Steel rail profile outlier detection and effective profile recognition method

A technology of outlier detection and contour, which is applied in the direction of measuring devices, optical devices, railway vehicle shape measuring devices, etc. Group segment and other problems, to achieve the effect of effective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

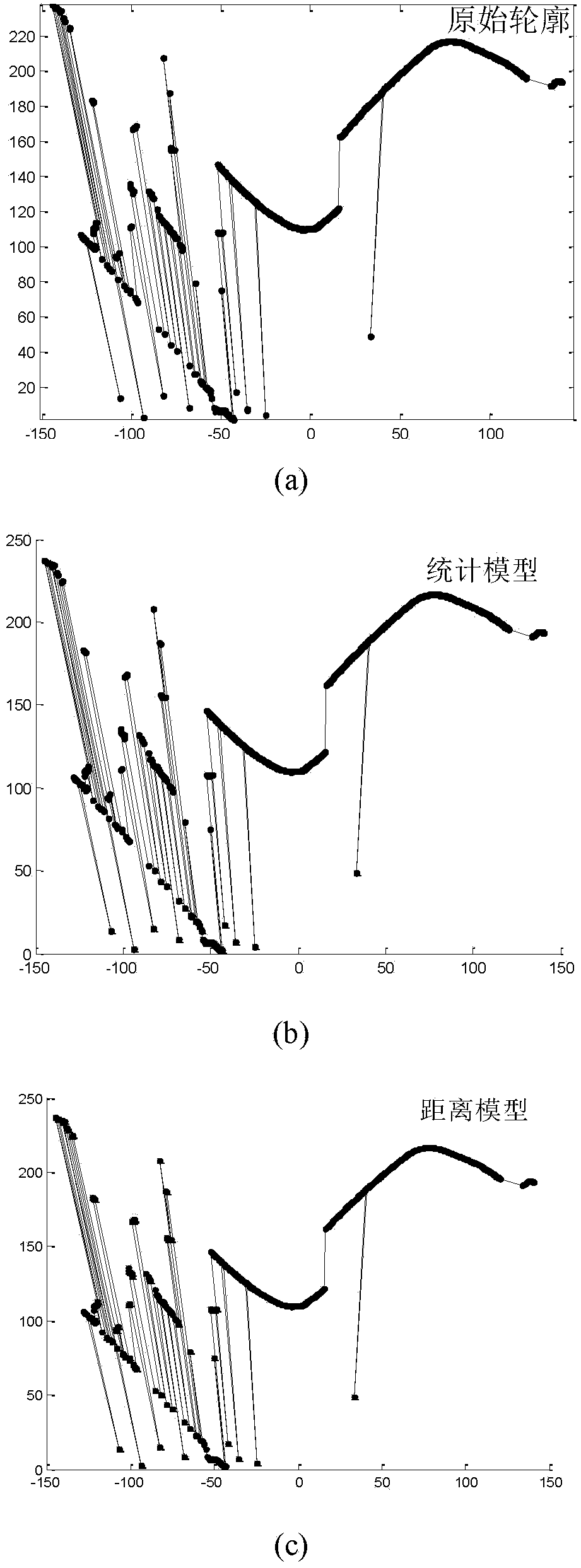

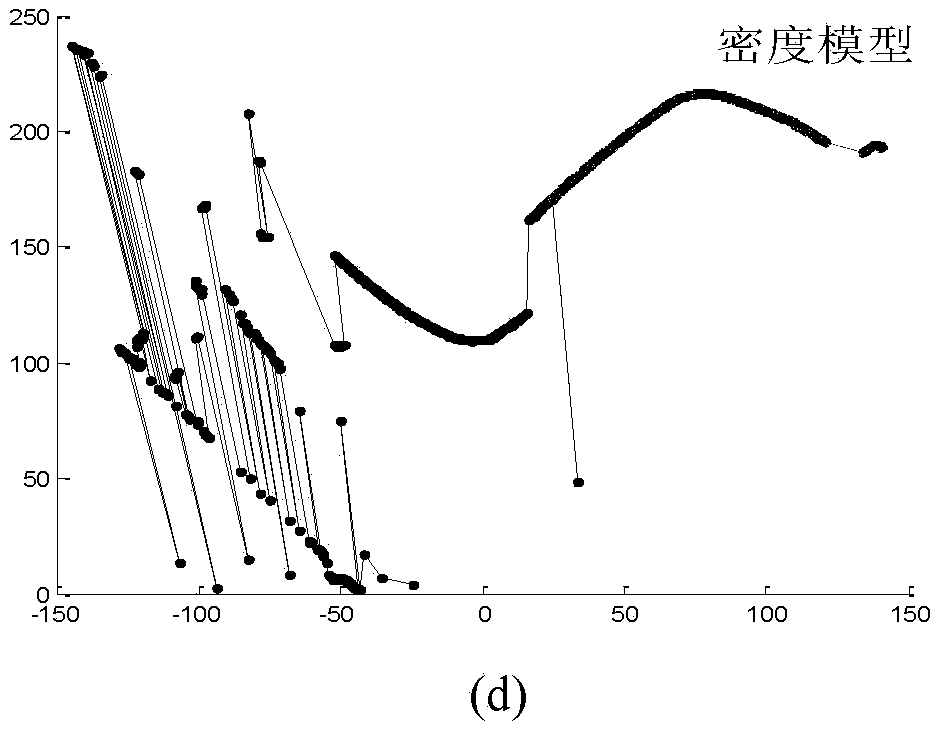

[0033] Considering that each profile shape has the characteristics of the rail head area, the rail jaw point and the inner straight line in the rail head area are used as the benchmarks for contour registration. Compared with the traditional rail waist area as the registration reference, the registration accuracy of the rail head area is low. We call it coarse registration. An outlier point and effective contour detection algorithm based on contour coarse registration is proposed. The specific detection process is as figure 2 shown.

[0034] Step 1: Contour splitting to remove sparse outliers

[0035] The distribution of normal contour data points is relatively dense, and the distance between adjacent points is small. Where there is a large jump in the distance between dots, there must be an anomaly. Based on this consideration, after obtaining the threshold of the distance between adjacent points on the normal contour curve, we first split the measured contour to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com