Automatic punching device and method for high-speed railway tunnel anchor implantation

A technology for drilling devices and tunnel anchors, which is applied to drilling equipment and methods, lifting devices, earthwork drilling and mining, etc., which can solve problems such as inability to guarantee the safety of construction personnel, damage to the health of construction personnel, and low construction efficiency, so as to save Effects of rework process, prevention of health damage, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

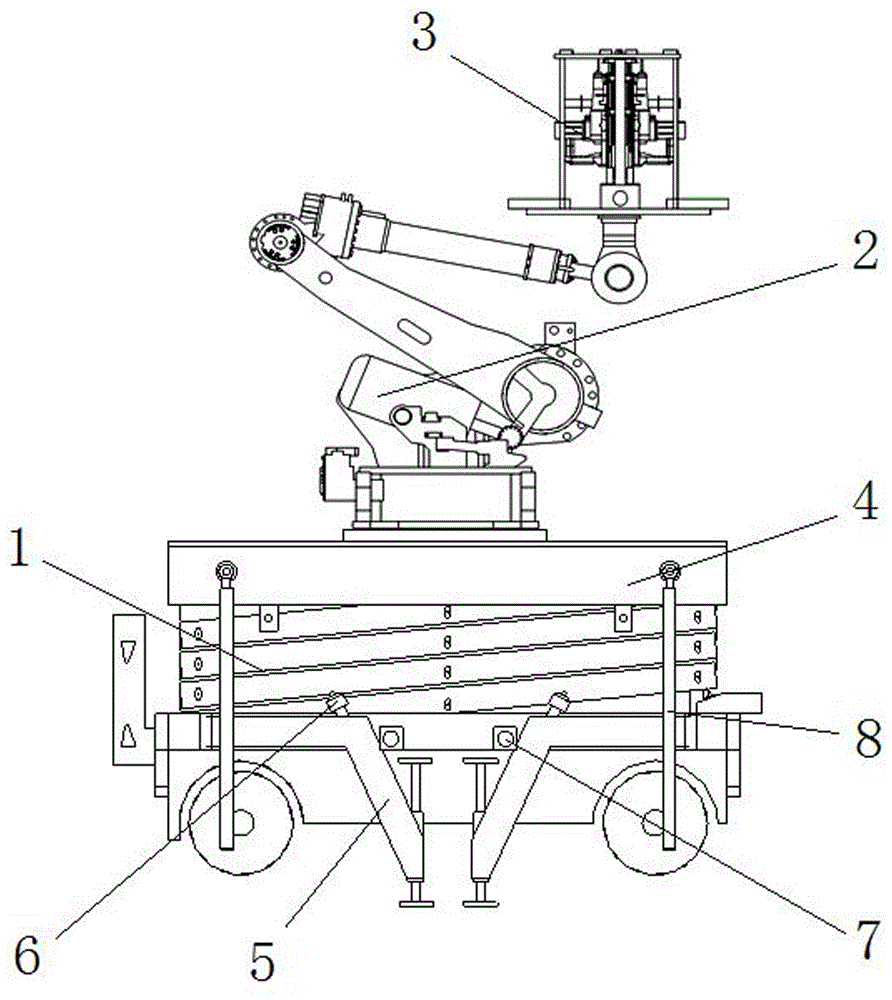

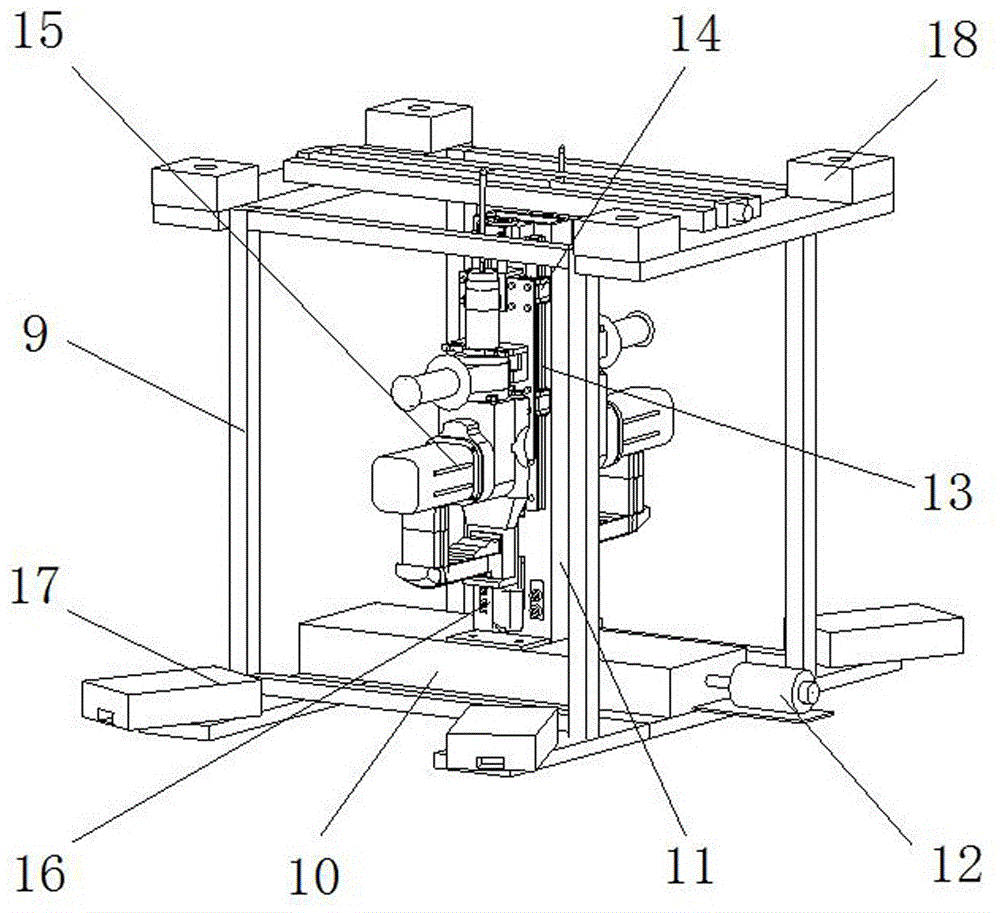

[0014] The automatic drilling device for high-speed railway tunnel anchor bolt implantation includes a hydraulic lift car 1, a six-axis mechanical arm 2, and a drilling platform 3. The top of the hydraulic lift car 1 is provided with a lifting platform 4 connected to the lower end of the six-axis mechanical arm 2. The upper end of the six-axis mechanical arm 2 is connected to the center of the bottom of the drilling platform 3, and the front and rear ends of the hydraulic lift vehicle 1 are provided with support legs 5 that can rotate horizontally and are located on the left and right sides of the platform, and support balls are provided on the support legs 5 The head 6 and the hoist 7, the wire rope of the hoist 7 is connected to the lifting platform 4, and the left and right sides of the front and rear ends of the lifting platform 4 are provided with a hydraulic telescopic rod that is universally hinged at one end and the other end can be placed on the corresponding supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com