Patents

Literature

38 results about "Force chain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

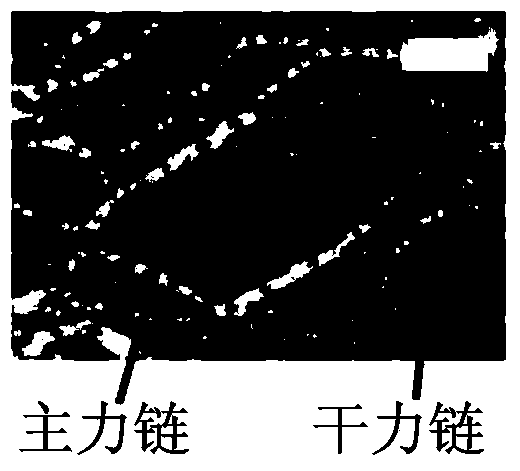

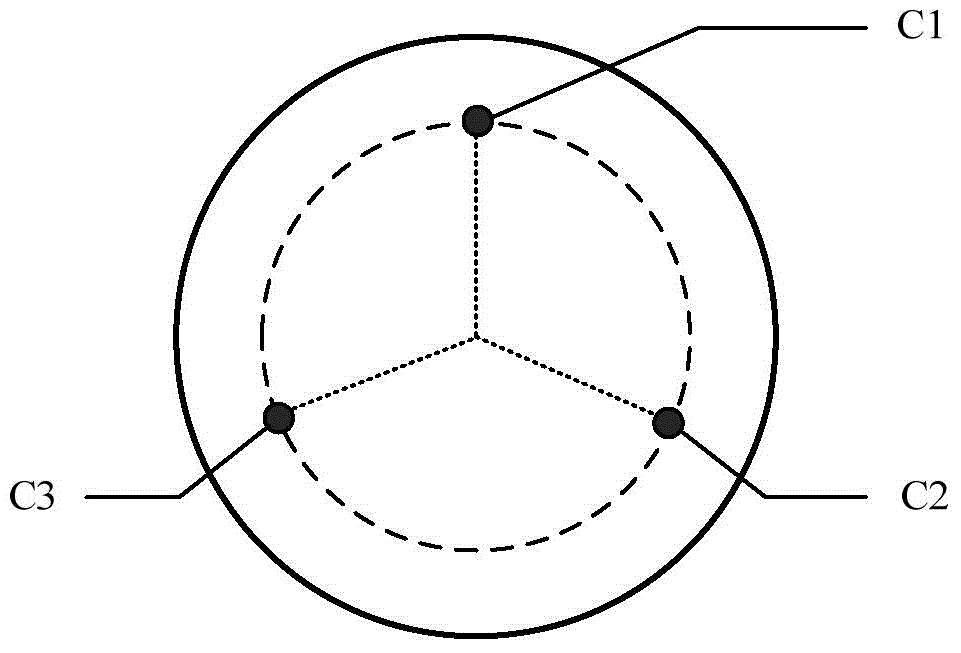

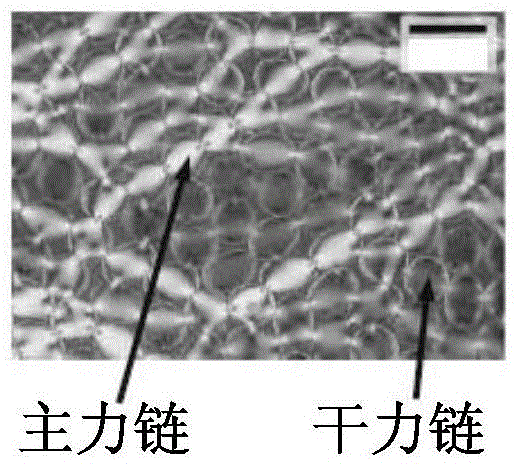

In the study of the physics of granular materials, a force chain consists of a set of particles within a compressed granular material that are held together and jammed into place by a network of mutual compressive forces.

