Chlorine zero-pressure control method applied to process for preparing alkali by utilizing zero-pole ionic membrane electrolytic cell

A technology of ionic membrane electrolyzer and zero pole distance, which is applied in the direction of electric fluid pressure control, electrolysis process, electrolysis components, etc., can solve the problems such as compression deformation of elastic body of zero pole distance electrolyzer, ion membrane damage, etc. Achieve the effect of improving equipment use efficiency, reducing equipment operating costs and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

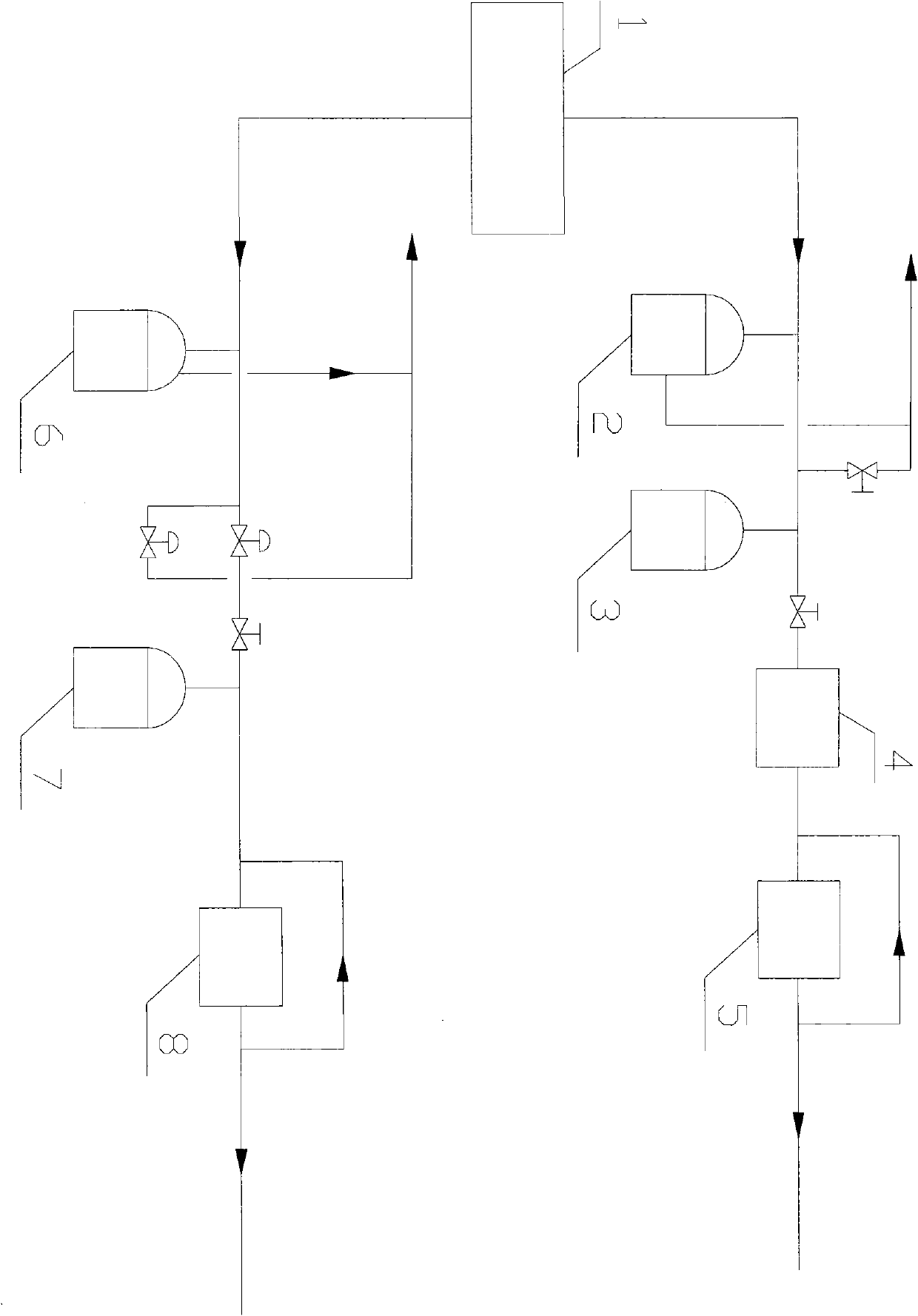

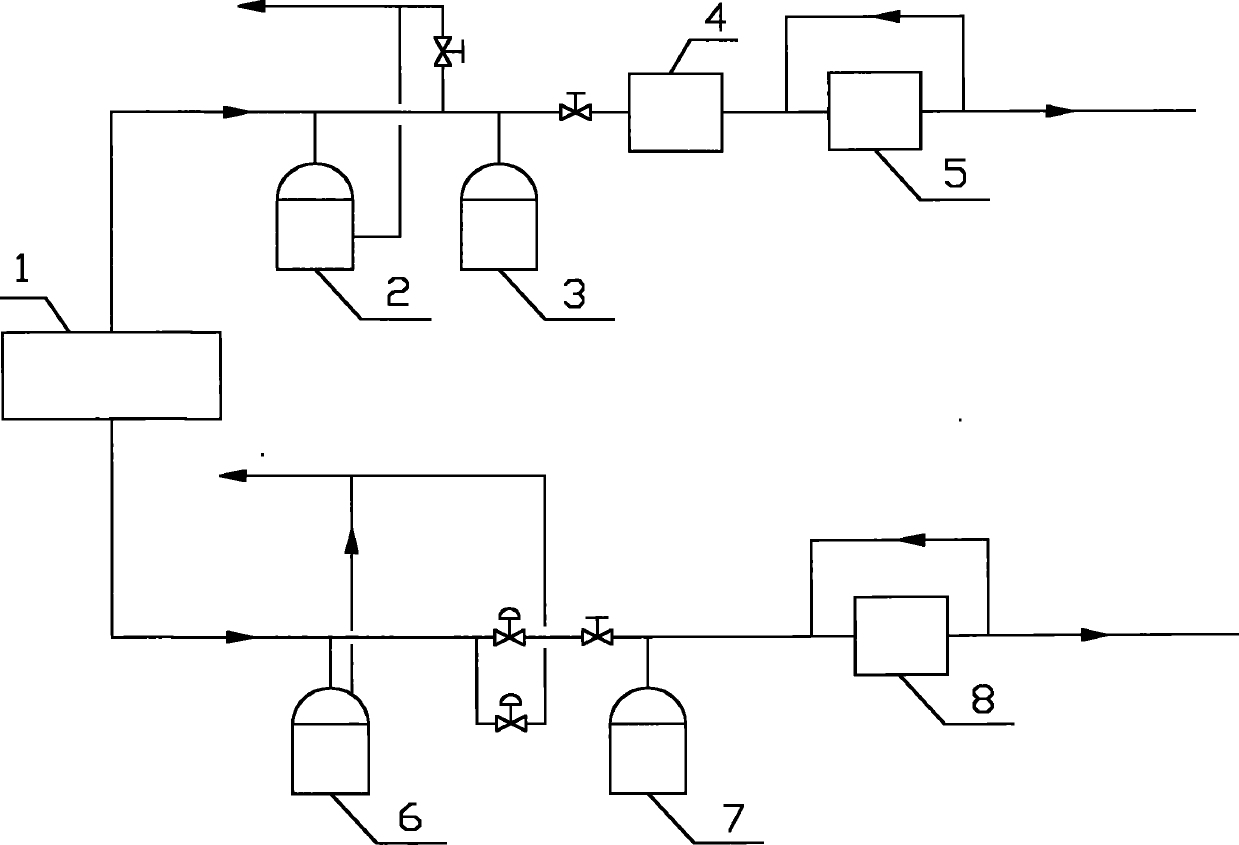

[0014] Refer to attached figure 1 , this embodiment includes successively connected zero pole distance sub-membrane electrolyzer 1, chlorine gas positive pressure water seal 2, chlorine gas negative pressure water seal 3, chlorine gas drying device 4, 3K chlorine compressor 5, hydrogen gas positive pressure water seal 6, hydrogen gas Negative pressure water seal 7, hydrogen compressor 8; after electrolysis of the refined brine in the zero-electrode distance electrolytic cell, the pressure of the electrolytic chlorine gas is set to (0±2)kPa, and the chlorine gas main pipe is only equipped with two on-off valves, one for dechlorination Drying, one detoxification, the purpose of setting the on-off valve is to quickly isolate the chlorine system from the follow-up process in the event of an emergency shutdown and change the detoxification, so as to ensure the stability of the anode negative pressure, and the chlorine gas enters the 3K chlorine compressor after being processed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com