Vulcanization type hydrogenation catalyst and preparation method thereof, and gasoline hydrodesulfurization method

A hydrogenation catalyst and vulcanization-type technology, applied in physical/chemical process catalysts, chemical instruments and methods, and hydrocarbon oil treatment, can solve problems such as poor selectivity, low sweetening activity, and harsh reaction conditions, and achieve effective removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a sulfurized hydrogenation catalyst, the method comprising:

[0035] (1) The carrier is impregnated with a solution containing the precursor of the active metal component A and the precursor of the active metal component B, the active metal component A is selected from the group VIII metal elements, and the active metal component B is selected from the group VIII metal elements VIB group metal elements;

[0036] (2) vulcanizing the solid material obtained after impregnating step (1);

[0037] Wherein, based on the respective metal elements, the molar ratio of the precursor of the active metal component A to the precursor of the active metal component B is 0.6-2.3:1;

[0038] The precursor of the active metal component B is ammonium thioacid.

[0039] The selection of the active metal component A, the active metal component B and the carrier in the present invention is as described above, and will not be repeat...

Embodiment 1

[0074] (1) Weigh 25.4g of ammonium thiomolybdate, add deionized water to prepare 110mL of aqueous solution, impregnate 100g of carrier with this solution for 6h, and then vacuum dry at 120°C for 4h to obtain Mo / Al 2 o 3 ;

[0075] (2) Weigh 22.1g cobalt nitrate and 21.55g EDTA, add deionized water to prepare 80mL solution, impregnate Mo / Al 2 o 3 6h, and then vacuum dried at 120°C for 4h to obtain the oxidation state CoMo / Al 2 o 3 ;

[0076] (3) For oxidation state CoMo / Al 2 o 3 Carry out wet vulcanization, the specific conditions include: in the presence of hydrogen, the oxidation state CoMo / Al 2 o 3 Contact reaction with cyclohexane containing 5% by weight of carbon disulfide at 300°C and 2.4MPa for 6h, and the volume space velocity of hydrogen is 1600h -1 , the volume ratio of hydrogen to oil is 400, and the reaction temperature is lowered to room temperature to obtain sulfurized hydrogenation catalyst S-1.

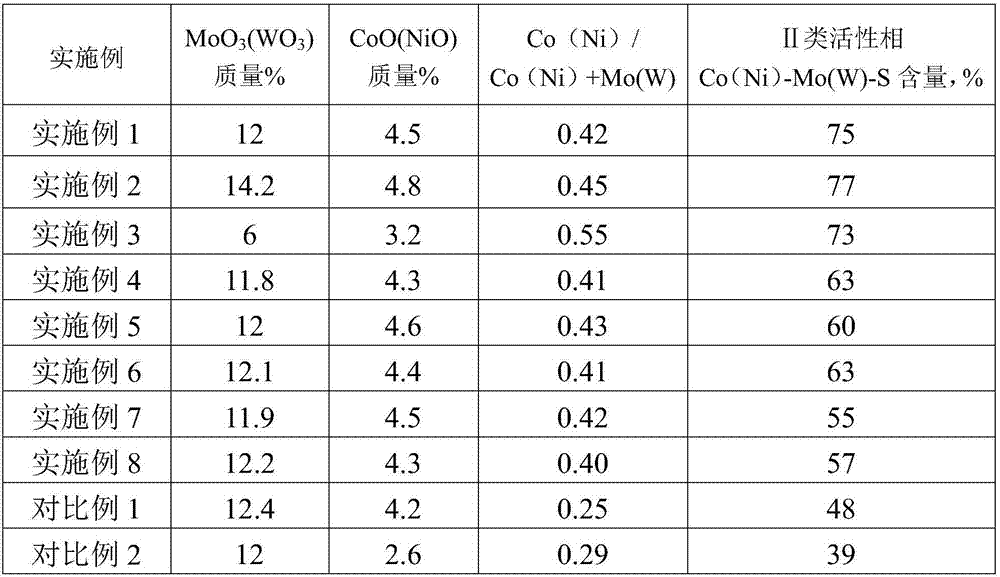

[0077] The component contents and XPS analysis results ...

Embodiment 2

[0079] (1) Weigh 31.8g of ammonium thiomolybdate, add deionized water to prepare a 110mL aqueous solution, impregnate 100g of carrier with this solution for 6h, and then vacuum dry at 120°C for 4h to obtain Mo / Al 2 o 3 ;

[0080] (2) Weigh 22.1g of cobalt nitrate and 14.2g of citric acid, add deionized water to make 80mL solution, impregnate Mo / Al 2 o 3 6h, and then vacuum dried at 120°C for 4h to obtain the oxidation state CoMo / Al 2 o 3 ;

[0081] (3) For oxidation state CoMo / Al 2 o 3 Carry out wet vulcanization, the specific conditions include: in the presence of hydrogen, the oxidation state CoMo / Al 2 o 3 Contact and react with straight-run gasoline distillate oil containing 3% by weight of carbon disulfide at 320°C and 3.2MPa for 10h, and the hydrogen volume space velocity is 600h -1 , the volume ratio of hydrogen to oil is 300, and the reaction temperature is lowered to room temperature to obtain sulfurized hydrogenation catalyst S-2.

[0082] The component con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com