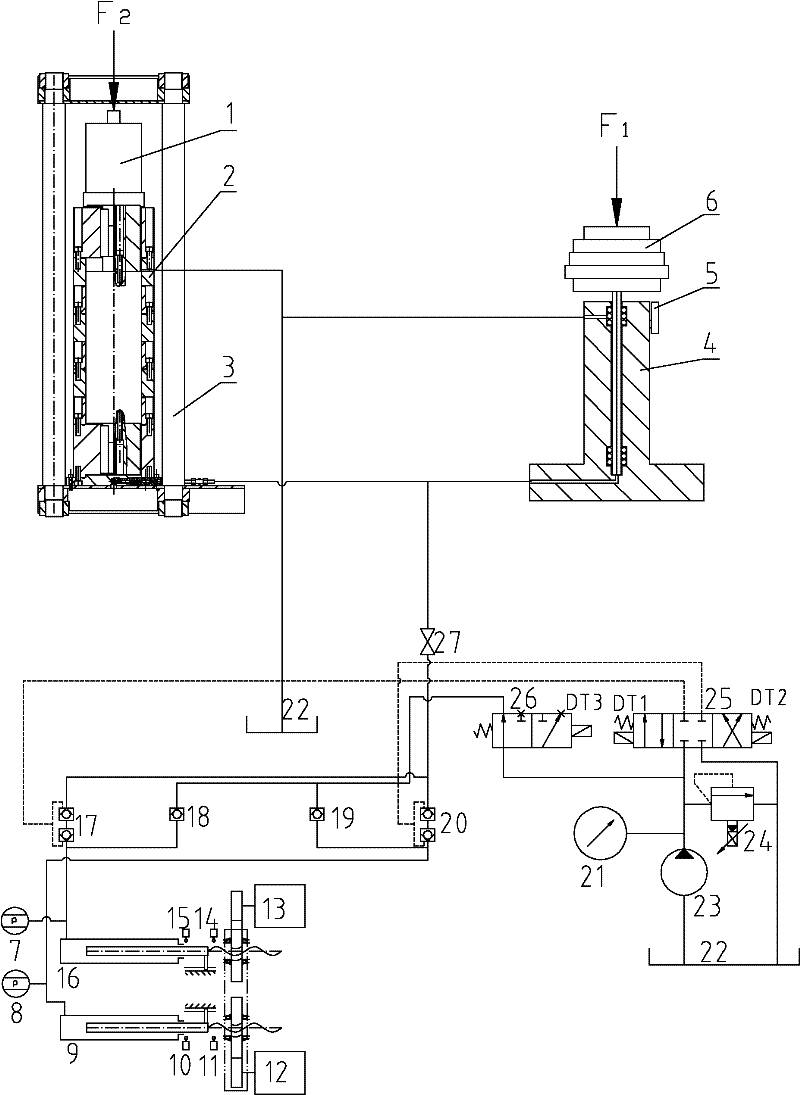

Rolling friction cylinder hydraulic type force standard machine

A rolling friction and standard machine technology, applied in the direction of measuring fluid pressure, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve the problem that the minimum stable flow cannot be reduced infinitely, difficulties, and force value accuracy reduction, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

