Patents

Literature

1322results about How to "Improve working precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

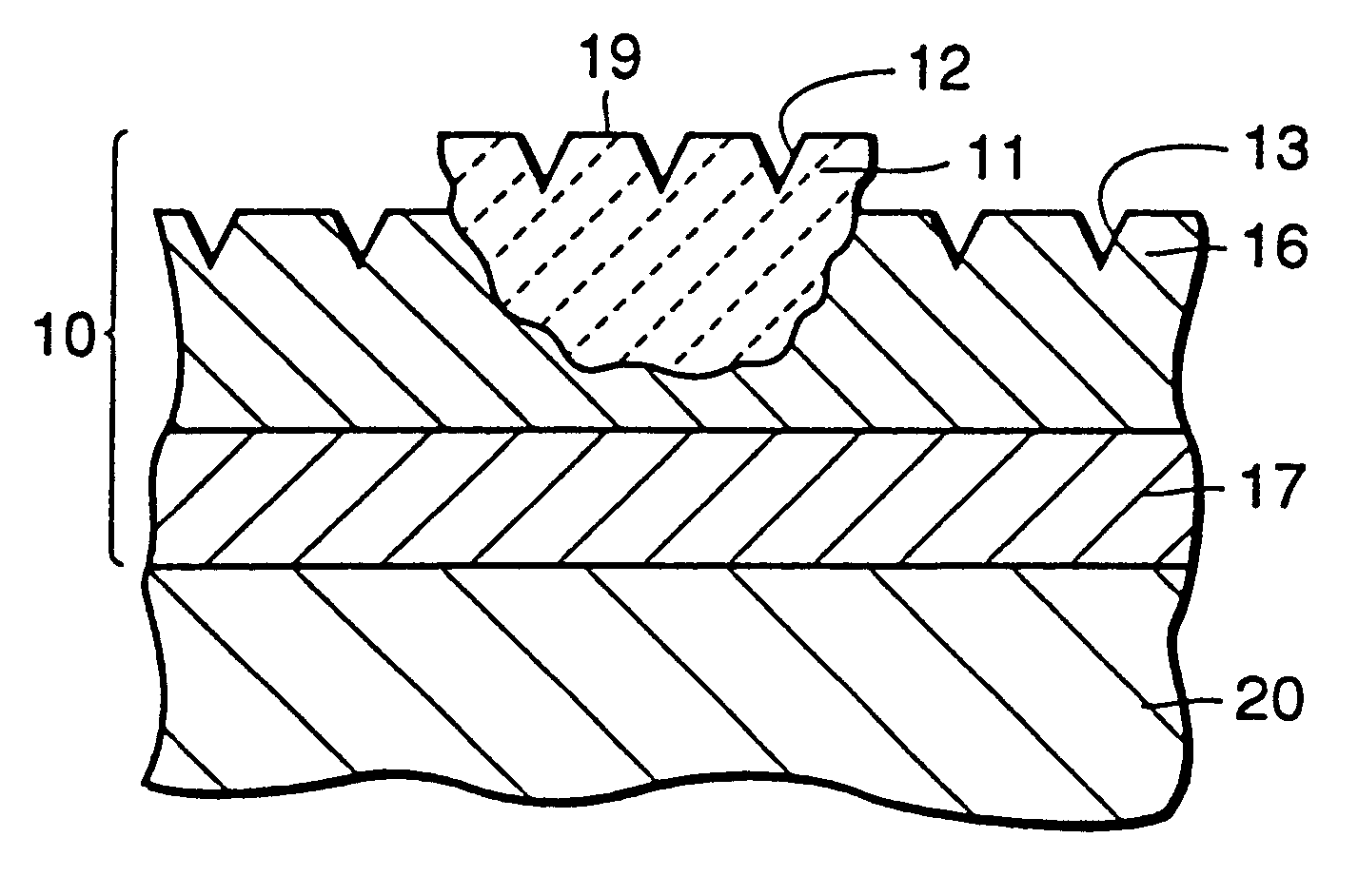

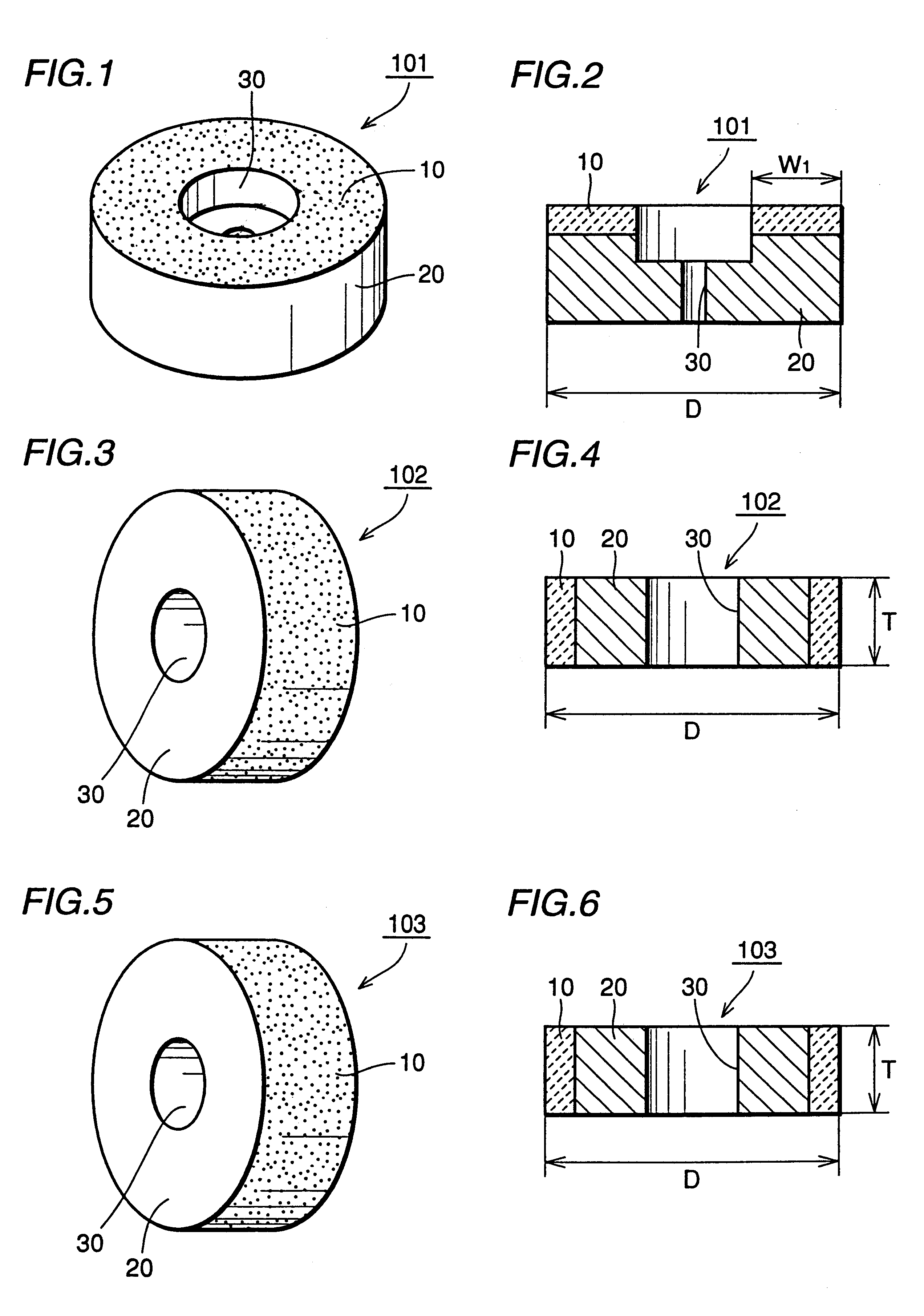

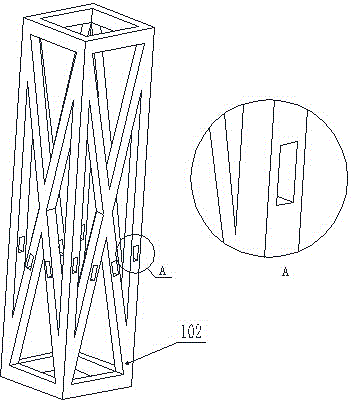

Superabrasive tool and method of manufacturing the same

InactiveUS6312324B1Improving accuracyConducive to flowMilling cuttersBonded abrasive wheelsGrindstoneNickel

A superabrasive tool such as a superabrasive grindstone (101; 102), a superabrasive dresser (103; 104; 105) or a superabrasive lap surface plate (106) includes a base (20) of steel and a superabrasive layer (10) formed on the base (20). The superabrasive layer (10) includes superabrasive grains (11) consisting of diamond grains, cubic boron nitride grains or the like and a holding layer consisting of a nickel plating layer (16) and a bond layer (17), or a brazing filler metal layer (18), holding the superabrasive grains (11) and fixing the same onto the base (20). Grooves (12) or holes (14) are formed on flat surfaces (19) of the superabrasive grains (11) exposed from the holding layer (16, 17; 18). The holding layer (16, 17; 18) holding and fixing the superabrasive grains (11) so that the surfaces of the grains are partially exposed is formed on the base (20). The grooves (12) or the holes (14) are formed by irradiating the surfaces of the superabrasive grains (11) exposed from the holding layer (16, 17; 18) with a laser beam (50). Working of high accuracy can be performed by forming the grooves (12) or the holes (14) on the surfaces of the superabrasive grains (11).

Owner:OSAKA DIAMOND INDAL

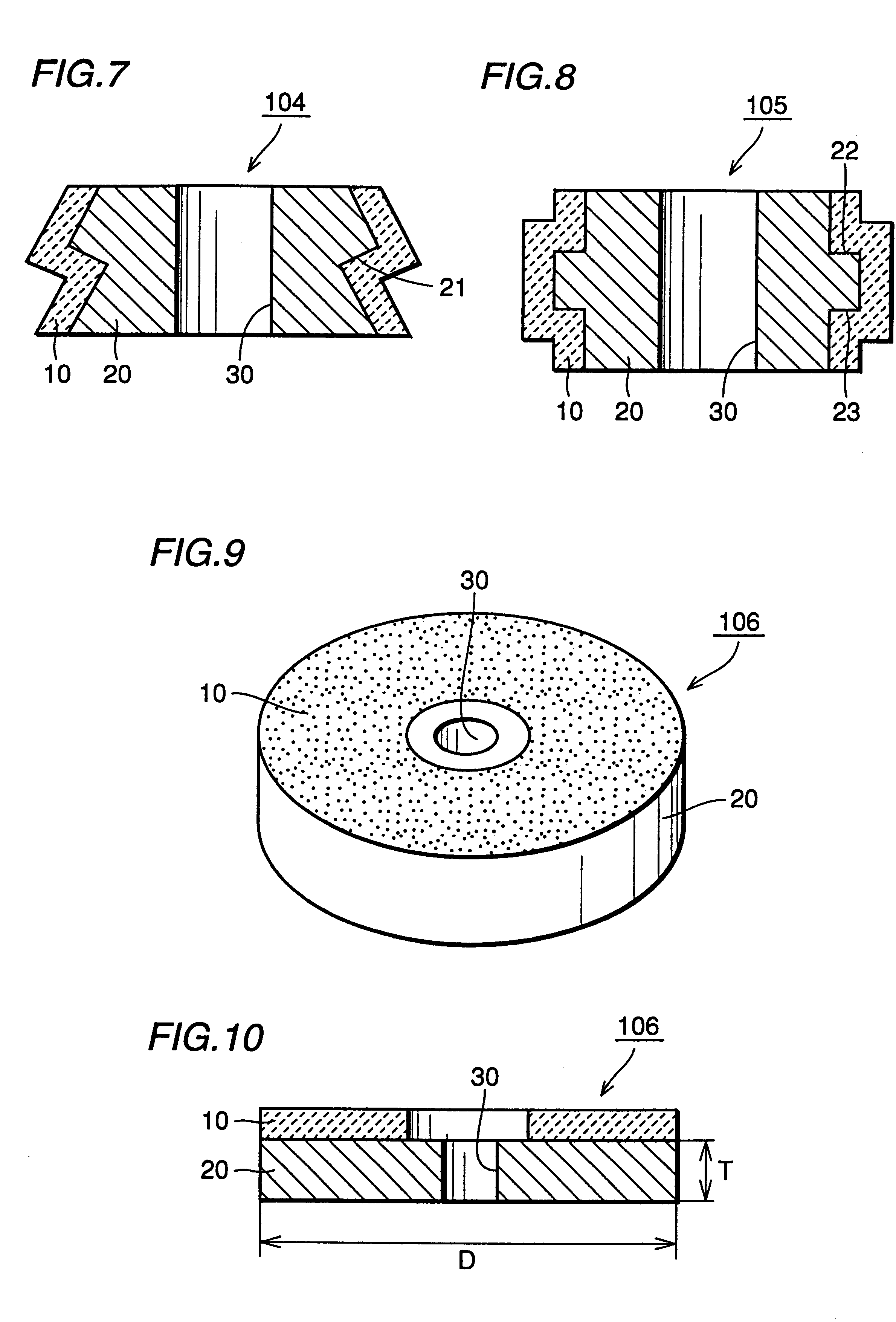

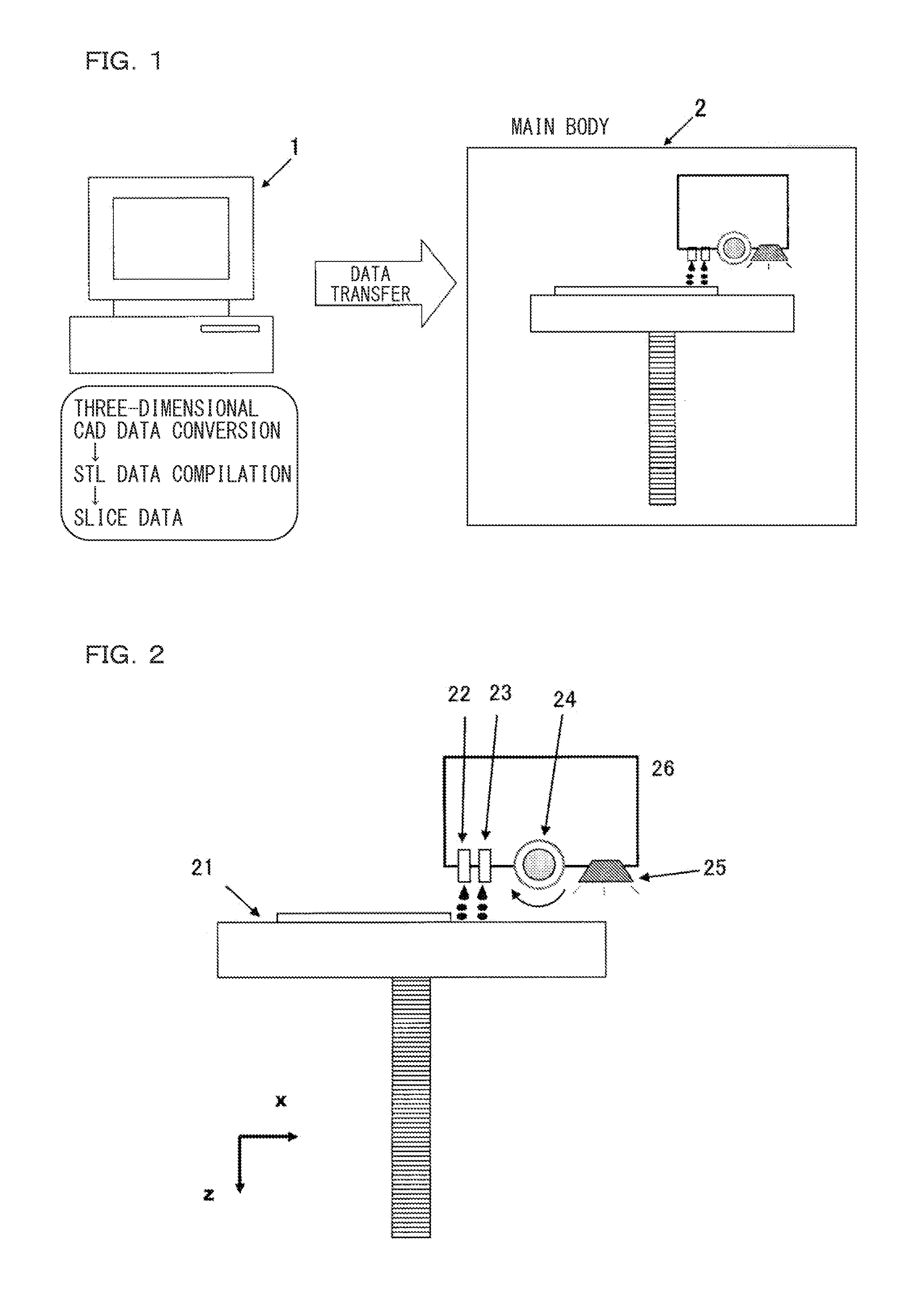

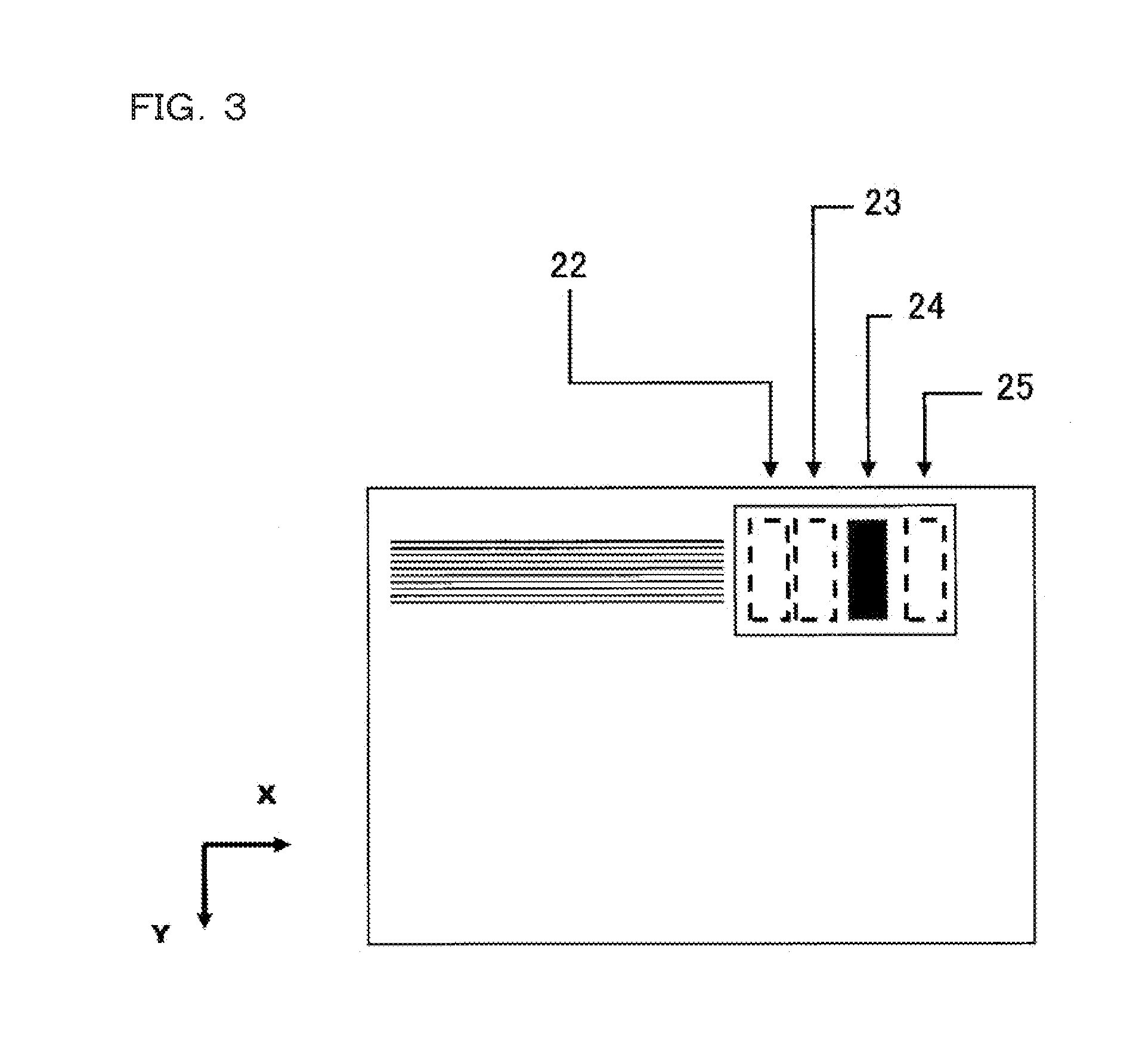

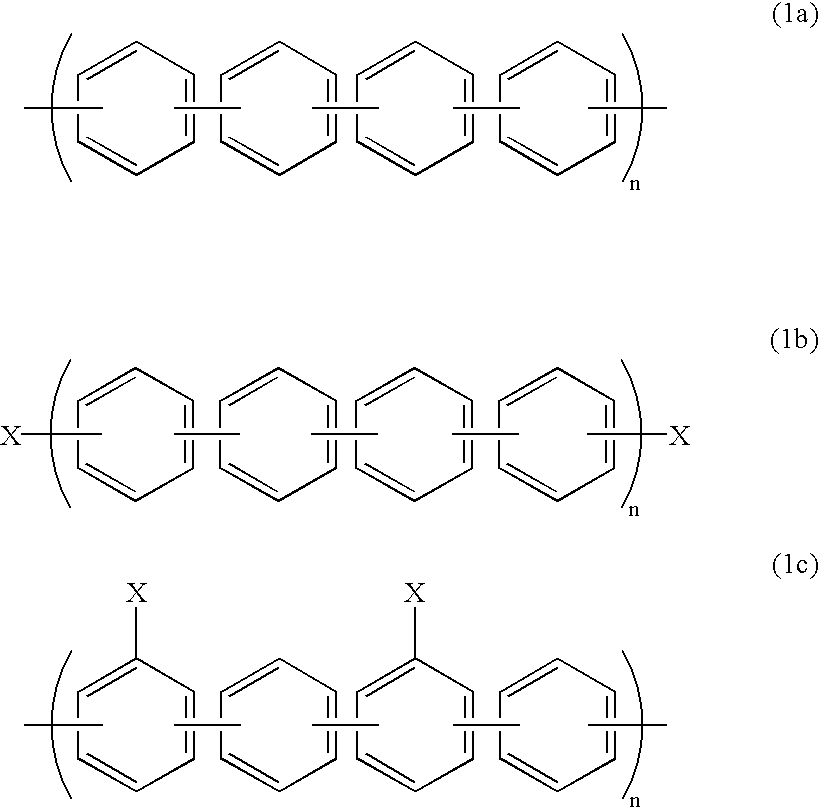

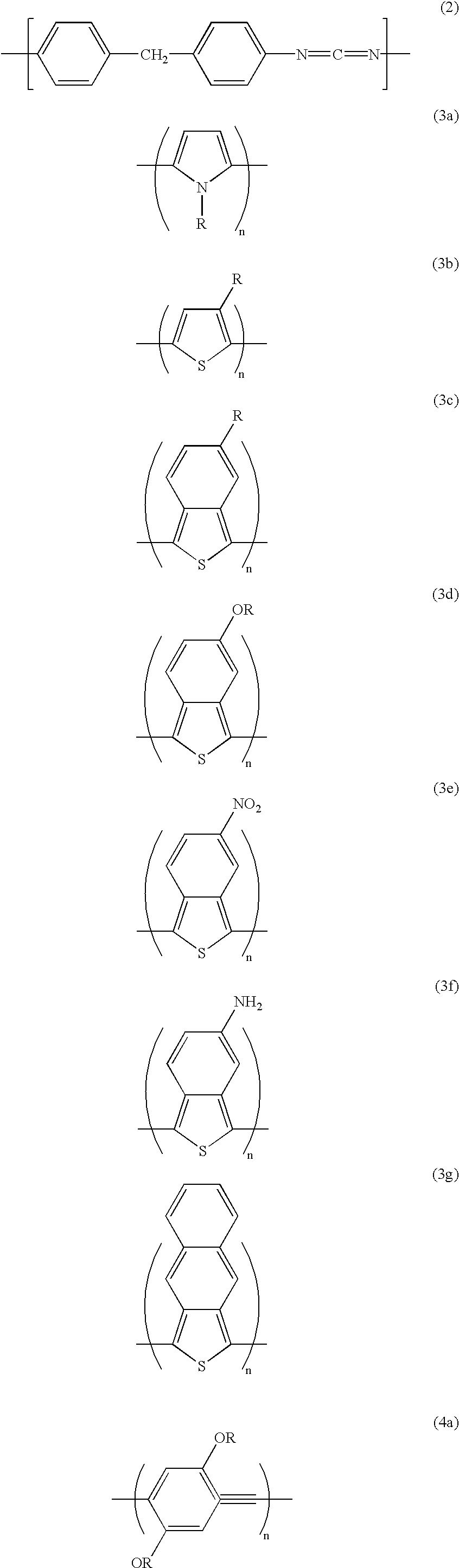

Modeling Material For Forming Photofabrication Model In Ink-Jet Three Dimensional Printing, Supporting Material For Supporting The Shape Of Photofabrication Model On Photofabrication And Production Method Of Photofabrication Model

ActiveUS20130234370A1Good water solubilityEasy to disassembleAdditive manufacturing apparatusInksSolubilityWater soluble

The present invention aims to provide a supporting material for supporting the shape of a photofabrication model on photofabrication in ink-jet three dimensional printing method in which the photocured product is excellent in solubility in water and is easy to remove after photofabrication, and the like. A modeling material for forming a photofabrication model in ink-jet three dimensional printing method containing a curable resin component with a weighted average of SP value of 9.0 to 10.3; and a supporting material for supporting the shape of a photofabrication model on photofabrication in ink-jet three dimensional printing method containing a water-soluble monofunctional ethylenically unsaturated monomer (F), polyoxypropylene glycol with a number average molecular weight of 100 to 5,000 and / or water (G), and a photopolymerization initiator (D).

Owner:KEYENCE

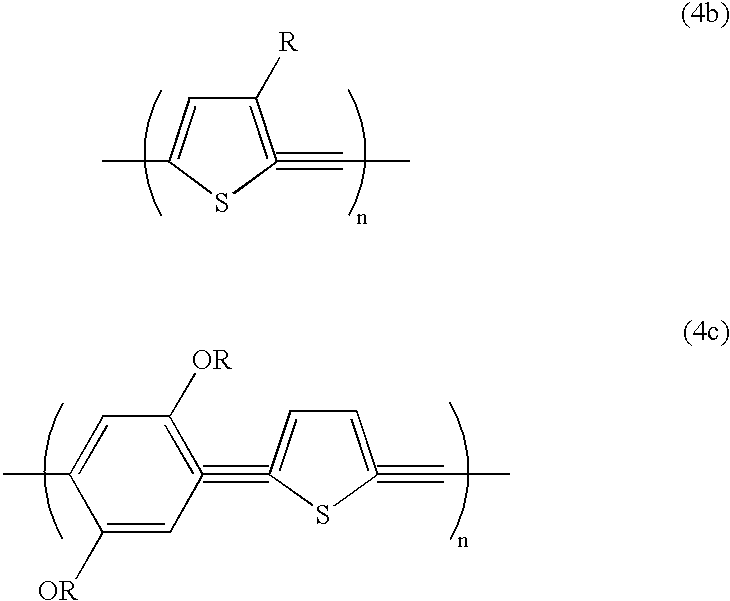

Method of manufacturing a semiconductor device using a polymer film pattern

InactiveUS6465290B1Good pn junction characteristicImprove featuresTransistorSemiconductor/solid-state device manufacturingHydrogen contentPolymer thin films

Claimed and disclosed is a method of manufacturing a semiconductor device, the method comprising the steps of forming a dummy gate on a semiconductor substrate, forming a source-drain diffusion region by introducing an impurity into the semiconductor substrate having the dummy gate as a mask, removing the dummy gate to form an opening, and forming a gate electrode within the opening with a gate insulating film formed below the gate electrode. The dummy gate is further formed by coating the semiconductor substrate with a polymer having a higher carbon content than hydrogen content so as to form a polymer film, forming a photoresist pattern on the polymer film, and transferring the pattern shape of the photoresist pattern onto the polymer film.

