Hot-water system of heat pump

A technology of heat pump hot water and water tank, which is applied in fluid heaters, lighting and heating equipment, damage protection, etc. It can solve the problems of long defrosting time, poor defrosting effect, and low heat, so as to achieve small impact, The effect of effective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

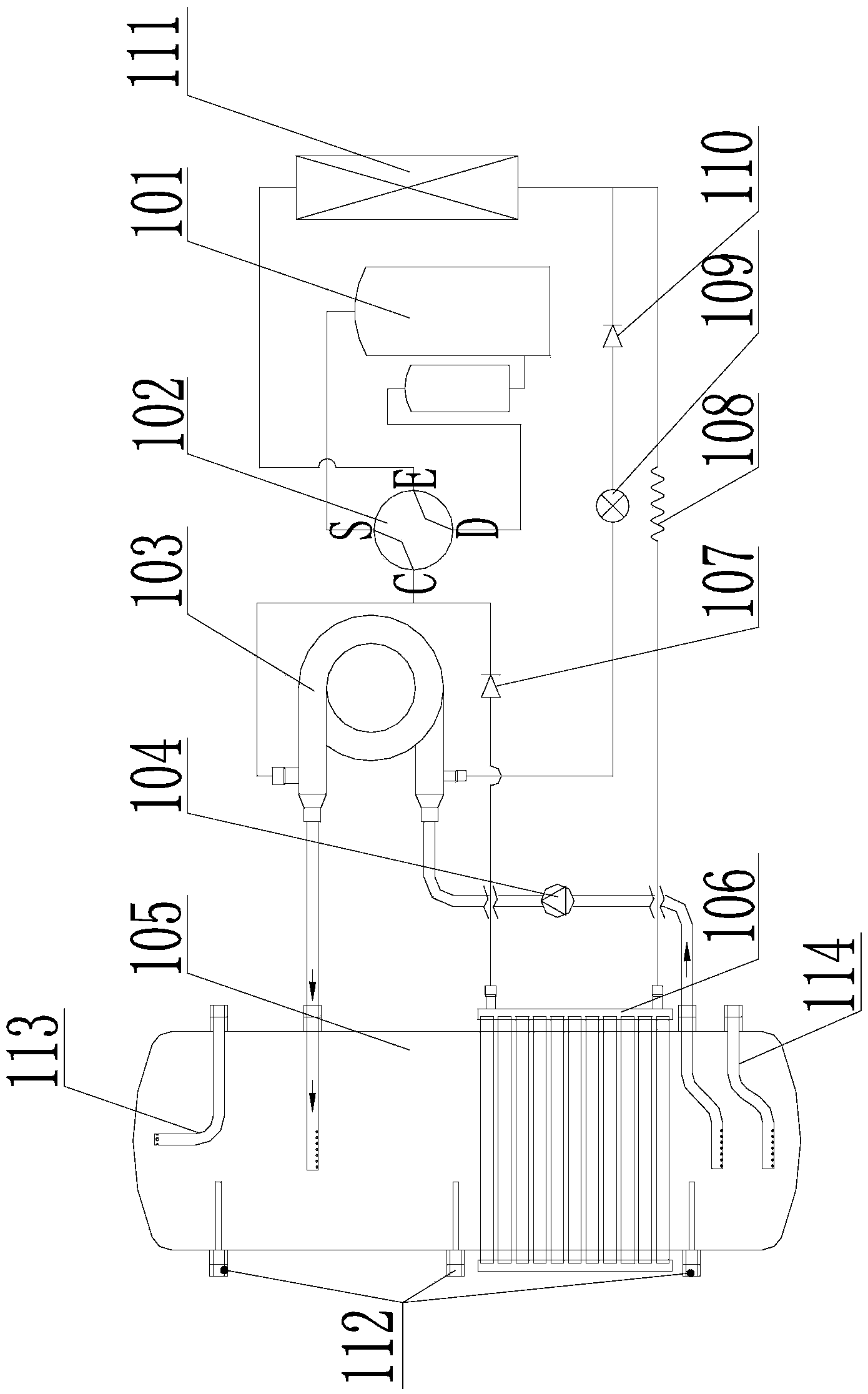

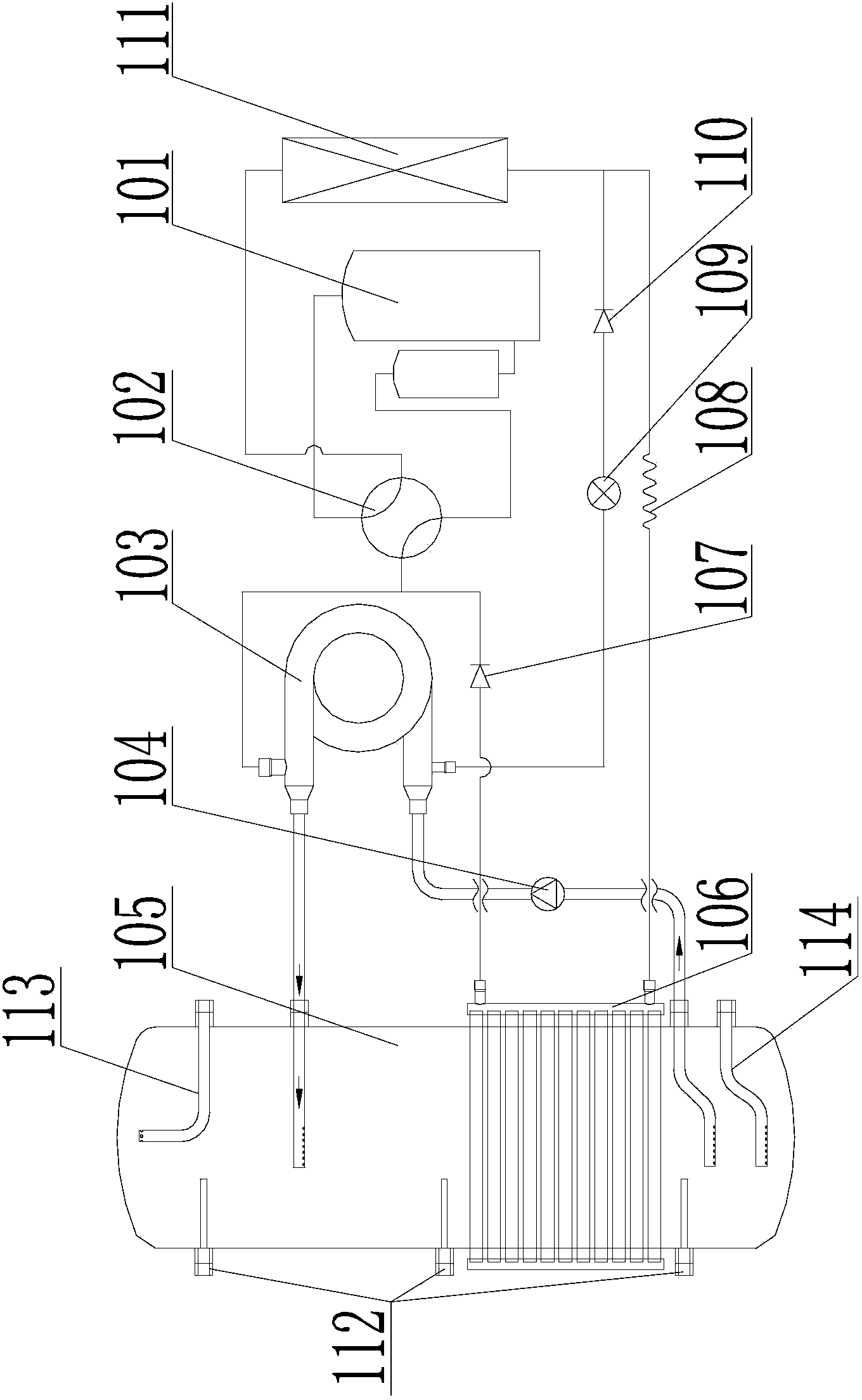

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] In this embodiment, the application provides a heat pump hot water system, which is suitable for directly heating the water in the water tank by using a sleeve heat exchanger when hot water is used; When there is frost in the evaporator), the coil heat exchanger is used to provide heat for defrosting. This defrosting process has little impact on the water temperature in the water tank and the comfort of the user, and it can be quickly and effectively removed. Frost accumulation on heat exchanger.

[0029] like figure 1 , figure 2 As shown, the above-mentioned heat pump hot water system includes a compressor 101, a four-way valve 102, an outdoor heat exchanger 111, a throttling device and a water tank 105. Of course, in order to improve the performance of the heat pump system, the system ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com