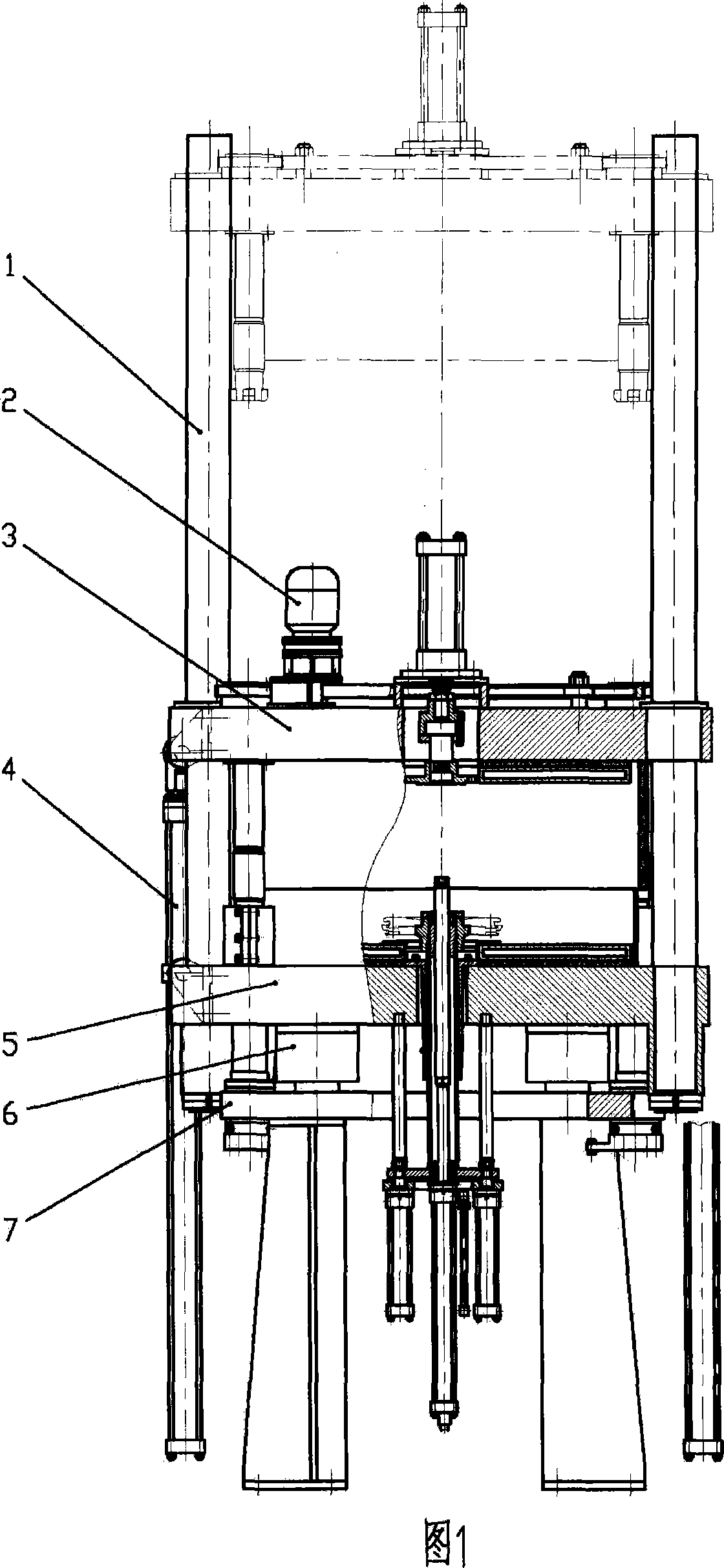

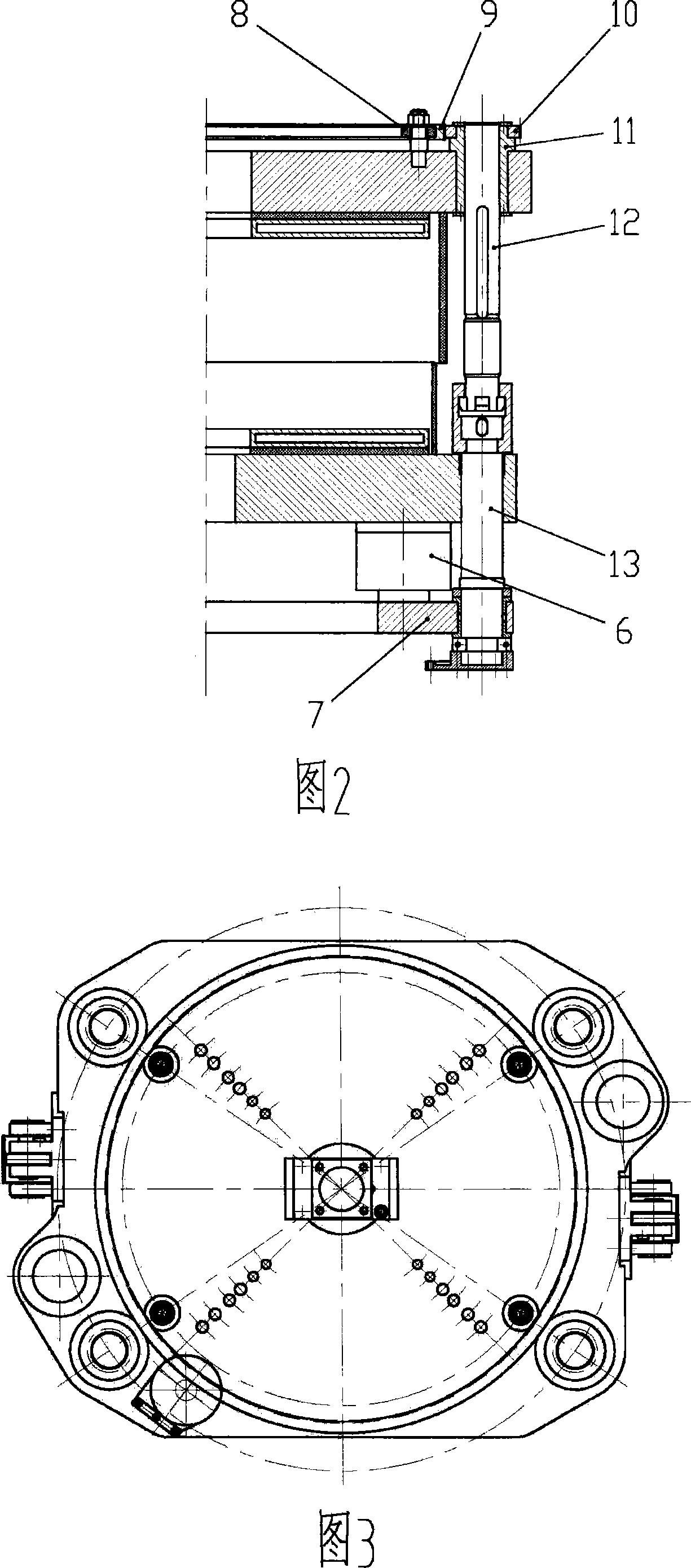

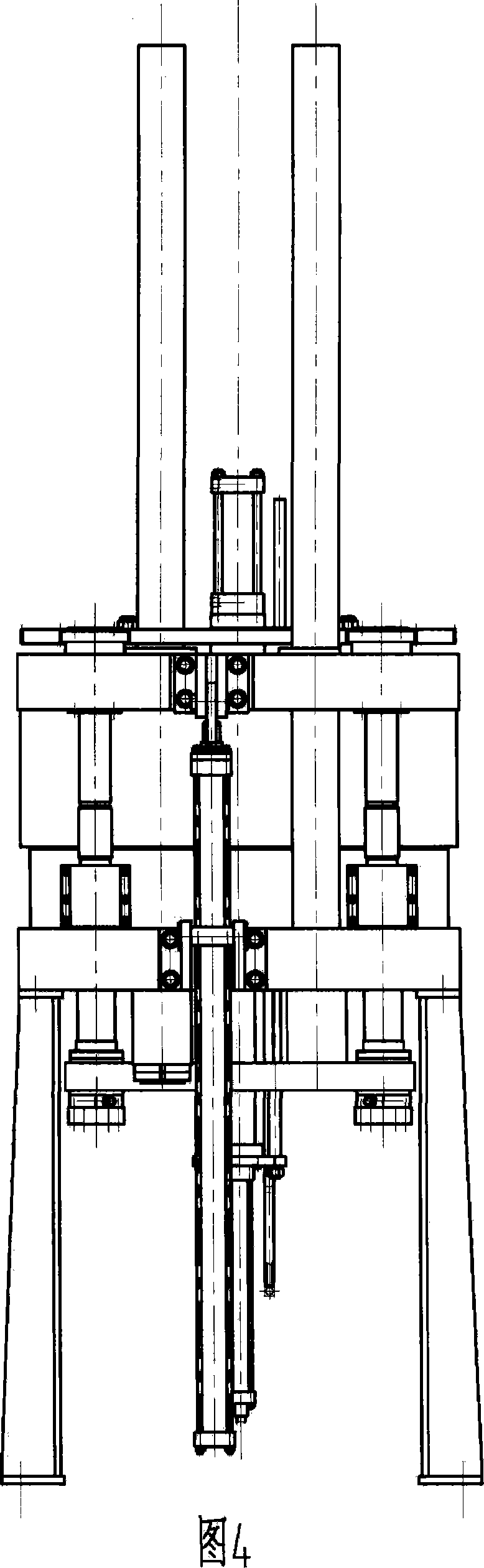

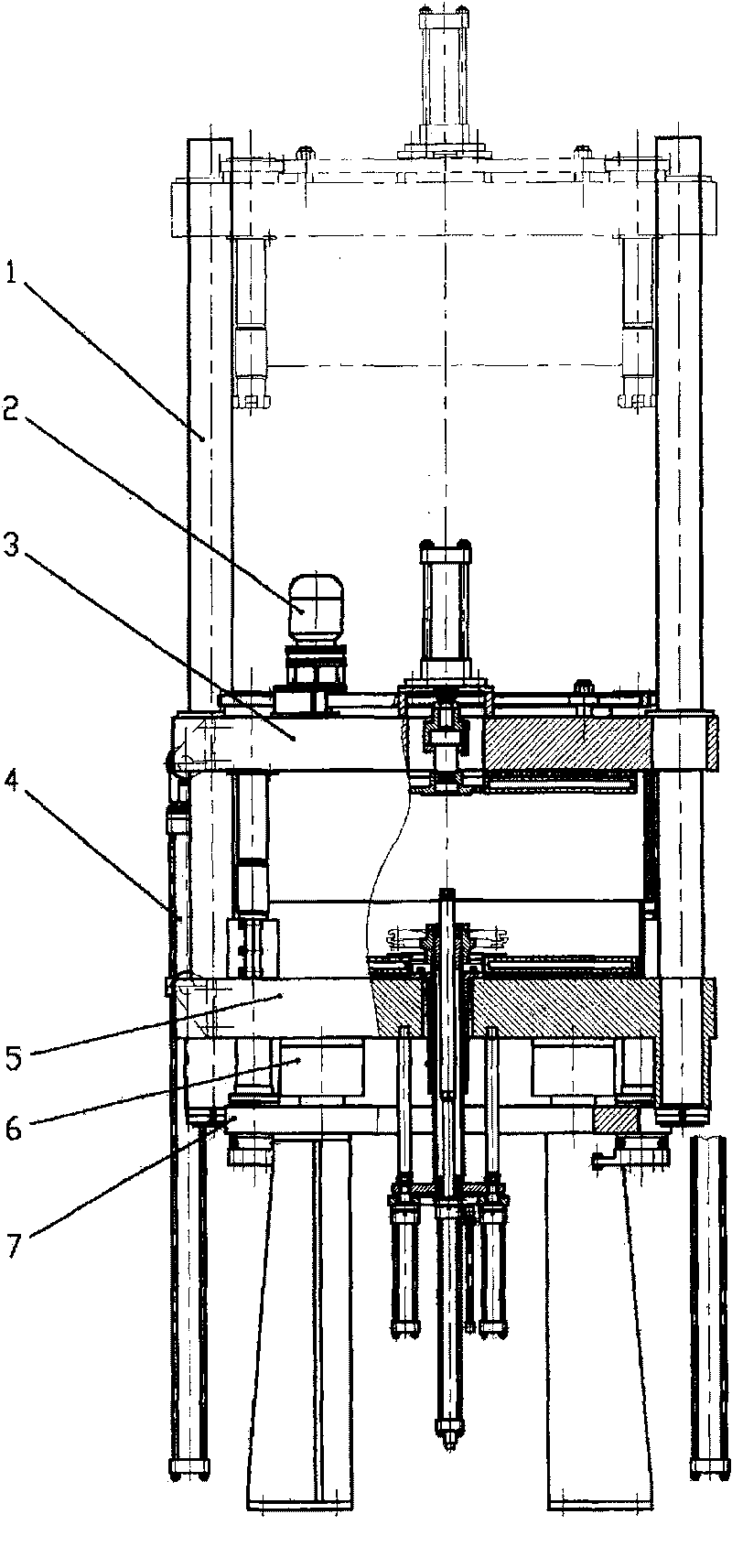

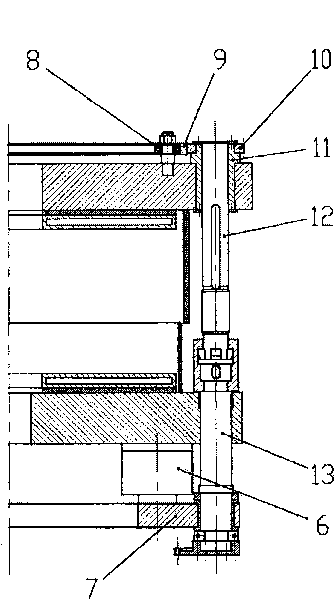

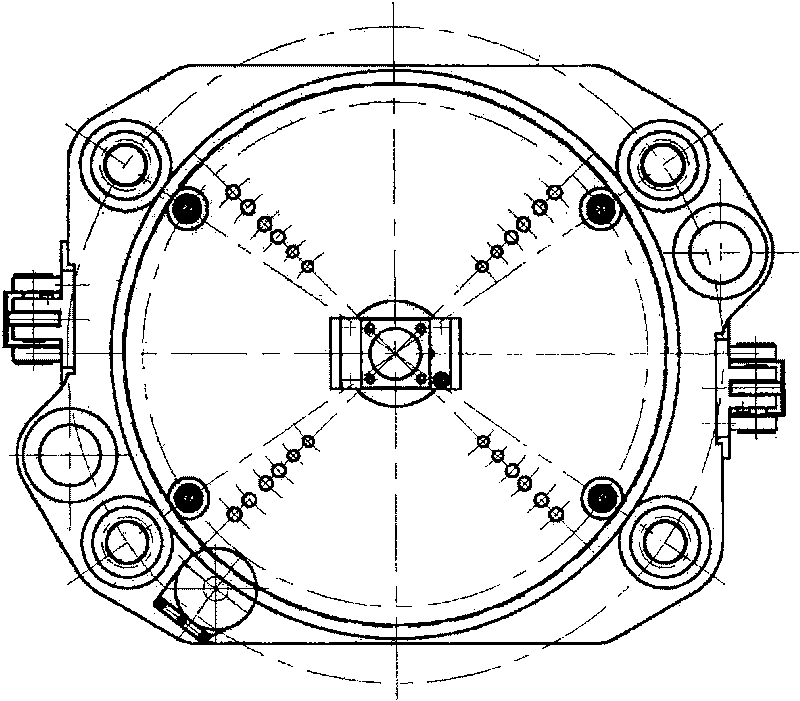

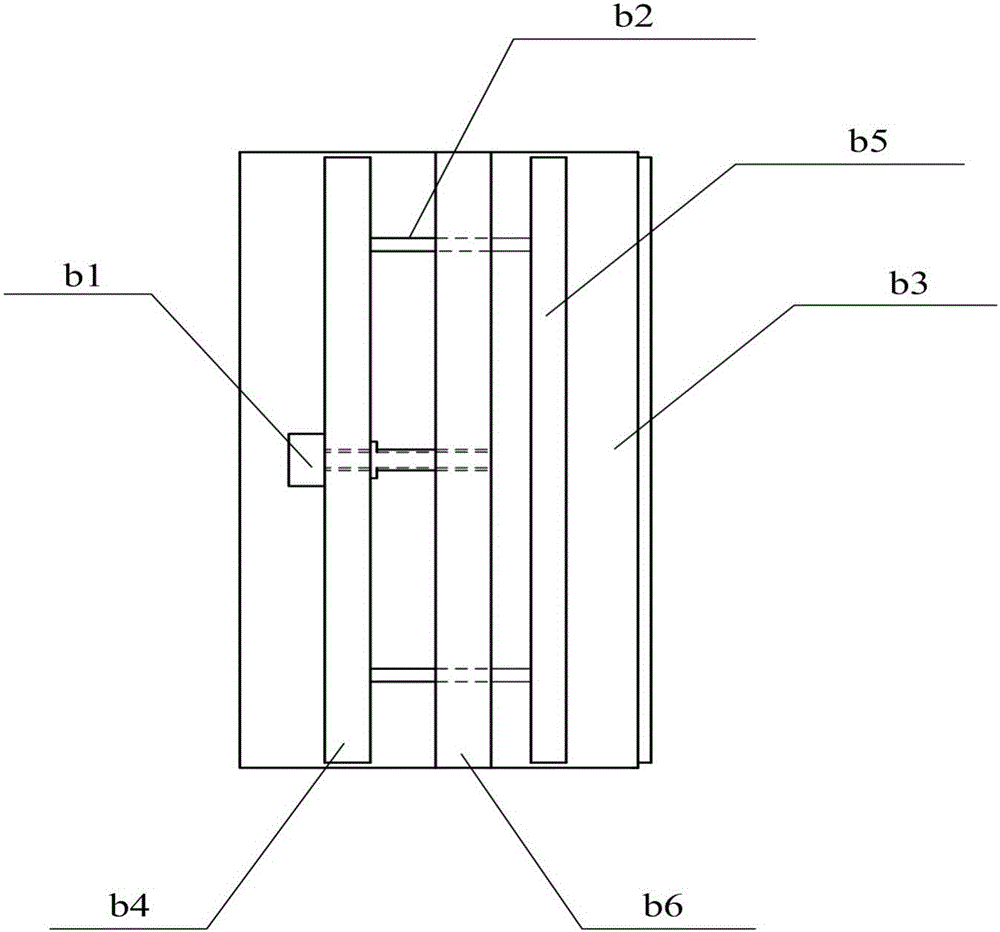

Pull rod lock mode hydraulic tyre vulcanizer

The invention discloses a hydraulic tire curing press with a pull rod locking module. The invention consists of a frame consisting of a lower beam and a supporting part, an upper beam, an upper and lower thermal plate, an opening and closing die cylinder, a central structure and a pressurized structure. The upper beam is driven by the opening and closing die cylinder and has freedom of moving from the top to the bottom. An upper die and a lower die are directly arranged between the upper thermal plate and the lower thermal plate and are respectively fixed connected with the upper beam and the lower beam. The pressurized structure consists of a pulling rod, a pressurized splint and a pressurized cylinder. The pulling rod is evenly arranged corresponding to the axle wire of in the tire module. The upper terminal of each pulling rod is fixedly connected with the upper beam and the lower terminal of each pulling rod is fixedly connected with the pressurized plate traveling through the lower beam; the pressurized cylinder is fixed on the bottom of the lower beam and the piston terminal of the cylinder is fixedly connected with the pressurized plate; the pulling rod is arranged with a locking die structure and an adjusting die structure. The invention increases the working precision and reducing the manufacturing cost, at the same time, the invention also has the advantages of avoiding the problem of oil leaking and contamination, being convenient for the cylinder maintenance, simplifying the forcing chain of the locking die force and reducing the manufacturing cost of the curing press.

Owner:SINO ARP TIRES EQUIP TECH (SUZHOU) CO LTD

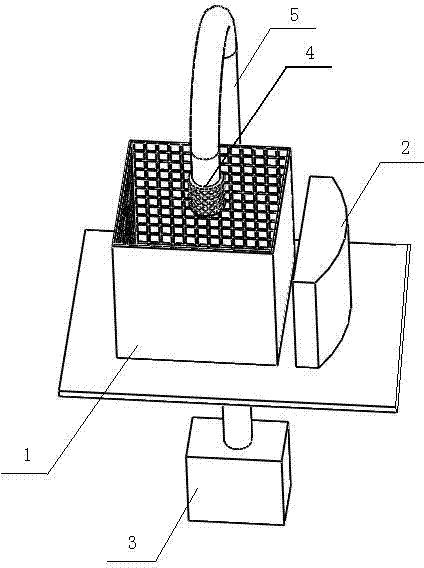

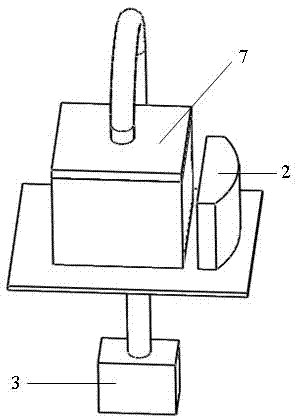

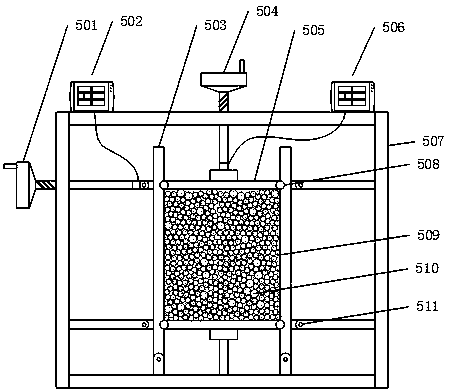

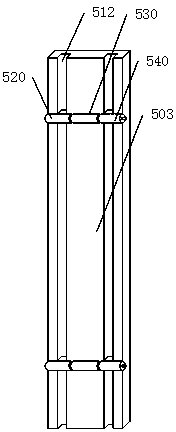

Device and method for measuring force chains of particle deposits

InactiveCN102353485BEfficient removalAvoid accumulationForce measurement by measuring optical property variationParticulatesFluorescence

The invention relates to a device and a method for measuring force chains of particle deposits, wherein the device for measuring the force chains of the particle deposits comprises a pressure-sensing container, a fluorescence spectrum detector, an air compressor, a semispherical pressure head and a feeding device of the semispherical pressure head; the semispherical pressure head extends into thetransparent pressure-sensing container; the feeding device is connected with the air compressor; the fluorescence spectrum detector is arranged on one side face of the pressure-sensing container; onewall face of the pressure-sensing container corresponds to the fluorescence spectrum detector; a cover of the pressure-sensing container is provided with an excitation light source; and a power source connector is further arranged on the cover. With the adoption of the device and the method provided by the invention, the occurrence of the deposit of particulate matters can be effectively prevented, the transfer manner of the force chains of the particle deposits is clearly understood, and the guidance for how to effectively remove the debris deposited beds from boreholes can be provided.