Owner:KK TOSHIBA

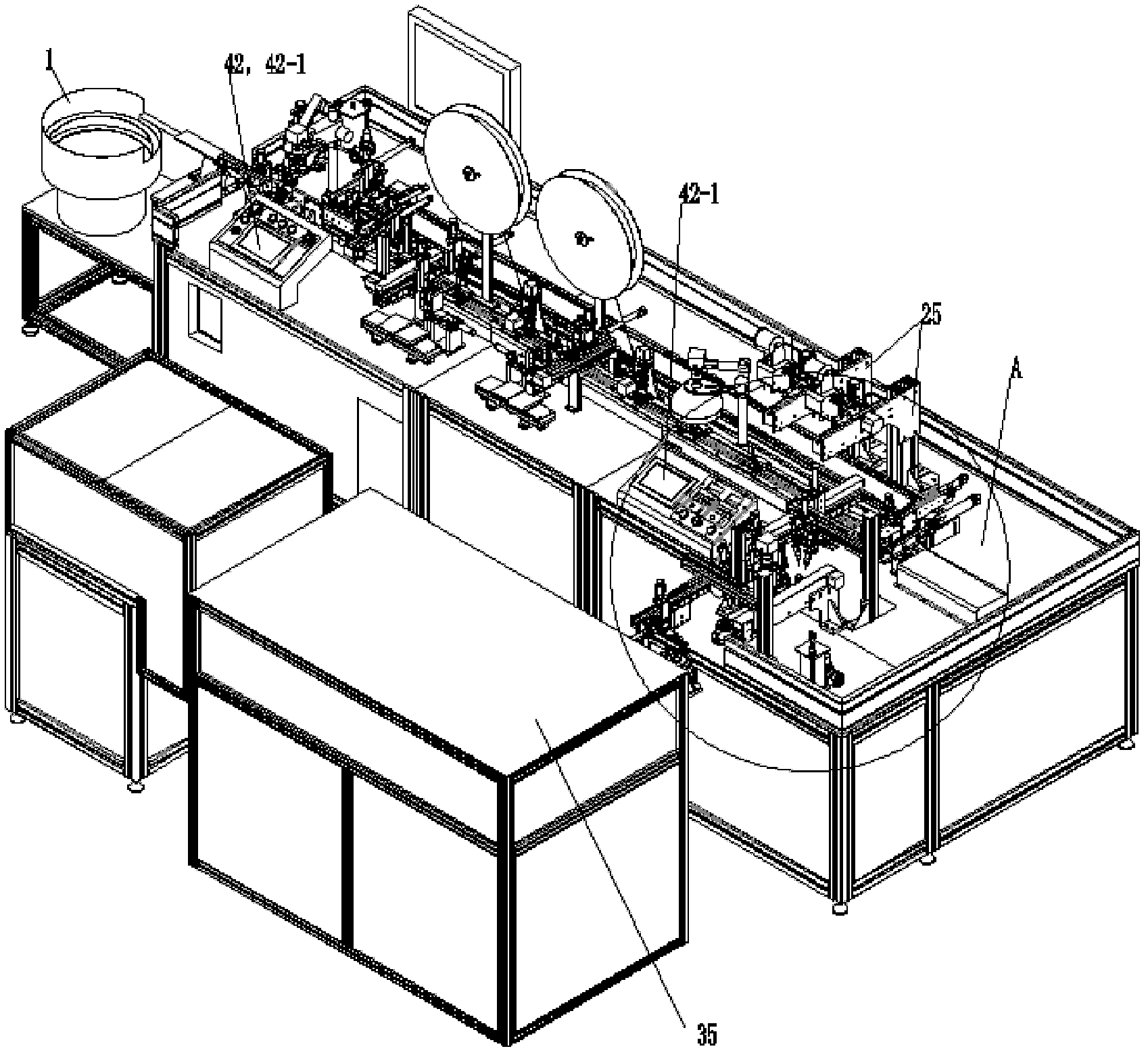

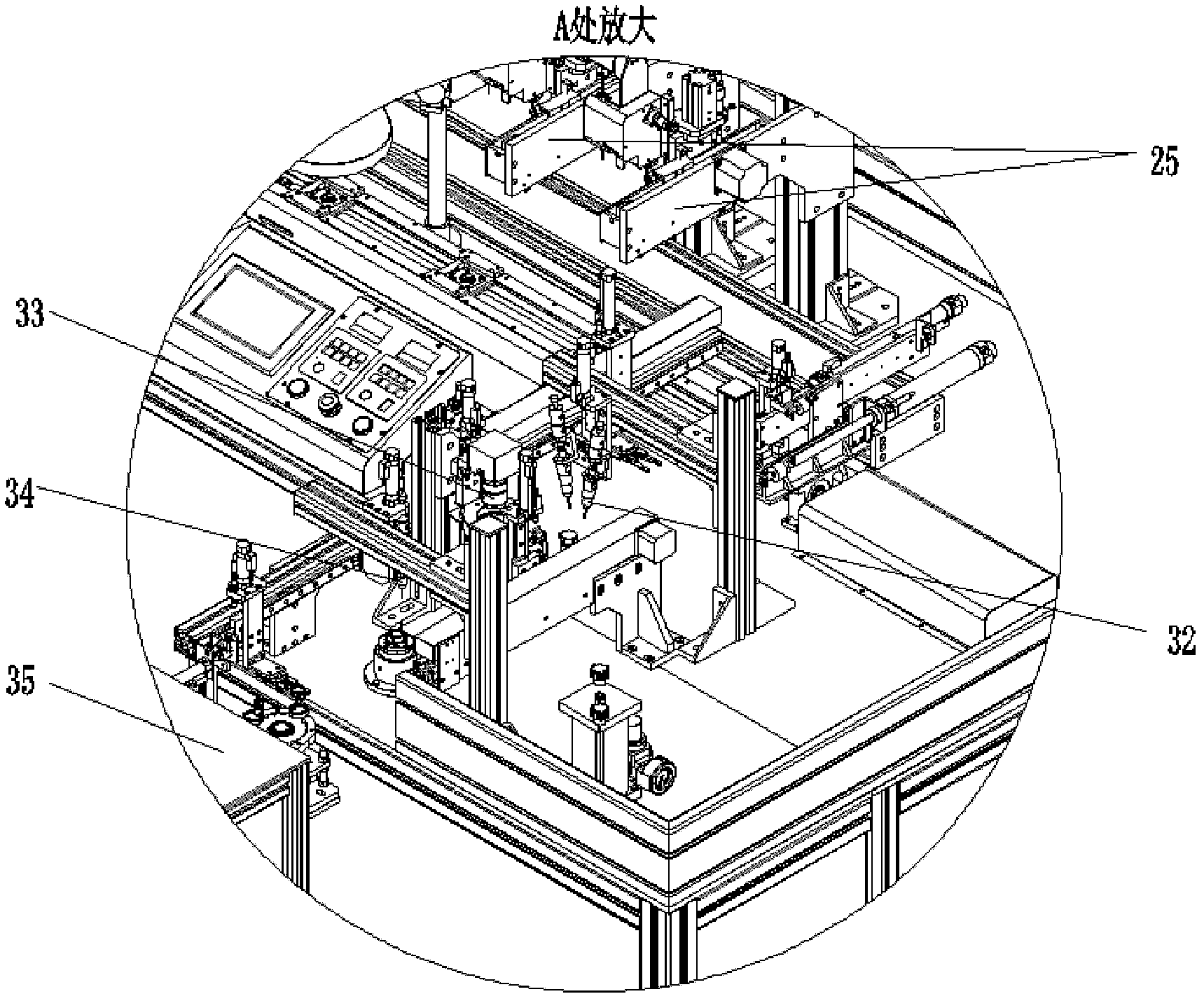

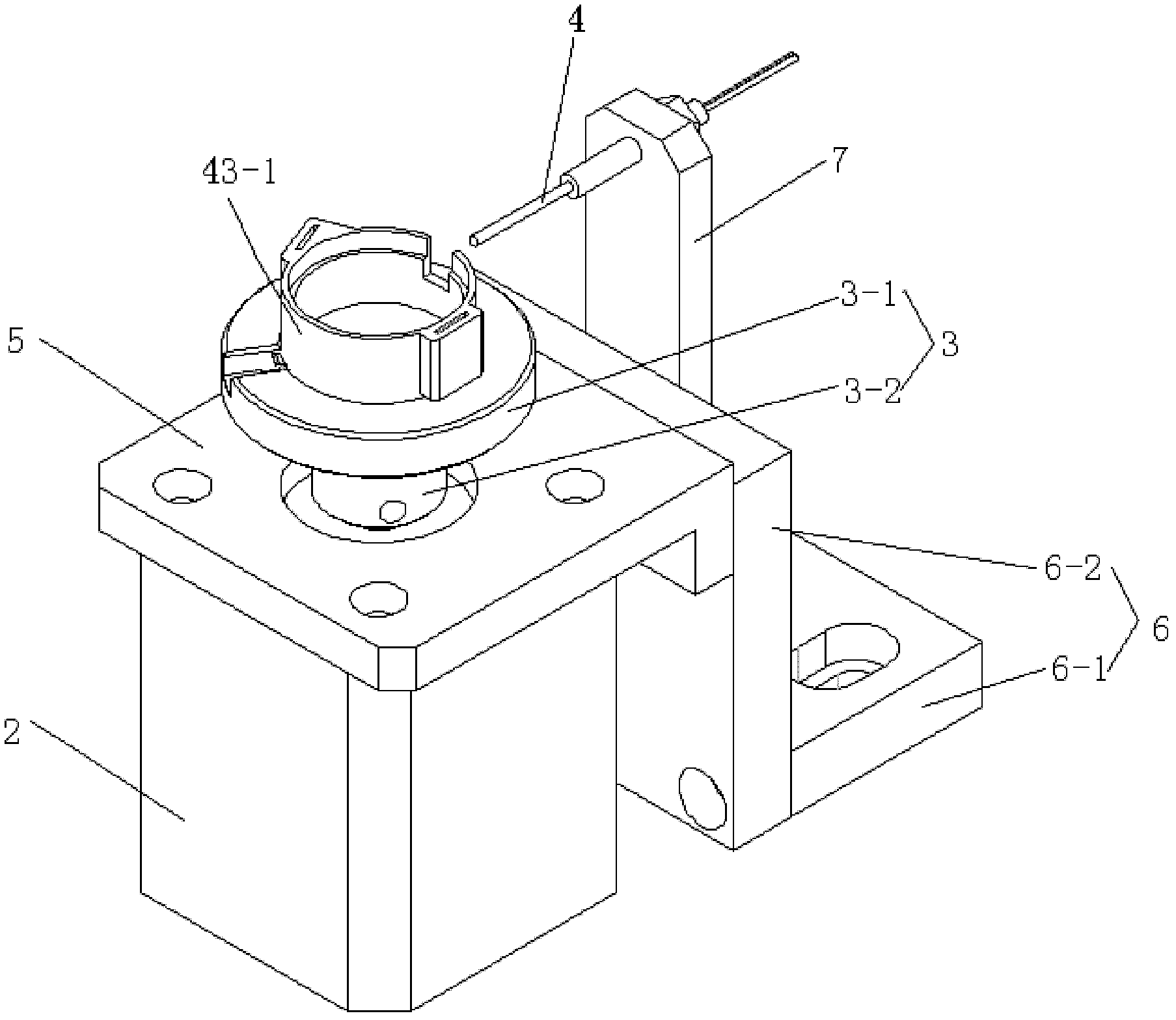

Automatic assembly production line of buzzers

ActiveCN102848187AGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

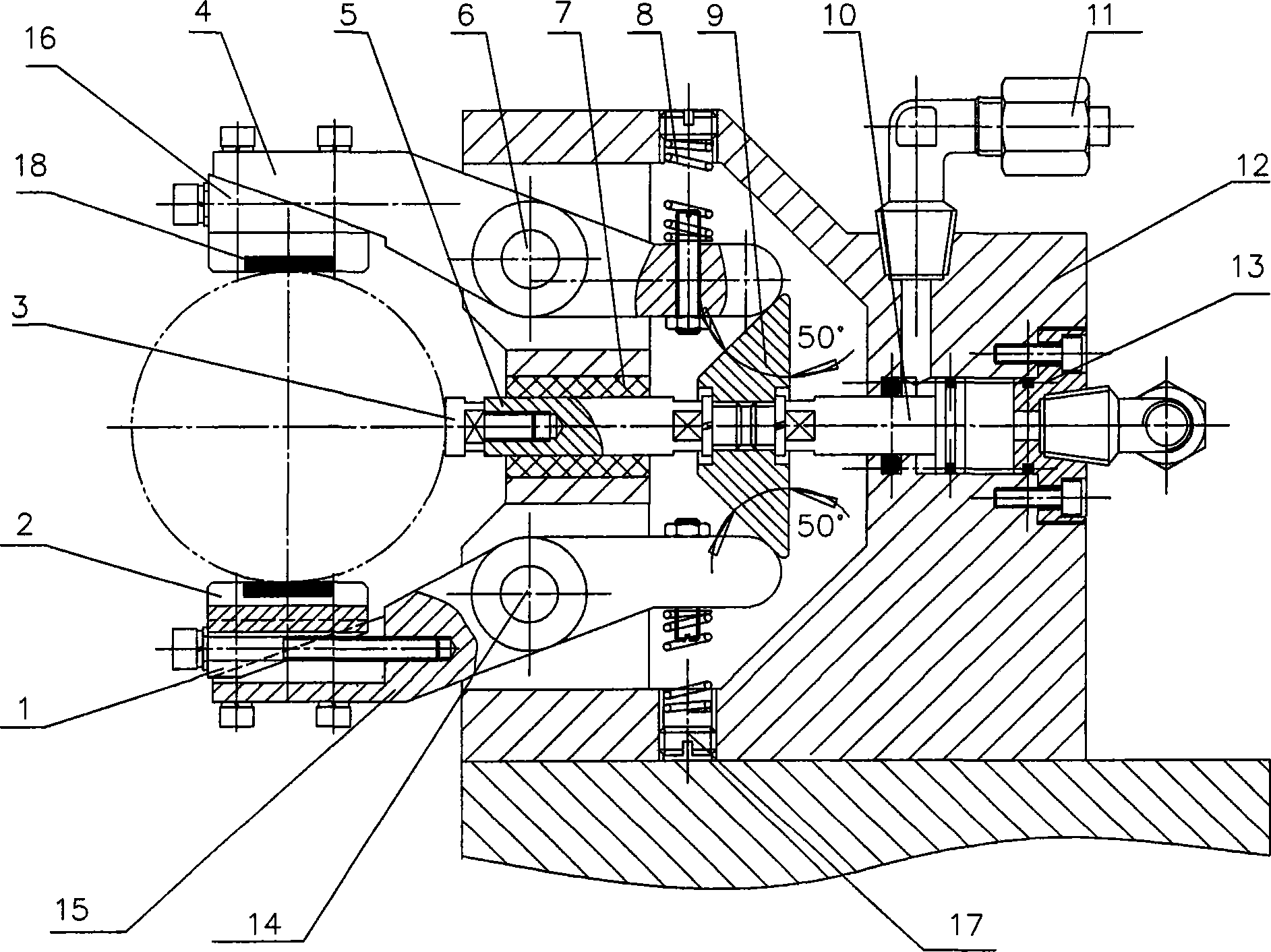

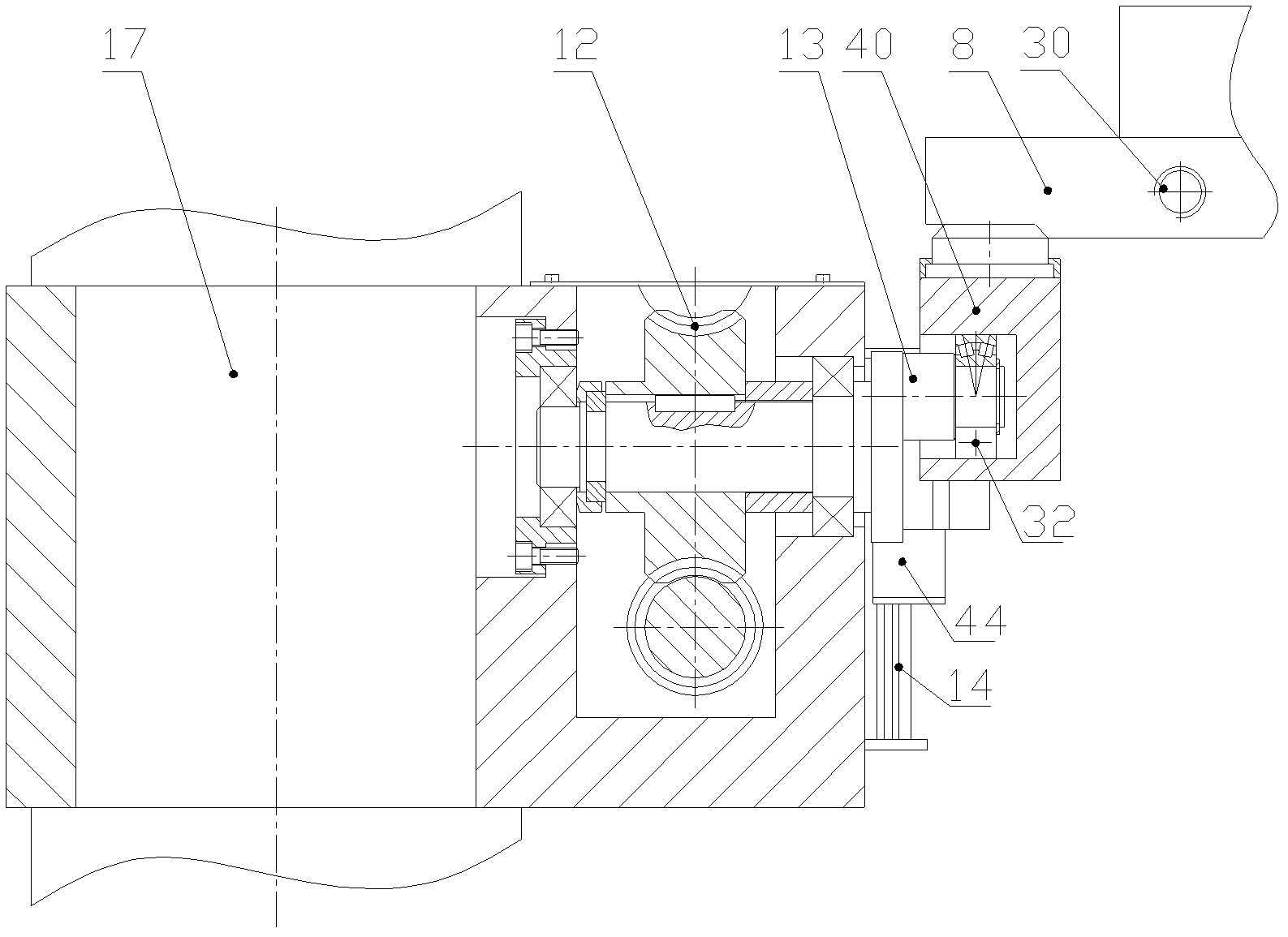

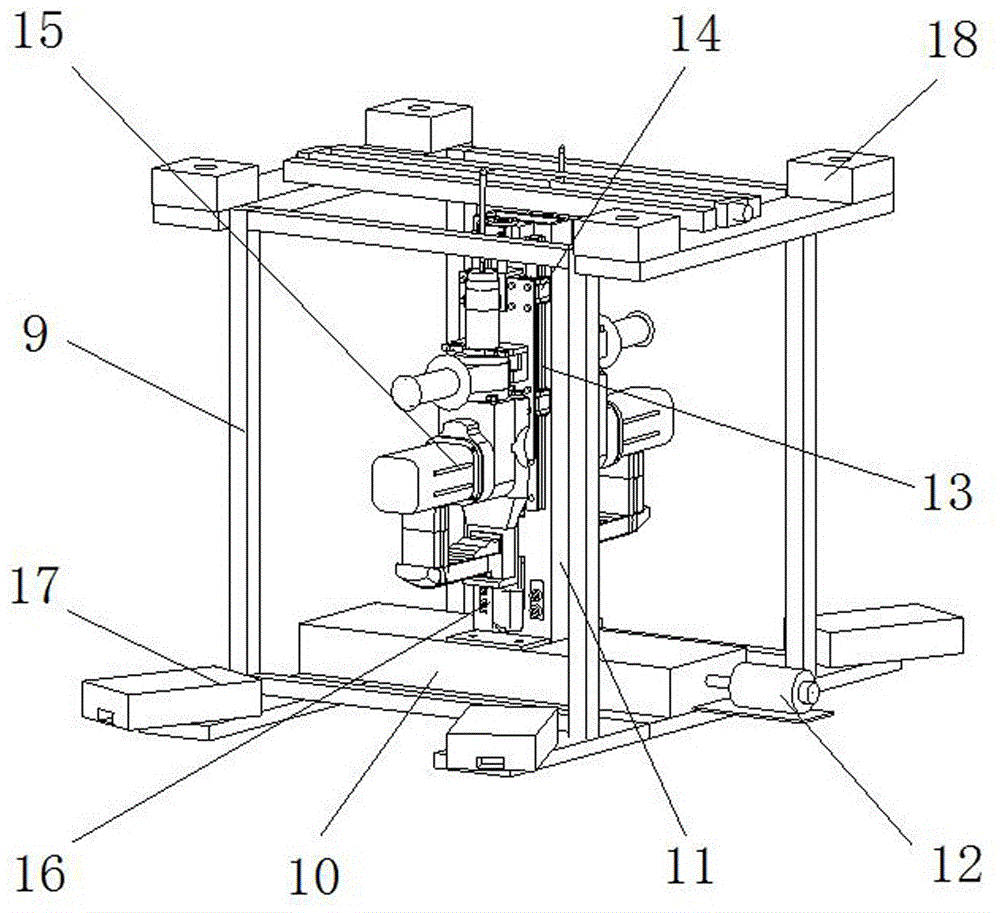

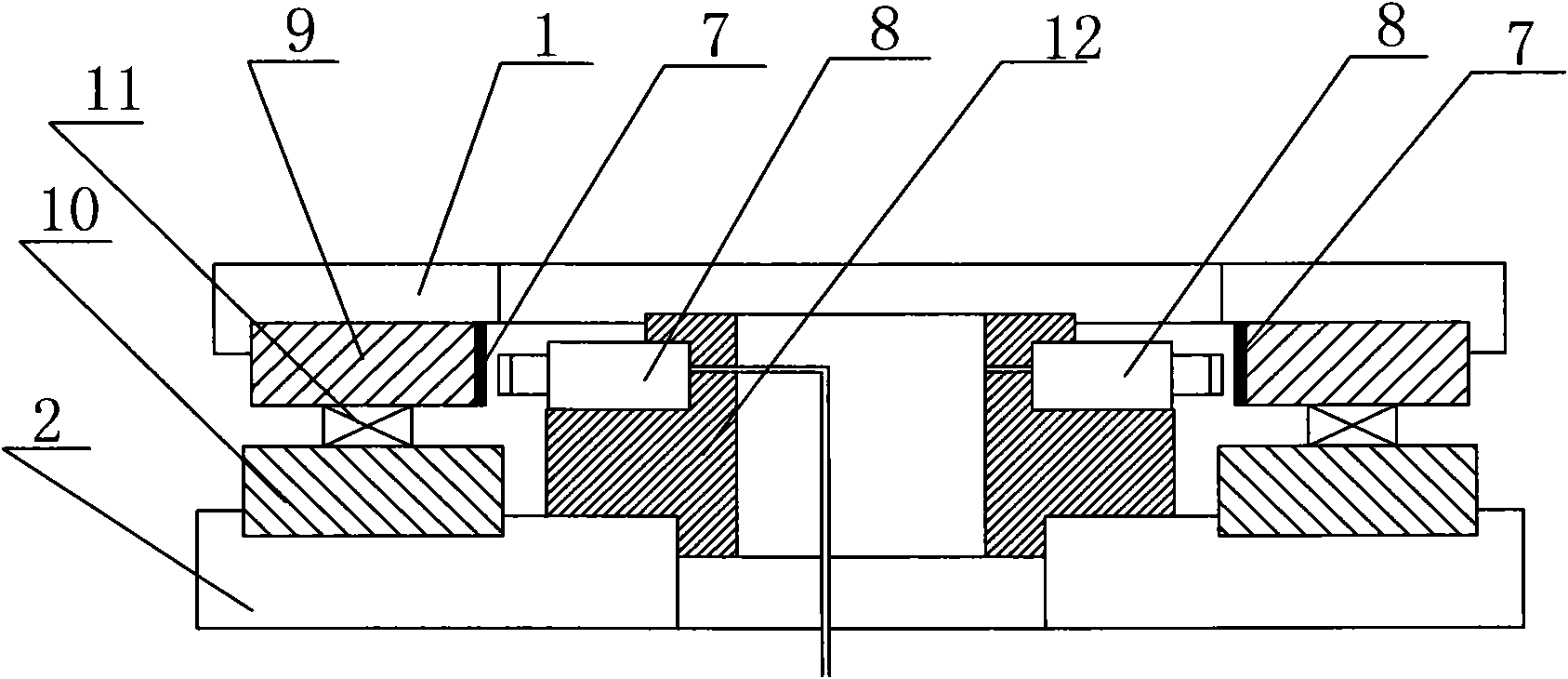

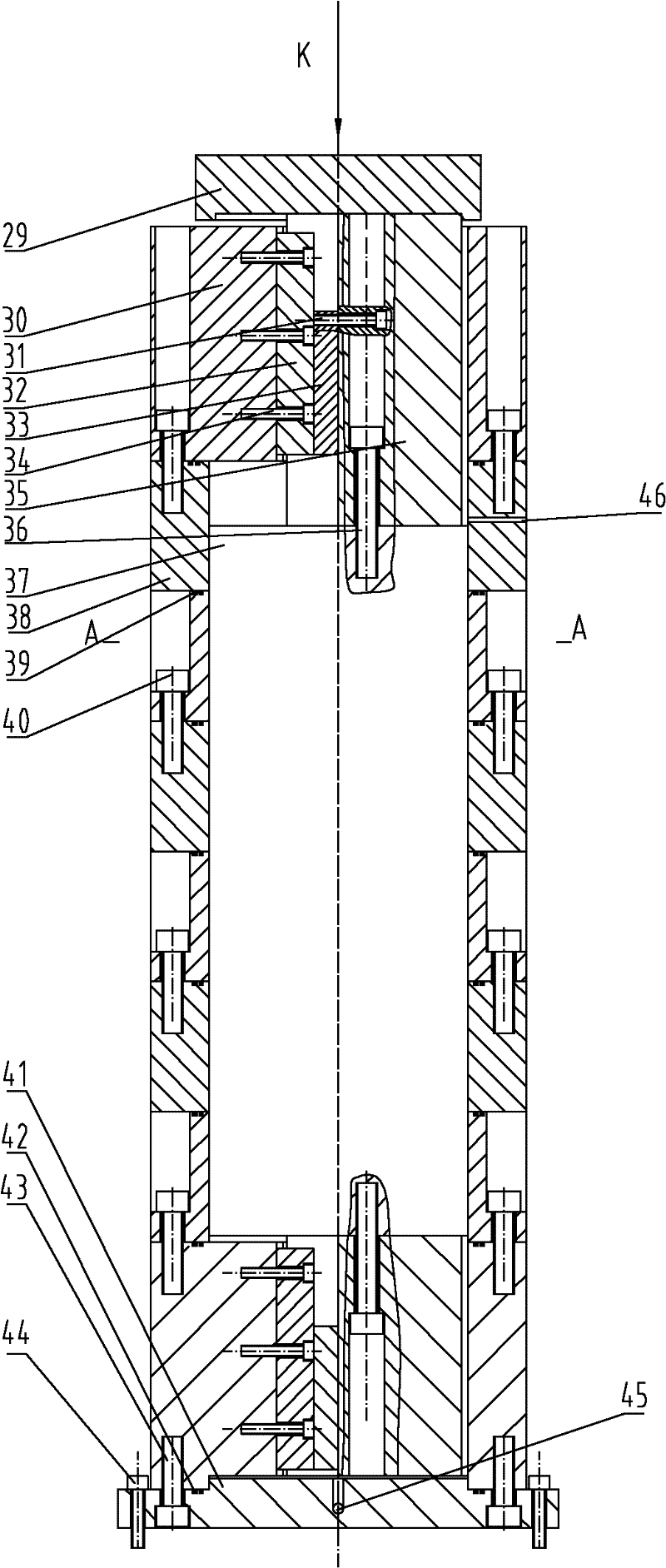

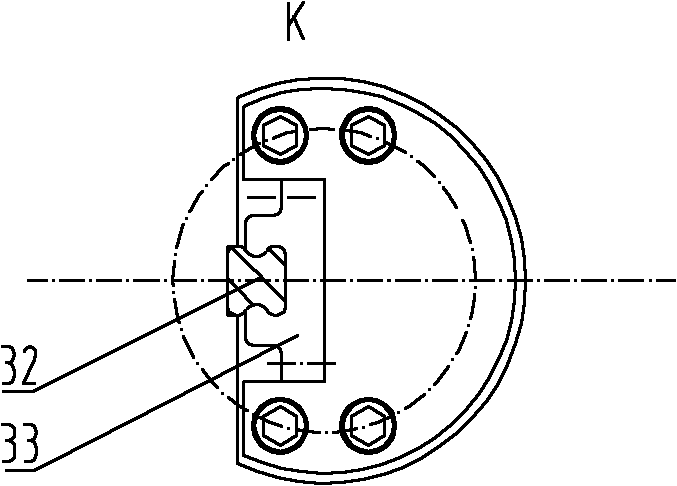

Autotracking centring clamping device for numerically controlled grinder

InactiveCN101116954AEliminate the effects of grindingEliminate the effects ofGrinding work supportsNumerical controlAxis of symmetry

The invention discloses an automatic follow centering and clamping device for a numerical control grinder. A middle clamping rod (5) is sleeved in a sliding way on a supporting body (12) which is provided with a driving mechanism which drives the middling clamping rod (5) to reciprocatingly move axially. An upper lever clamping arm (4) and a lower lever clamping arm (15) are hinged on the supporting body (12) with the middle clamping rod (5) axis of symmetry. The clamping ends of the upper lever clamping arm (4) and the lower lever clamping arm (15) are corresponding to the clamping end of the middling clamping rod (5) which is provided with a symmetric cuniform-shaped block (9) corresponding to opening ends of the upper lever clamping arm (4) and the lower lever clamping arm (15). The supporting body (12) is provided with an elastic device which keeps the clamping ends of the upper lever clamping arm (4) and the lower lever clamping arm (15) open. The invention is an automatic follow centering and clamping device applying automatic follow and moving, automatic centering and automatic compensating to a numerical control grinder.