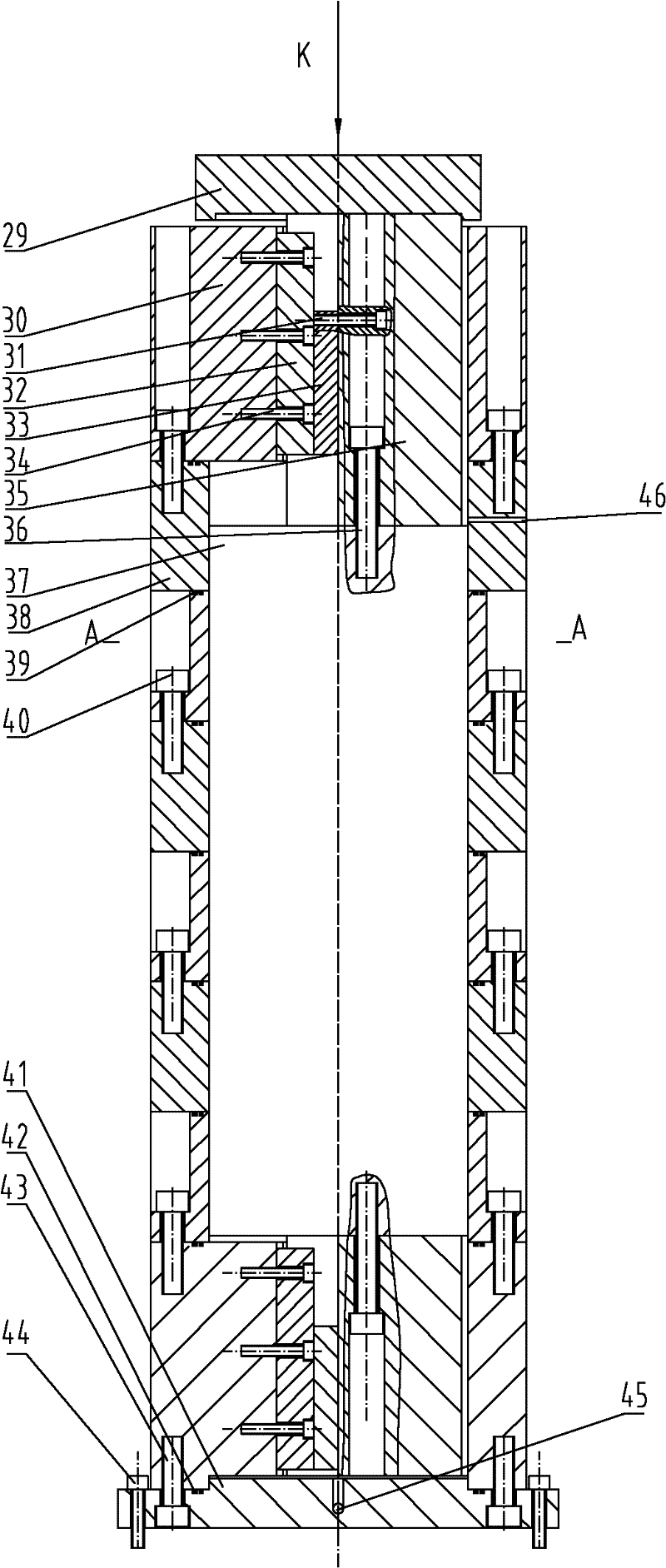

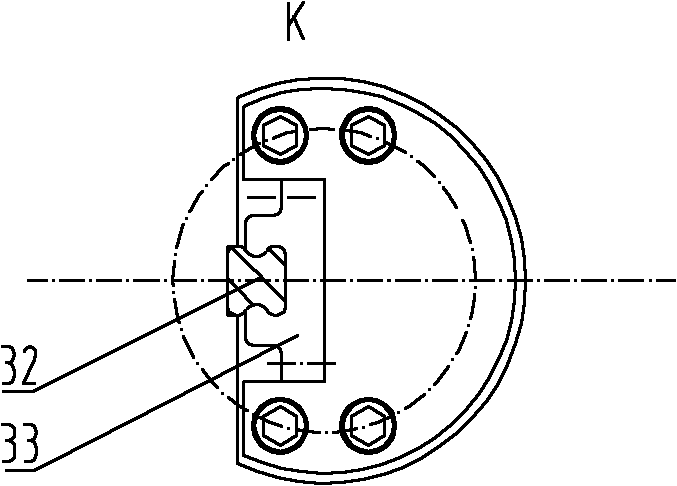

[0065] A 10MN hydraulic force standard machine, the maximum working pressure p max =62MPa, set the diameter of the plunger of rolling friction oil cylinder I 2 D=460mm, the gap length L=800mm, the diameter of the plunger of rolling friction oil cylinder II 4 d=20mm, and the length l=200mm. Magnification ratio i=529. Select the dynamic viscosity of hydraulic oil μ=180×10 -4 , according to the six-level precision of mechanical processing, take the rolling friction cylinder I 2 clearance δ 1 =0.04mm, rolling friction cylinder II 4 clearance δ 2 = 0.015 mm. According to the formula of liquid flow in circular gap under eccentric condition

[0066] Q L = πDδ 3 12 μL ΔP ( 1 + 1.5 ϵ 2 ) ± u 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com