Owner:NORTHEAST GASOLINEEUM UNIV

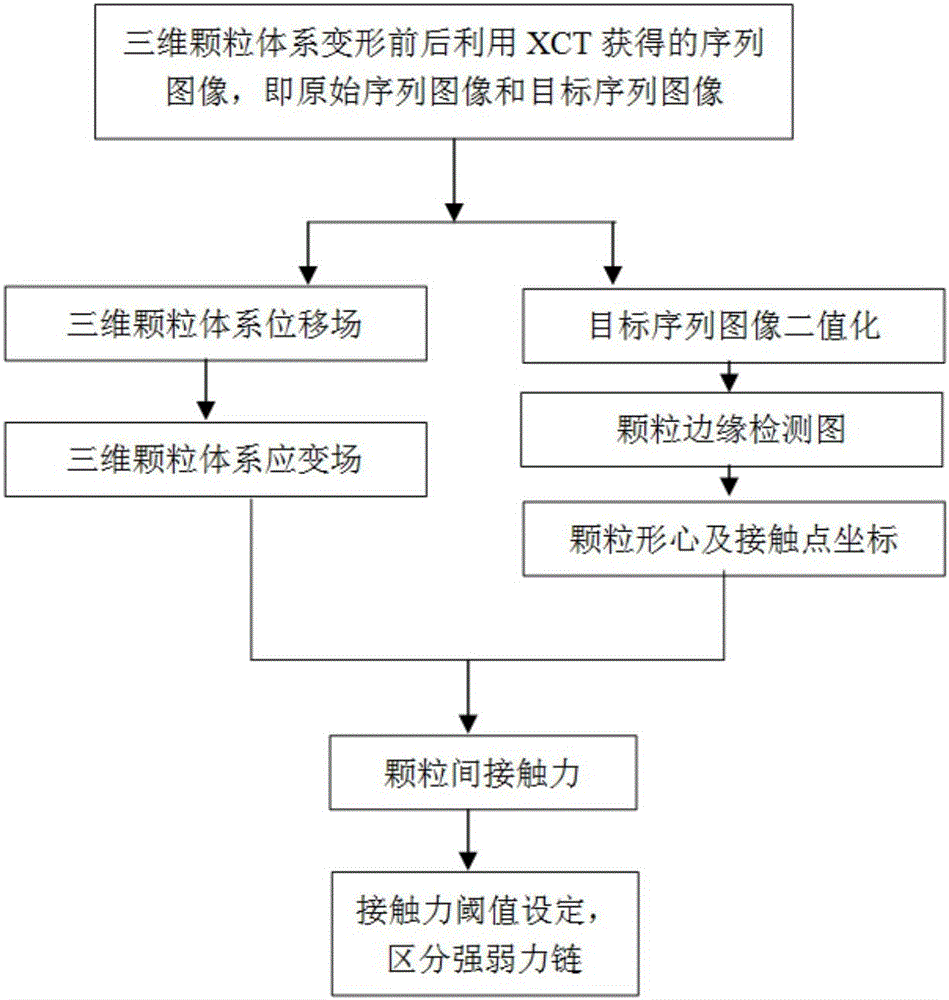

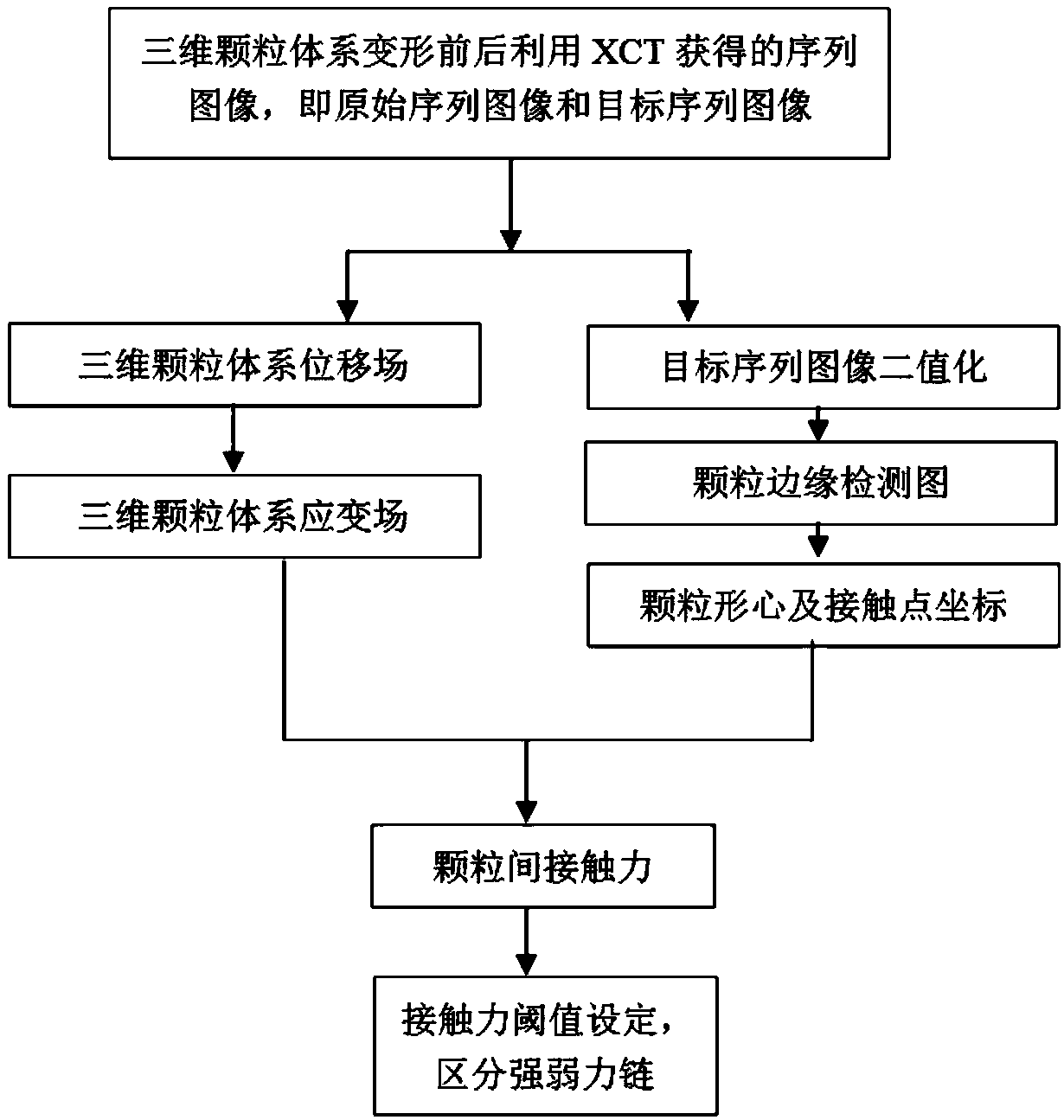

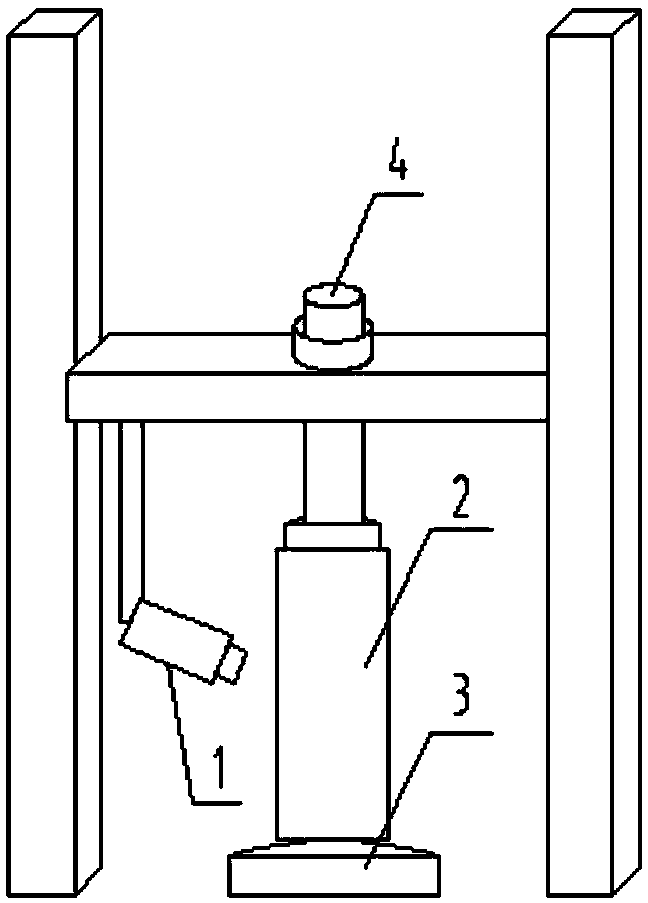

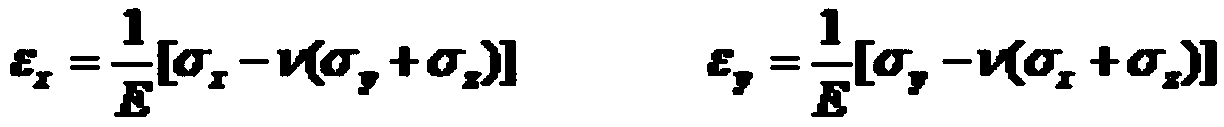

Contact force calculating and force chain recognizing method for particles in three-dimensional particle system

ActiveCN106769436APromote research progressImprove practicalityMaterial strength using tensile/compressive forcesContact forceForce chain

The invention belongs to the technical field of particle system force chain recognition and relates to a contact force calculating and force chain recognizing method for particles in a three-dimensional particle system. The method comprises the steps of putting balls into a rigid container to form the three-dimensional particle system, utilizing a loading pressure head to pressurize the three-dimensional particle system, collecting an original sequence image and a target sequence image through an XCT scanner, utilizing a digital body related method to analyze the obtained original sequence image and the target sequence image to obtain stress of all points, then performing image edge detection on a target image, recognizing a particle centroid, reading coordinates of the particle centroid and position coordinates of contact points of all particles, establishing an equation set according to balance conditions of all the particles and solving the equation set to obtain magnitude and direction of contact force fi of all the contact point positions on each particle. The method has a simple principle, is convenient and flexible to use and has strong practicability, application environment friendliness and wide market prospect; in addition, required equipment is simple and easy to obtain, and measurement results are accurate.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

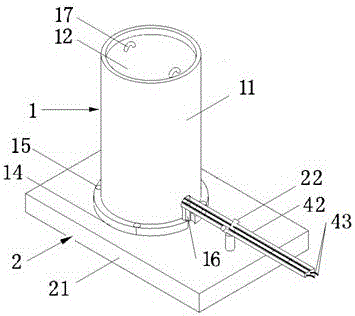

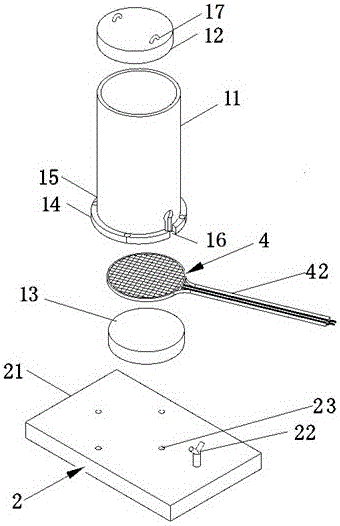

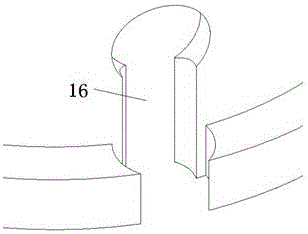

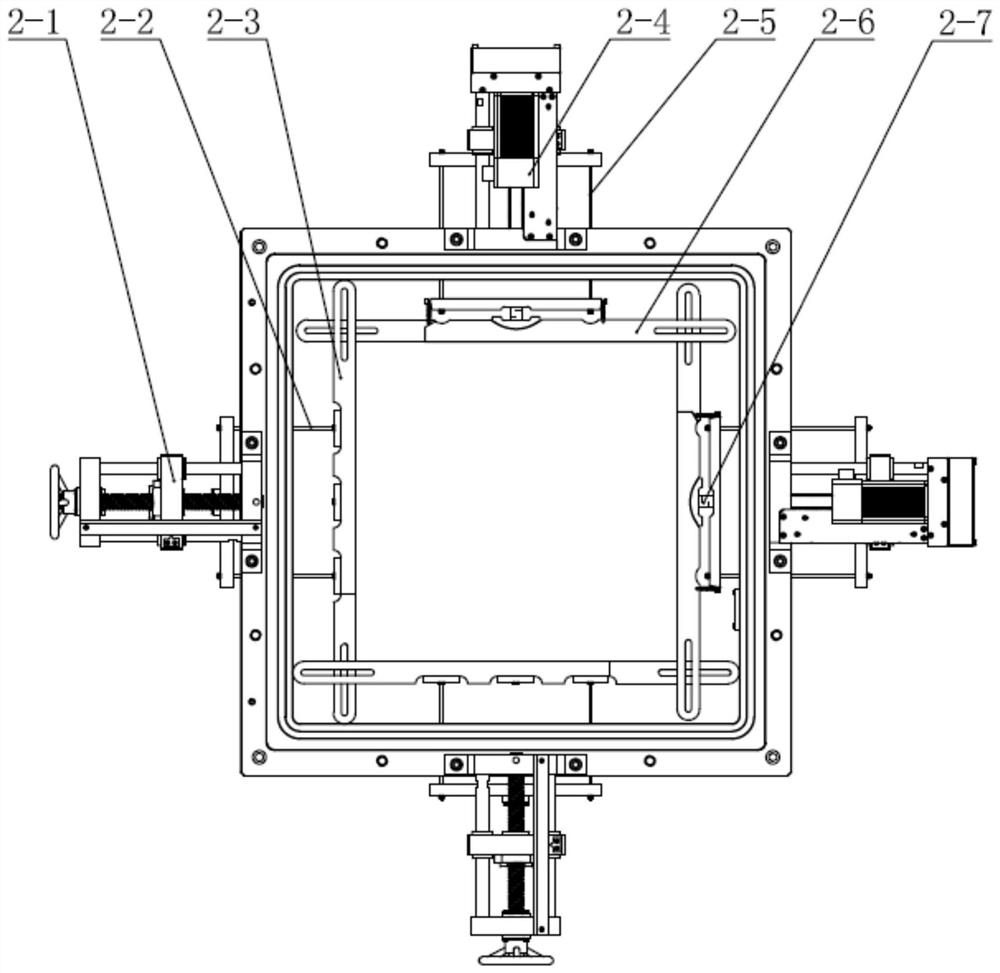

Contact force measurement test apparatus of granular material force chain structure, and application method thereof

ActiveCN106248263ASimple structureEasy to operateForce measurement using piezo-resistive materialsMeasurement testTransducer

The invention discloses a contact force measurement test apparatus of a granular material force chain structure. The apparatus comprises a cylinder container, a fixation device, a power loading device, a thin film pressure transducer and a data calibration and acquisition system, wherein the cylinder container comprises a cylinder used for containing a granular material whose contact force needs to be measured, an upper piston used for covering an upper-end opening of the cylinder and a lower piston used for covering a bottom-end opening of the cylinder; the fixation device is used for fixing the cylinder; the power loading device can directly act on the upper piston and is used for providing a load needed during a test; the thin film pressure transducer is mainly composed of a sensor thin film portion; the sensor thin film portion is arranged between the sensing granular material and the lower piston; and the data calibration and acquisition system comprises a modulator, a calibration device, a USB gatherer and acquisition control software, and the thin film pressure transducer is connected with the data calibration and acquisition system. The test apparatus provided by the invention has higher precision and sensitivity and can more accurately carry out a contact force test and research of the granular material force chain structure.