Owner:HUNAN UNIV

Superabrasive electrodeposited cutting edge and method of manufacturing the same

InactiveUS6098609AGood precisionImprove working precisionRevolution surface grinding machinesBonded abrasive wheelsBiomedical engineeringThin walled

PCT No. PCT / JP96 / 00206 Sec. 371 Date Jul. 30, 1997 Sec. 102(e) Date Jul. 30, 1997 PCT Filed Feb. 1, 1996 PCT Pub. No. WO96 / 23630 PCT Pub. Date Aug. 8, 1996A cutting edge comprising a mass of superabrasive particles (2) electrodeposited on a thin-walled metallic base member (1) along a border (6) of said base member, wherein said mass (2) forms one or more layers at said border of said base member and fixed thereto, and each layer contains parts comprising at least five superabrasive particles (3) in a row in an extending direction of said base member from said border, so as to improve free-cut performance, decrease kerf width and prolong the life of cutting tool.

Owner:ISHIZUKA HIROSHI

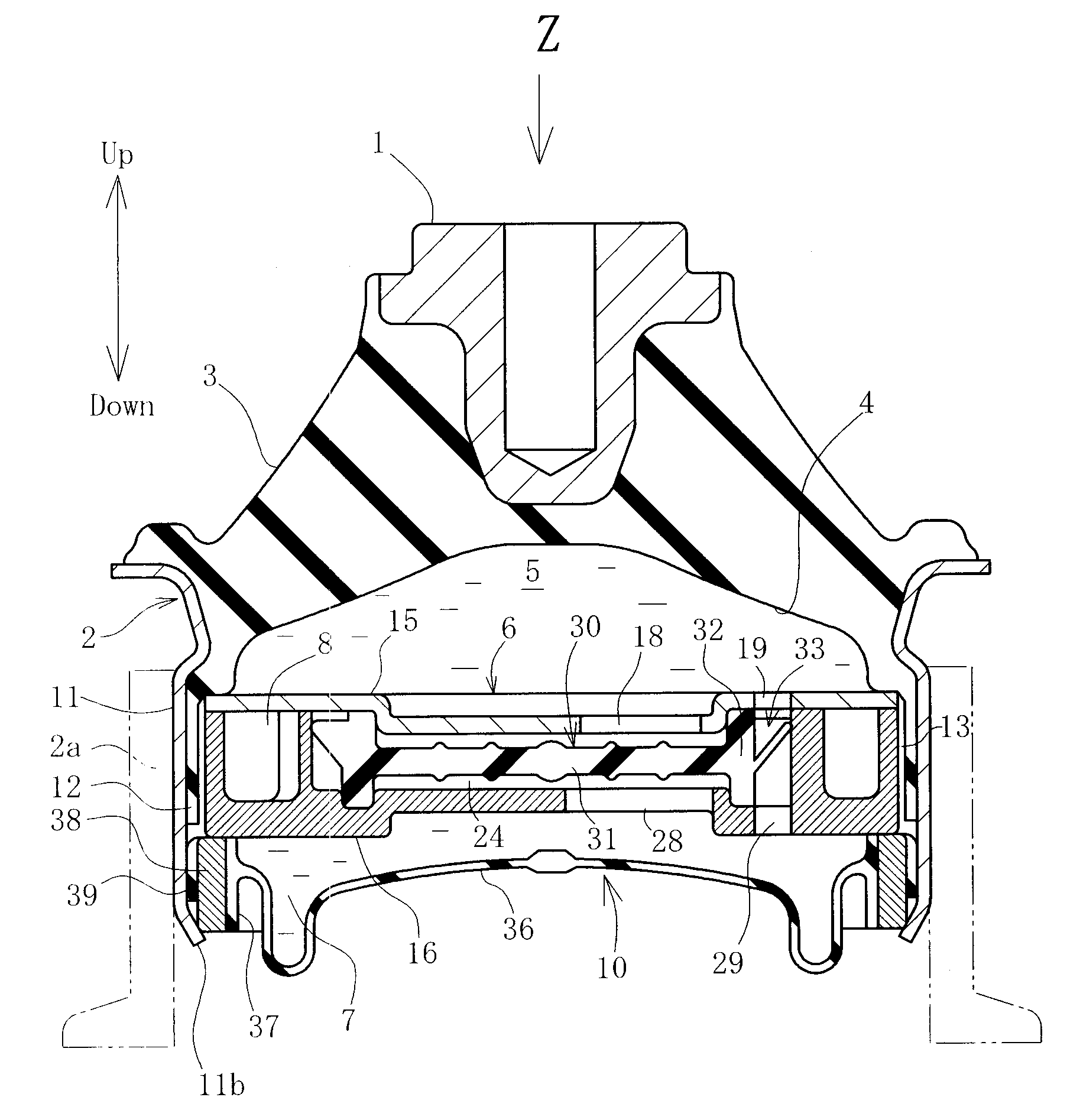

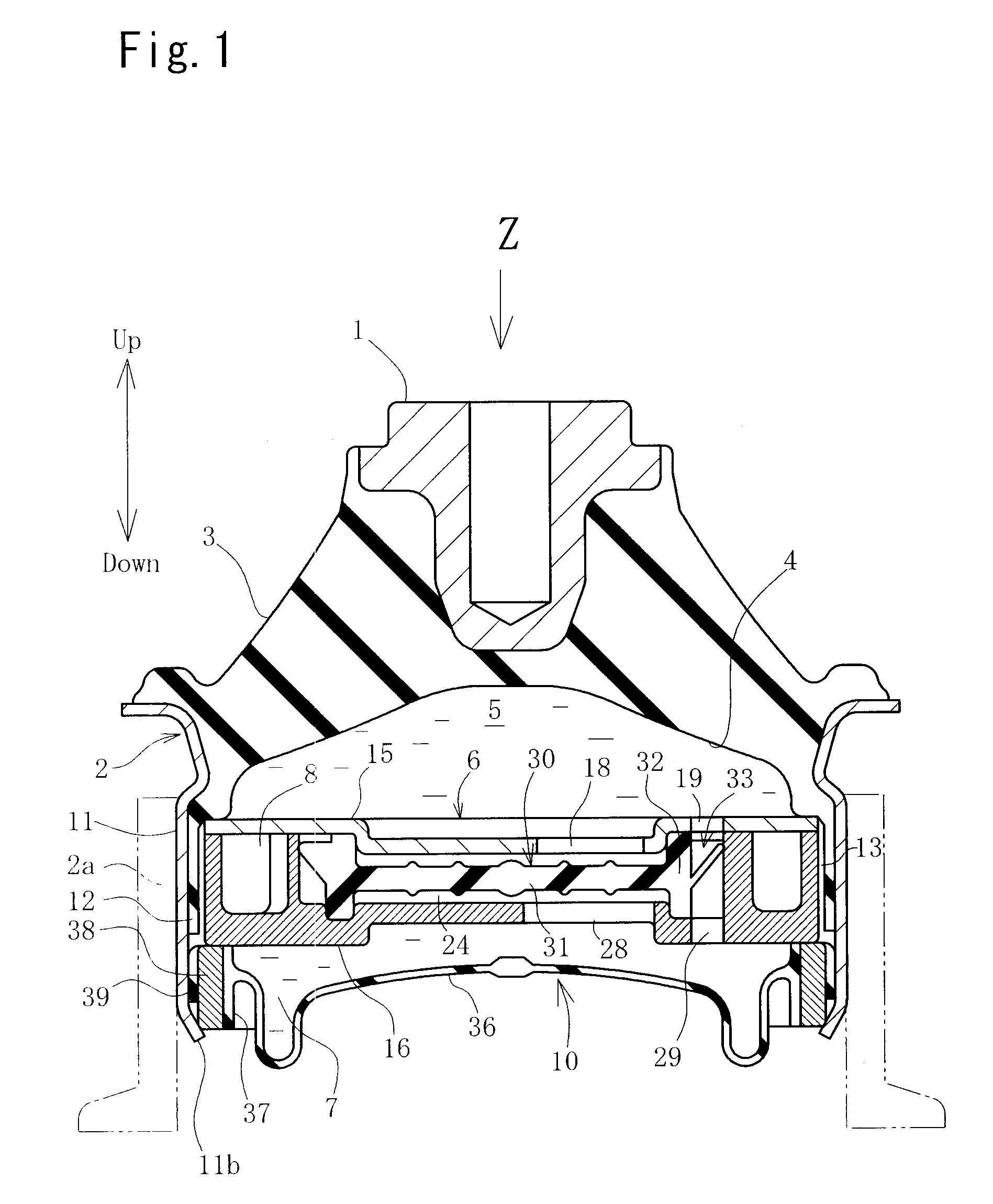

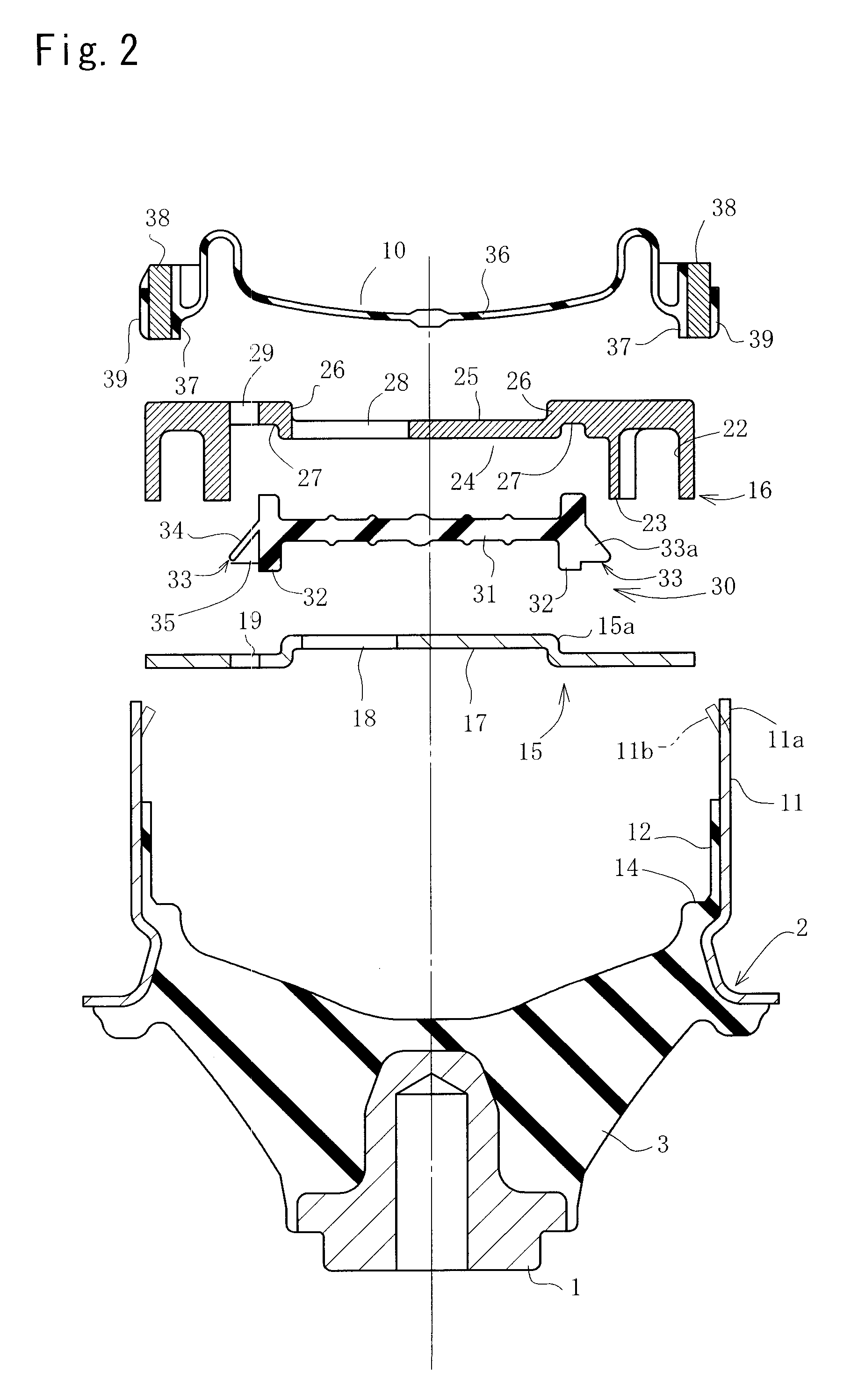

Liquid sealed vibration isolating device

ActiveUS20100072683A1Improve working precisionAccurate leakageMachine framesLiquid springsCavitationEngineering

To form a relief valve for preventing the generation of the cavitation phenomenon into a simple and accurately operable structure, there are provided a central thin wall portion and a fixing portion in an elastic diaphragm provided in the partition member to have the fixing portion fixed in position. A relief valve is integrally formed with an outer peripheral portion of the fixing portion. The relief valve is provided with an inclined surface formed on the side of a secondary liquid chamber and a recessed portion opened on the side of a primary liquid chamber and has a difference in rigidity in the circumferential direction. When the primary liquid chamber turns negative pressure, a hydraulic liquid in the secondary liquid chamber opens the relief valve and leaks to the primary liquid chamber so as to prevent the generation of the cavitation phenomenon.

Owner:YAMASHITA RUBBER CO LTD +1

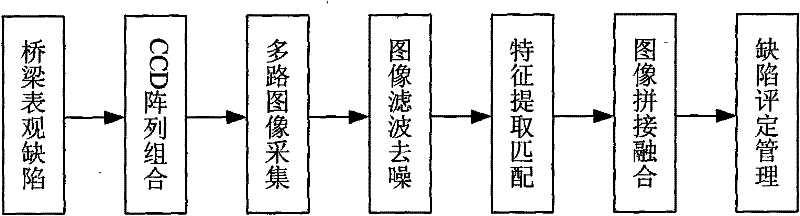

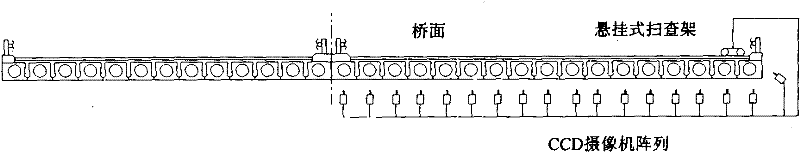

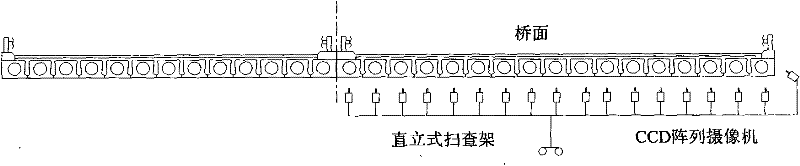

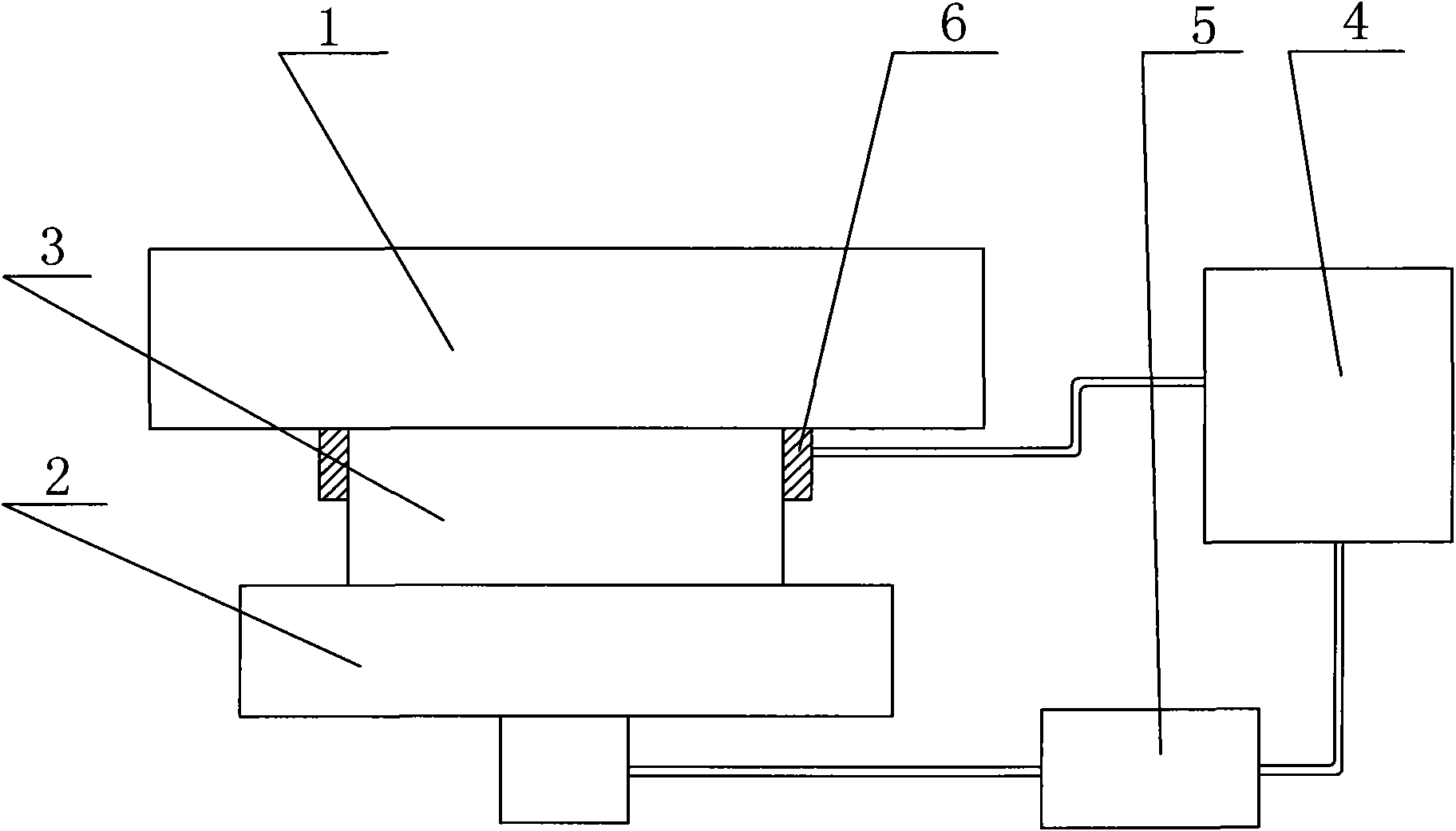

Bridge apparent state automatic detection device and method based on charge coupled device (CCD) array photographic technique

InactiveCN102183525AGuaranteed normal operationShorten the timeOptically investigating flaws/contaminationProcess systemsTime efficient

The invention relates to a bridge apparent state automatic detection device based on a charge coupled device (CCD) array photographic technique and a bridge apparent state automatic detection method based on a charge coupled device (CCD) array photographic technique. The bridge apparent state automatic detection device consists of a CCD video camera array, a scanning frame, an image acquisition card, a computer, detection management software and a detection vehicle and is characterized in that: the CCD video camera array is arranged on the scanning frame; the bottom of the scanning frame is fixed on the detection vehicle positioned on or below a bridge; the CCD video camera array is connected with the image acquisition card through leads; the image acquisition card is arranged on the computer; the CCD video camera array transmits synchronous bridge bottom and side defect images to the computer in real time; and the detection management software realizes synthesis, processing, defect identification and data management of the bridge apparent defect images. A computer video technique is applied to the bridge apparent defect detection and a judgment result is directly provided by a reliable CCD automatic data acquiring and process system, so that time is saved, working efficiency and precision are improved, and the normal operation state of the bridge can be guaranteed.

