Angular displacement measuring and controlling device for revolving platform

A technology of measurement and control device and rotary table, which is applied in the direction of measurement device, electric device, program control, etc., can solve the problems of increased operation error and low rotation angular displacement accuracy, and achieves improved measurement accuracy, improved work accuracy, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

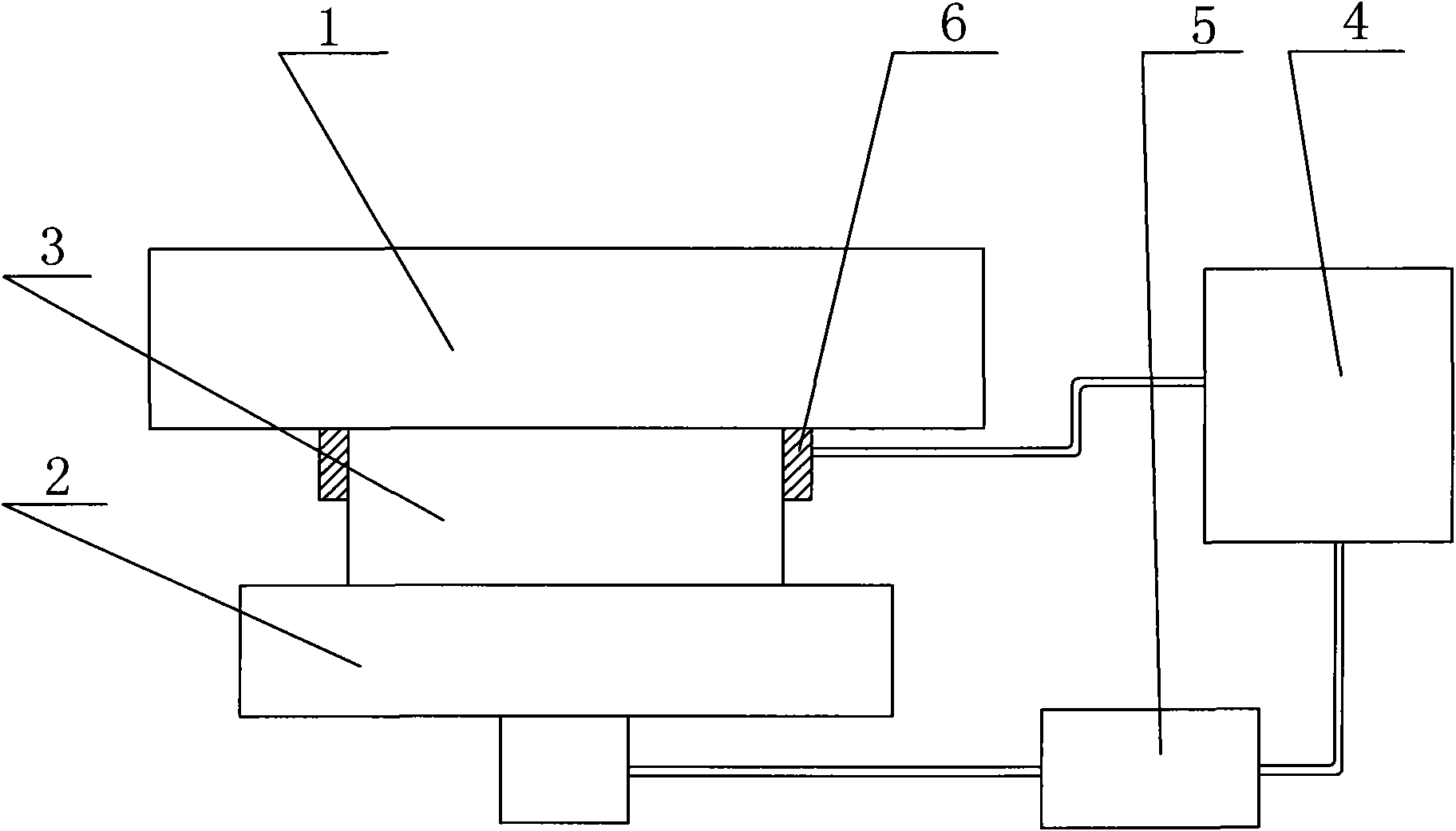

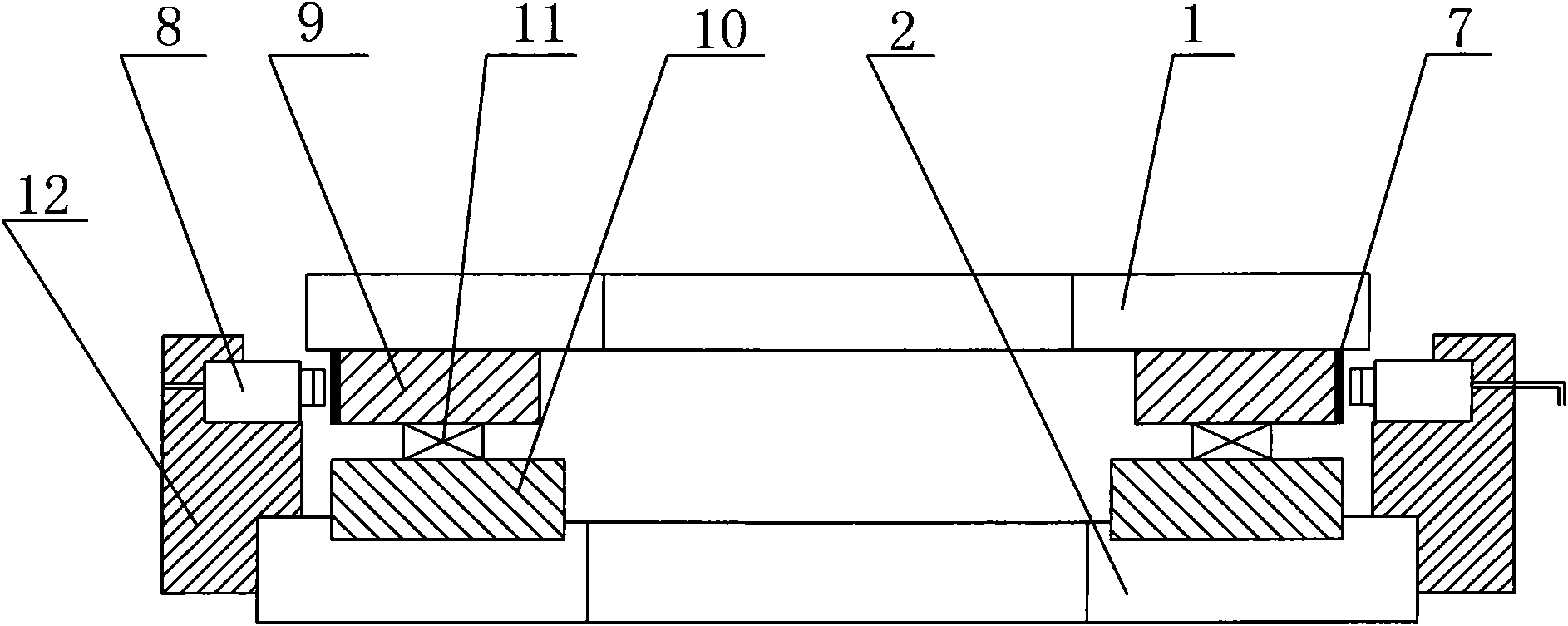

