Autotracking centring clamping device for numerically controlled grinder

An automatic tracking and clamping device technology, which is applied in the direction of grinding workpiece support, etc., can solve the problems of limited application range, poor application process, and journal size error, and achieve the effect of convenient adjustment, convenient installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

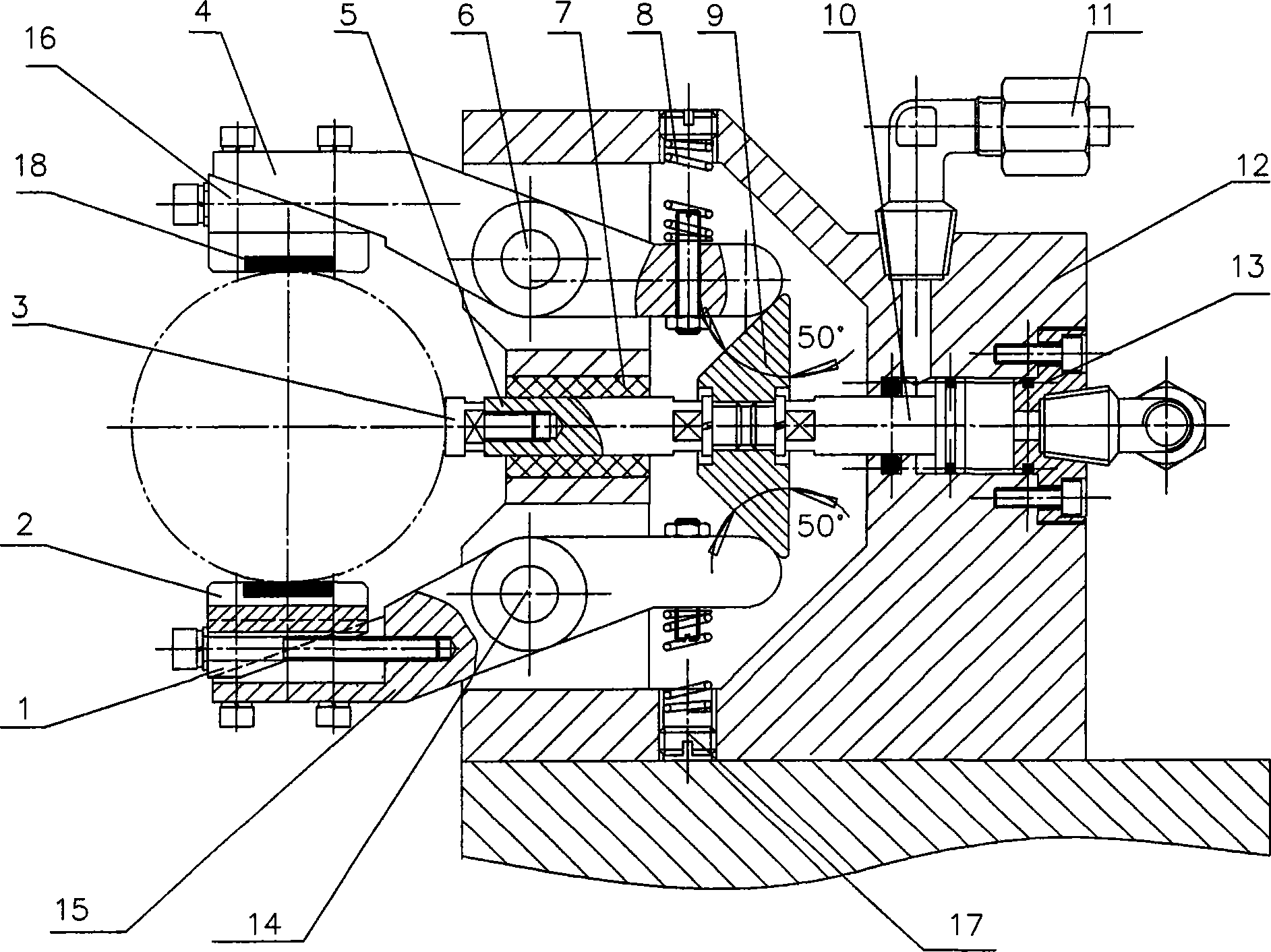

[0018] Referring to the accompanying drawings, an intermediate clamping rod 5 is slidably fitted on the support body 12 through the guide sleeve 7. The front end of the intermediate clamping rod 5 is an intermediate support alloy 3, and the upper lever clamping arm 4 and the lower lever clamping arm 15 are clamped in the middle. The holding rod 5 is a symmetrical axis and is hinged on the support body 12 through the first hinge 6 and the second hinge 14. The clamping end of the upper lever clamping arm 4 and the lower lever clamping arm 15 and the clamping end of the middle clamping rod 5 The ends correspond to determine a circle, and the clamping end of the upper lever clamping arm 4 and the lower lever clamping arm 15 is provided with an upper fine-tuning block 16 and a lower fine-tuning block 1, and an upper support is provided on the upper fine-tuning block 16 and the lower fine-tuning block 1 Alloy 18 and lower support alloy 2, the support body 12 is provided with an oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com