Owner:单宝华 +1

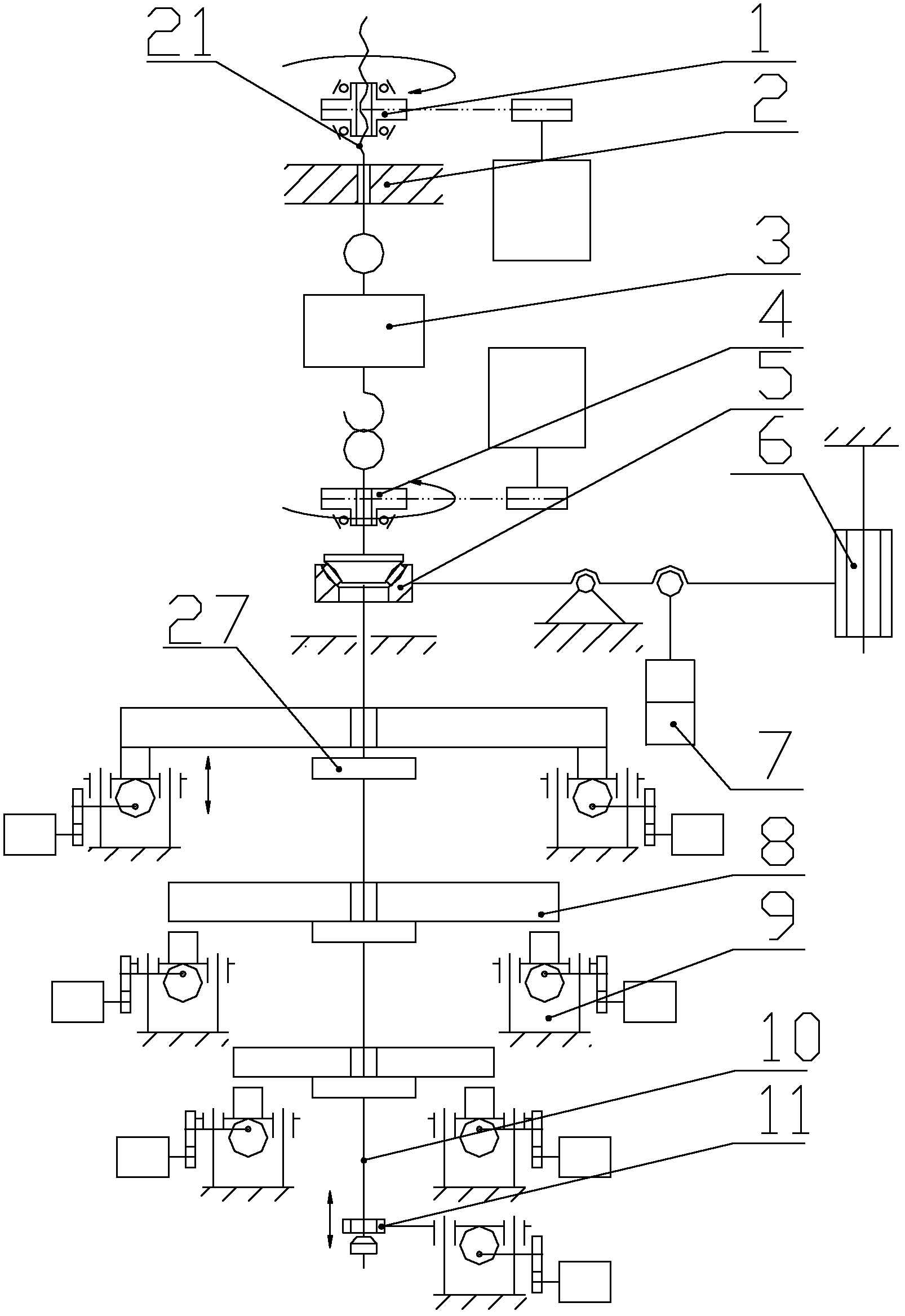

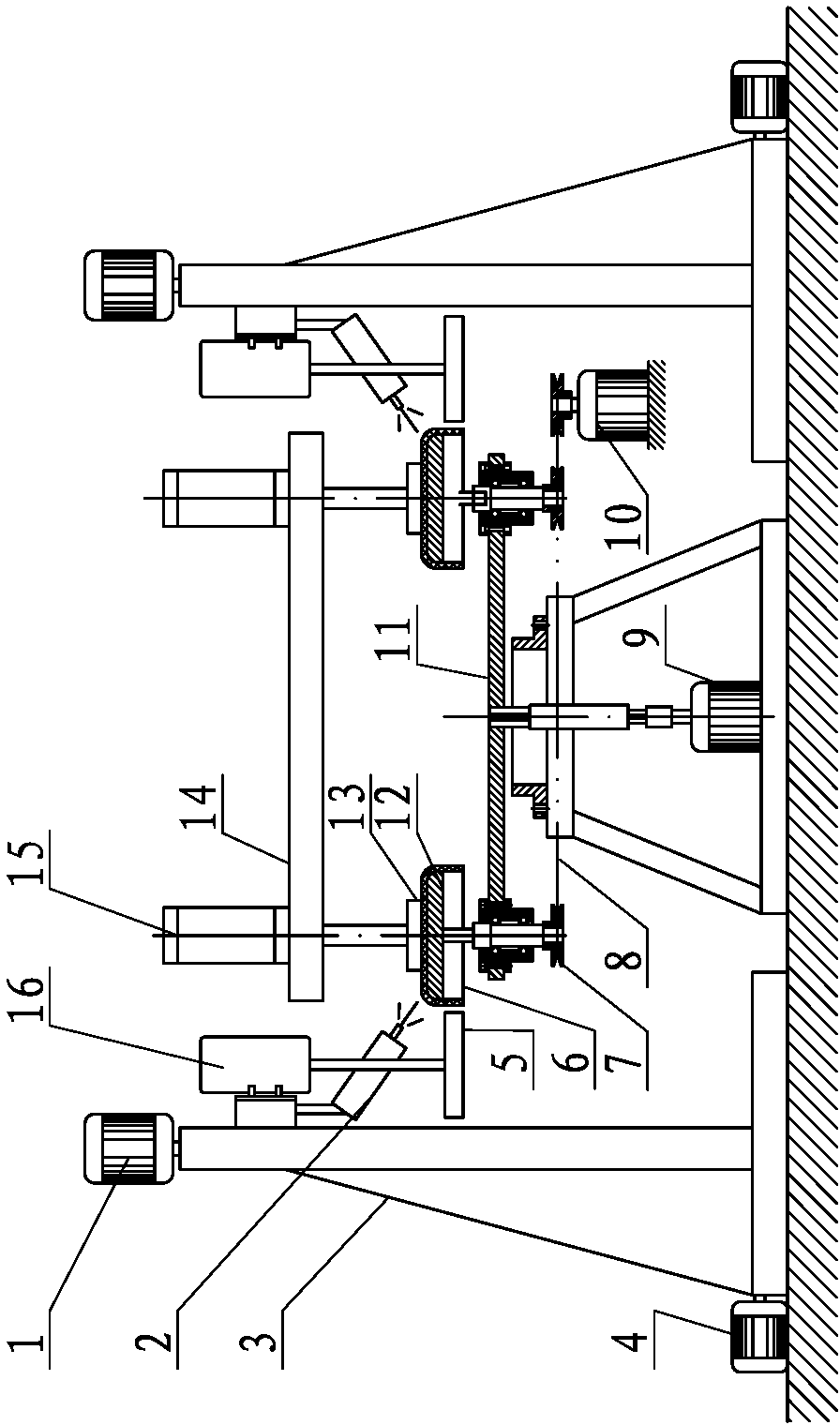

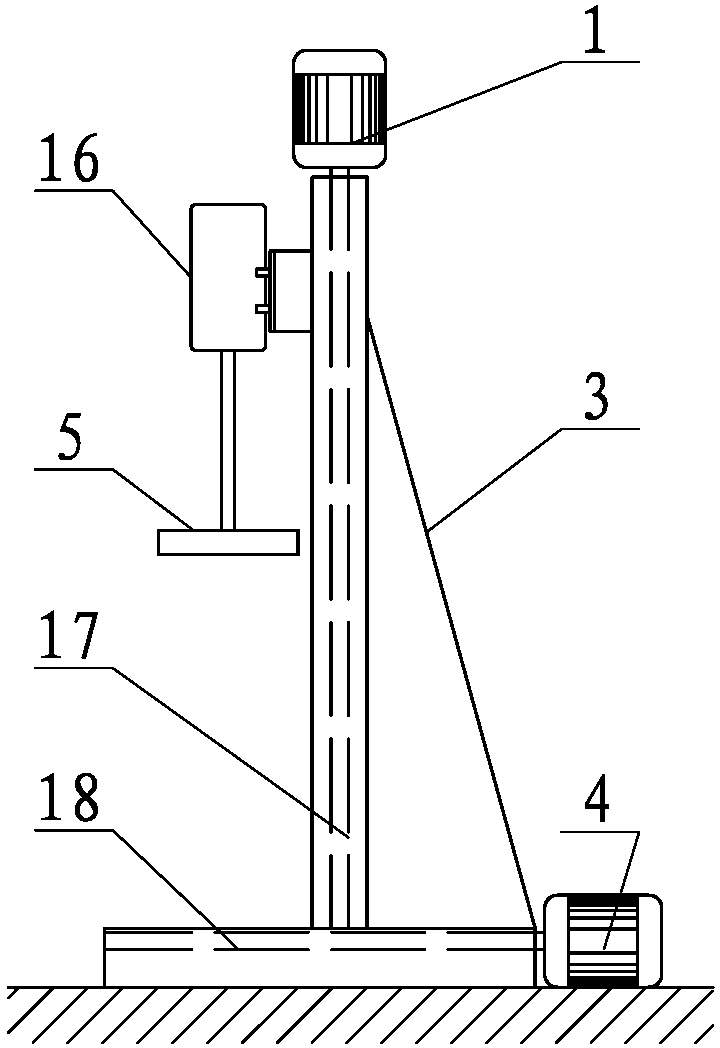

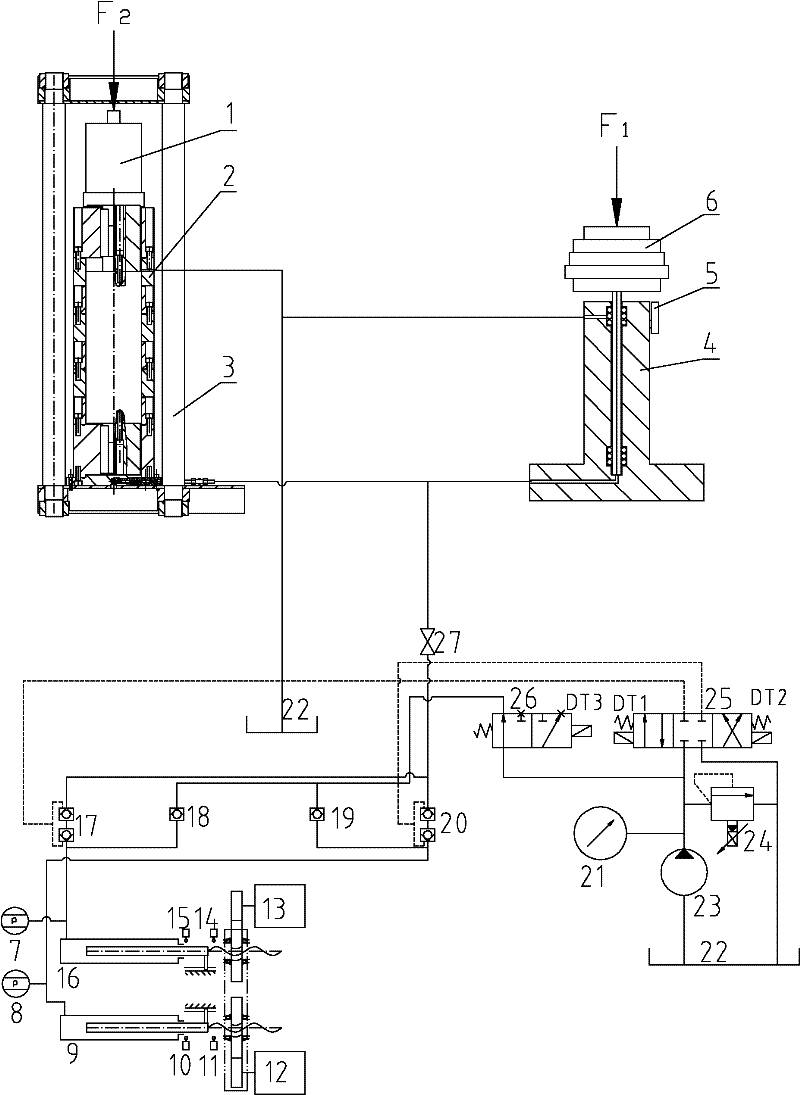

Testing machine for testing crane scale and method for disassembling and assembling weight thereof

InactiveCN102426051AImprove working precisionEasy accessWeighing apparatus testing/calibrationEngineeringMechanical engineering

The invention discloses a testing machine for testing a crane scale and a method for disassembling and assembling a weight thereof. The testing machine for testing a crane scale comprises a position adjustment control device, a rack, a weight, a weight drive mechanism, a weight swing mechanism, a suspender and an anti-swing mechanism, wherein the weight swing mechanism comprises a weight swing mechanism shell, a motor No.3, a stop dog, a worm, a worm gear and a weight swing mechanism driving part, the worm and the weight swing mechanism driving part are installed in the weight swing mechanismshell and are in rotating connection, the worm gear is sleeved on the weight swing mechanism driving part and is fixedly connected with the weight swing mechanism driving part, and the worm and the worm gear are engaged with each other, the output shaft of the motor No.3 fixed on the weight swing mechanism shell is fixedly connected with the worm, the stop dog is installed in a through groove of the weight swing mechanism driving part, the weight swing mechanism is installed at the center of a middle cross beam of the rack, the weight swing mechanism driving part is sleeved on the suspender, and a through hole on the weight swing mechanism driving part is in clearance fit with the suspender. The invention also provides a method for disassembling and assembling the weight in the testing machine.

Owner:JILIN UNIV

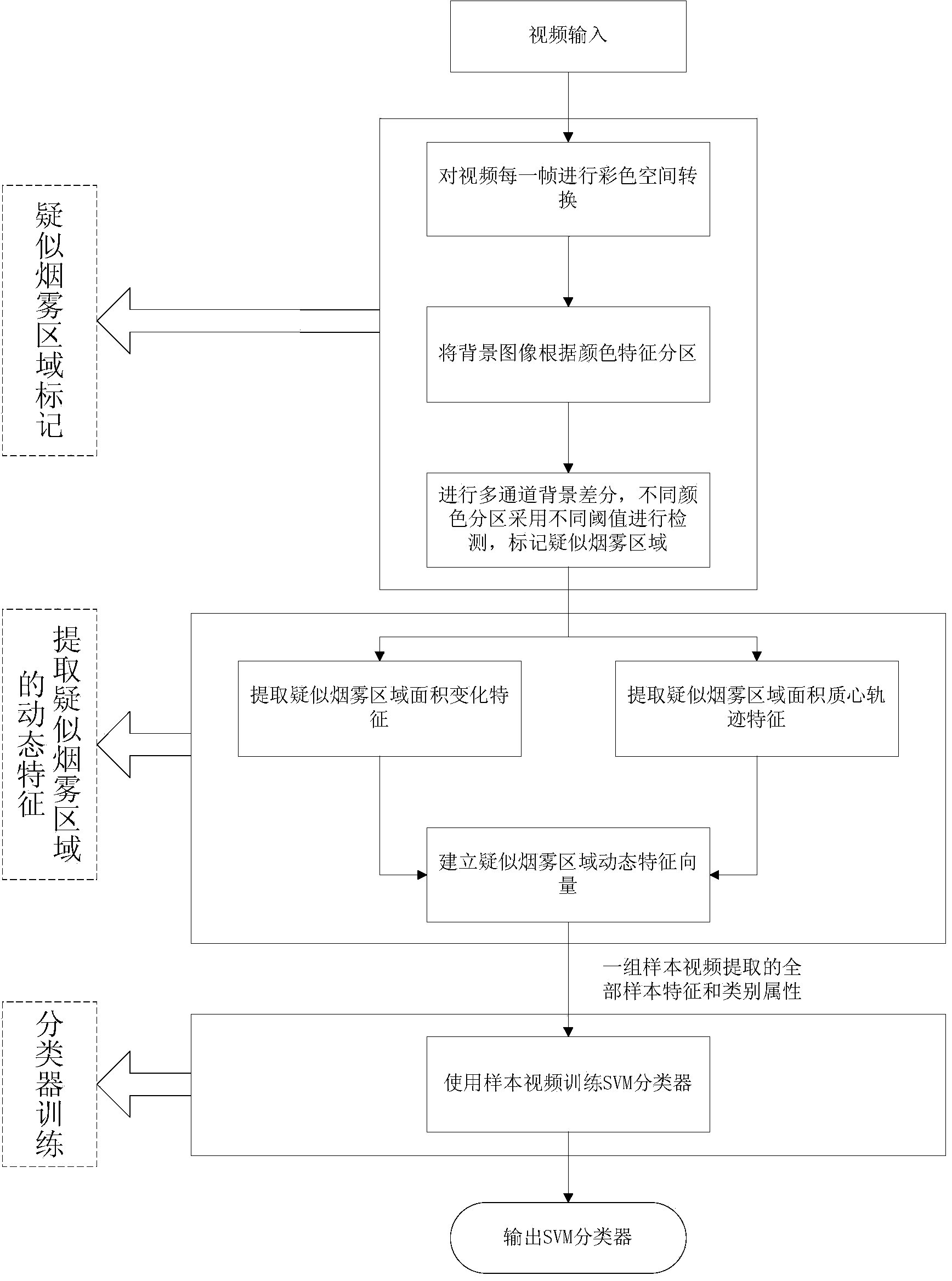

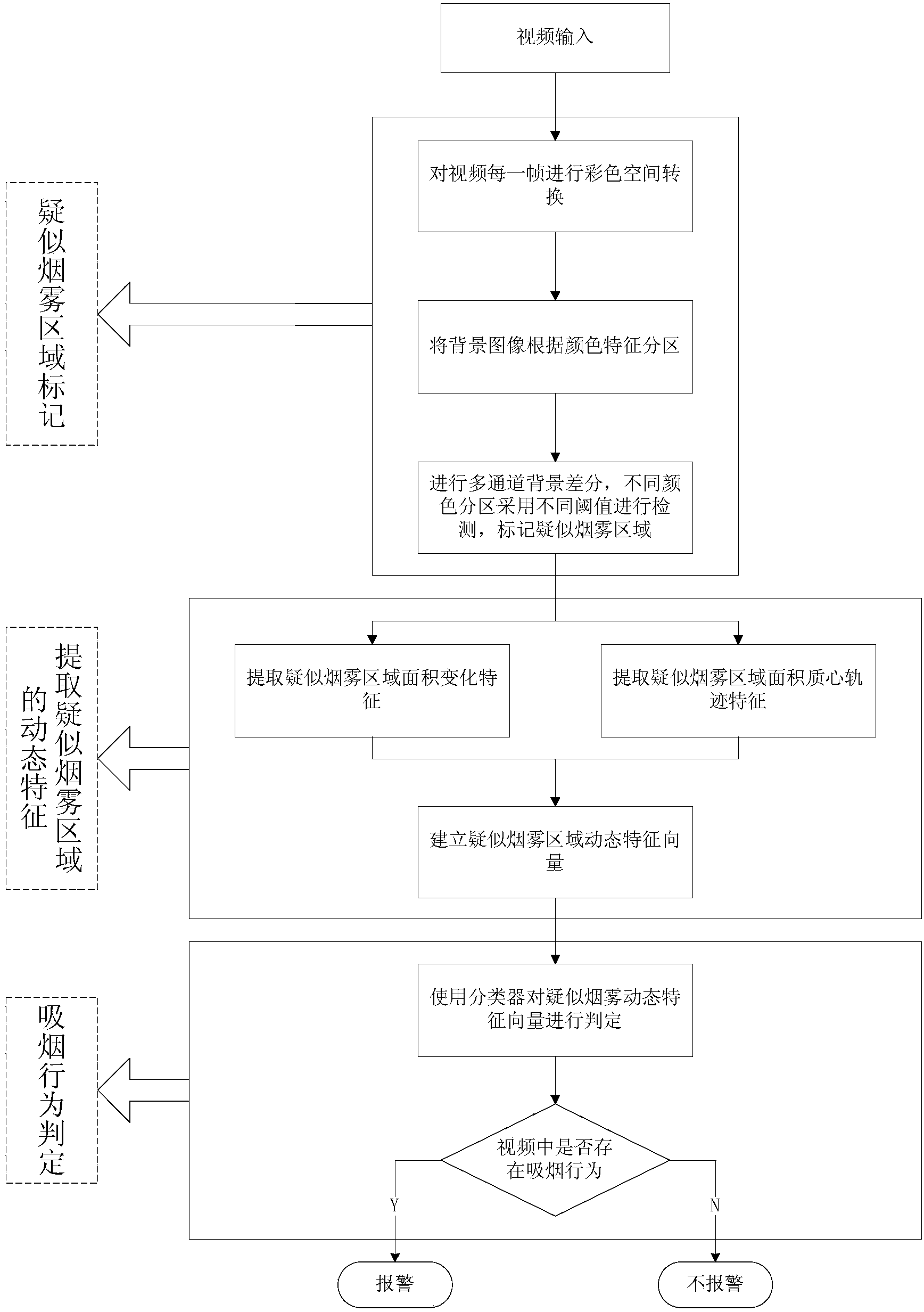

Cigarette smoke detection method based on computer vision

InactiveCN104050480AEasy to manageImprove work efficiencyCharacter and pattern recognitionFeature vectorPublic place

The invention discloses a cigarette smoke detection method based on computer vision. The method comprises the two stages of classifier generation and cigarette smoke detection. The classifier generation stage comprises the steps of receiving sample video information, extracting a suspected cigarette smoke area through multichannel background subtraction, extracting motion features of the suspected area and combining the extracted motion features into a feature vector training support vector machine. The cigarette smoke detection stage comprises the steps of receiving the video information to be detected, extracting dynamic features of the suspected cigarette smoke area and combining the dynamic features into a feature vector input classifier through the same method used in the classifier generation stage, and judging whether cigarette smoke exists in the suspected area. By means of the cigarette smoke detection method based on computer vision, large-range cigarette smoke detection in a simple scene can be achieved, and smoke control work in a public place is facilitated.

Owner:YANSHAN UNIV

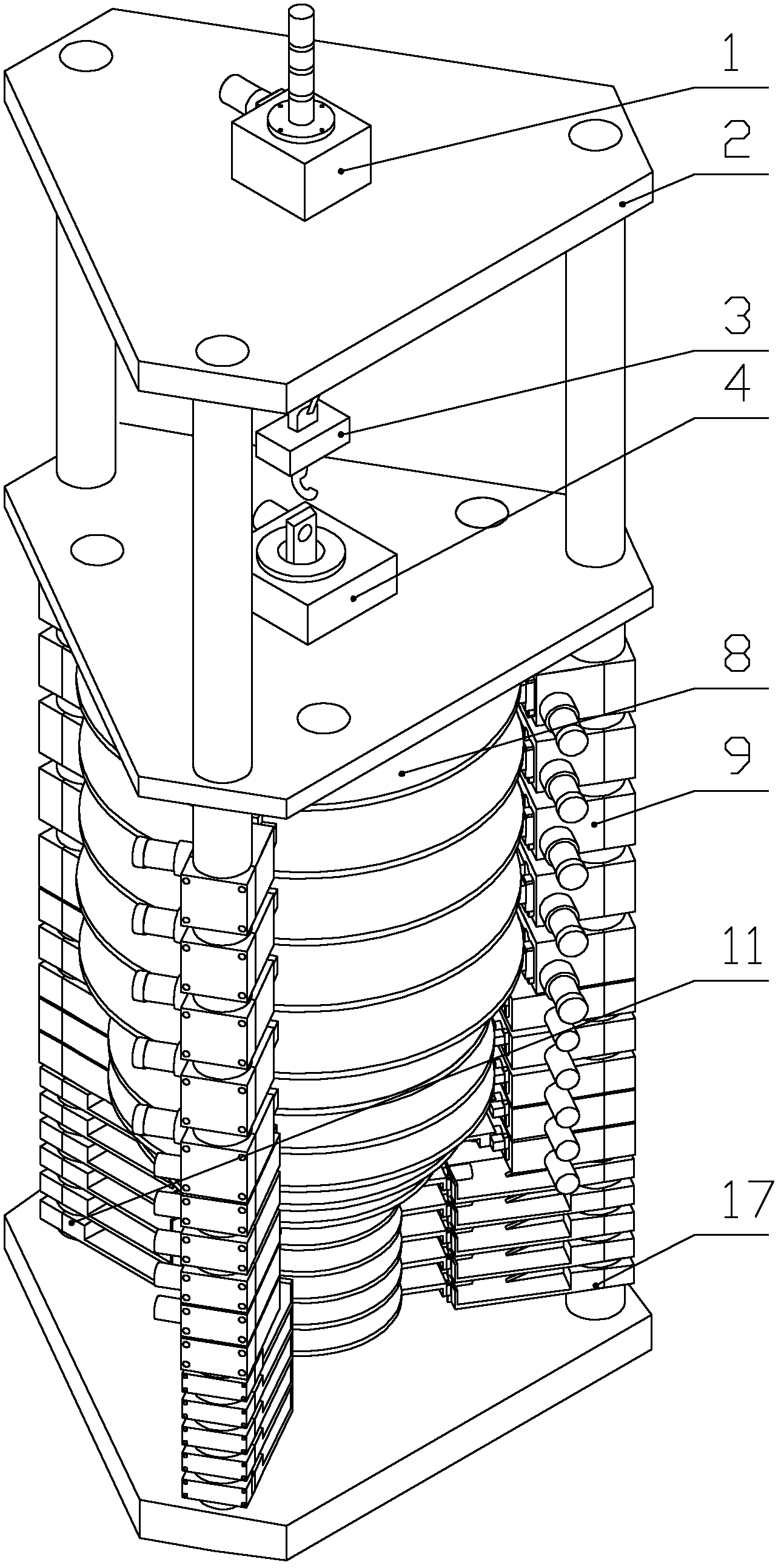

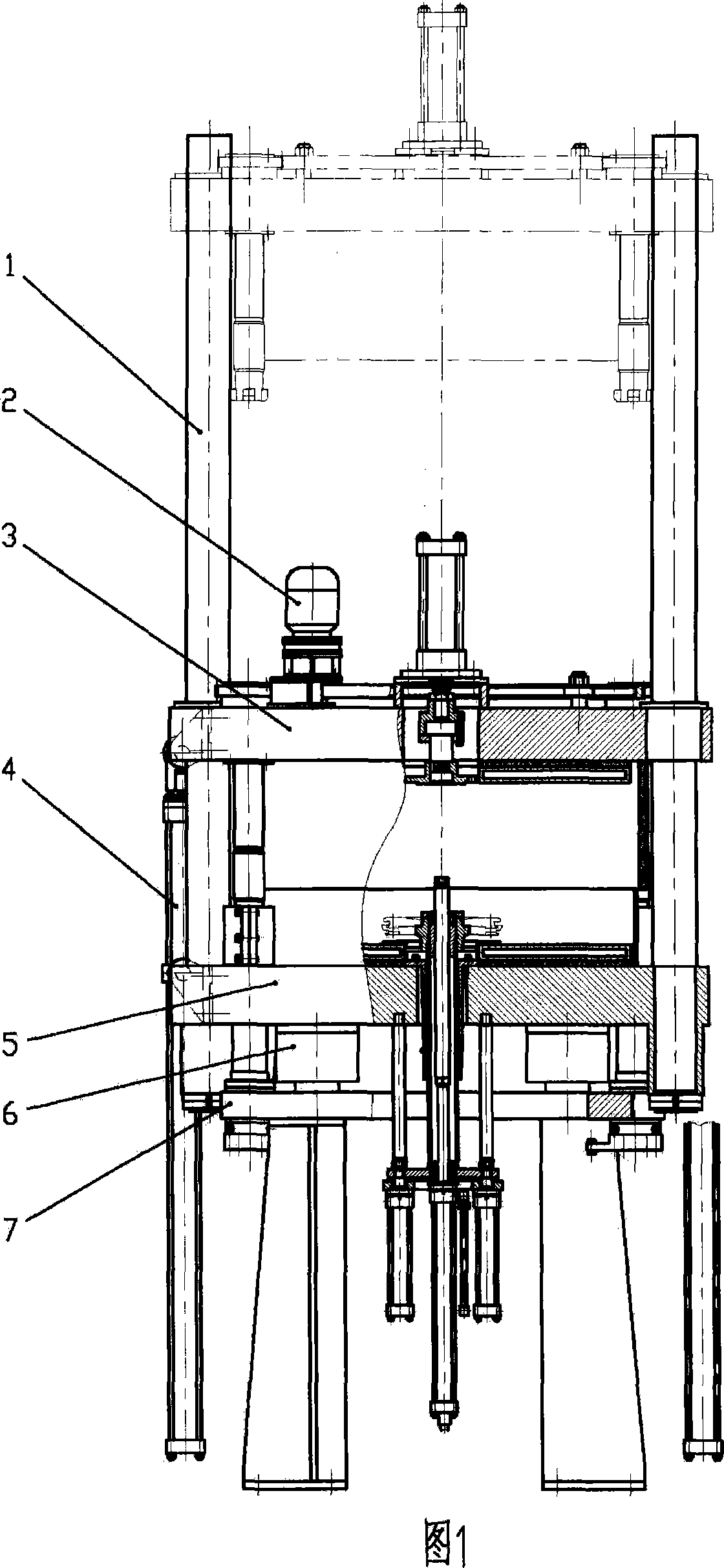

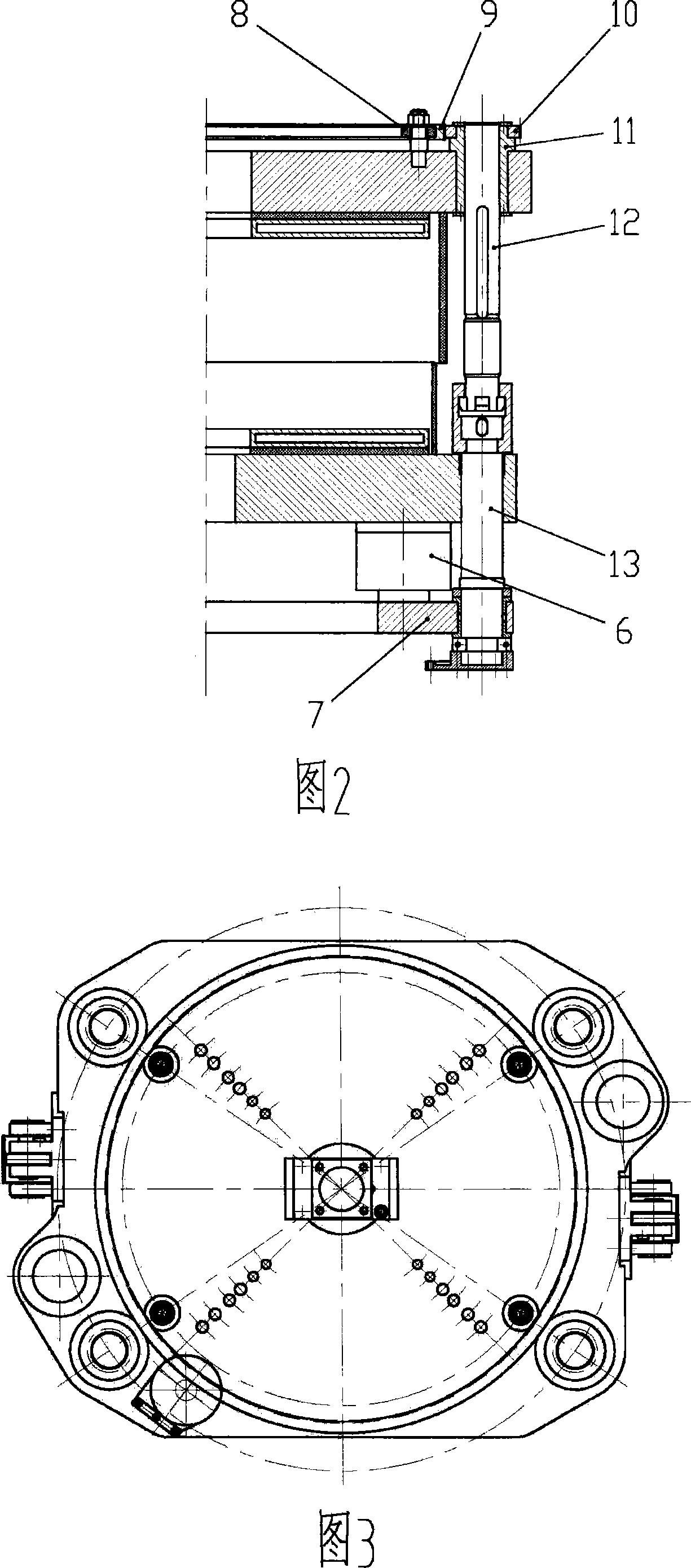

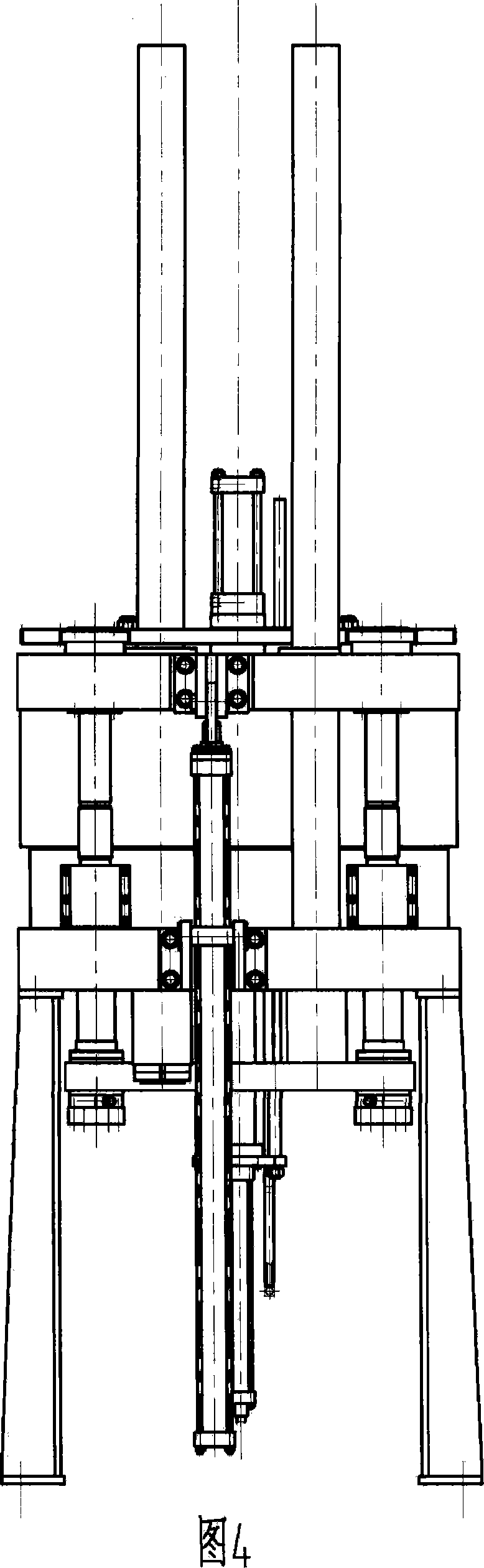

Pull rod lock mode hydraulic tyre vulcanizer

The invention discloses a hydraulic tire curing press with a pull rod locking module. The invention consists of a frame consisting of a lower beam and a supporting part, an upper beam, an upper and lower thermal plate, an opening and closing die cylinder, a central structure and a pressurized structure. The upper beam is driven by the opening and closing die cylinder and has freedom of moving from the top to the bottom. An upper die and a lower die are directly arranged between the upper thermal plate and the lower thermal plate and are respectively fixed connected with the upper beam and the lower beam. The pressurized structure consists of a pulling rod, a pressurized splint and a pressurized cylinder. The pulling rod is evenly arranged corresponding to the axle wire of in the tire module. The upper terminal of each pulling rod is fixedly connected with the upper beam and the lower terminal of each pulling rod is fixedly connected with the pressurized plate traveling through the lower beam; the pressurized cylinder is fixed on the bottom of the lower beam and the piston terminal of the cylinder is fixedly connected with the pressurized plate; the pulling rod is arranged with a locking die structure and an adjusting die structure. The invention increases the working precision and reducing the manufacturing cost, at the same time, the invention also has the advantages of avoiding the problem of oil leaking and contamination, being convenient for the cylinder maintenance, simplifying the forcing chain of the locking die force and reducing the manufacturing cost of the curing press.

