Method and device for eliminating desulfurized white smoke

A technology for white smoke and flue gas, which is applied to combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of increasing the energy consumption and cost of white smoke treatment, and achieve the reduction of equipment construction and maintenance costs, and low operating energy consumption. , The effect of simplifying the structure of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

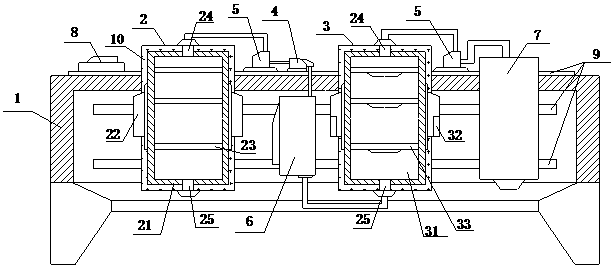

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

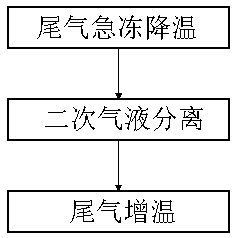

[0023] Such as figure 1 and 2 As shown, a method and device for eliminating desulfurization white smoke comprises the following steps:

[0024] In the first step, the flue gas is rapidly frozen and cooled, and the flue gas to be treated after desulfurization passes through the cooling equipment, so that the flue gas to be treated passes through at least three continuous temperature zones in the range of 10°C to -20°C to cool down in turn, and the flue gas in the flue gas is cooled. The droplet components are condensed at low temperature, and the condensed large droplets are initially separated from the flue gas;

[0025] The second step is the second gas-liquid separation. The flue gas after the first step of quick freezing and cooling is boosted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com