Owner:WUHAN UNIV

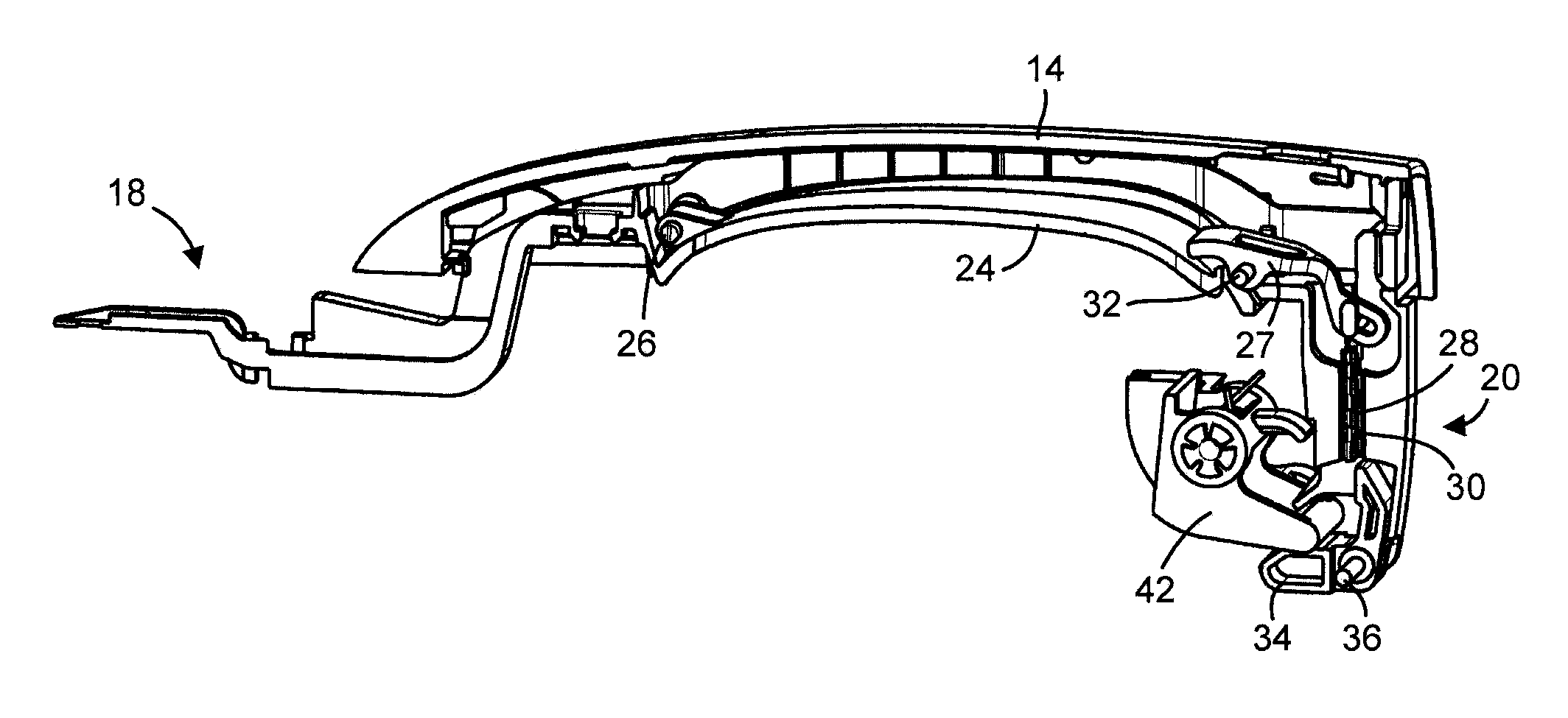

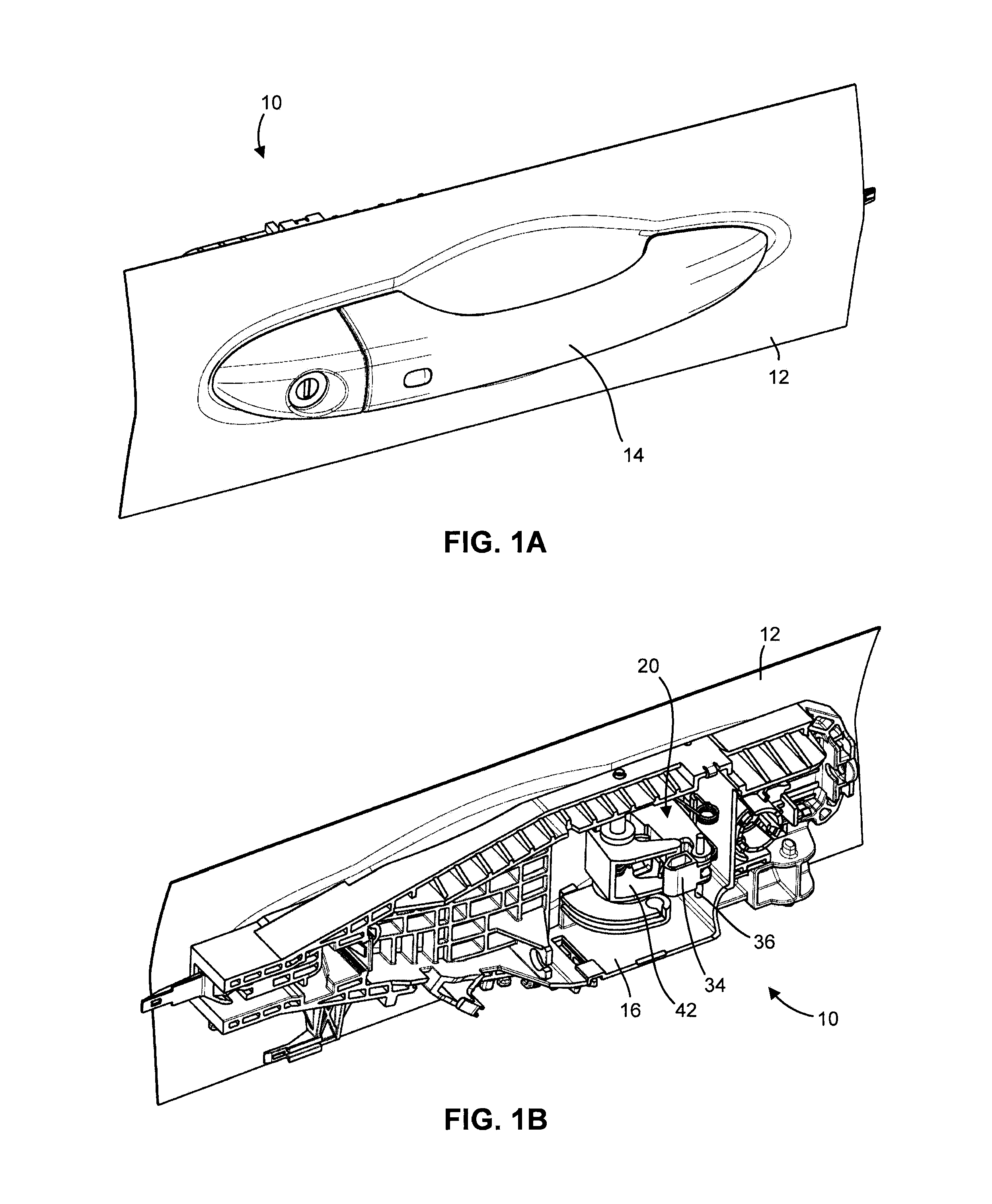

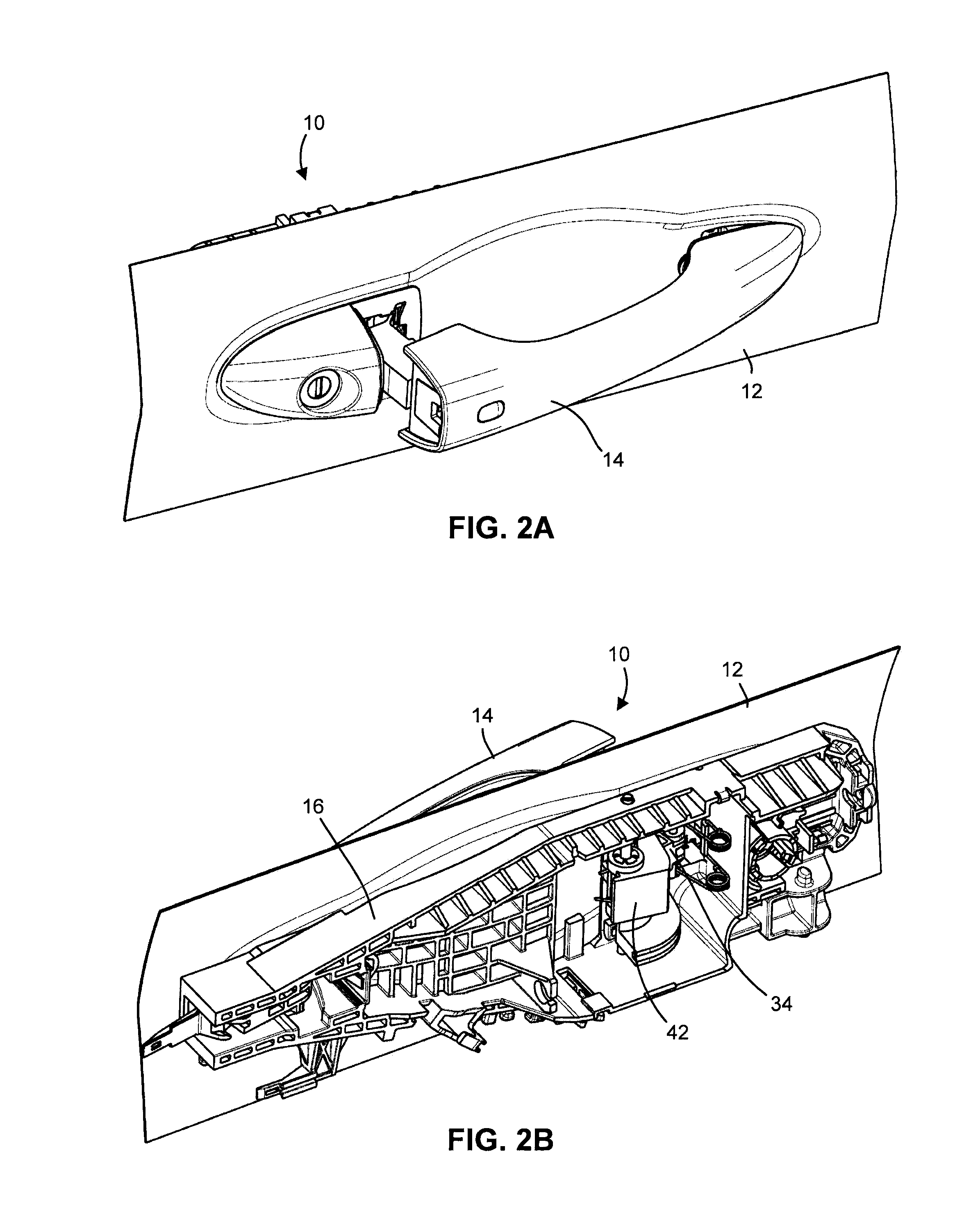

Vehicular door handle assembly with deployable latch connection

When activated, a handle assembly selectively allows the door latch of a door of a motor vehicle to be released. The handle assembly includes a base fixedly secured to the door and a handle assembly which in its passive state has minimal to no presence in the opening chain of the door latch. The handle assembly includes a handle strap with a handle grip or activation lever which allows completion of the force chain to the latch, thus selectively allowing desired door opening.