Owner:SINO ARP TIRES EQUIP TECH (SUZHOU) CO LTD

Automatic stainless pan polishing equipment

InactiveCN103273410ANo pollutionNo harmPolishing machinesGrinding work supportsElectrical controlEngineering

The invention belongs to the technical field of polishing and particularly relates to automatic stainless pan polishing equipment. The automatic stainless pan polishing equipment is characterized in that the equipment comprises an electrical control device, a workbench, fixing clamps, supports and polishing devices, the fixing clamps are mounted on the workbench through a rotating device, the workbench is connected with a workbench motor and driven by the same to rotate, the polishing devices are mounted on the supports through a moving device, and the electrical control device is connected with and controls the polishing devices, the rotating device, the workbench motor and the moving device. The automatic stainless pan polishing equipment is reasonable in structural design and high in working efficiency, polished products are shining, dust pollution and damages to human bodies cannot be caused in the process of operating, labor intensity of workers is reduced, production cost is lowered, and a brand-new automatic polisher equipment capable of replacing manpower is provided.

Owner:冯会民

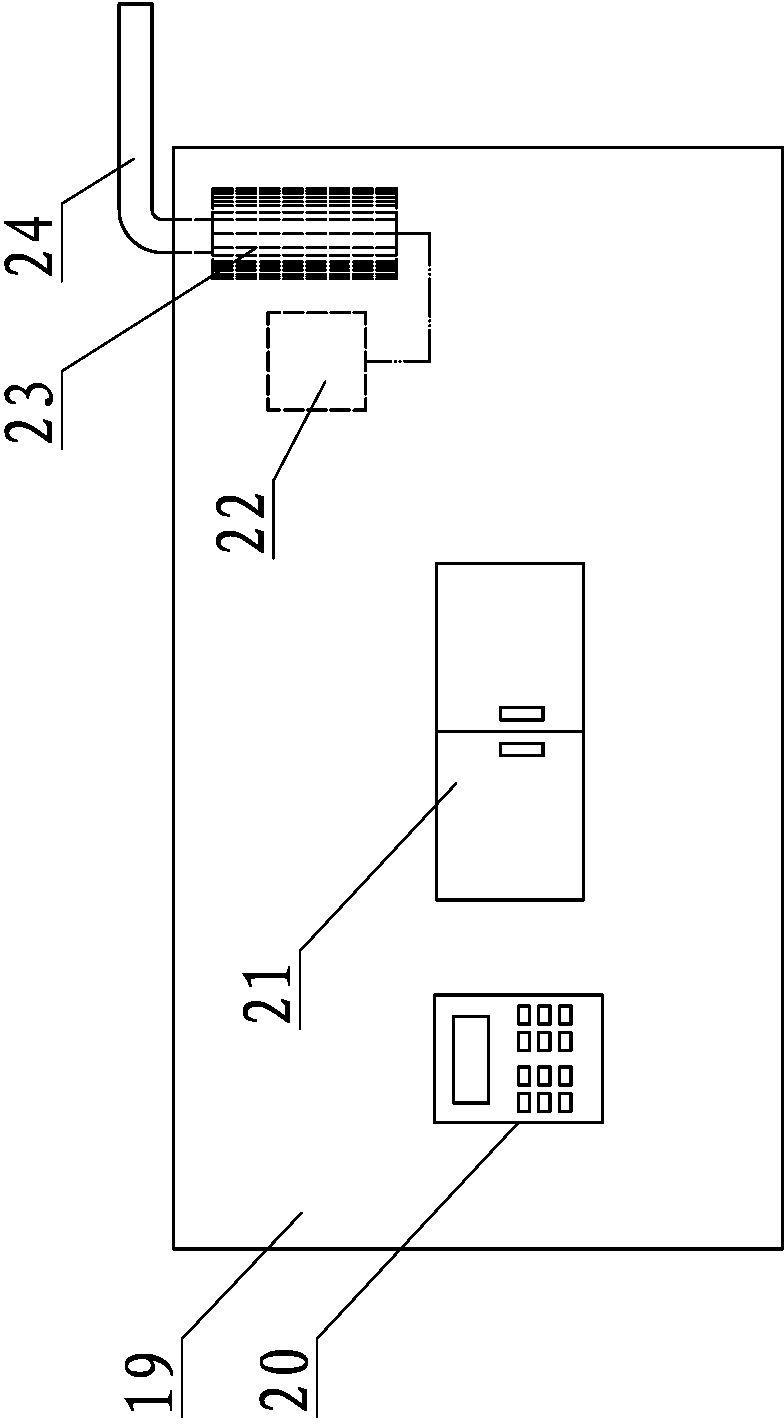

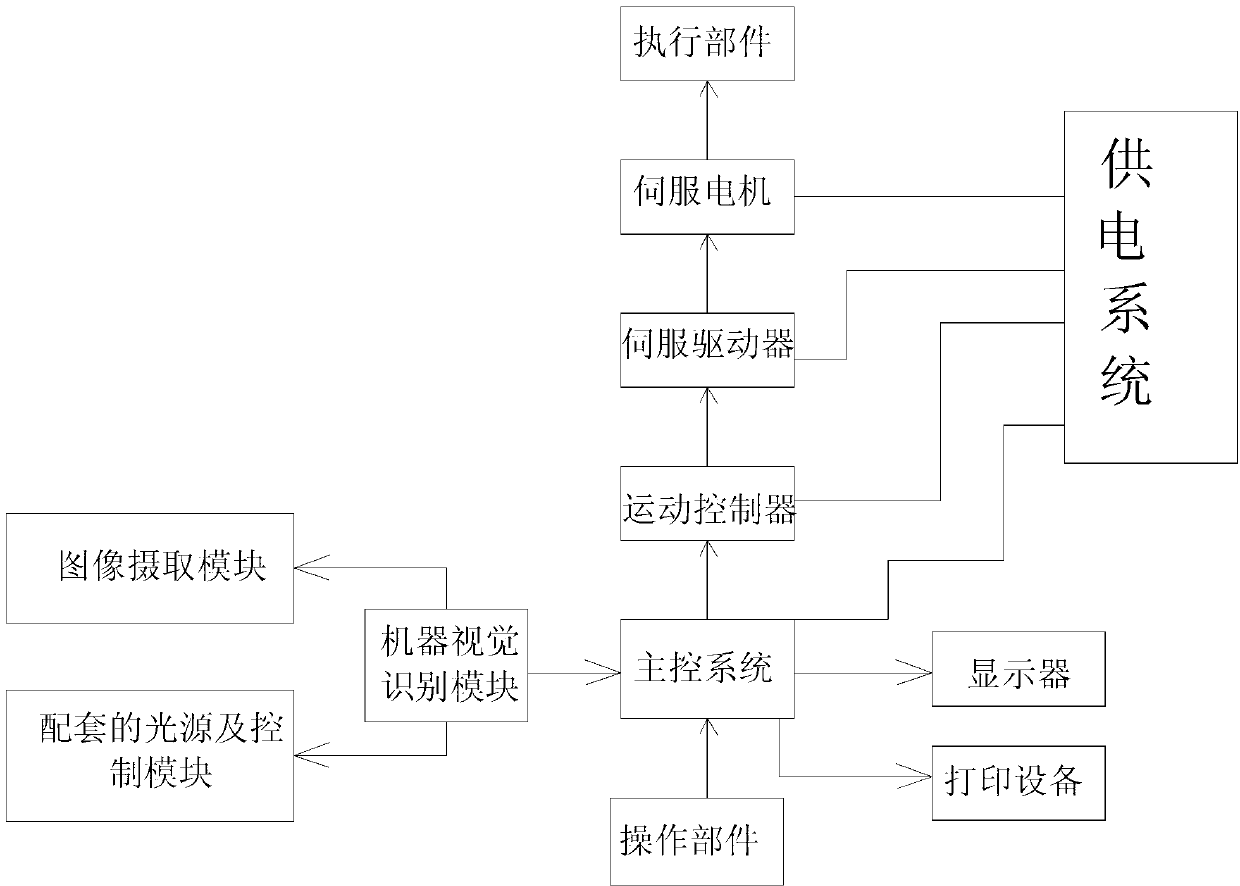

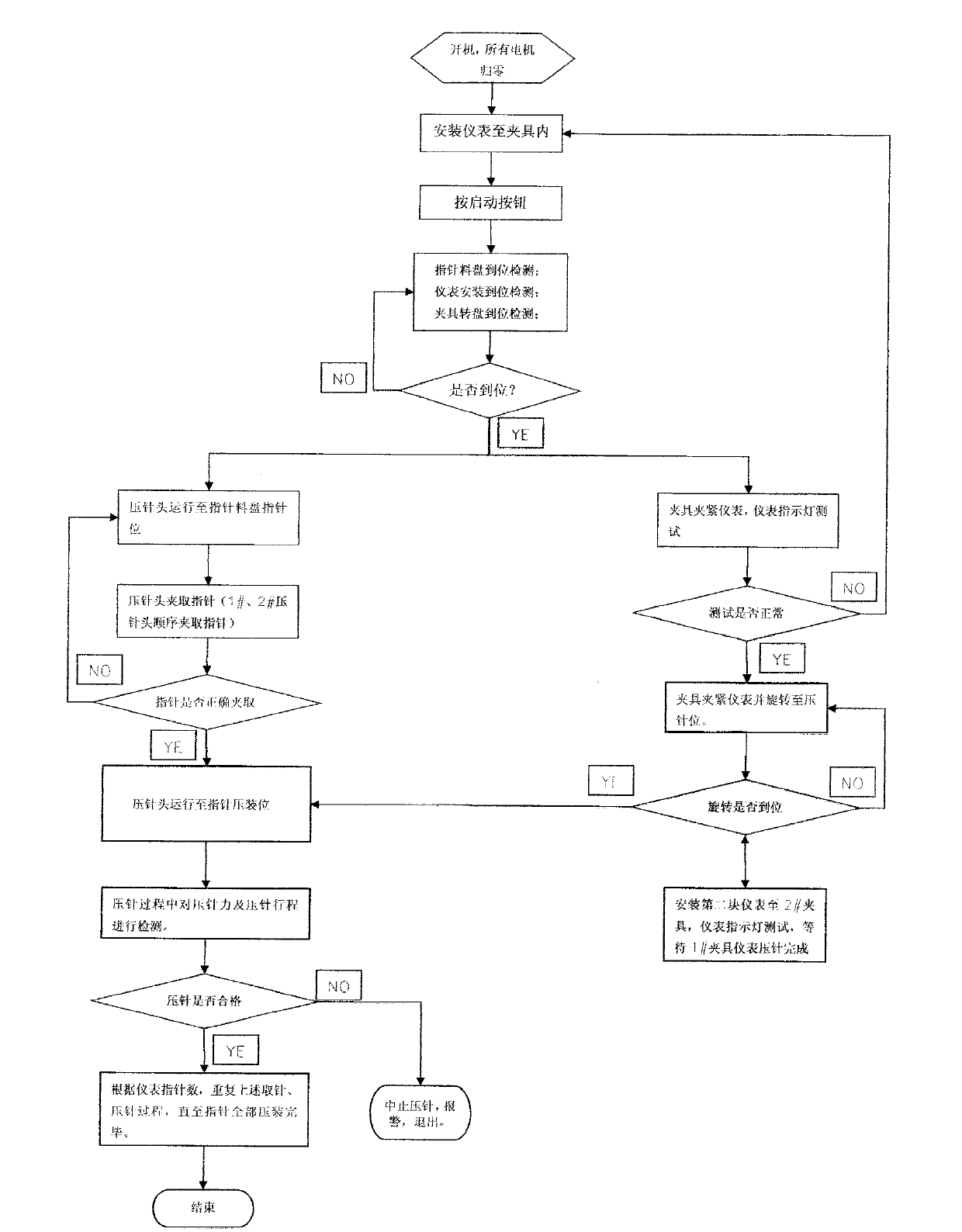

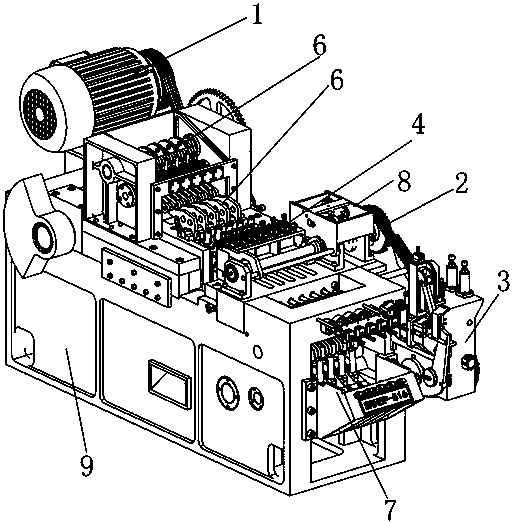

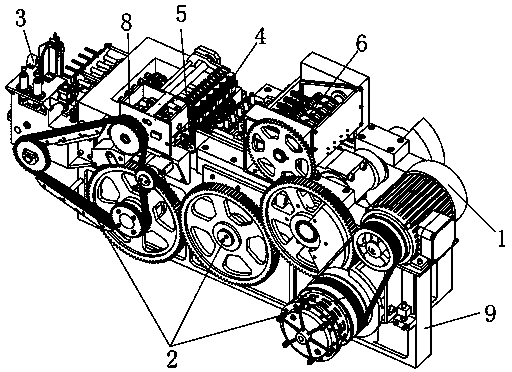

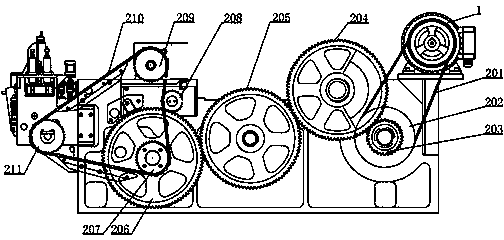

Instrument indicator pressing system based on machine vision recognition

ActiveCN102990331AImprove work efficiency and precisionPrecise pressure controlMetal working apparatusMotor driveEngineering

The invention provides an instrument indicator pressing system based on machine vision recognition and relates to the field of an instrument indicator mounting technology. The instrument indicator pressing system comprises a main control system; the main control system is in control connection with an operation part, a machine vision recognition module, a movement controller, a display system and a printing system; the pressing system further comprises a power supplying system for providing a power supply for each part; the movement controller is in control connection with a servo driver; the servo driver drives a servo motor; and the servo motor drives an executing part which is mounted on a three-dimensional coordinate movement device and can do three-dimensional movement on the three-dimensional coordinate movement device. According to the instrument indicator pressing system disclosed by the invention, indicator pressing and correction movement can be carried out through the three-dimensional coordinate movement device; a three-dimensional movement system can control a plurality of indicator pressing heads to take a piece to carry out indicator pressing at the same time; and meanwhile, depth and pressure values of pressing the indicator are designed according to requirements and the accurate control on the depth and pressure values of pressing the indicator can be realized, so that the working efficiency and the accuracy of pressing the indicator are greatly improved.

Owner:HEFEI YONGGAO ELECTRONICS SCI & TECH

Cold heading machine

ActiveCN104174802AMeet sporting requirementsNot easy to move at high speedUpsetting pressesSwagging pressesMotor driveBack support

The invention discloses a cold heading machine. The cold heading machine comprises a machine body, wherein a main motor, a drive system, a linear feeding device, a rotary clamp, a cutter system, an adjustable male die ejecting mechanism and a closed back support are arranged on the machine body; the main motor is arranged at a first end of the machine body, and the drive system is arranged at an output end of the main motor; the linear feeding device is arranged at a second end of the machine body, and the closed back support is arranged on one side of the feeding device; the rotary clamp and the male die ejecting mechanism are arranged in the middle of the machine body; and the cutter system is arranged below the rotary clamp. After the main motor of the machine is started, the main motor drives the linear feeding device, the rotary clamp, cutters, the male die ejecting mechanism and the like through the drive system to finish processing steps of feeding, cutting, upsetting, finished product ejecting and the like. The cold heading machine has the advantages that the drive efficiency can be improved, the high-speed driving is realized, the working efficiency and precision of the cold heading machine are improved, and the like.

Owner:HUANGSHAN SHENGRUI HEAVY IND MACHINERY

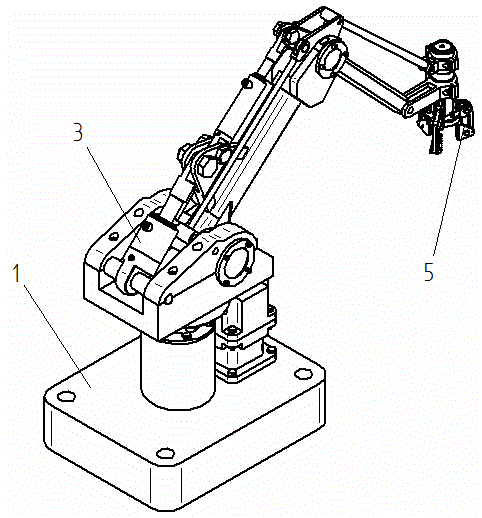

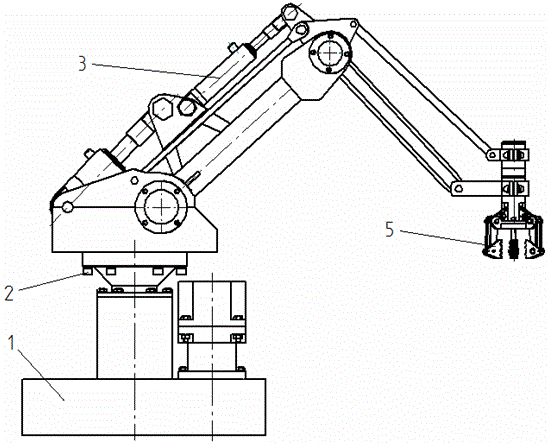

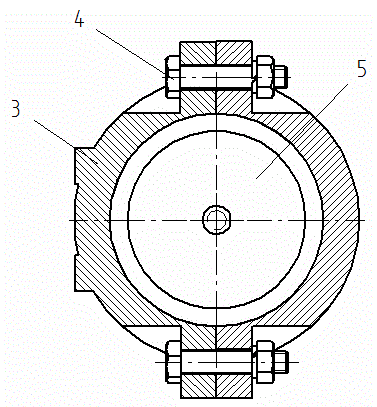

Novel pneumatic manipulator

ActiveCN104002304AFlexible structureImprove working precisionProgramme-controlled manipulatorGripping headsAttitude controlPolyester

The invention relates to a novel pneumatic manipulator and belongs to the technical field of industrial robots. The novel pneumatic manipulator comprises a base, a manipulator arm and a manipulator claw, wherein the base and the manipulator arm are connected together through a hexagon socket screw I; the manipulator arm and the manipulator claw are connected into a whole through a connecting bolt. The manipulator claw has four degrees of freedom, is light and handy in structure and can quickly respond to a control command and enhance working accuracy and production efficiency. The novel pneumatic manipulator is high in carrying capacity and safe and reliable in working process. A polyester rubber mat is embedded in the position where an end effector of the manipulator makes contact with a workpiece, and therefore the surface of the workpiece can be well protected. With regard to the attitude control over the manipulator claw of the end effector, an attitude control servo system is replaced by a series-connection parallel four-bar mechanism, in this way, the working accuracy is enhanced, and the manipulator is more convenient to control.

Owner:KUNMING UNIV OF SCI & TECH

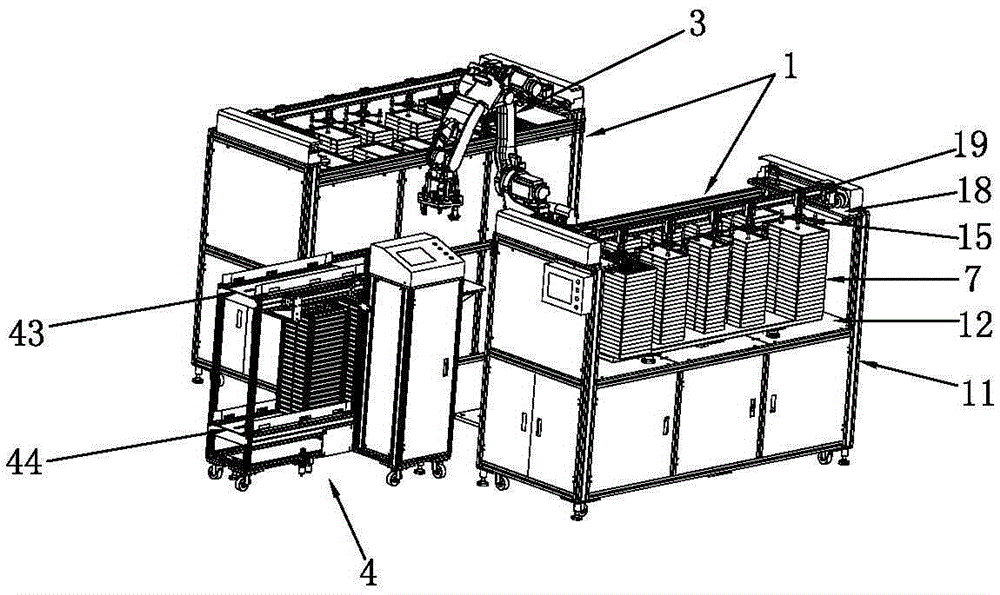

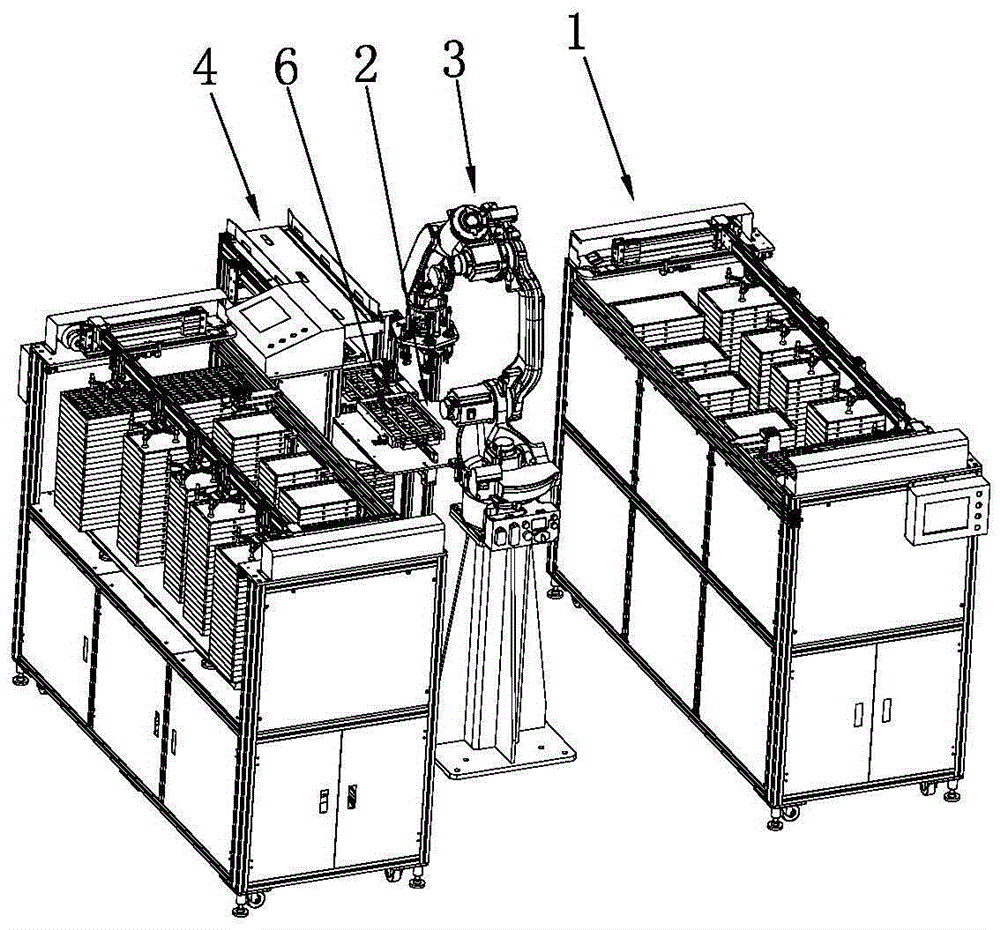

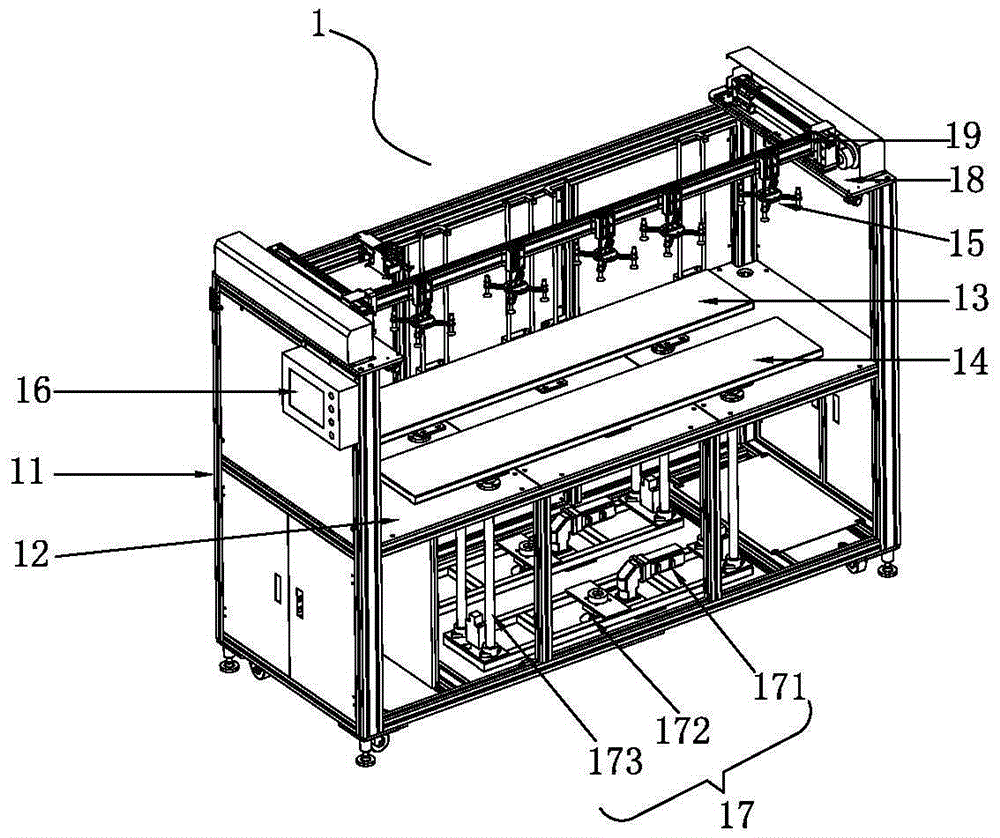

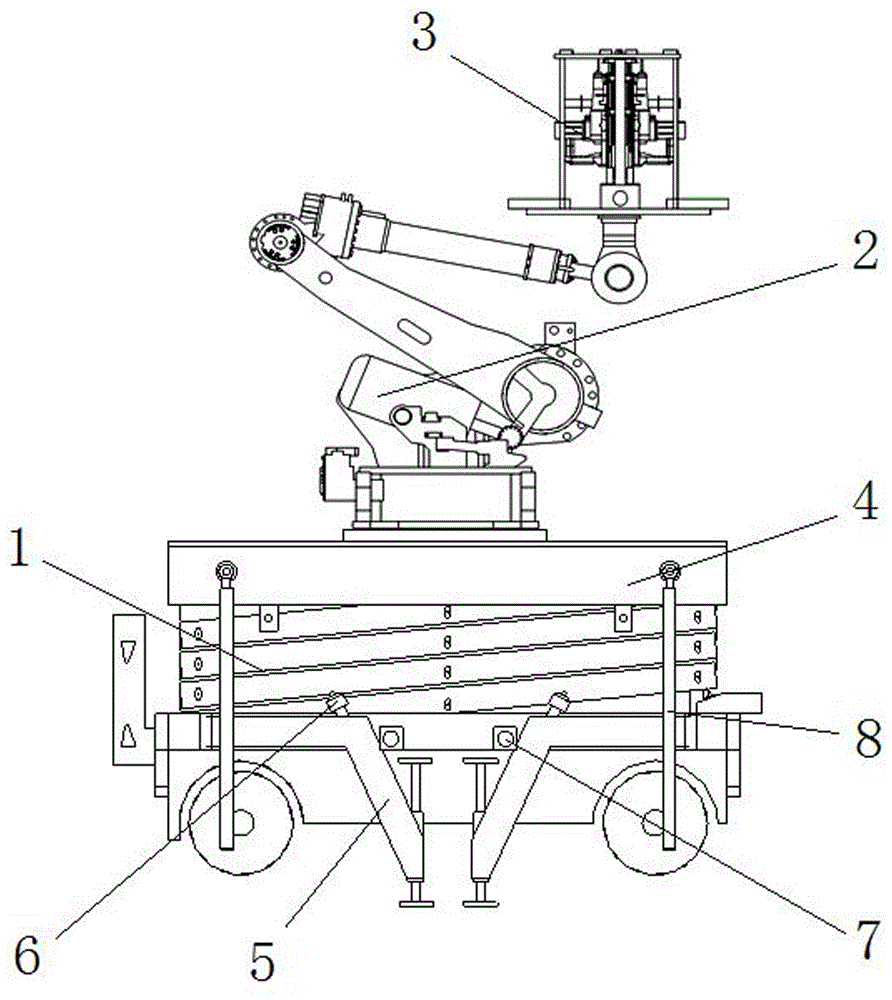

Full-automatic part sorting and conveying system

ActiveCN105364450AReduce labor intensityImprove work efficiency and precisionSortingMetal working apparatusTemporary storageRhythm

The invention relates to the technical field of sorting equipment, in particular to a full-automatic part sorting and conveying system. The full-automatic part sorting and conveying system comprises an automatic feeding device, a receiving working table, a part grasping robot hand and an automatic material conveyor, wherein the automatic feeding device is used for conveying parts to a sucking grasping station in a classified mode, the receiving working table is used for supporting a distributing tray with a containing cavity, the distributing tray completes part distribution on the receiving working table, the part grasping robot hand rotates back and forth between the automatic feeding device and the receiving working table to place the parts into the containing cavity of the distributing tray from the sucking grasping station, and the automatic material conveyor is used for putting the distributing tray containing the parts into a material frame and then automatically outputting the material frame to a temporary storage zone for assembly. The full-automatic part sorting and conveying system has the automatic feeding, automatic sorting and automatic outputting functions, effectively relieves the labor intensity of operators, improves the working efficiency and accuracy of part sorting, guarantees that the production rhythm of a subsequent assembly process is in good order, and is beneficial for promoting automatic line production.

