Automatic stainless pan polishing equipment

A technology of automation equipment and stainless steel pots, applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of high labor intensity, harm to human health, high cost, etc., to reduce production costs and labor The effect of improving strength and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

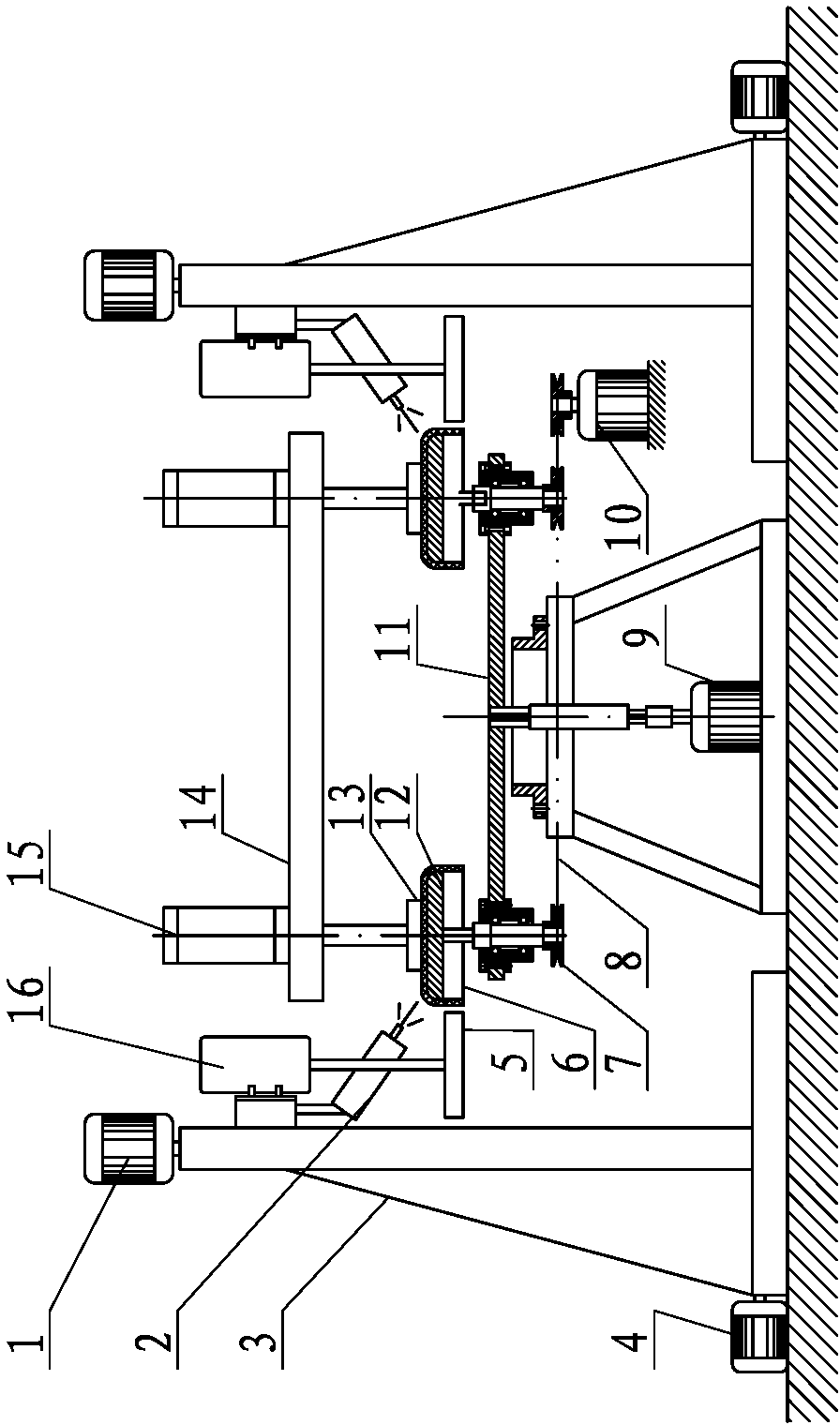

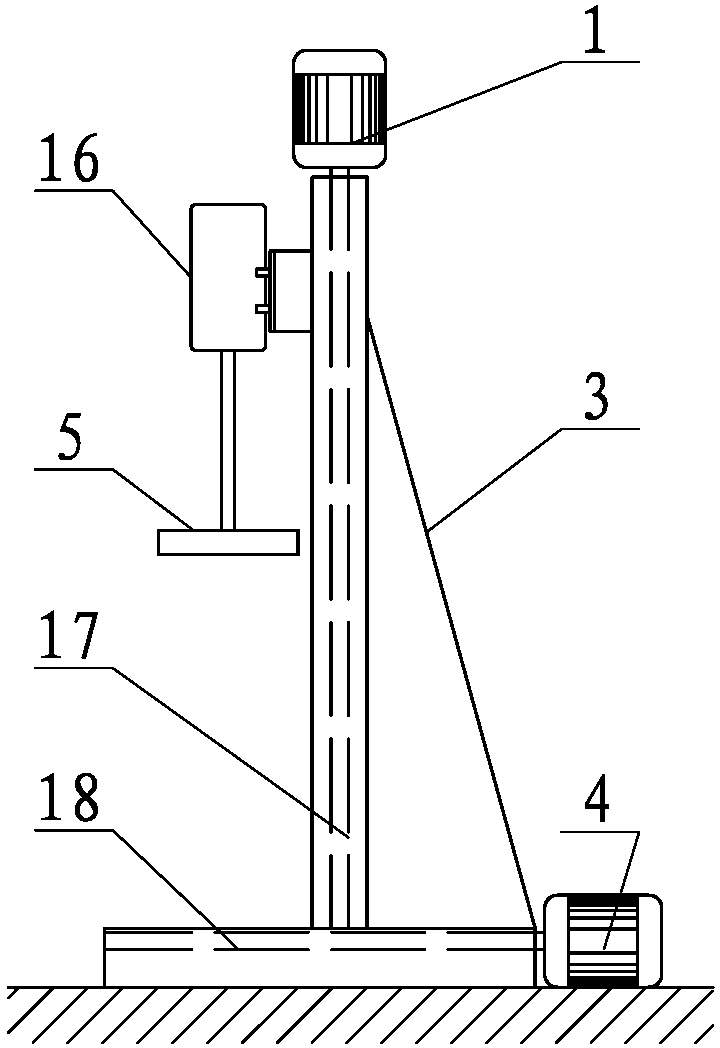

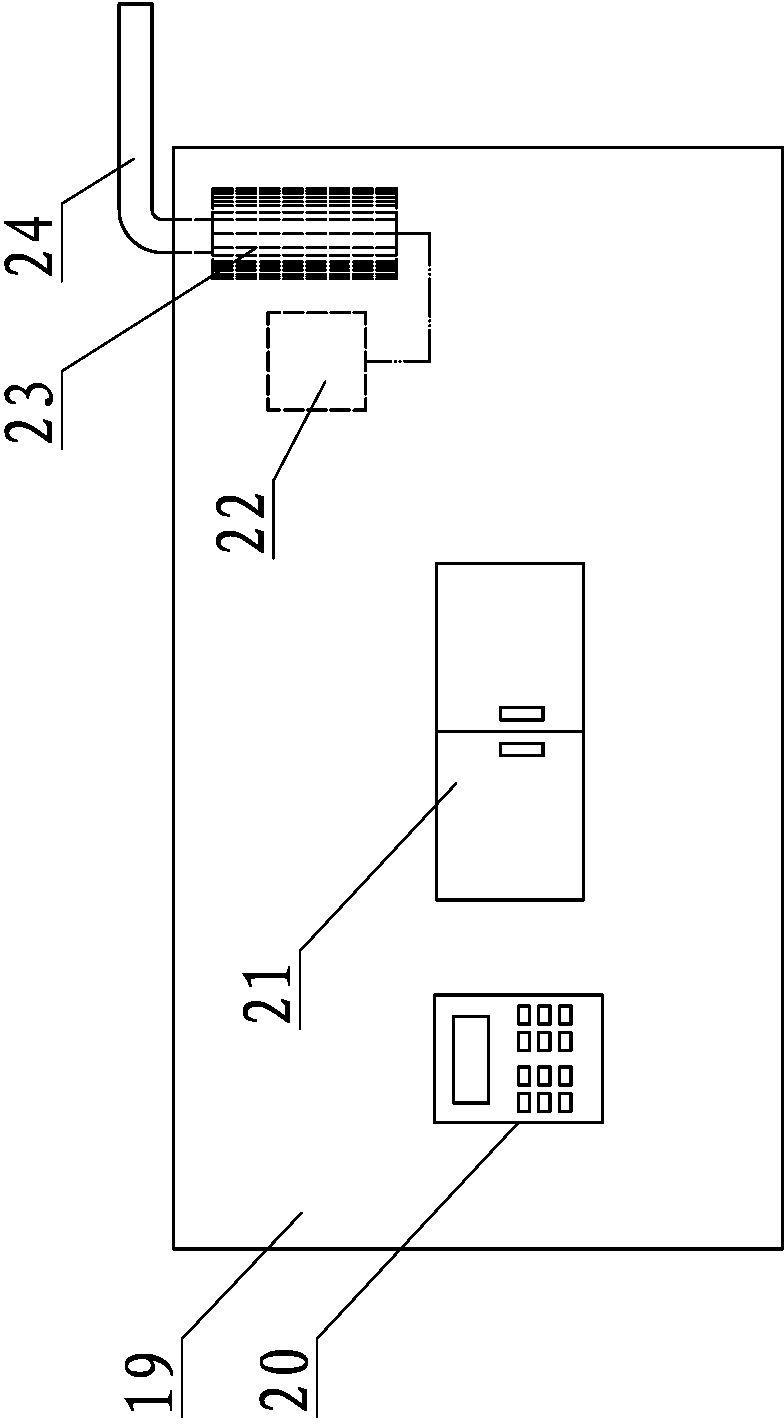

[0038] Embodiment 1: Surface polishing operation of stainless steel pot body

[0039] Such as figure 1 As shown, in this embodiment, the fixing fixture is installed on the workbench 11 through the rotating device; the workbench 11 is connected to the workbench motor 9, and can be driven to rotate by the workbench motor 9; the polishing device is installed on