Owner:HUF NORTH AMERICA AUTOMOTIVE PARTS MFG

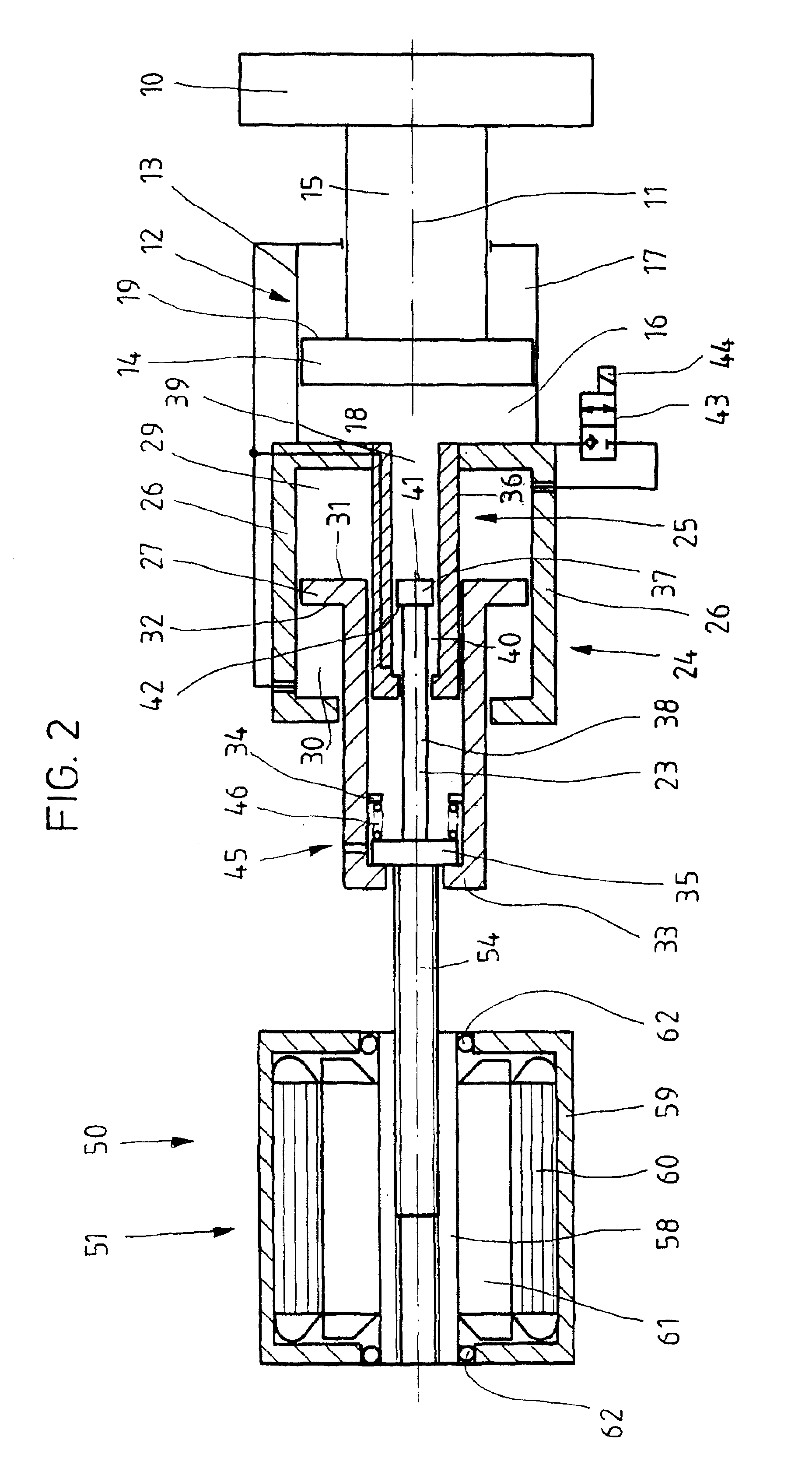

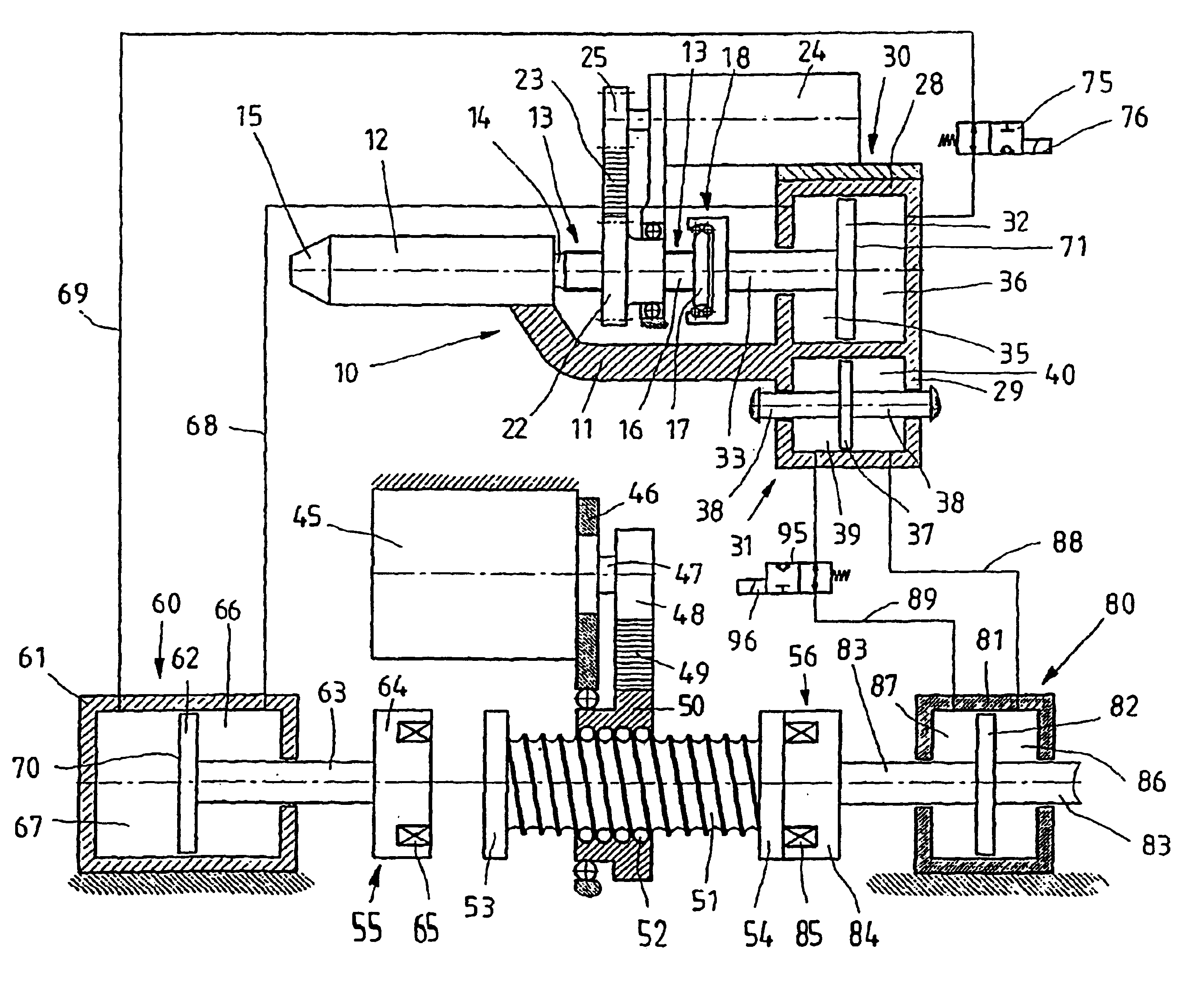

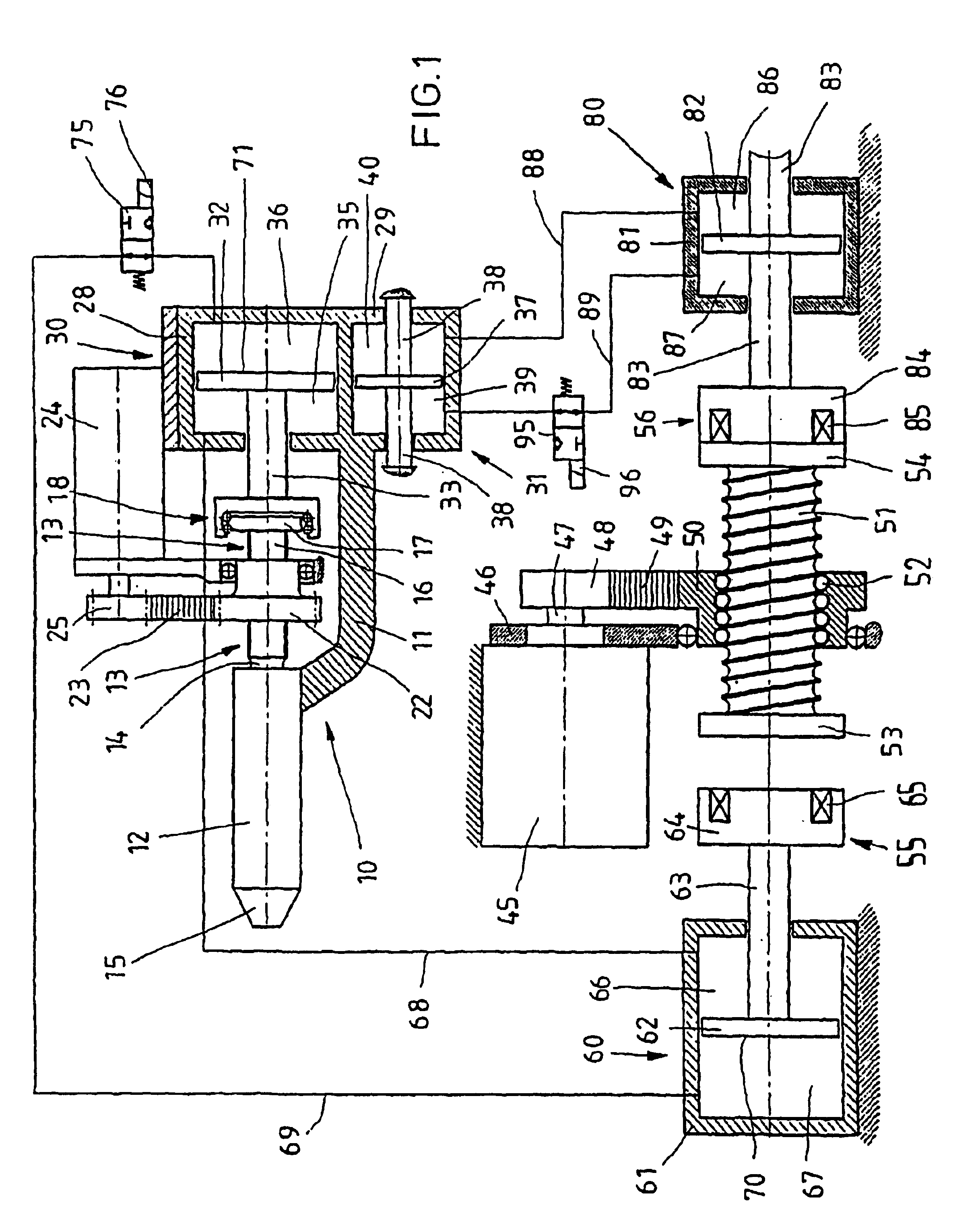

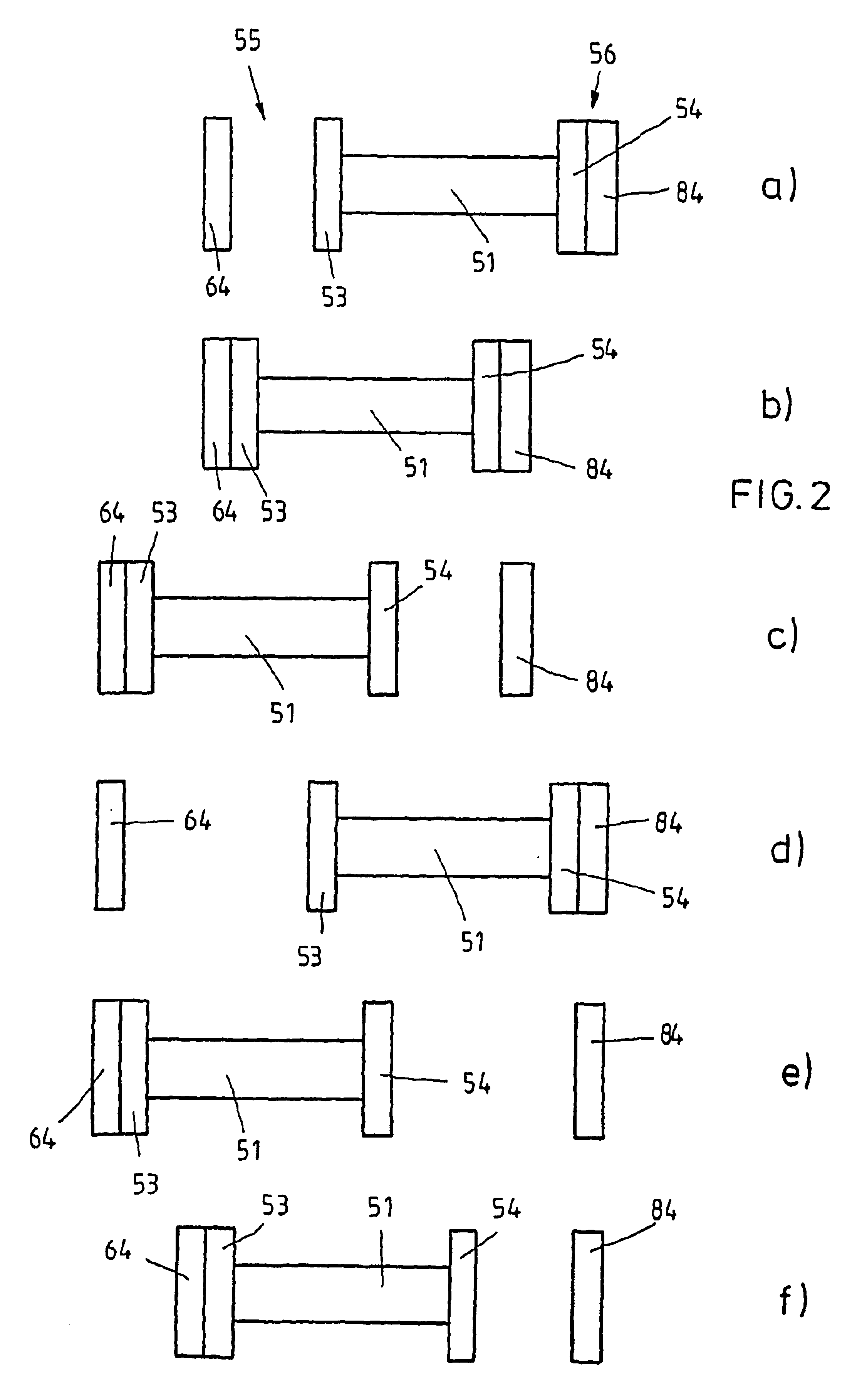

Drive mechanism, particularly for a closing unit, an injection unit or an ejector of a plastic injection moulding machine

A drive mechanism for an injection molding machine has an output element that is moveable in a straight line and an electric motor drive unit having an electric motor and a piston-cylinder unit which has a first piston-cylinder unit in the force chain between the output element of the electric-motor drive unit and the movable component. A rapid actuating movement is possible and, the action of a high force is also achievable wherein a second piston-cylinder unit and a third piston-cylinder unit. A fluidic connection between the first cylinder chamber and the second cylinder chamber is controllable via a valve. When the valve is open, the second hydraulic piston displaces pressurized liquid from the second cylinder chamber into the first cylinder chamber, to actuate the movable component and, when the valve is closed, the third hydraulic piston displaces pressurized liquid from the third cylinder chamber into the first cylinder chamber to exert a high force on the movable component.

Owner:BOSCH REXROTH AG

Device and method for measuring force chains of particle deposits

InactiveCN102353485AEfficient removalAvoid accumulationForce measurement by measuring optical property variationParticulatesFluorescence

The invention relates to a device and a method for measuring force chains of particle deposits, wherein the device for measuring the force chains of the particle deposits comprises a pressure-sensing container, a fluorescence spectrum detector, an air compressor, a semispherical pressure head and a feeding device of the semispherical pressure head; the semispherical pressure head extends into thetransparent pressure-sensing container; the feeding device is connected with the air compressor; the fluorescence spectrum detector is arranged on one side face of the pressure-sensing container; onewall face of the pressure-sensing container corresponds to the fluorescence spectrum detector; a cover of the pressure-sensing container is provided with an excitation light source; and a power source connector is further arranged on the cover. With the adoption of the device and the method provided by the invention, the occurrence of the deposit of particulate matters can be effectively prevented, the transfer manner of the force chains of the particle deposits is clearly understood, and the guidance for how to effectively remove the debris deposited beds from boreholes can be provided.