Owner:DONGGUAN TIANFU LIDE IND CO LTD

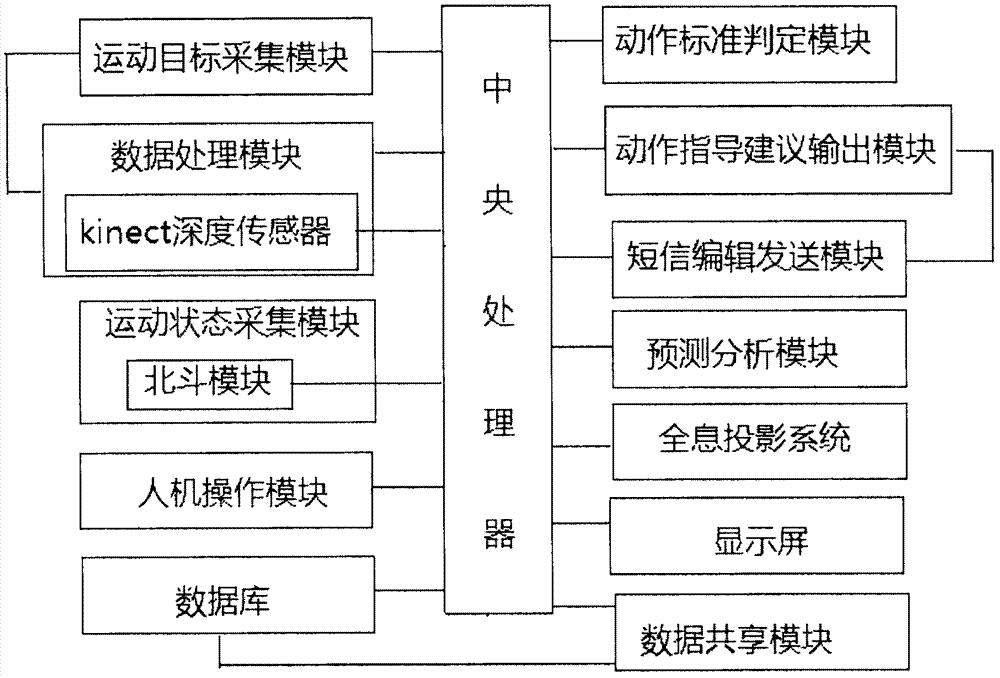

Sports training assessment system

The invention discloses a sports training evaluation system, which includes a sports target identification module, a sports state acquisition module, a data processing module, an action standard judgment module, an action guidance suggestion output module, a man-machine operation module, a prediction analysis module and a central processing unit . The invention realizes the automatic determination and guidance of sports training actions, improves the training efficiency, makes the actions more standardized, and also reduces the workload of the coach; through the collection of the exercise state and the athlete's vital sign state, real-time monitoring of the athlete's physical condition is realized. Monitoring and comprehensive evaluation avoid the occurrence of excessive movement; in the process of video collection, the recognition of moving targets is realized, which improves the work efficiency and accuracy of the entire system.

Owner:QUFU NORMAL UNIV

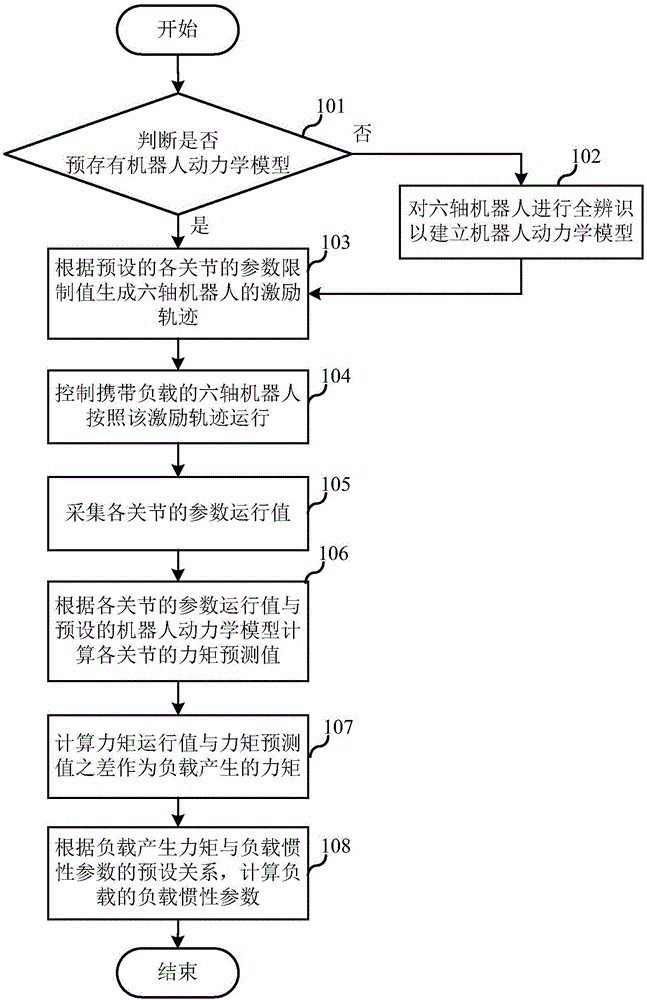

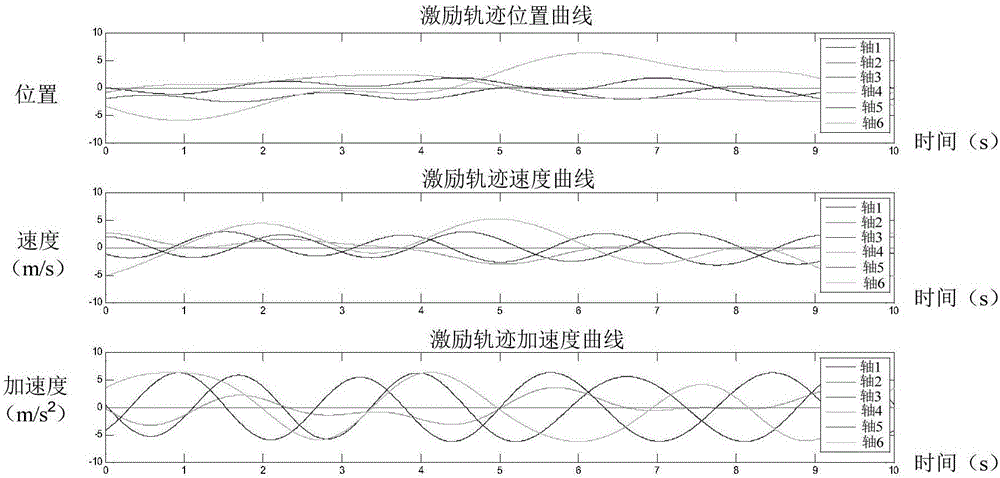

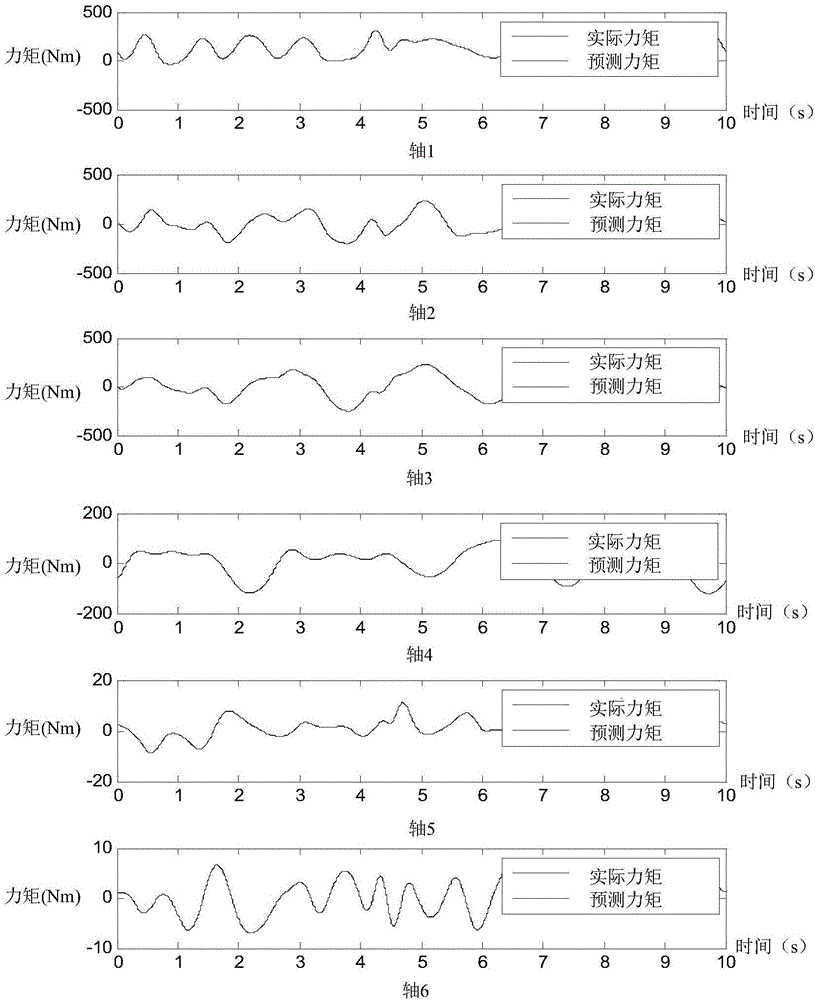

Method and module for distinguishing load of six-axis robot

ActiveCN106346477ASimple installation and debuggingImprove working precisionProgramme-controlled manipulatorLoad generationComputer module

The embodiment of the invention relates to the technical field of robot control, and discloses a method and a module for distinguishing a load of a six-axis robot. The method for distinguishing the load of the six-axis robot comprises the following steps: according to a preset parameter limiting value of each joint, generating an excitation track of the six-axis robot; when the six-axis robot carrying the load is controlled to run along the excitation track, collecting a parameter running value of each joint; according to the parameter running value of each joint and a preset robot dynamics model, calculating a torque predicting value of each joint; calculating a difference between the torque running value and the torque predicting value, the difference serving as torque produced by the load, and according to preset relationship of the torque produced by the load and a load inertia parameter, calculating the load inertia parameter. The embodiment of the invention also provides the module for distinguishing the load of the six-axis robot. The module for distinguishing the load of the six-axis robot disclosed by the embodiment has the advantage that compared with the prior art, the parameter running value of the robot is collected on line, and the load inertia parameter of the robot is distinguished; because a six-dimensional force sensor is not used, the cost is reduced.

Owner:SHANGHAI STEP ELECTRIC +1

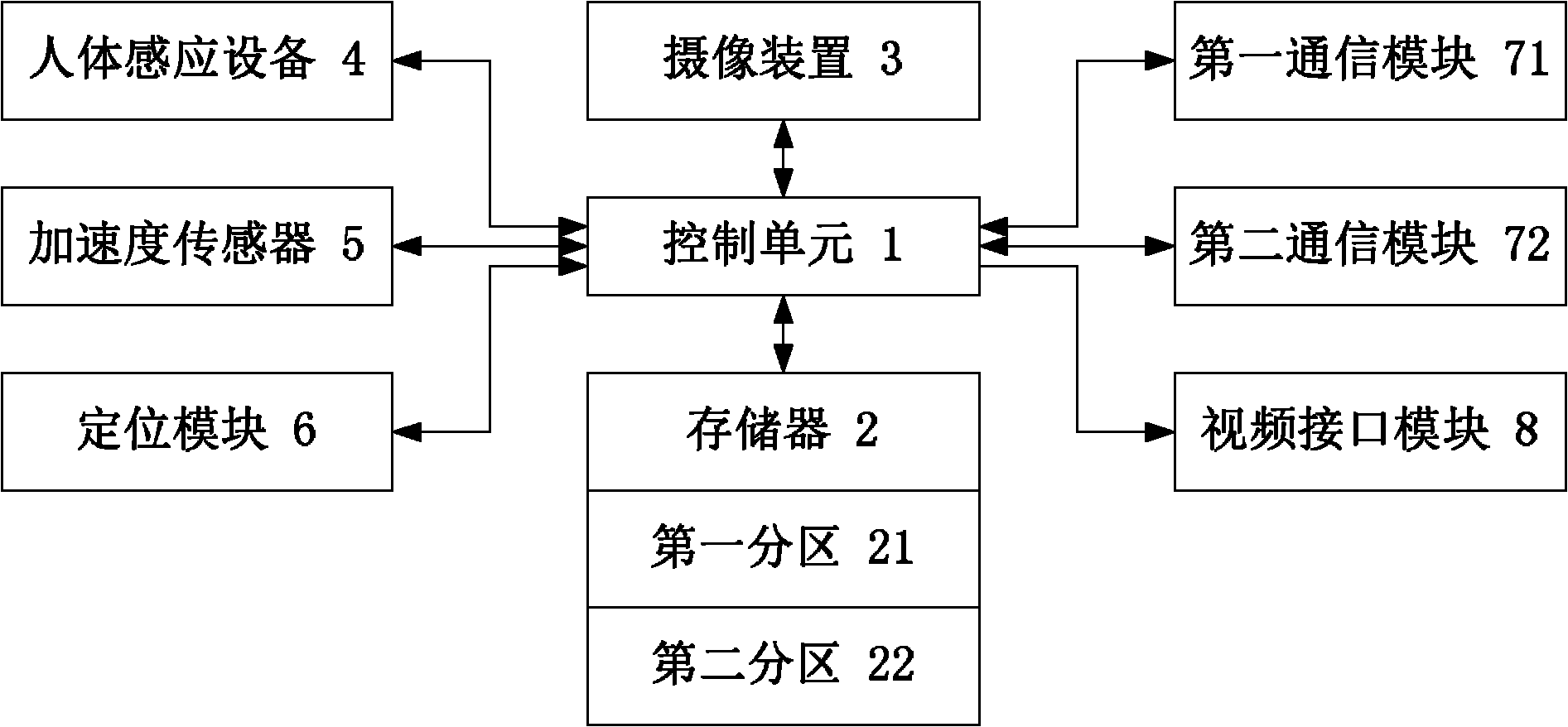

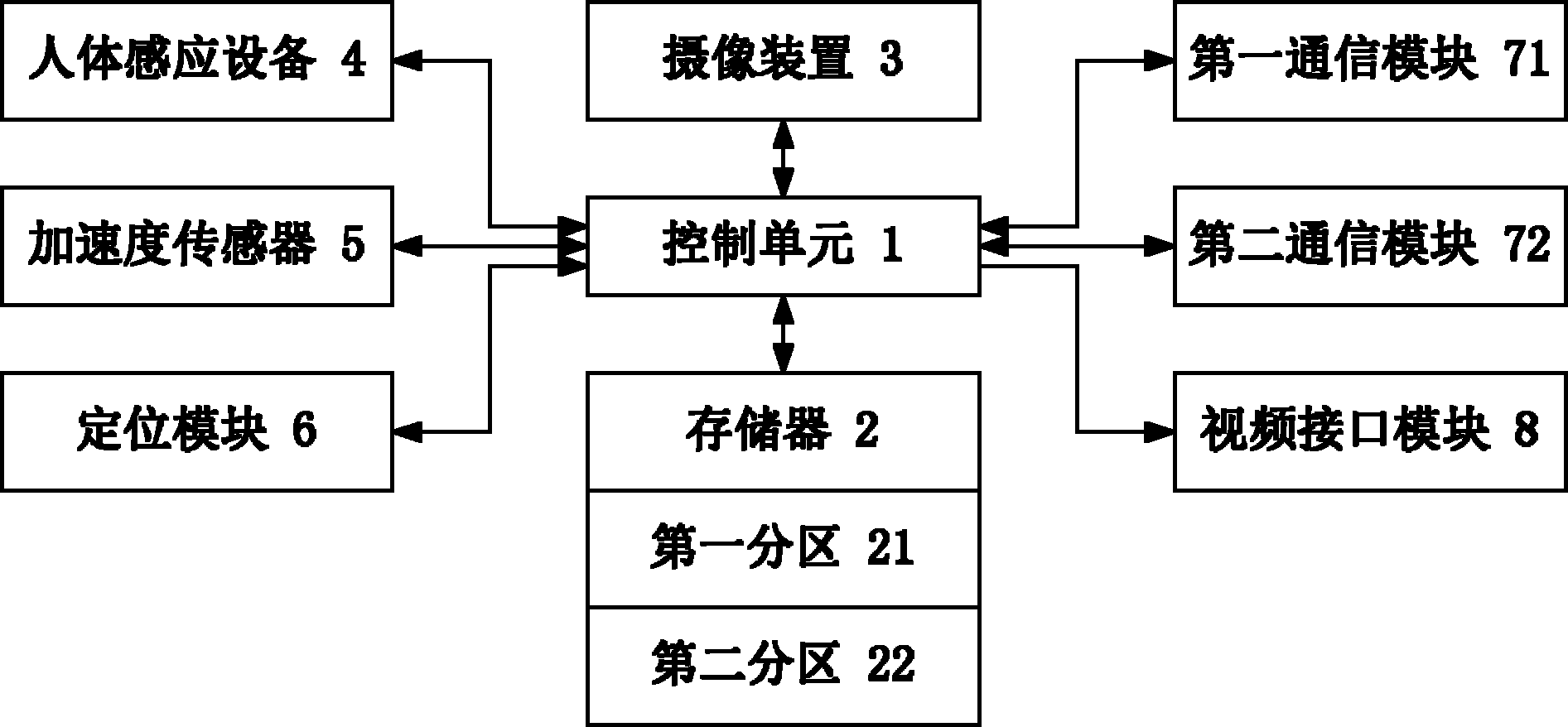

Video recording instrument of vehicle

InactiveCN102145683AEasy to investigateNot easy to formatTelevision system detailsRegistering/indicating working of vehiclesVideo recordVideo recording

The invention provides a video recording instrument of a vehicle, which comprises human body induction equipment, an acceleration sensor, a photographing device, a control unit and a storage, wherein the human body induction equipment is used for generating a first signal when a human body approaches the human body induction equipment; the acceleration sensor is used for generating a second signal when the movement of an automobile is detected; the control unit drives the photographing device to automatically detect the human body and identify the face of the human body when an automobile is in a shut-down state if the first signal and the second signal are received and meet preset conditions, and stores the photographing data as special data in a first partition after the successful identification, and the control unit judges whether the second signal which meets the preset conditions exists when detecting that the automobile is in a startup state, and stores the photographing data as the special data in the first partition if the second signal which meets the preset conditions exists, or stores the photographing data as ordinary data in a second partition; and the storage is used for storing the special data. In the invention, the acquisition, the storage and the safe transmission of the photographing data carrying human face information of a person who approaches the automobile are realized by dint of a microwave sensor, the acceleration sensor and the photographing device.

Owner:STEELMATE CO LTD

Travelling-wave linear ultrasonic micromotor

ActiveCN102097974AEasy to installImprove job stabilityPiezoelectric/electrostriction/magnetostriction machinesEngineeringMicromotor

The invention discloses a travelling-wave linear ultrasonic micromotor which belongs to the technical field of ultrasonic motors and is mainly characterized by comprising a stator, wherein the stator is shaped as an annular hollow slice, and a piezoelectric ceramic ring is arranged on the surface of the stator; driving mechanisms are distributed on the outer edge of the stator, the lateral edges of the driving mechanisms are provided with a plurality of guide rails along the axial direction of the stator, and the driving mechanisms correspond to and is in contact with the guide rails; and a pretightening mechanism is connected to one end surface of the stator and in contact with the guide rails. The invention aims at providing the travelling-wave linear ultrasonic micromotor which has the advantages of compact structure, small occupying space, stability of working and high precision and is suitable for the aspects of optical lens, biology, medical treatment, micromachine, the science and technology for national defense, and the like.

Owner:GUANGDONG JIAHE MICROMOTOR

Automatic punching device and method for high-speed railway tunnel anchor implantation

InactiveCN106703689APrevent health damageEliminate human errorLifting devicesAnchoring boltsRailway tunnelLaser ranging

The invention discloses an automatic punching device and method for high-speed railway tunnel anchor implantation and solves problem that health of construction staff is damaged, punching accuracy is poor in anchor implantation, construction efficiency is low and security of the construction staff cannot be guaranteed in existing tunnel anchor implantation. Each of the front end and the rear end of a hydraulic life truck is provided with a support leg, each support leg is provided with a support ball head and a winch, each of the front end face and the rear end face of a lift platform is provided with a hydraulic telescopic rod, each of the upper and lower ends of a frame-type housing is provided with a horizontal chute, a fixing pillar is vertically arranged in the two horizontal chutes, a horizontal servo motor and vertical chutes are arranged in the fixing pillar, each of the vertical chutes is provided with an electric hammer, vertical servo motors are arranged under the electric hammers, a gravity sensor and a laser range finder are arranged at the lower end of the frame-type shell, and a radar range instrument is arranged at the upper end of the frame-type shell. By the arrangement, working accuracy is greatly improved, and danger coefficient in construction is reduced.

