Method for removing silicon out of aluminium alloy

A technology of aluminum alloy and silicon element, applied in the field of metal materials, can solve problems such as changing alloy composition, and achieve the effect of effective removal, low price and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

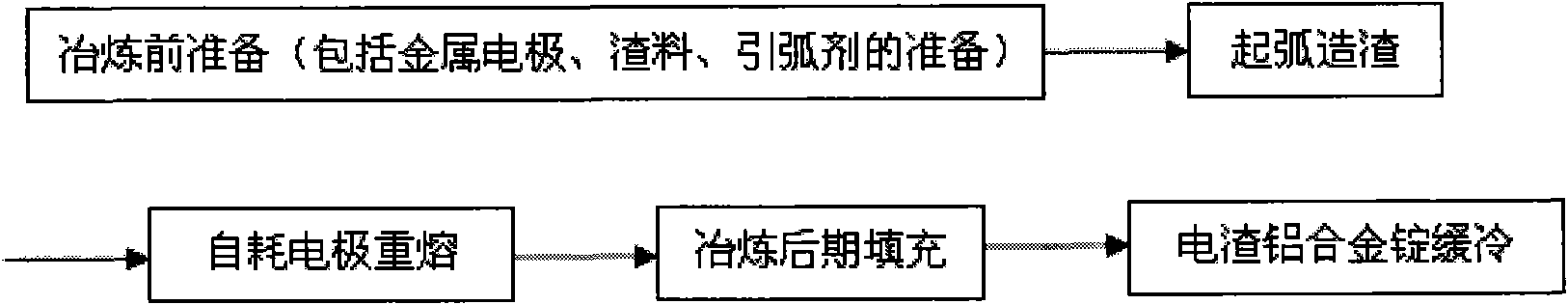

Method used

Image

Examples

Embodiment 1

[0032] Cast the aluminum alloy into a consumable electrode rod, the size of the aluminum alloy electrode is Φ70mm, and the weight is 12 kg; the arc starting agent is 15g of carbon electrode; the inner diameter of the crystallizer is 100mm; put the consumable electrode rod into the electroslag furnace, Add slag material and carry out electroslag remelting with a voltage of 40V and a current of 300-400A; when remelting the self-consumable electrode, pass argon gas into the crystallizer and control the current at 300A; after the smelting is completed, cut off the power supply and cool down , to obtain aluminum alloy, the electroslag material selected is Na 3 AlF 6 , the amount added is 15% of the weight of the consumable electrode, which is 1.8 kg.

[0033] In this example, the silicon content of the aluminum alloy with a silicon content of 0.33% is reduced to 0.17% after refining.

Embodiment 2

[0035] Cast the aluminum alloy into a consumable electrode rod, the size of the aluminum alloy electrode is Φ62mm, and the weight is 11 kg; the arc starting agent is 12g of carbon electrode; the inner diameter of the crystallizer is 100mm; put the consumable electrode rod into the electroslag furnace, Add slag material and carry out electroslag remelting with a voltage of 40V and a current of 500-550A; when remelting the self-consumable electrode, pass argon gas into the crystallizer and control the current at 1000A; after the smelting is completed, cut off the power supply and cool , to obtain aluminum alloy, the selected electroslag material is 30% MgF 2 +30%KCl+40%MgCl 2 , the addition amount is 5% of the weight of the consumable electrode, which is 0.55 kg.

[0036] In this example, the silicon content of the aluminum alloy with a silicon content of 0.20% is reduced to 0.12% after refining.

Embodiment 3

[0038] Cast the aluminum alloy into a consumable electrode rod, the size of the aluminum alloy electrode is Φ60mm, and the weight is 10 kg; the arc starting agent is 12g of carbon electrode; the inner diameter of the crystallizer is 100mm; put the consumable electrode rod into the electroslag furnace, Add slag material and carry out electroslag remelting with a voltage of 45V and a current of 500-600A; when remelting the self-consumable electrode, pass argon gas into the crystallizer and control the current at 600A; after the smelting is completed, cut off the power supply and cool down , to obtain aluminum alloy, the selected electroslag material is 30% MgF 2 +40%KCl+30%MgCl 2 , the addition amount is 5% of the weight of the consumable electrode, which is 0.5 kg.

[0039] In this example, the silicon content of the aluminum alloy with a silicon content of 0.22% is reduced to 0.11% after refining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com