Owner:NORTHEAST GASOLINEEUM UNIV

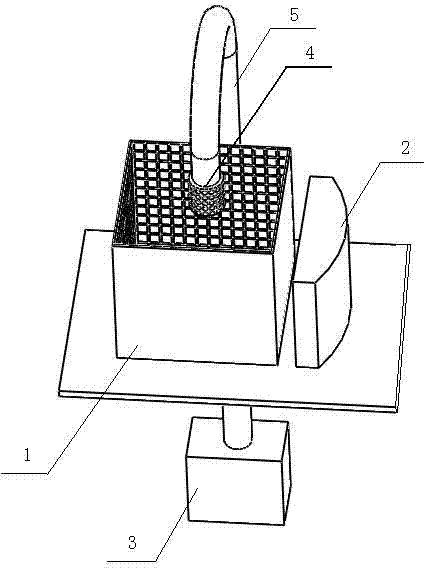

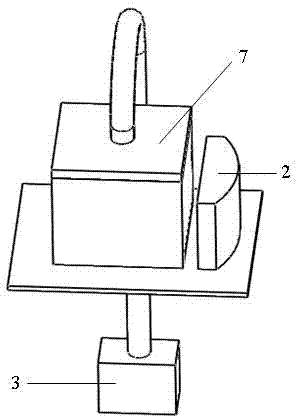

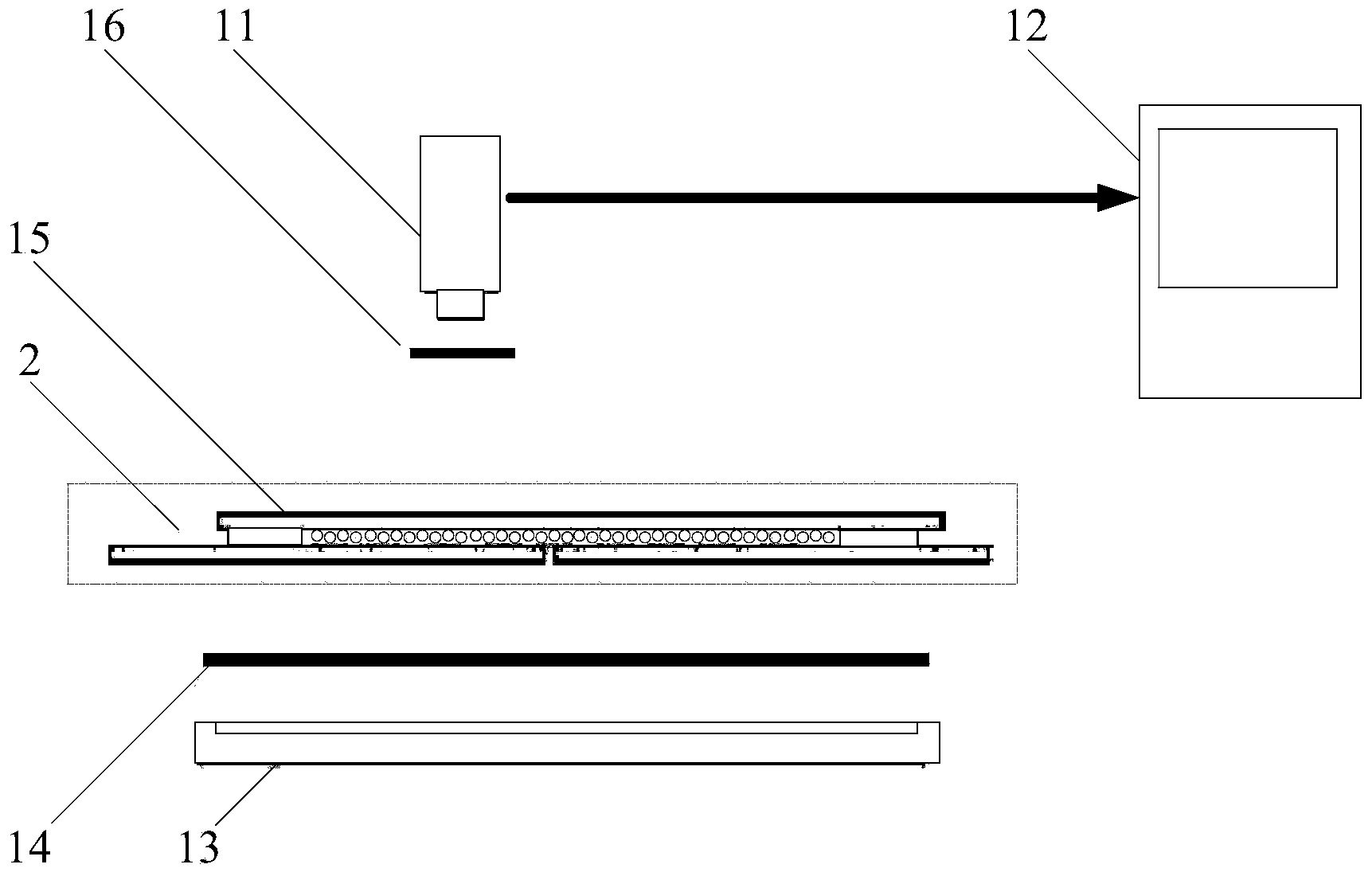

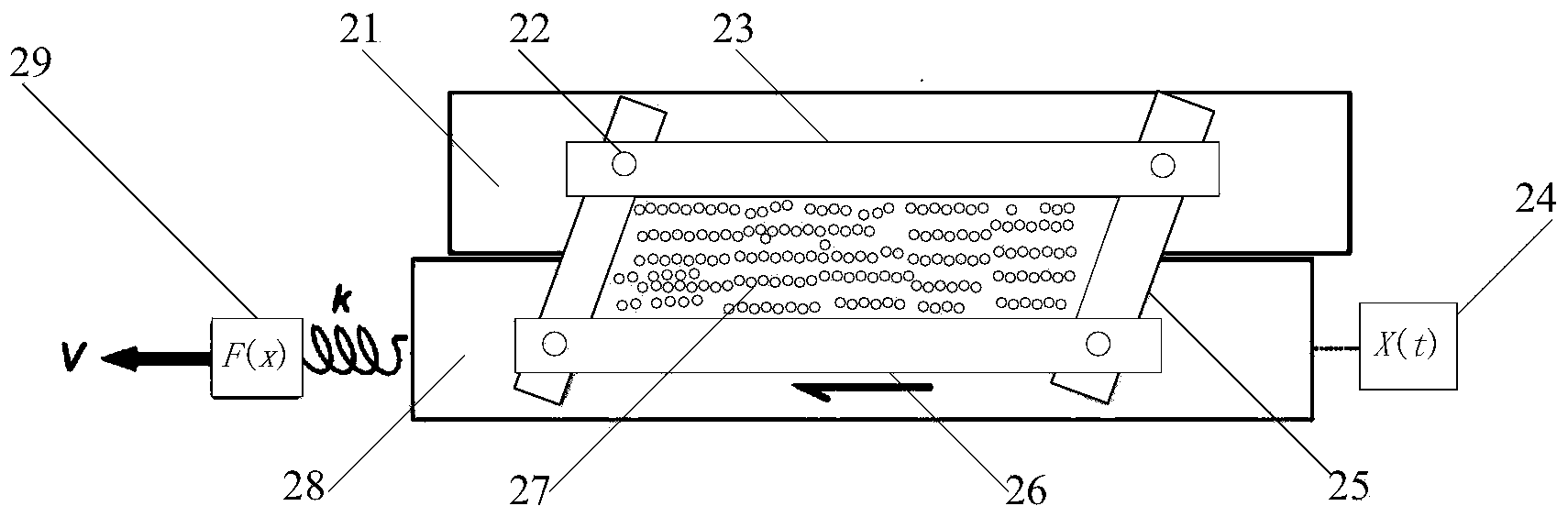

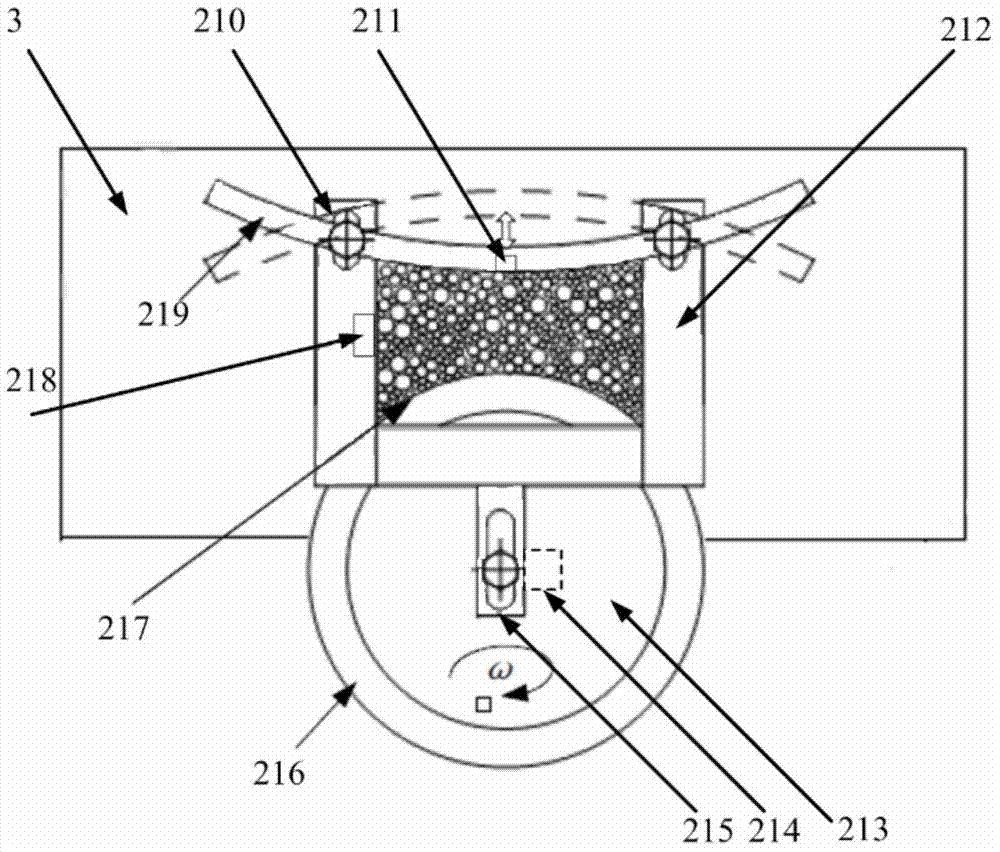

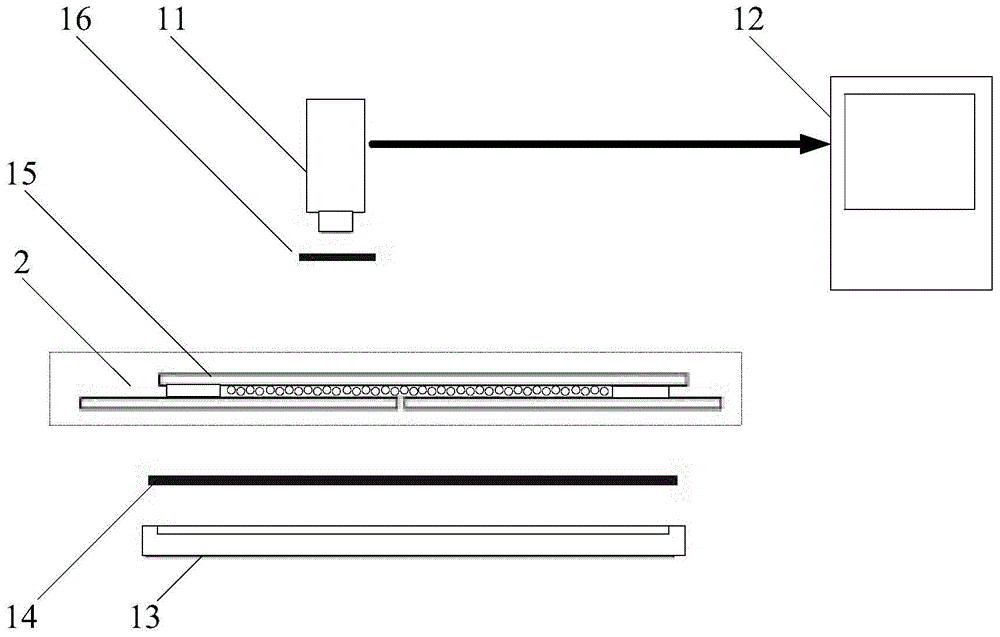

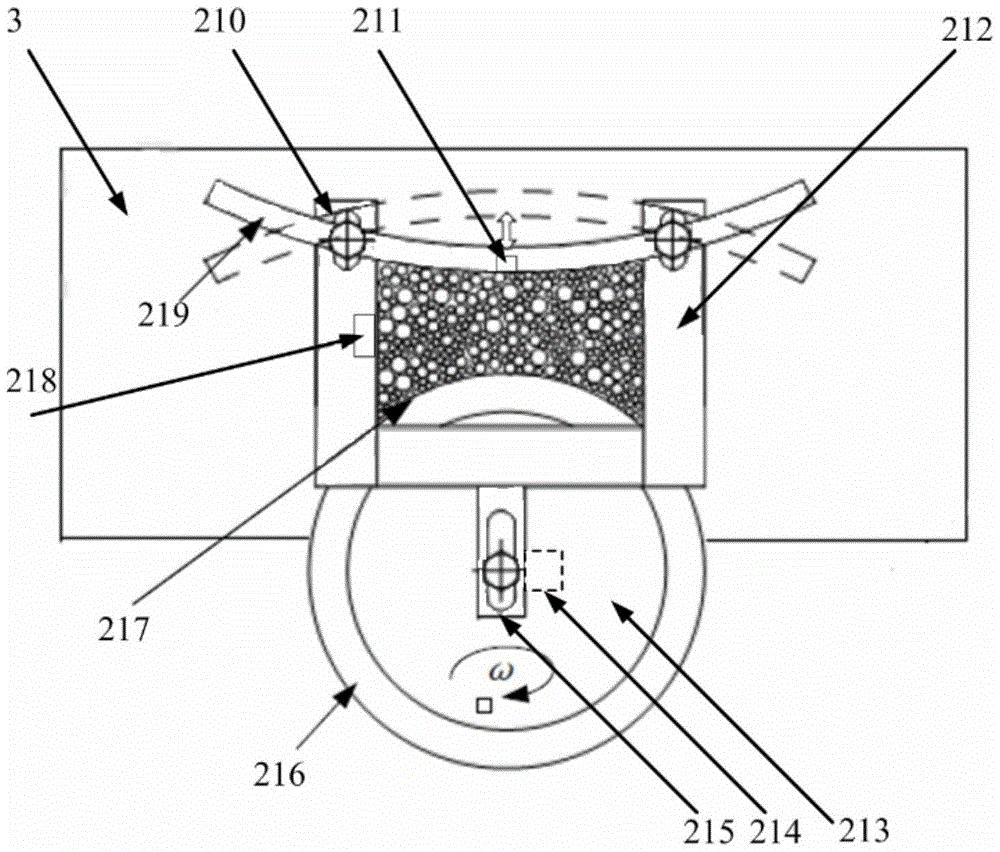

Dynamic force chain observation device of flexible polishing wear particle group

ActiveCN104316231AIdeal control parametersRealize simulationForce measurement by measuring optical property variationImaging processingWear particle

The invention provides a dynamic force chain observation device of a flexible polishing wear particle group. The dynamic force chain observation device comprises an image processing device and a particle control device. The image processing device comprises a light source generator, a light source collector and a data analyzer. The light source generator is located at the bottommost end of an observation region. The light source transmitted by the light source generator penetrates through a lower polarized light device and points to a particle control device in the observation region composed of the lower polarized light device and an upper polarized light device. The upper surface of the particle control device is covered with a transparent baffle. The light source collector is located over the upper polarized light device. The light source collection view of the light source collector covers the light source transmitted out by the upper polarized light device. The data input end of the data analyzer is connected with the data output end of the light source collector. The data signal output end of the data analyzer is connected with a display screen of the data analyzer. The dynamic force chain observation device has the advantages that the external applying parameters of photoelastic particles can be detected in real time, the motion state of the photoelastic particles can be adjusted through sliding blocks, and simulation of the flexible polishing machining test is achieved.

