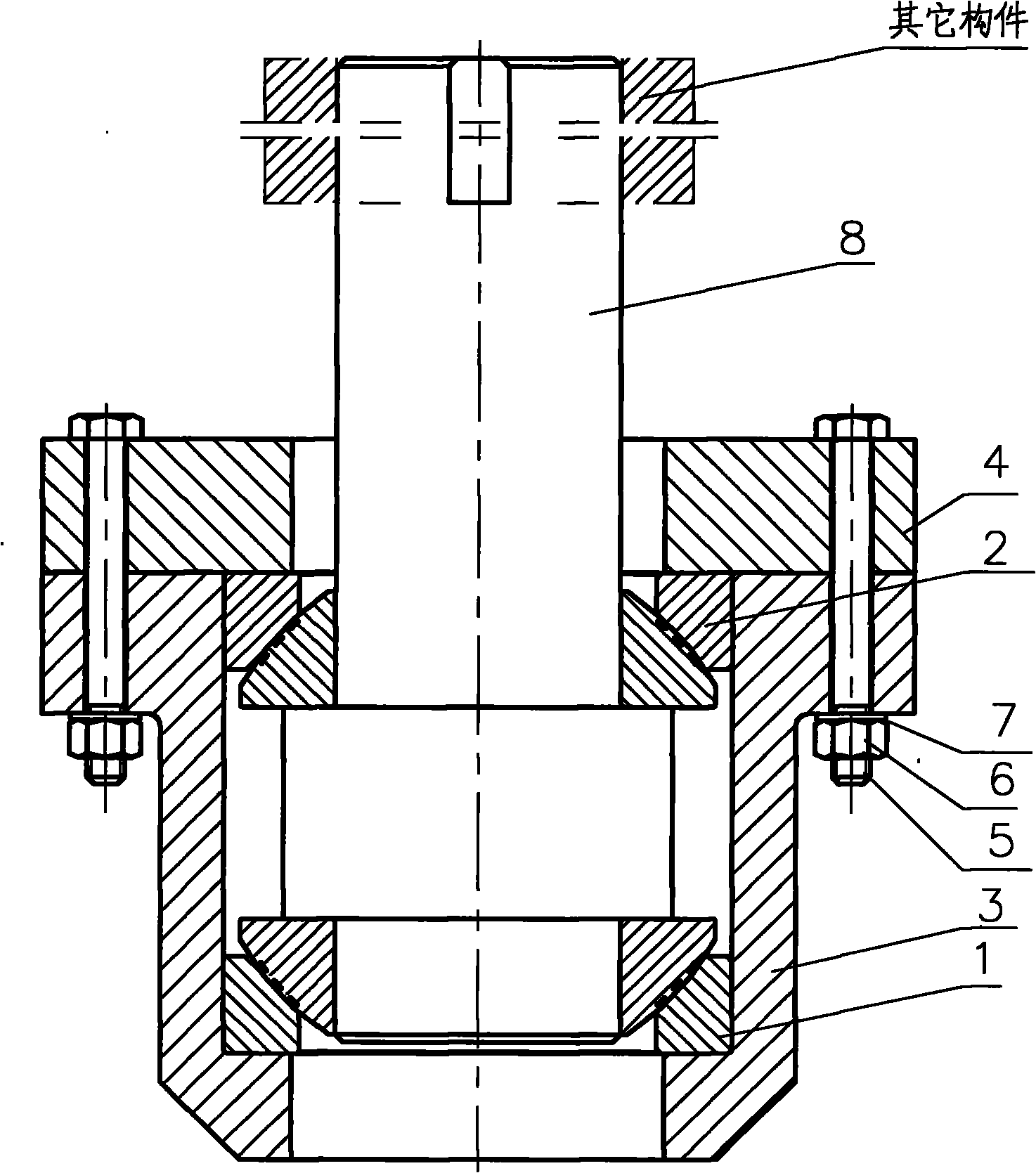

[0010] As shown in Figure 1, the universal joint unit of the structural member of the present invention is composed of a thrust joint bearing 1, a thrust joint bearing 2, a fixed base 3, a fixed cover plate 4, a high-strength fixing bolt 5, a nut 6, a washer 7 and a mandrel 8 , it is characterized in that: the thrust joint bearing 1 and the thrust joint bearing 2 are installed in pairs on one end of the mandrel 8, the pair of thrust joint bearings and the mandrel are put into the inner hole of the fixed base 3 together, and there is a fixed cover with a hole in the middle The plate 4 covers the large end face of the seat ring of the thrust joint bearing 2, and is connected with the fixed base 3, and is fixed by a plurality of high-strength fixing bolts 5, nuts 6, and washers 7 to form a hinged unit structure. The thrust joint bearing is made of stainless steel.

[0011] During installation, the end of the fixed base in the hinge unit is connected with a component of the buildi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com