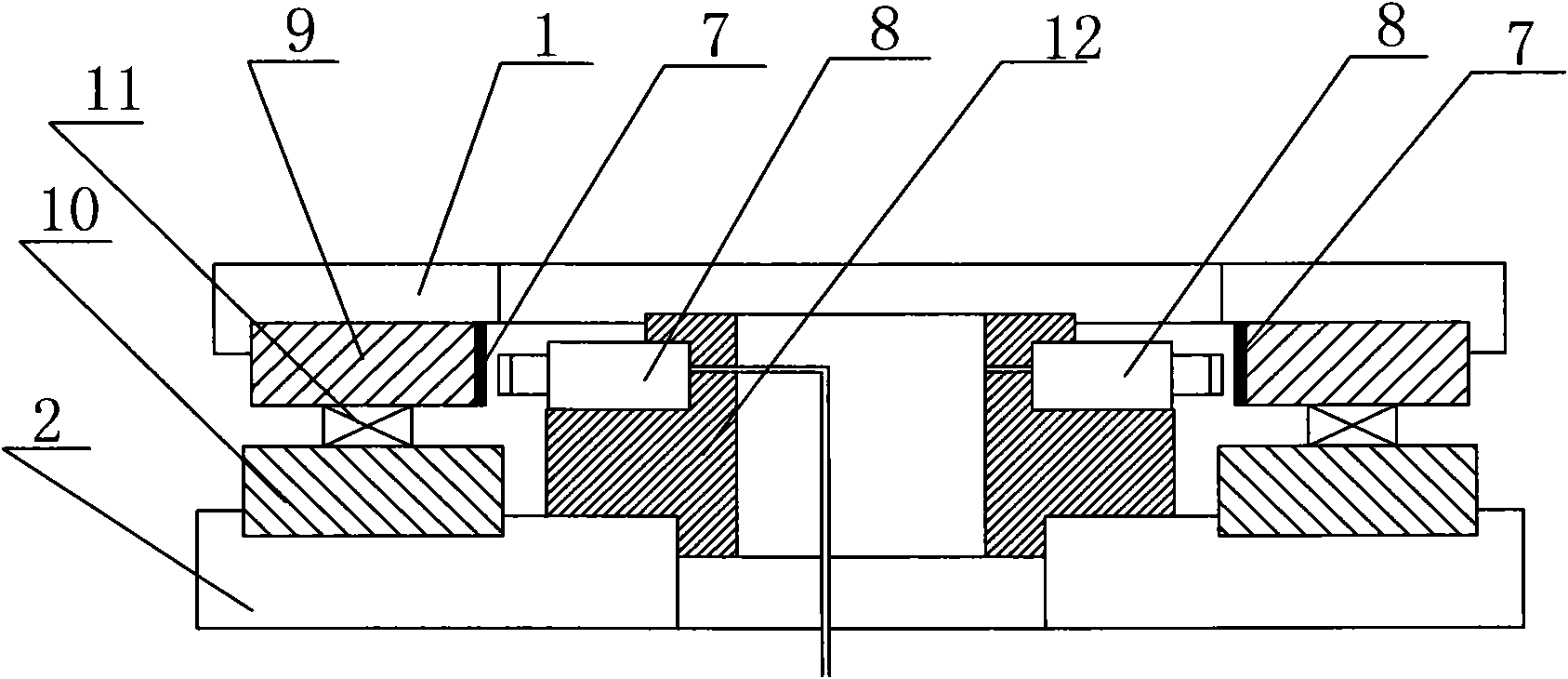

[0018] Such as figure 1 , figure 2 with image 3 As shown, an angular displacement measurement and control device of a turntable includes a platen 1 of the turntable, a bearing seat 2 of the turntable, a bearing unit 3, a control system 4, a driving device 5 and a measuring device 6, and the measuring device 6 It is composed of a magnetic scale 7 and a sensor 8. The action of the driving device 5 is controlled by the signal of the control system 4. A bearing unit 3 is provided between the platen 1 and the support seat 2. The fixing frame 12 surrounds the outer wall or inner wall of the bearing unit 3. Set on the supporting seat 2, a magnetic scale 7 is provided on the inner or outer wall of the moving coil 9 of the bearing unit 3, and at least one sensor 8 is provided on the fixed frame 12 opposite to the magnetic scale 7, and the signal output terminal of the sensor 8 Access control system 4.

[0019] In the present invention, the magnetic grating ruler 7 has two setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com