Owner:NORTH ENG OF THE ELECTRIFICATION BUREAU GROUP CRCC

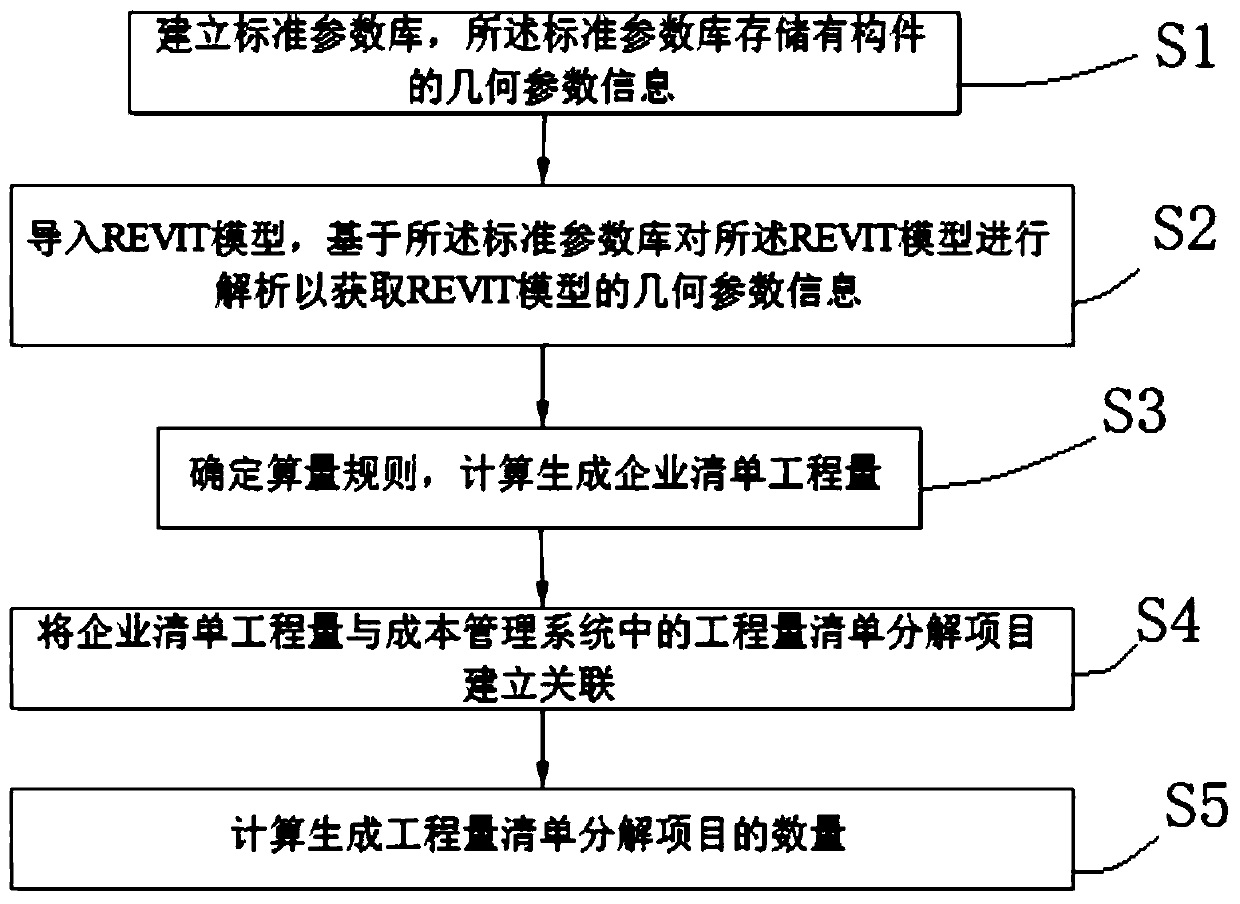

Engineering calculation method and system based on BIM technology, computer equipment and readable storage medium

The invention discloses an engineering calculation method and system based on a BIM technology, and belongs to the technical field of infrastructures represented by railway engineering. The method comprises the steps of establishing a standard parameter library, and storing geometrical parameter information of a component in the standard parameter library; importing an REVIT model, and analyzing the REVIT model based on the standard parameter library to obtain geometric parameter information of the REVIT model; determining a calculation rule, and calculating and generating an enterprise list engineering quantity; correlating the enterprise list engineering quantity with engineering quantity list decomposition projects in a cost management system; and calculating the quantity of the generated engineering quantity list decomposition items. The system comprises a standard library module, an import analysis module, a first association module, a calculation module, a second association module and a calculation module. According to the method, the calculation efficiency can be improved, the engineering quantity information of the model is quickly obtained based on the BIM model information, and the engineering quantity and the report form required by the enterprise cost management system are generated.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

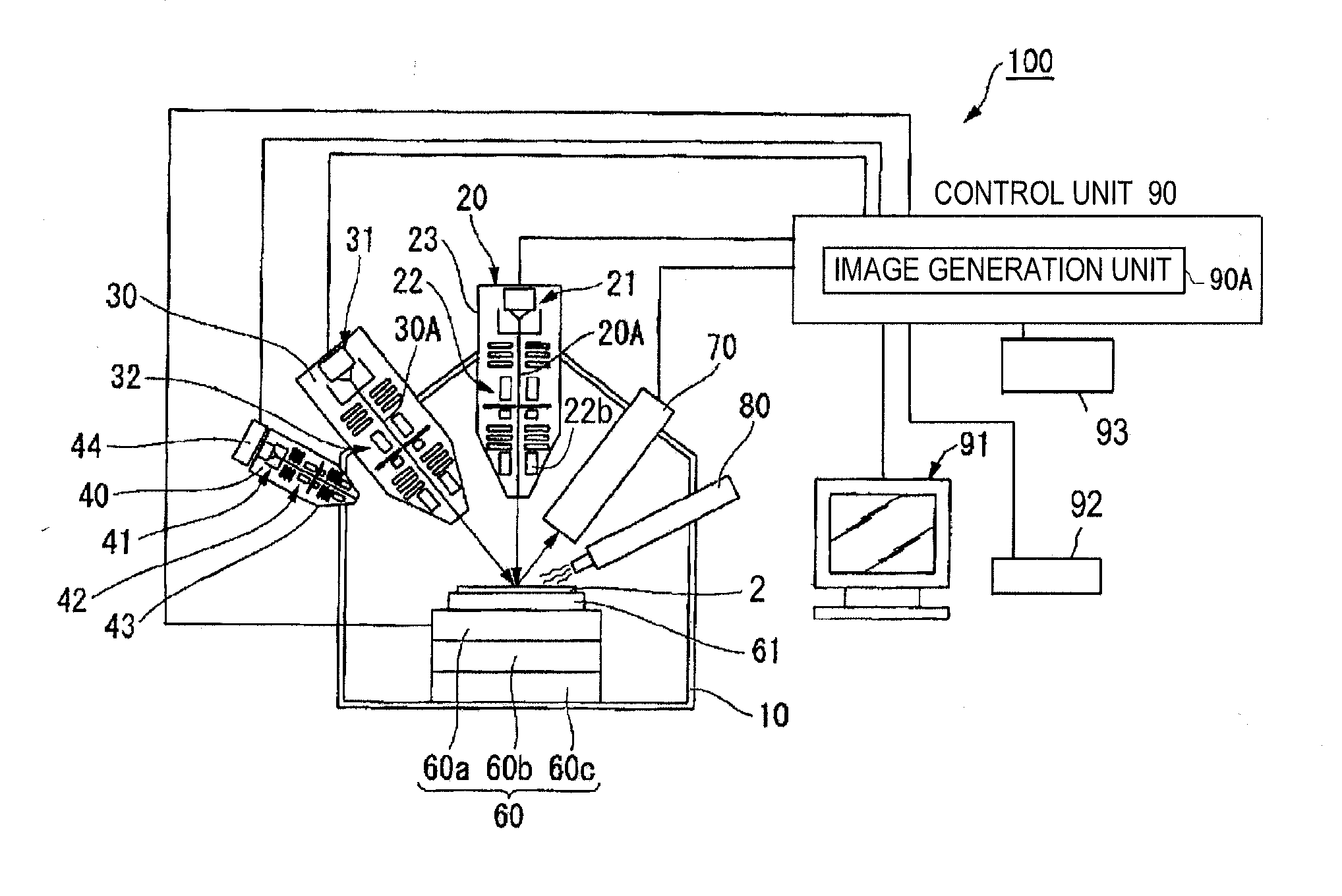

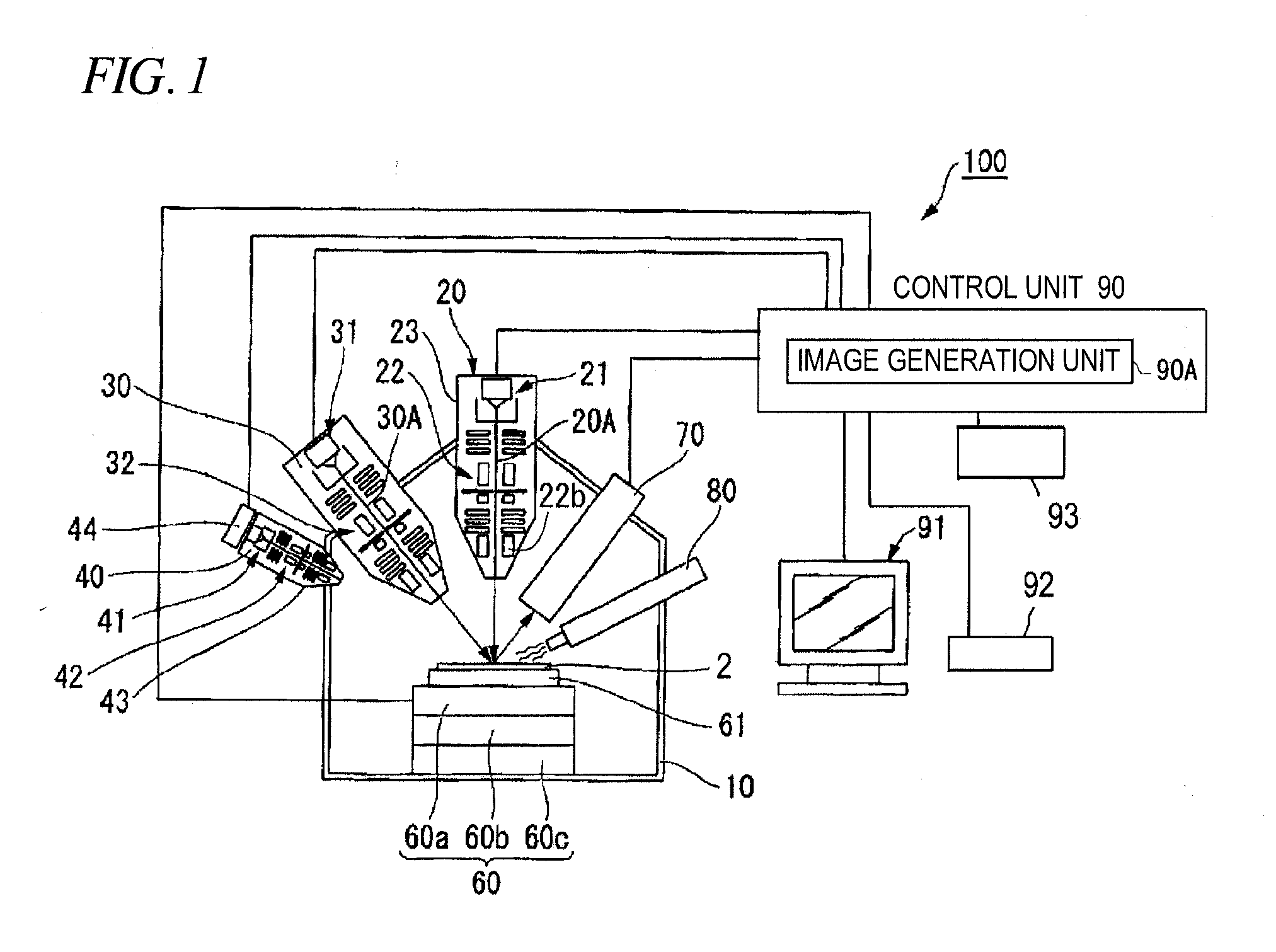

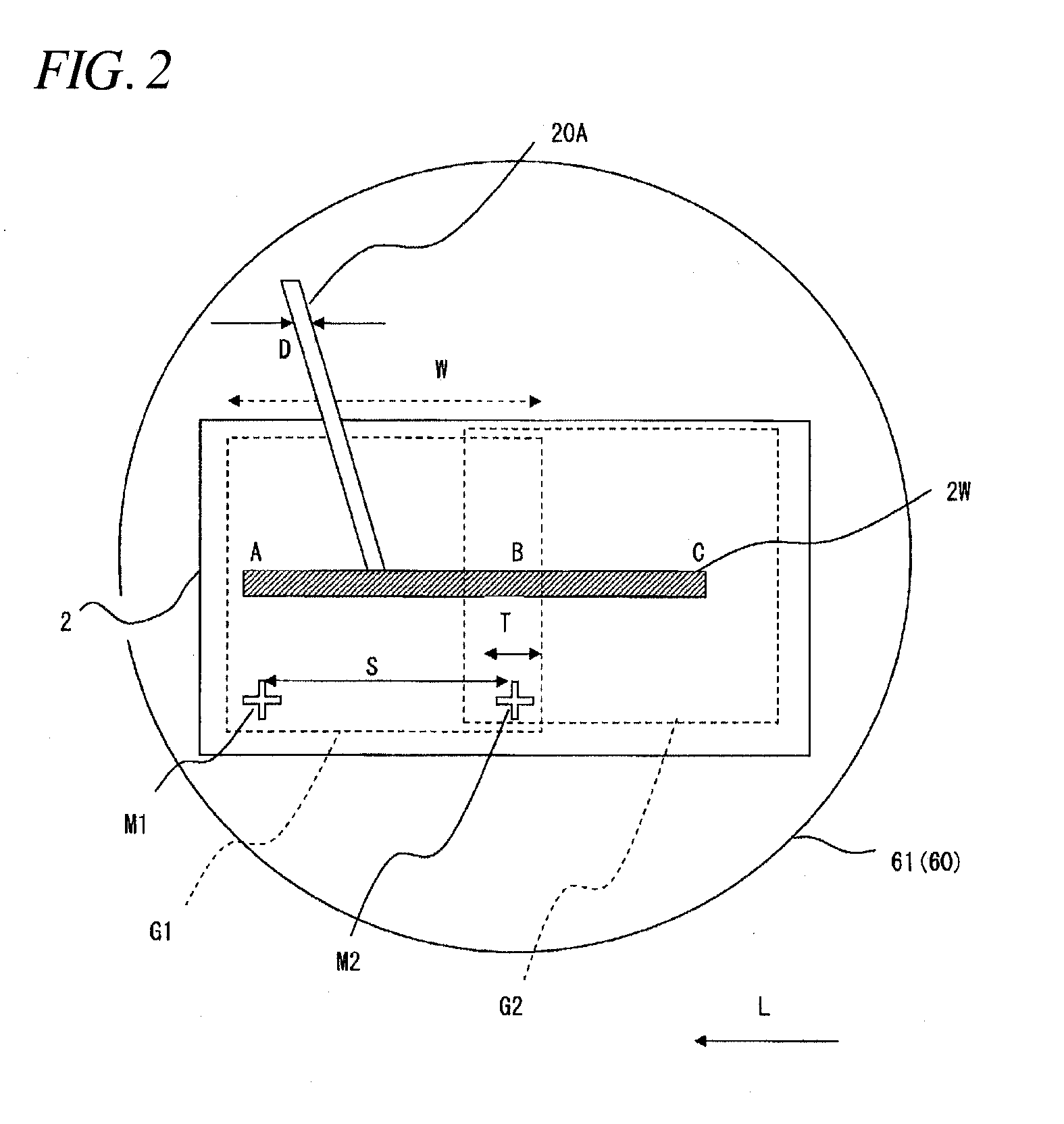

Focused ion beam apparatus and method of working sample using the same

ActiveUS20140291512A1Improve working precisionImprove accuracyMaterial analysis using wave/particle radiationElectric discharge tubesLocation detectionIon beam

A focused ion beam apparatus includes: an image generation unit which generates a sample image including location detection marks formed on a sample based on secondary charged particles generated with emission of a focused ion beam to a sample; a display unit which displays a sample image; and a control unit which, in a case of performing working by emitting the focused ion beam to a working region beyond a display range, moves a sample stage, detects locations of the location detection marks included in the sample image after the movement of the sample stage as reference marks from the location detection marks included in the sample image before moving the sample stage, and controls an emission location of the focused ion beam based on the reference marks detected in the sample image after being moved.

Owner:HITACHI HIGH TECH SCI CORP

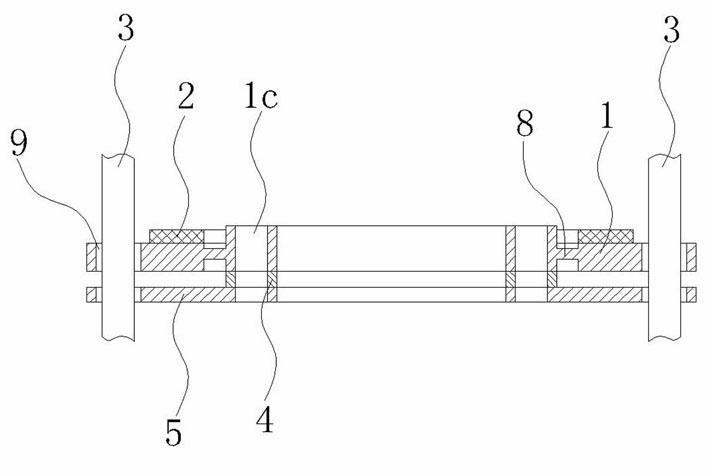

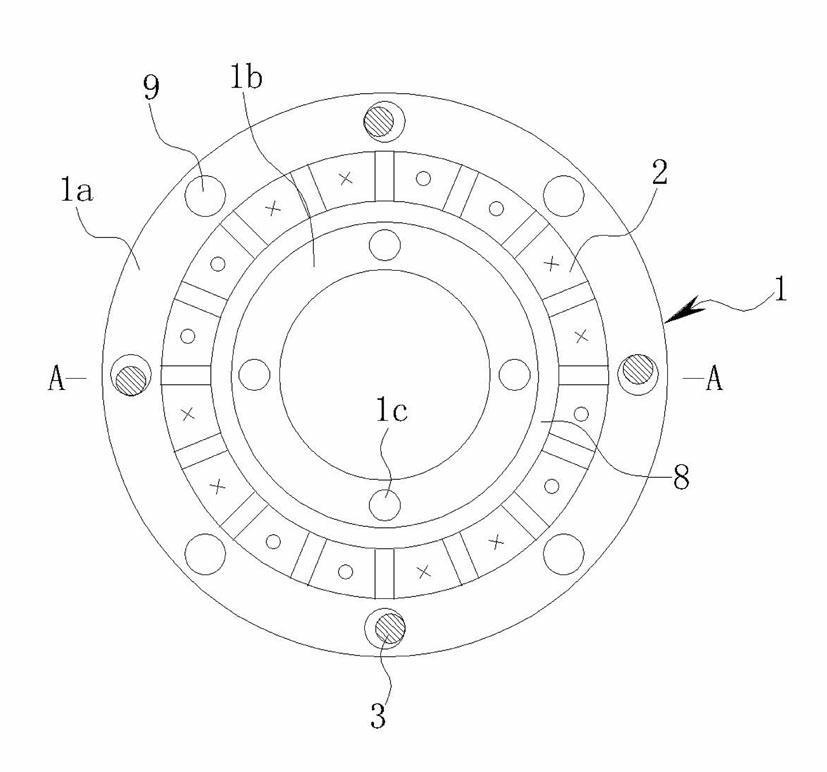

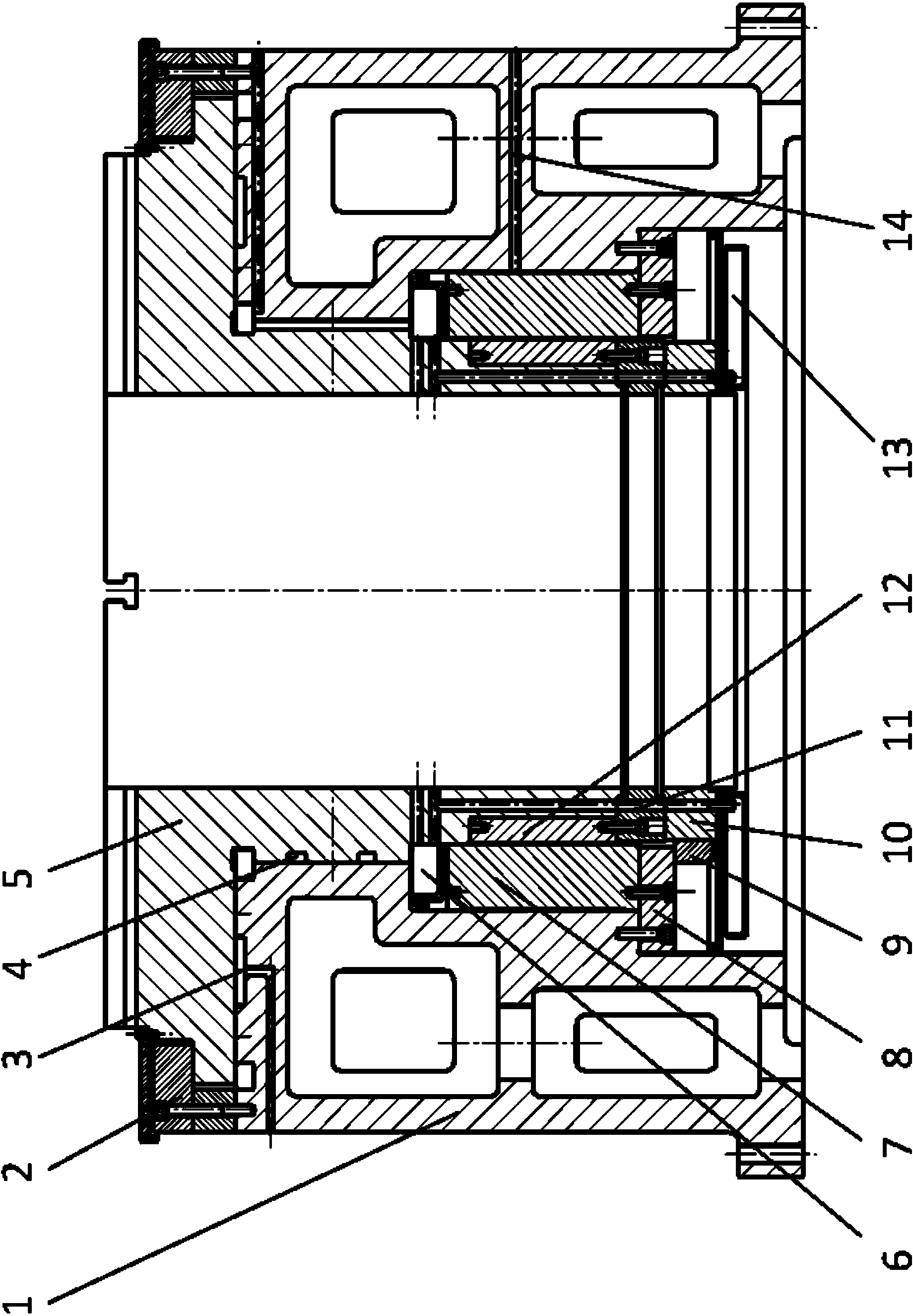

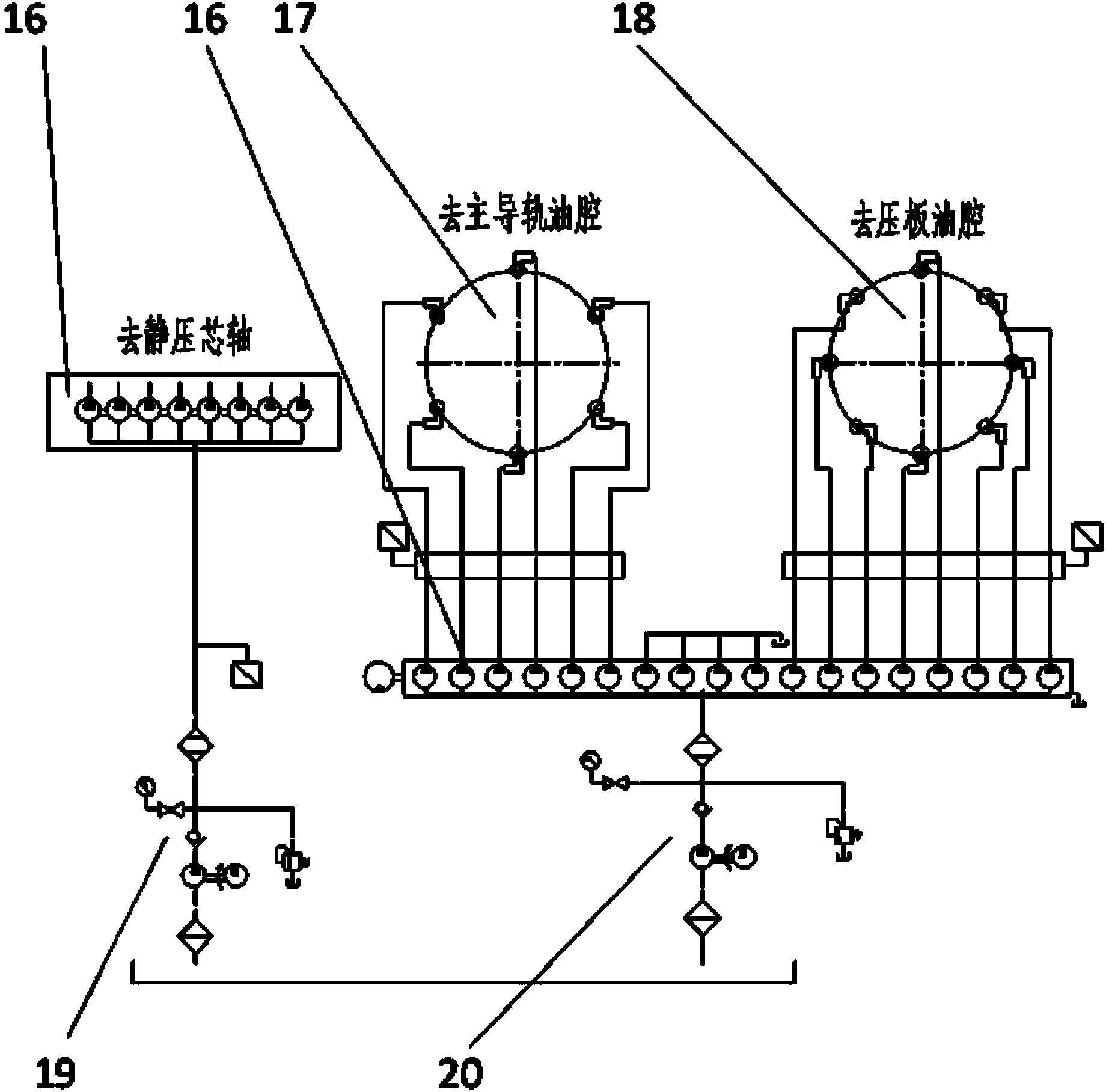

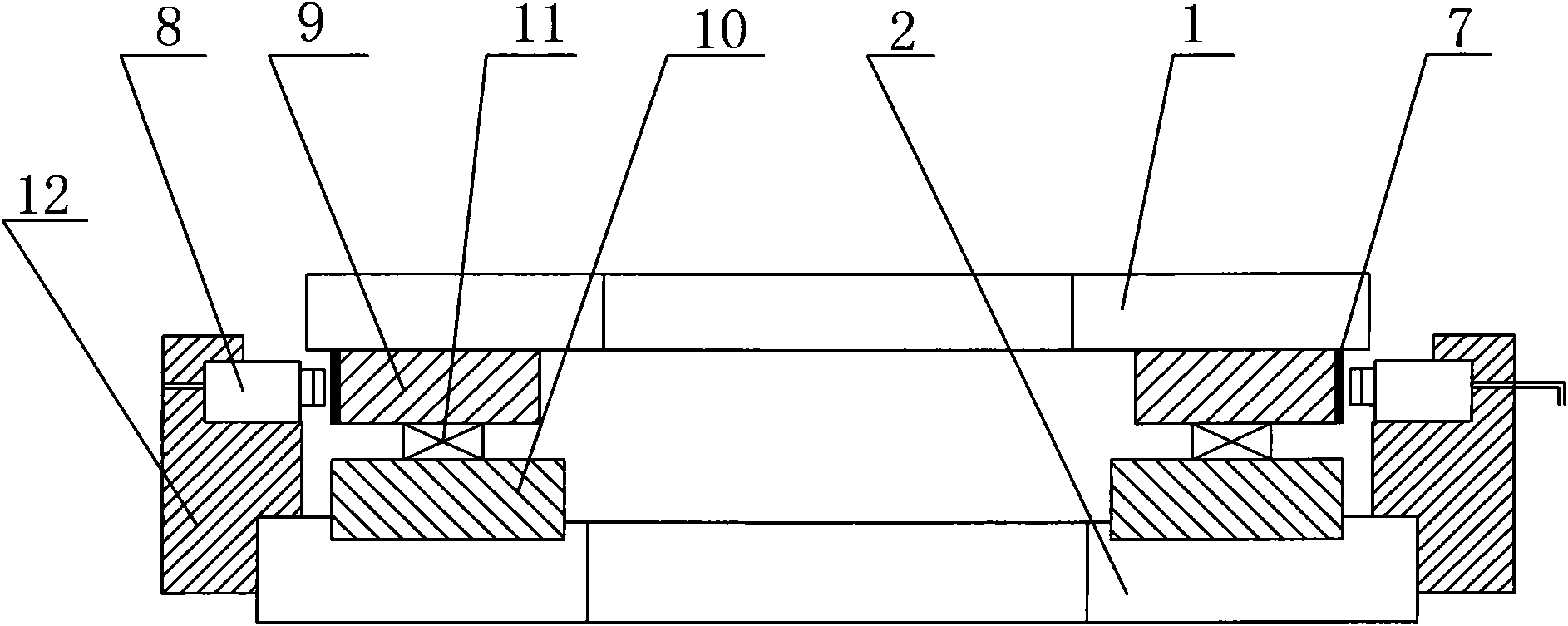

Static pressure heavy-load direct-drive high-accuracy rotating table

ActiveCN103624555AReduce skew errorLarge viaMeasurement/indication equipmentsFeeding apparatusGratingFrictional coefficient

A static pressure heavy-load direct-drive high-accuracy rotating table comprises a rotating platform composed of a base (1), a pressing board (2), a main guide rail static pressure oil cavity (3), a static pressure core shaft oil cavity (4), a work table top (5), a static pressure oil return system (6), a torque motor stator (7), a stator fixing support (8), a reading head (9), a steel belt type optical grating installation support (10), a rotor installation support (11), a torque motor rotor (12), an oil collection pot (13), a water cooling system (14), a gear distributor (15), a multi-head pump (16), a main guide rail oil cavity (17), a pressing board oil cavity (18), a core shaft pump station system (19), a guide rail pump station system (20), an oil supply system and an oil return system. The static pressure heavy-load direct-drive high-accuracy rotating table is directly driven by the large-torque motor rotor, achieves zero transmission, and is compact in structure and reliable in work; a very low frictional coefficient characteristic of a hydrostatic guide rail is combined, and the rotating table is high in servo rigidity, high in dynamic response speed and small in static difference.