Owner:菏泽建数智能科技有限公司

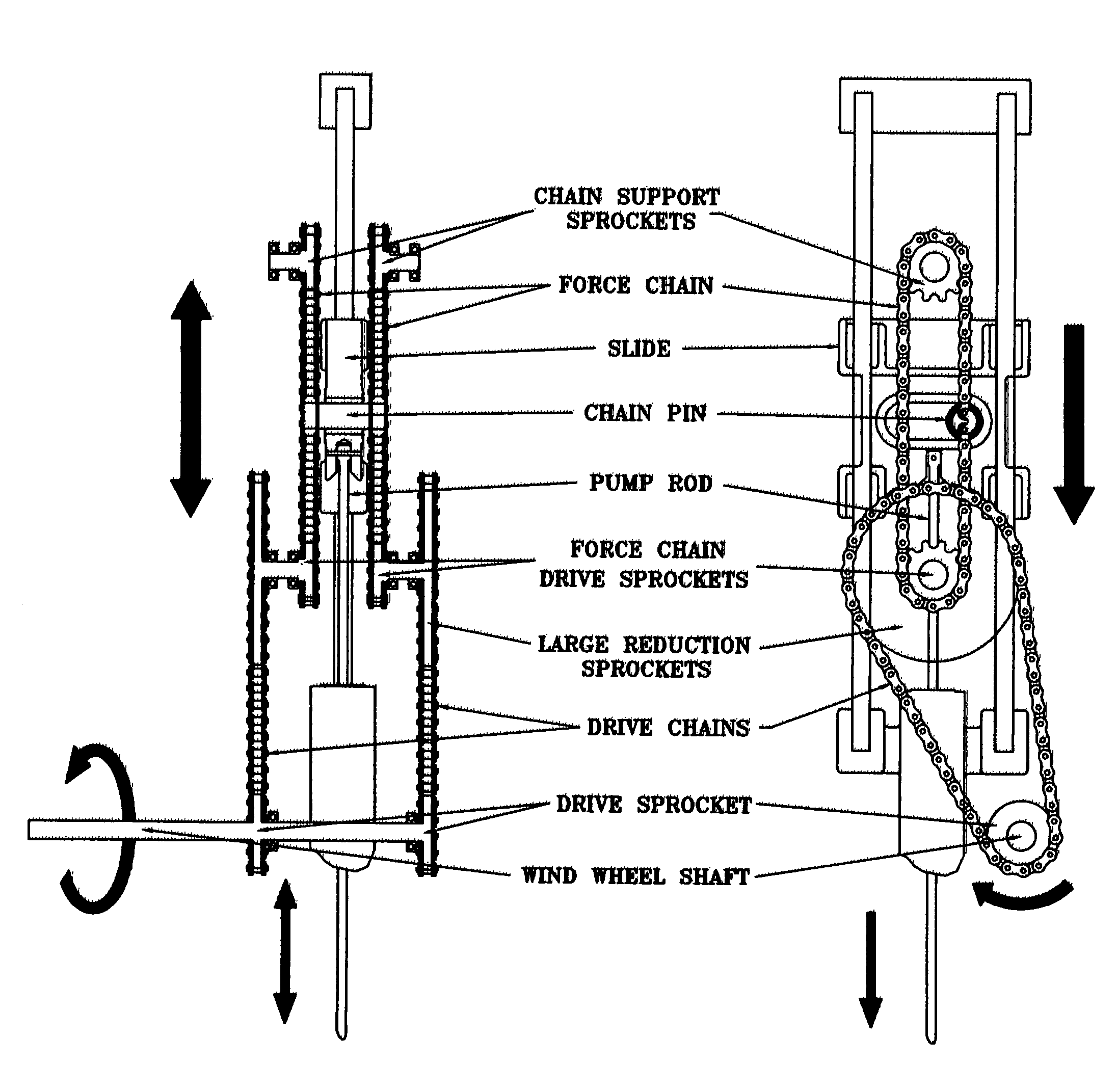

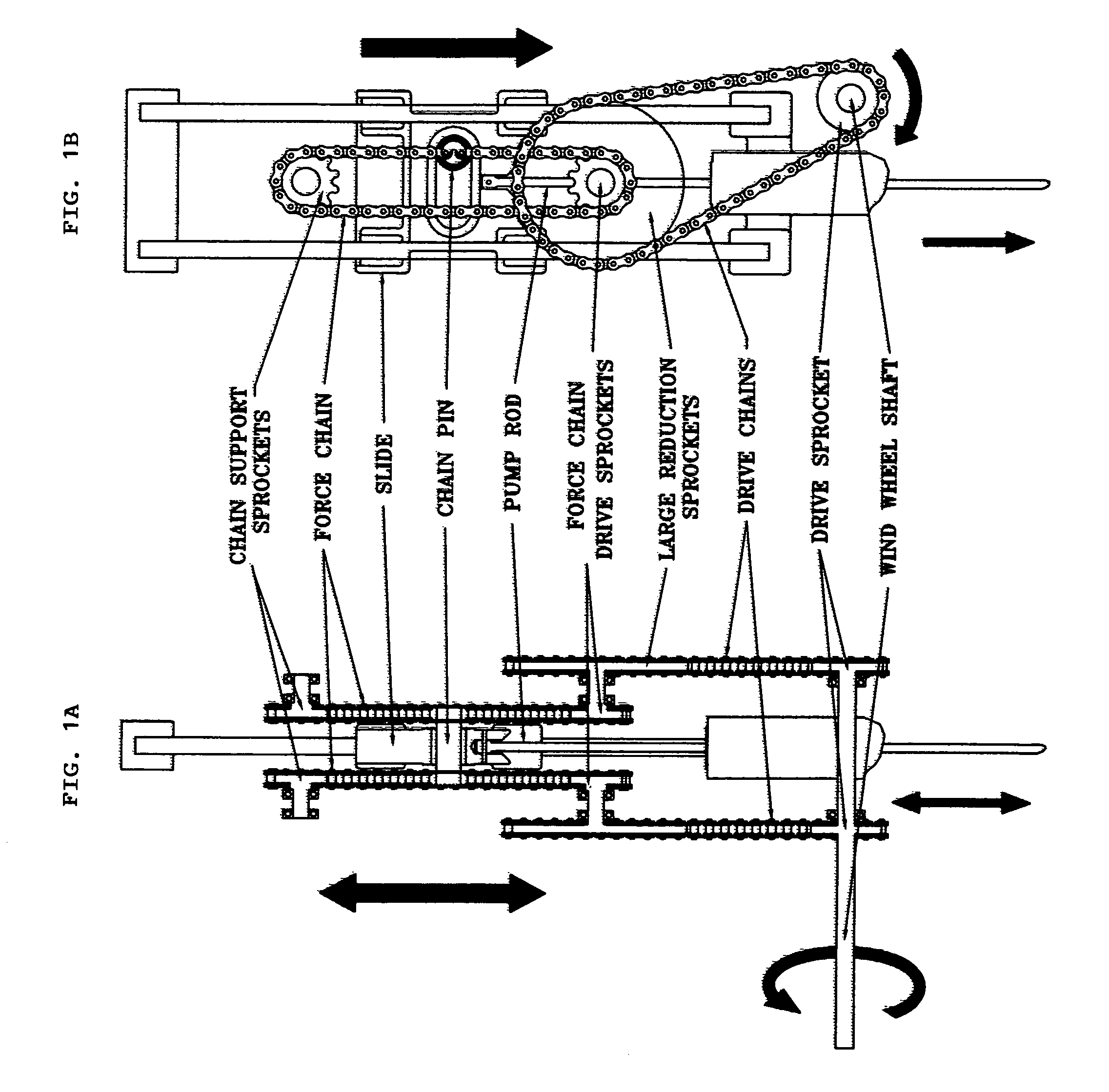

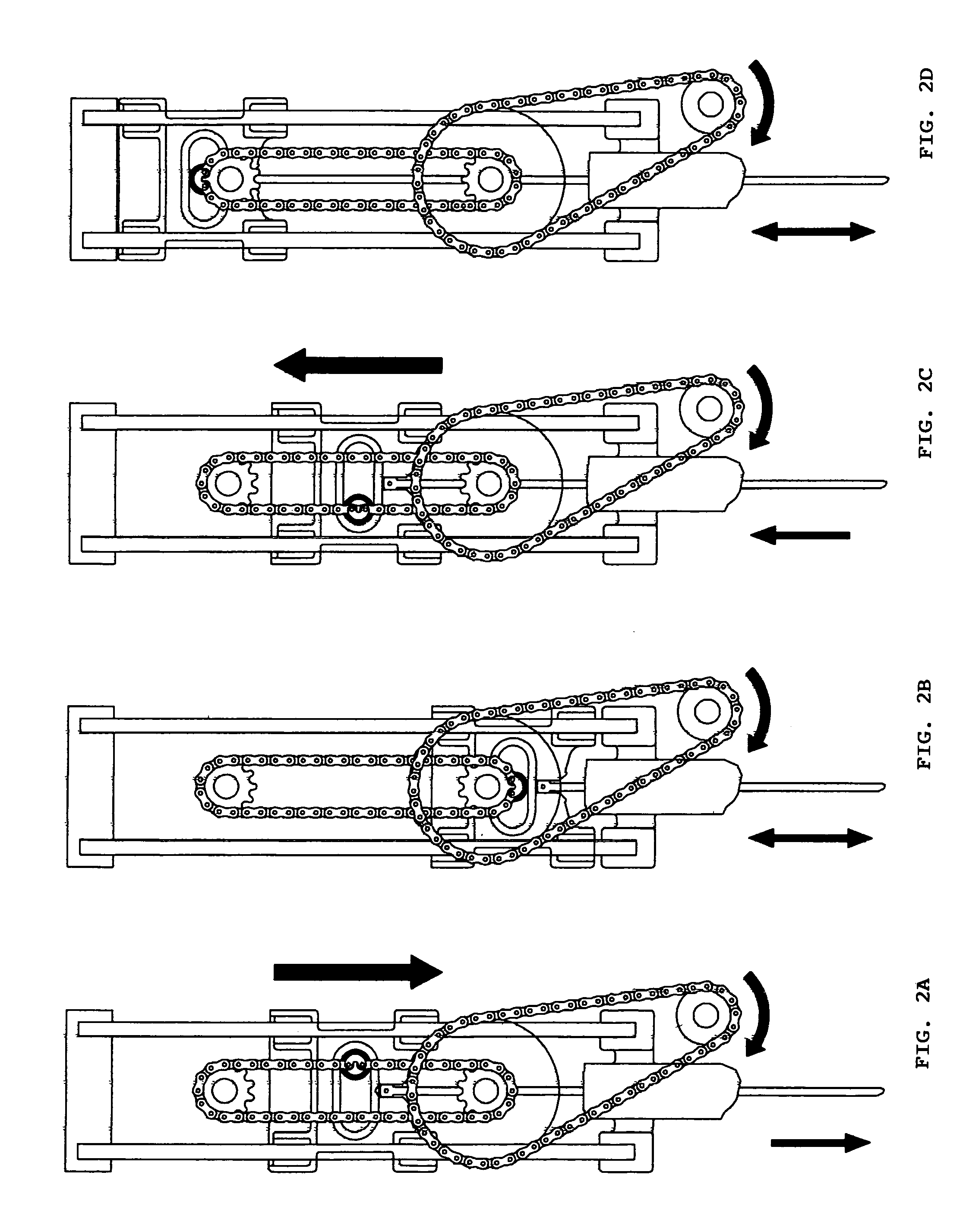

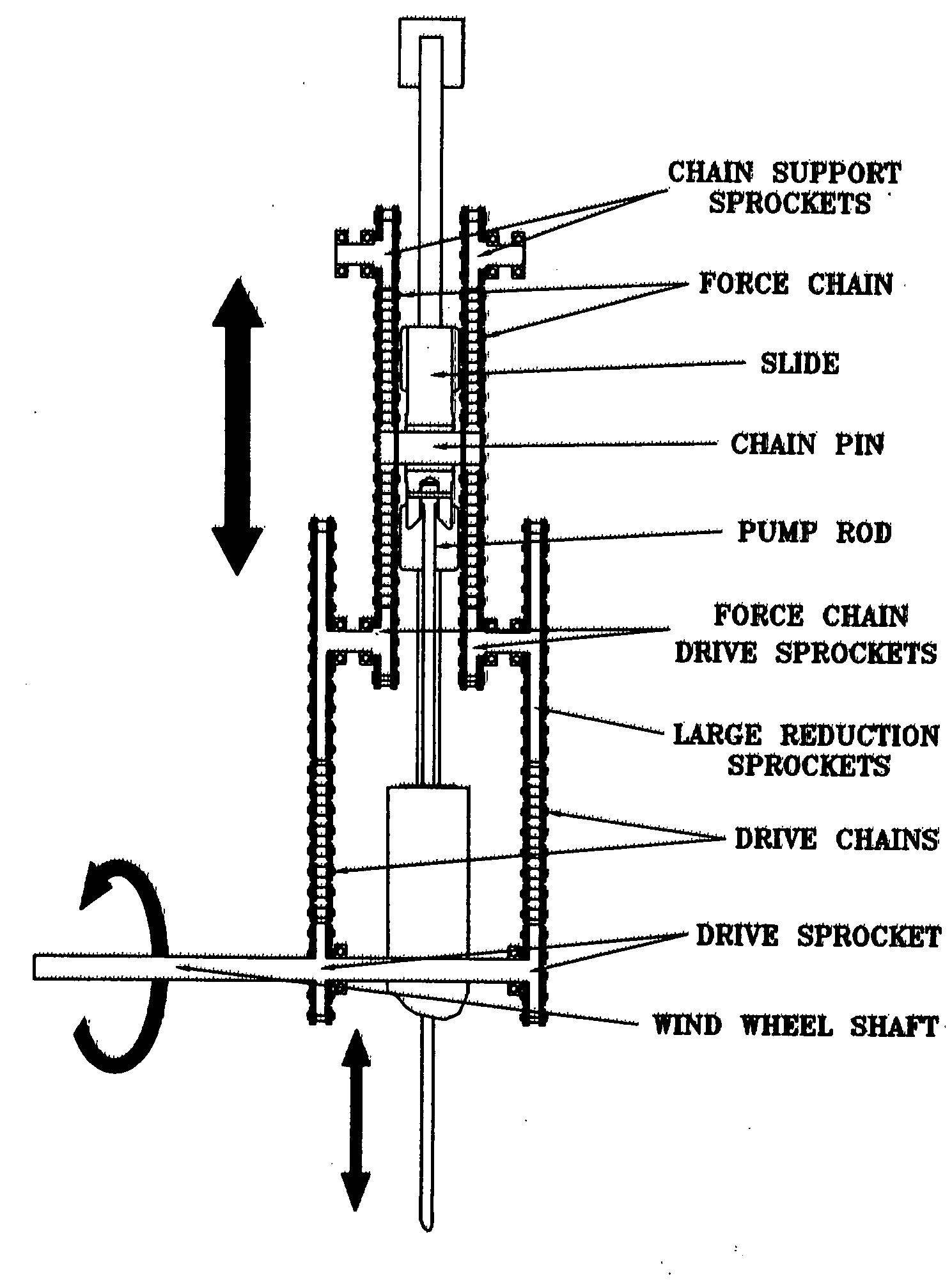

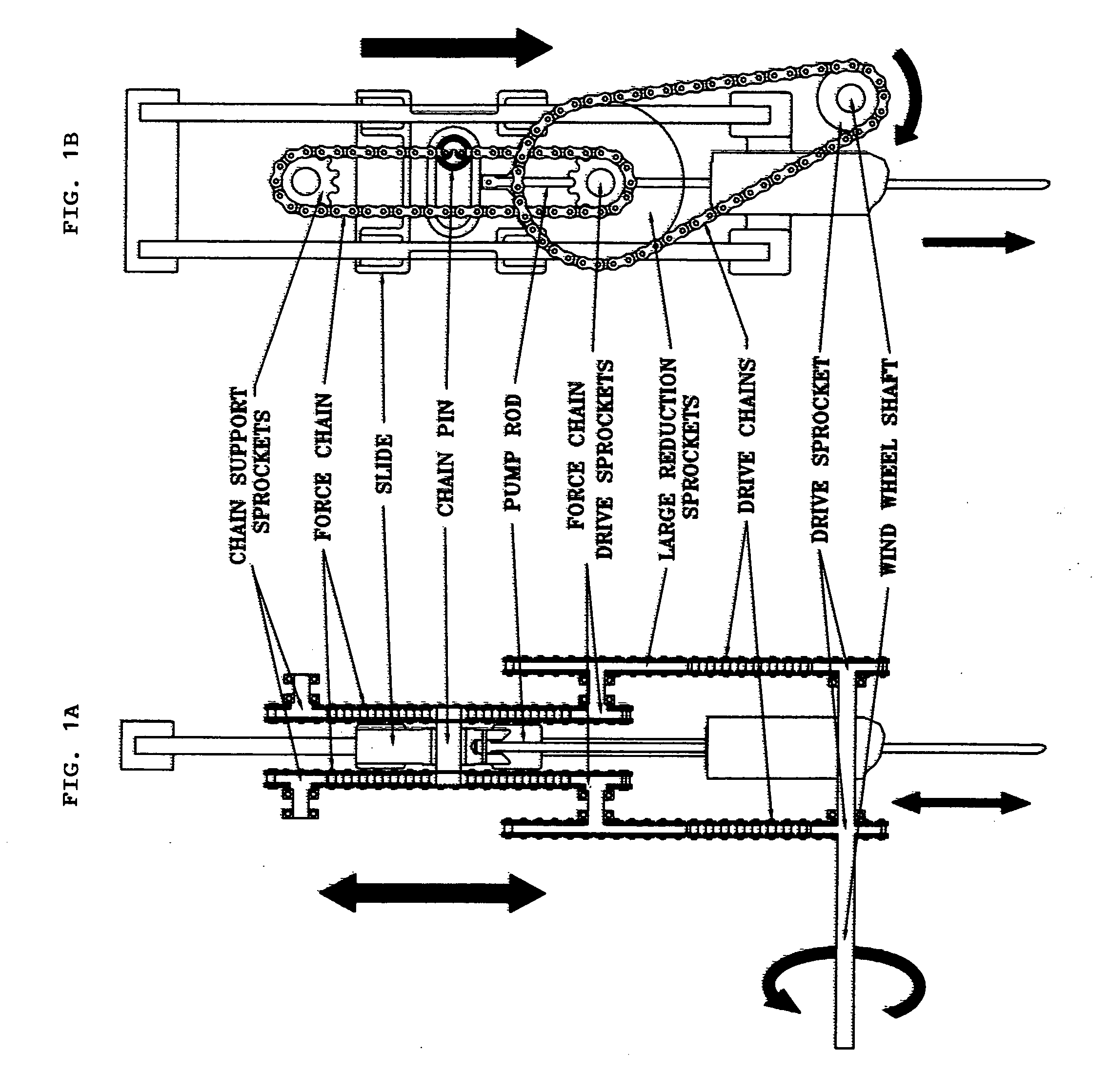

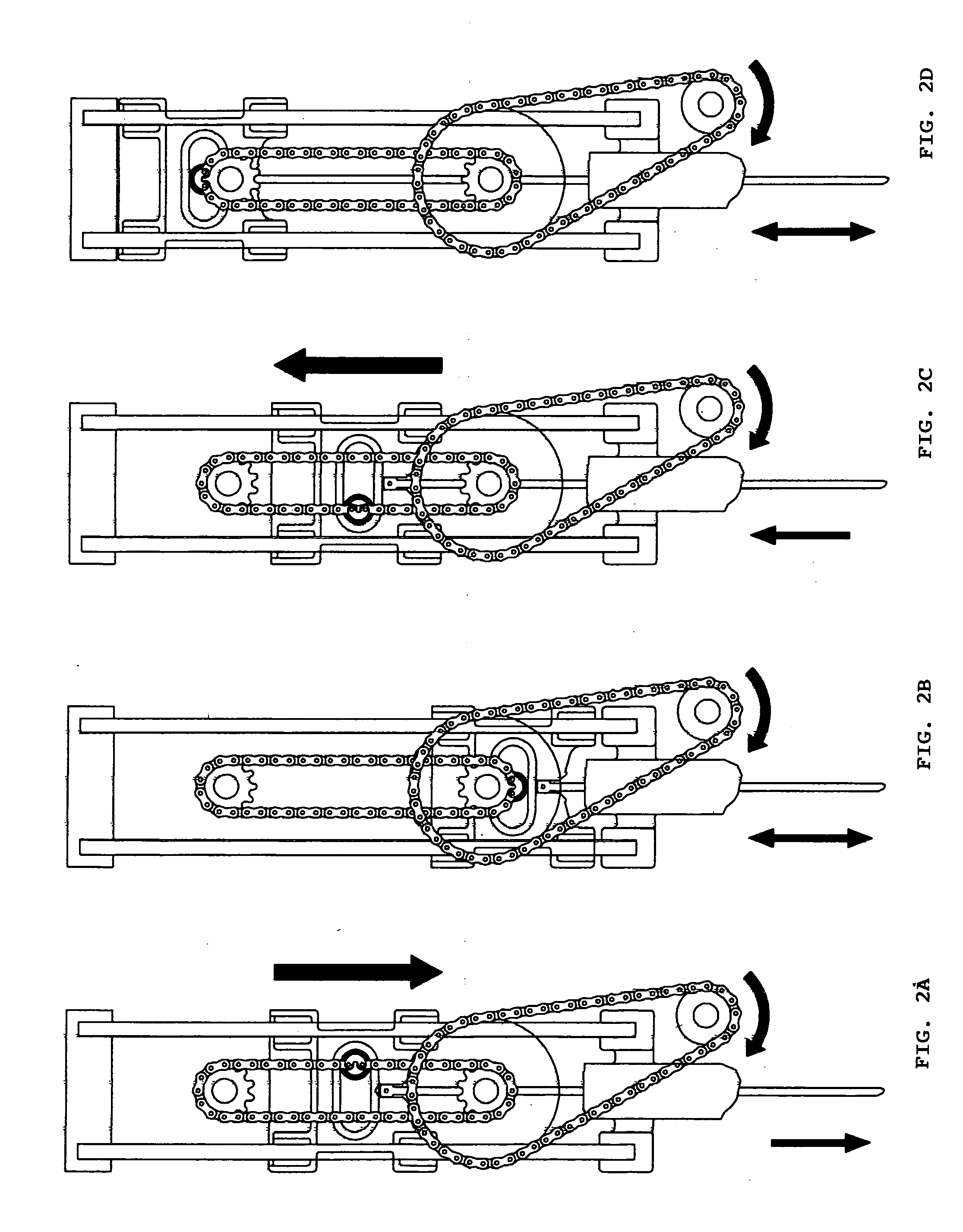

Mechanism for converting mechanical energy for wind powered energy systems

InactiveUS6969926B2Improve efficiencyHigh energyEnergy industryWind motor combinationsPower cycleMechanical energy

An improved drive mechanism for a windmill has: (a) a drive chain driven into movement by a wind wheel shaft driven into rotation by wind movement against a wind wheel; (b) a drive chain sprocket driven by the drive chain and coupled to a force chain sprocket to correspondingly drive a force chain; (c) a chain pin coupled at one position to the force chain and also coupled to a captive slide; and (d) a pump rod connected to the slide and driven an equal distance in each direction by the driven slide in order to convert full mechanical force equally on both the full upstroke and the full downstroke of the pump rod. The improved drive mechanism improves the efficiency of the power cycle by transitioning to the full upstroke with only a minimal dwell on either end of the stroke for transition to movement in the opposite direction. Full mechanical force can thus be applied equally on both the full upstroke and the full downstroke. A high reliability oil bucket chain link lubrication system is used to flood the entire chain mechanism with abundant oil to avoid the problems in traditional pumps of loss of priming, seal wear, etc.

Owner:CONLON THOMAS R