the support 3 through the moving device ; The electric control device 20 connects and controls the polishing device, the rotating device, the table motor 9 and the moving device.

[0040] The polishing device includes a polishing motor 16 and a polishing wheel 5 , the rotating shaft of the polishing motor 16 is connected to the polishing wheel 5 and can drive the polishing wheel 5 to rotate; the electric control device 20 is connected to and controls the polishing motor 16 . When the polishing device carried out the external throwing operation, the rotating shaft of the polishing motor 16 was vertically arranged, and the ...

Embodiment 2

[0049] Embodiment two: the inner surface polishing operation of the stainless steel pot body

[0050] Such as Figure 4 Shown is the structural diagram of polishing the inner surface of the stainless steel pot body 6 in the present invention. When the polishing device carries out the internal throwing operation, the rotating shaft of the polishing motor 16 forms an angle of 0-90 degrees with the horizontal plane, and the polishing wheel 5 is attached to the inner surface of the stainless steel pot body 6 . Embodiment two differs from embodiment one in that:

[0051] Such as Figure 5 As shown, the polishing motor 16 is installed on the support 3 through the angle adjustment device 25 and the moving device. The angle adjusting device 25 includes a motor mounting plate 27 , the upper end of which is hinged on the support 3 , and the lower end of the motor mounting plate 27 is connected to the support 3 through an adjusting bolt 28 . The polishing motor 16 is mounted on a mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com