Owner:NANJING GONGDA CNC TECH

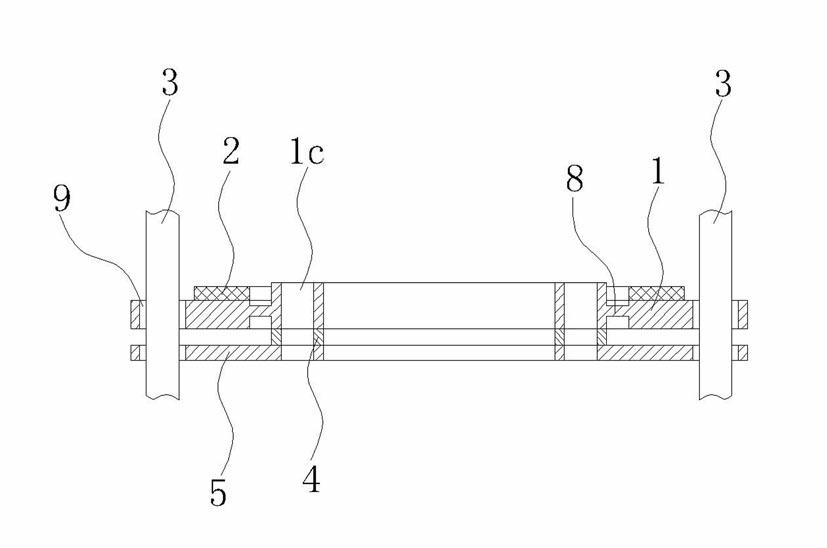

Angular displacement measuring and controlling device for revolving platform

InactiveCN101819421AImprove working precisionHigh measurement accuracyProgramme controlBearing assemblyMeasurement deviceFixed frame

The invention discloses an angular displacement measuring and controlling device for a revolving platform, which comprises a platform plate of the revolving platform, a supporting seat of the revolving platform, a bearing unit, a control system, a driving device and a fixed frame. The action of the driving device is controlled through a signal of the control system; the bearing unit is arranged between the platform plate and the supporting seat; the fixed frame is arranged on the supporting seat by surrounding the inner wall or the outer wall of the bearing unit; a magnetic scale is arranged on the inner wall or the outer wall of a moving coil of the bearing unit; at least one sensor is arranged on the fixed frame opposite to the magnetic scale; and a signal output end of the sensor is connected to the control system. In the invention, a measuring device is arranged on the revolving platform; a completely new high-precision revolving bearing unit with angle controlling and measuring functions are formed by combining the control system; and the angular displacement measuring and controlling device measures and monitors the bearing in real time by arranging the magnetic scale on the bearing body and combining the sensor and feeds an angular displacement signal back to the control system so as to improve the working precision of the precise revolving platform.

Owner:SHIBIAI SPECIAL BEARING LUOYANG

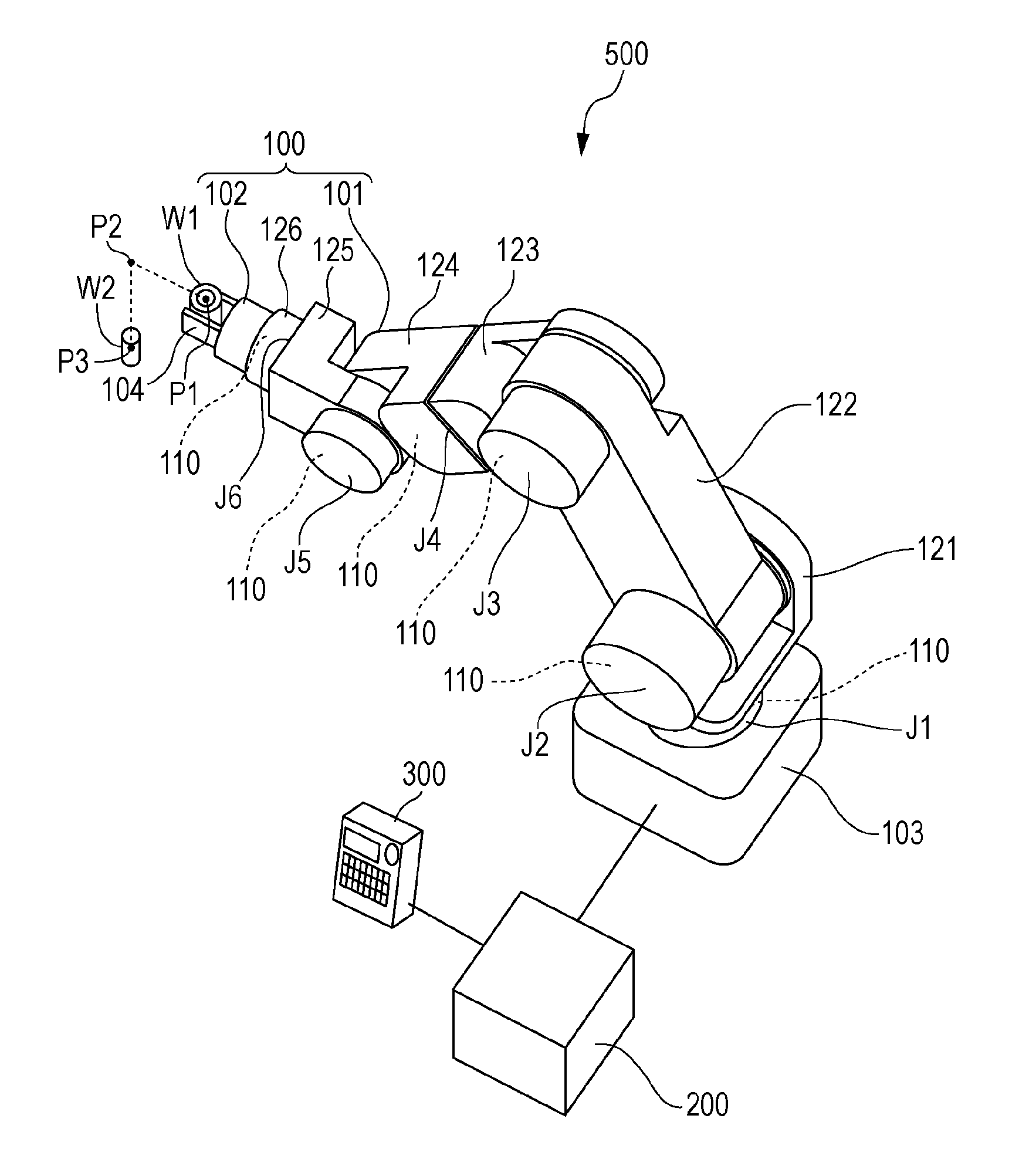

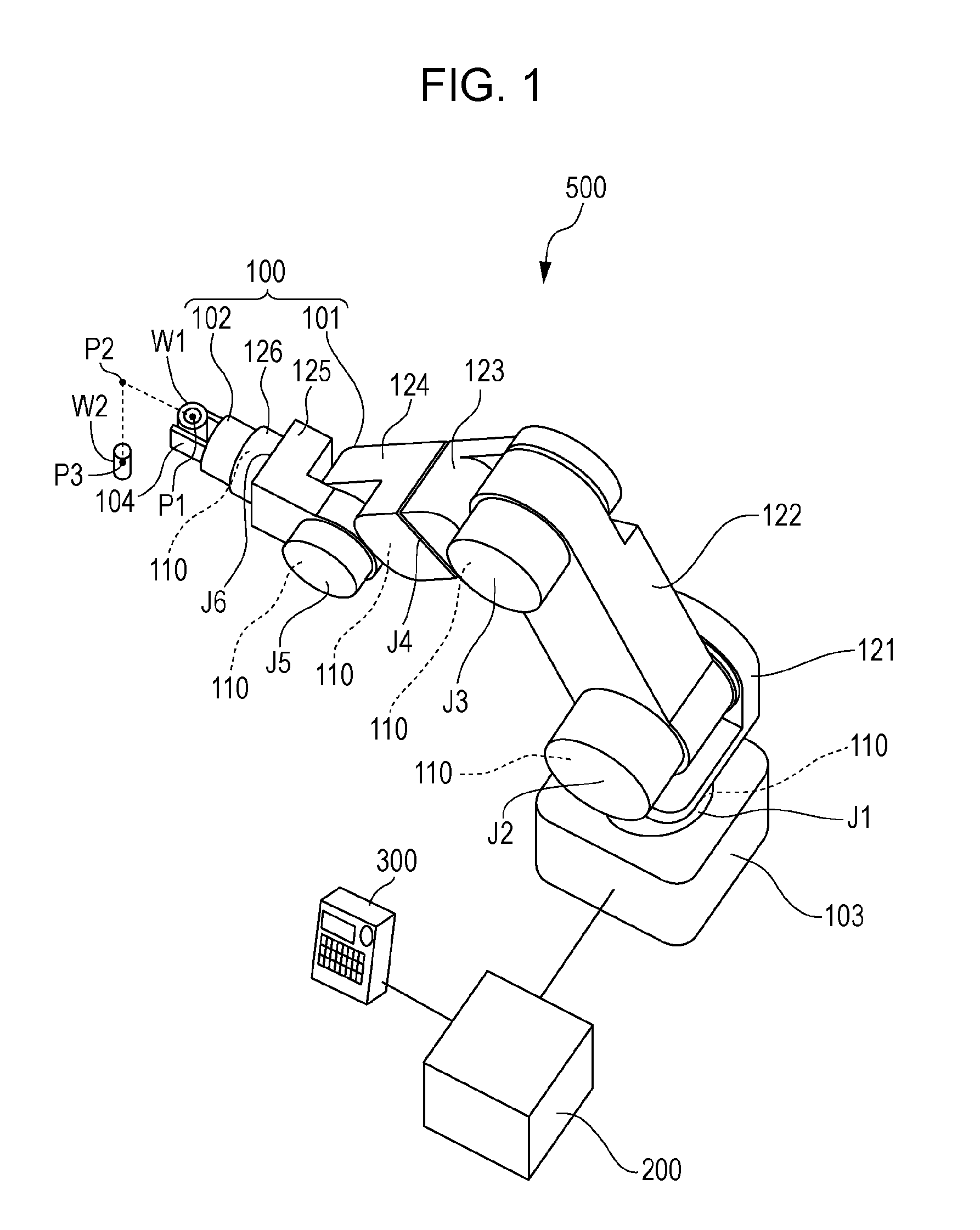

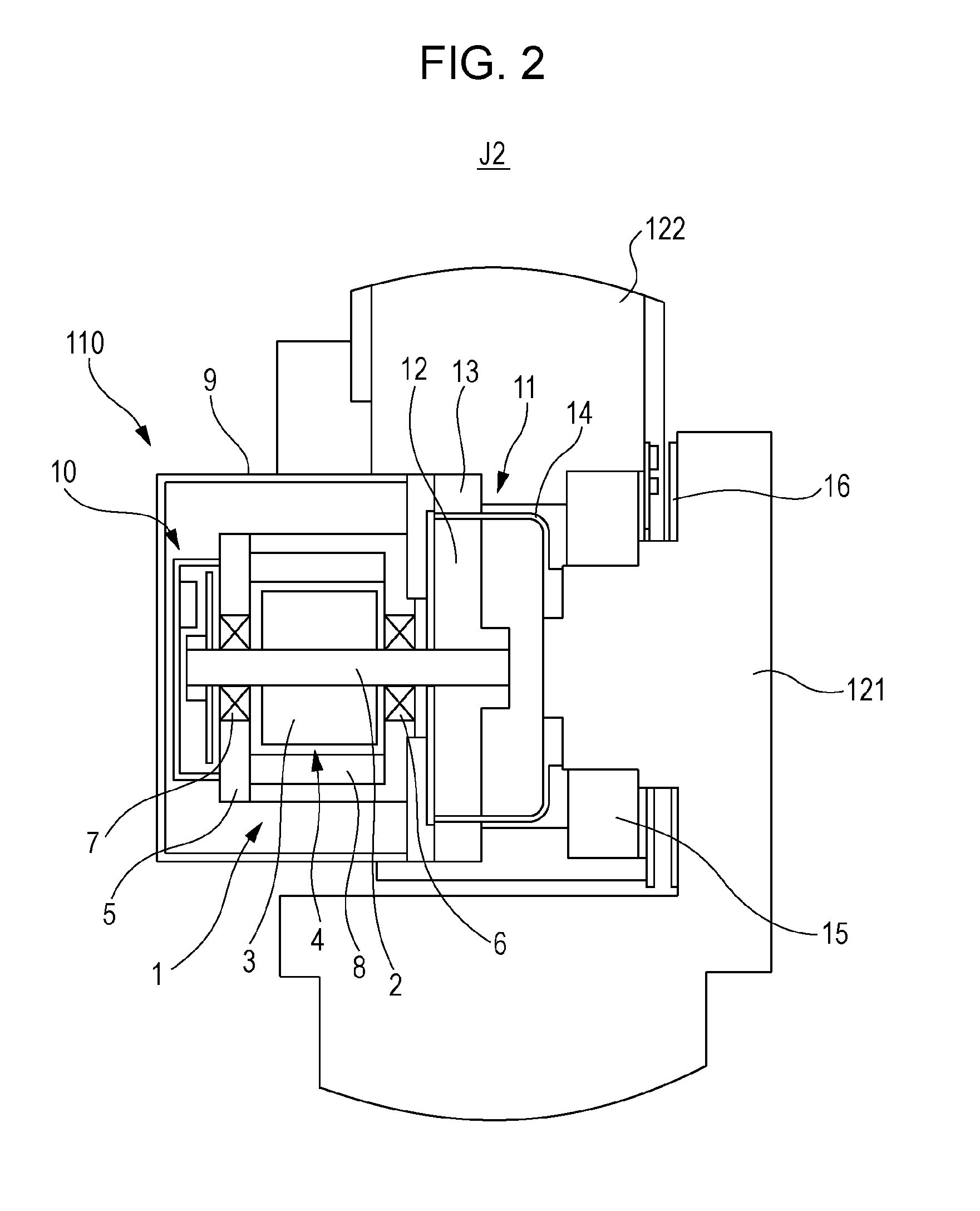

Robot controlling method, robot apparatus, program, recording medium, and method for manufacturing assembly component

ActiveUS20150360369A1Convenience to workImprove working precisionProgramme-controlled manipulatorMechanical apparatusAngular degreesRobot control

Feedback control is carried out on respective servomotors so that detection angles detected by respective input-side encoders become target angles to be obtained when a leading end of a robot has moved to a positioning completion position of a first motion. Subsequently, the position of the leading end of the robot is obtained on the basis of the detection angles detected by the respective output-side encoders. The time from a time point at which the detection angles detected by the input-side encoders are brought to the target angles through the feedback control to a time point at which a vibration width of the calculated position of the leading end of the robot relative to the positioning completion position converges within a convergence range is obtained. The obtained time is set in the stopping duration of the robot.

Owner:CANON KK

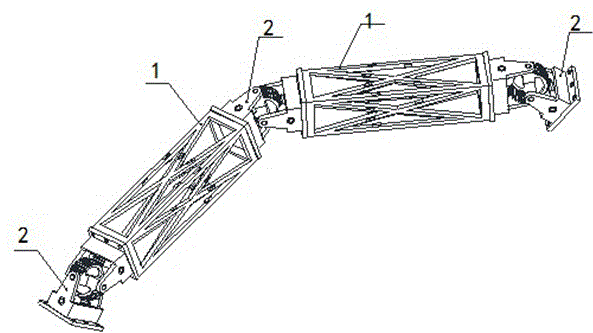

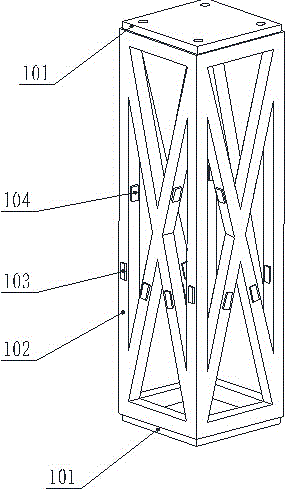

Modularized robot based on intelligent mechanical arm

ActiveCN104858892AImprove working precisionHigh degree of standardizationJointsArmsVibration measurementEngineering

The invention discloses a modularized robot based on an intelligent mechanical arm, and belongs to the field of robots. The modularized robot based on the intelligent mechanical arm comprises the intelligent mechanical arm and modularized joints. The intelligent mechanical arm is cascaded into a robot having multiple degrees of freedom by the modularized joints. The intelligent mechanical arm comprises a body framework, a piezoelectric ceramic actuator, and stress sensors. The stress sensors are installed on the body framework; and the stress sensors installed on the body framework constitute a group which is used for measuring the overall deformation status of the body framework in its motion process. The piezoelectric ceramic actuator is installed inside the body framework and is used for compensating the overall deformation of the body framework in its motion process. The modularized robot employs the intelligent mechanical arm section based on the vibration measurement and the compensation in association with the feature that the modularized robot is easy to manufacture to increase the standardization degree of the robot, and to increase the adaptability of the robot to different working conditions as well, thereby increasing the working accuracy of the robot.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Rolling friction cylinder hydraulic type force standard machine

InactiveCN102175387ASimple structureReduce frictionFluid pressure measurementForce/torque/work measurement apparatus calibration/testingEngineeringCommunicating vessels

The invention provides a rolling friction cylinder hydraulic type force standard machine which belongs to the technical field of mechanical engineering. The main body of the hydraulic type force standard machine consists of a rolling friction plunger type hydraulic cylinder I used as the core and a communicating vessel formed by two rolling friction plunger type hydraulic cylinders according to the Pascal principle. The complete hydraulic type force standard machine also comprises a force measuring instrument, a frame, a rolling friction cylinder II, a displacement sensor, a counterweight, a hydraulic oil feeding system and a hydraulic subsidiary loop. The force standard machine has high working precision; oil cylinder structure and the manufacturing process are simplified; the loading time can be efficiently controlled in the working process; the high pressure hydraulic pump is unnecessary; no pressure and flow pulsation phenomenon exists; the flow control is precise and stable; the minimum stable flow requirement can be met by controlling the precise displacement of plungers; and the stable and accurate system working pressure is maintained.

Owner:JILIN UNIV

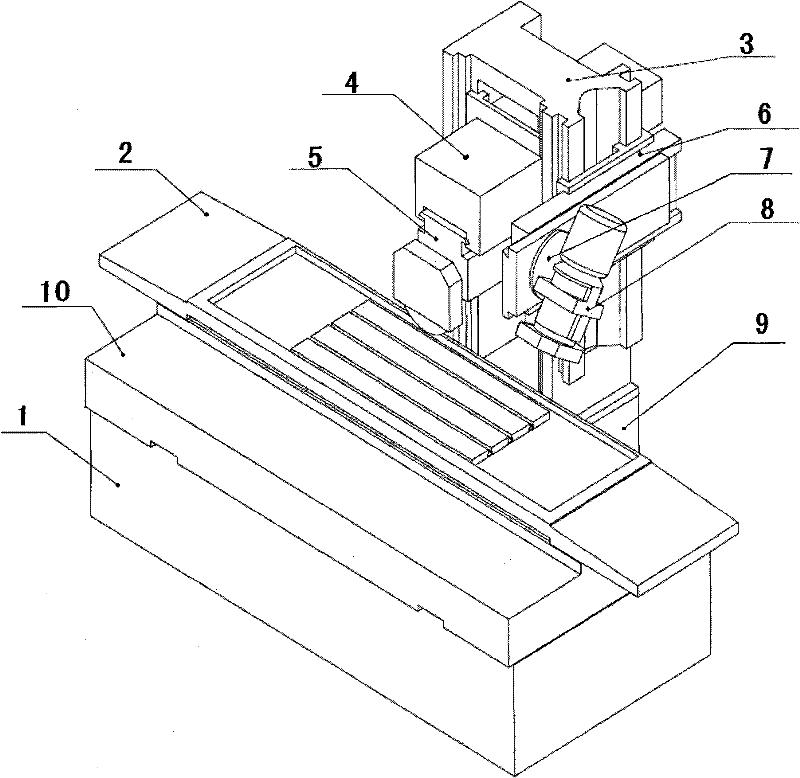

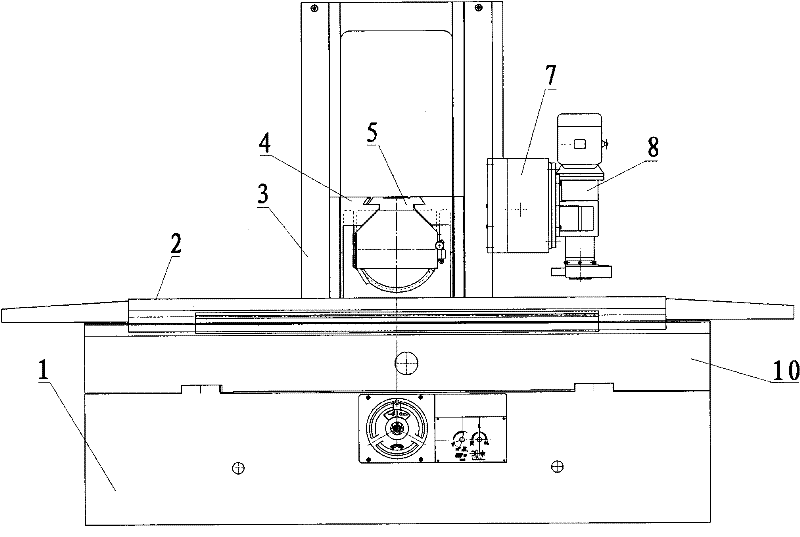

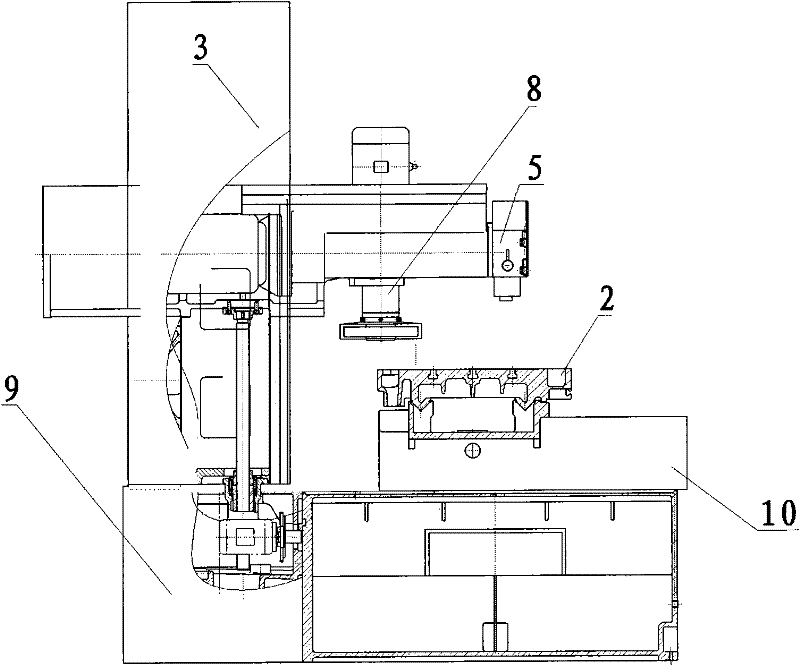

Grinding Center

InactiveCN102259282ACompact structureImprove transmission efficiencyRevolution surface grinding machinesControl systemEngineering

A grinding processing center, in order to solve the problem of single function of the existing grinding machine, it includes a bed, a large carriage, a workbench, a column, a horizontal grinding head assembly and a vertical grinding head assembly, a lubrication system, and a control system. The control system includes The computer numerical control system and servo system mainly adopt the vertical and horizontal double grinding head structure with external memory, which can realize six-axis linkage, compact structure and high transmission efficiency, which can meet various grinding processing needs.

Owner:XIANGTAN SANFENG CNC MACHINE TOOL

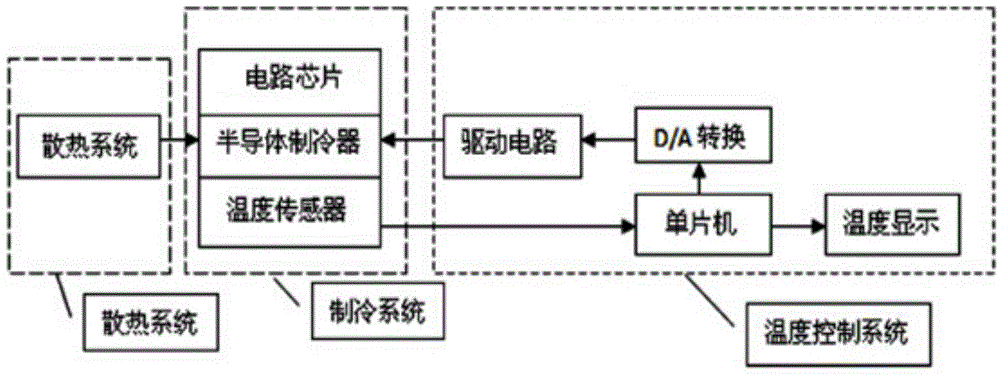

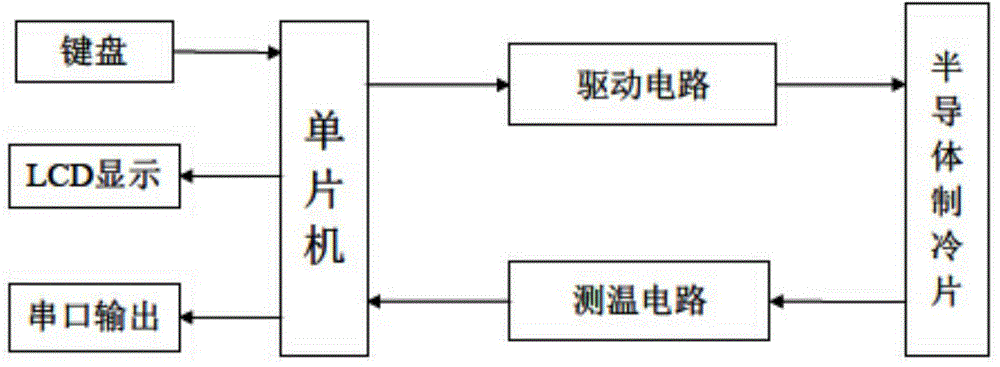

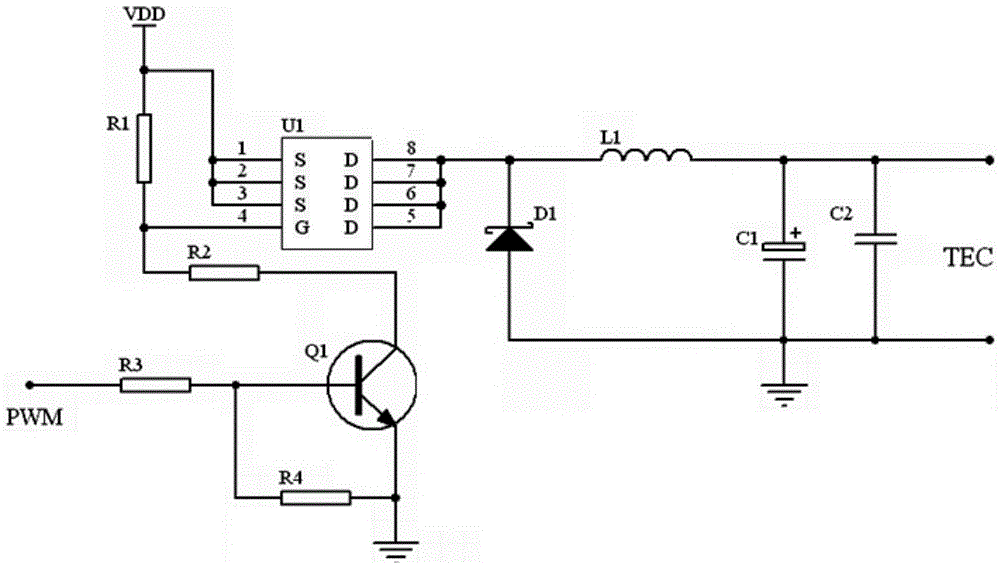

Noise reduction and temperature control system based on semiconductor refrigeration mechanism

ActiveCN104062990AImprove efficiencyImprove working precisionAuxillary controllers with auxillary heating devicesEngineeringNoise reduction

The invention discloses a noise reduction and temperature control system based on a semiconductor refrigeration mechanism. The noise reduction and temperature control system based on the semiconductor refrigeration mechanism comprises a heat radiating system, a refrigeration system and a temperature control system. The heat radiating system adopts a heat tube heat radiating fin, the refrigeration system comprises a circuit chip, a semiconductor refrigerator and a temperature sensor, and the temperature control system comprises a driving circuit, a D / A converter, a single chip microcomputer and a temperature displayer. The noise reduction and temperature control system is designed based on the Peltier effect and can create a low-temperature working environment for a circuit chip, reduce multiple types of noise relevant with the temperature, effectively improve signal to noise ratio and widen a dynamic range. The noise reduction and temperature control system based on the semiconductor refrigeration mechanism is simple in structure and low in cost and has the advantages of being free of refrigerants, good in environment-friendly performance, free of moving parts, low in vibration and noise and the like.

Owner:吴丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com