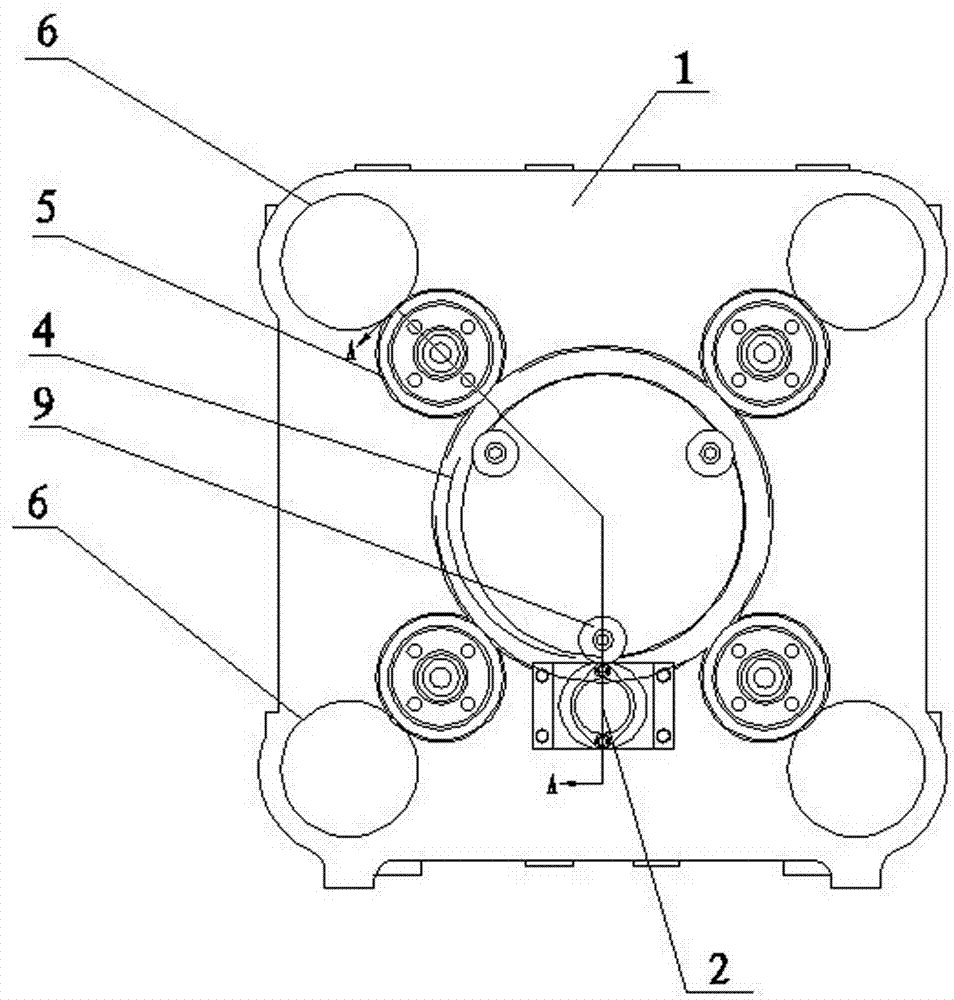

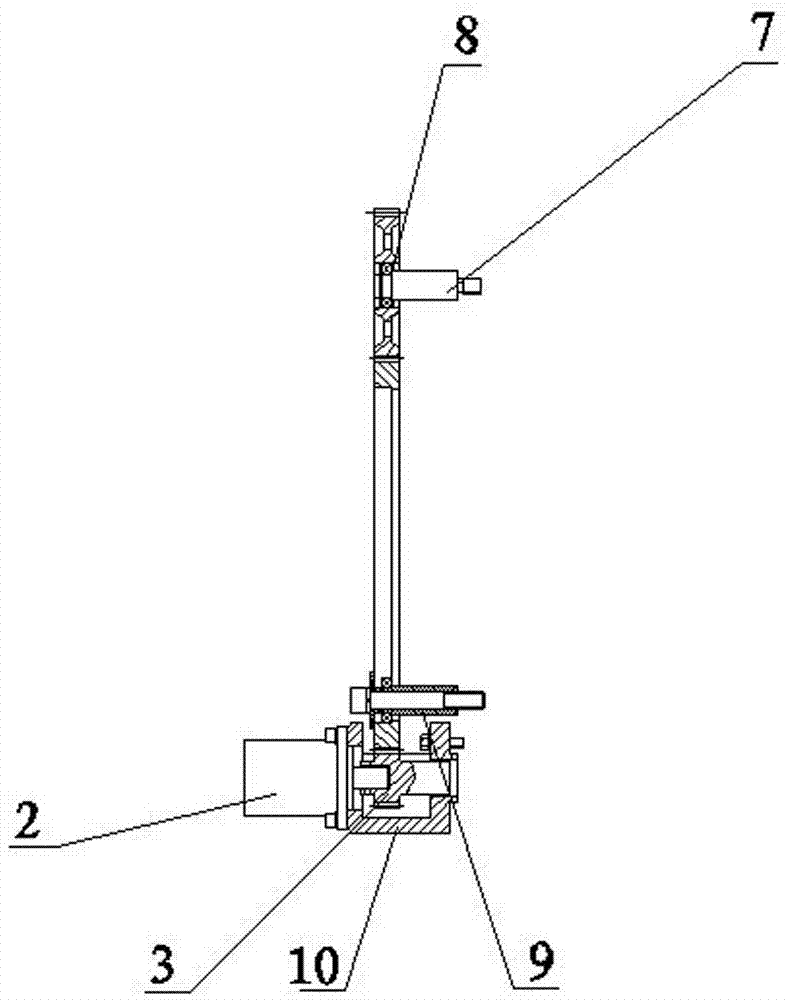

Mold adjusting apparatus

The invention discloses a mold adjusting apparatus of a drawbar type injection molding machine. The apparatus is arranged on an end face of an injection molding machine mold adjusting template. The apparatus comprises a motor, and mold adjusting nuts. The mold adjusting nuts rotate under the driving of the motor. The motor is connected to a first gear. A gear ring is arranged at the center of the end face of the mold adjusting template. The first gear is engaged with the gear ring. Four second gears are uniformly distributed on the outer side of the gear ring. Each second gear is connected to the mold adjusting template through a core shaft arranged at the center of the second gear. The second gears are respectively engaged with the gear ring. A third gear is linked on the outer diameter of each mold adjusting nut. The third gears are engaged with the second gears. Each second gear is positioned between a corresponding third gear and the gear ring. With the mold adjusting apparatus provided by the invention, a driving force chain-transmission characteristic of prior arts is eliminated, and the driving force is transmitted by gear engagement, such that the purpose of mold adjusting is achieved. The transmission precision is high, the transmission process is smooth, the structure is simple, and the installation is convenient. Therefore, the mold adjusting process can be carried out more convenient, and the mold adjusting controlling is more precise.

Owner:WUXI TIANHUI MOLDING MACHINE

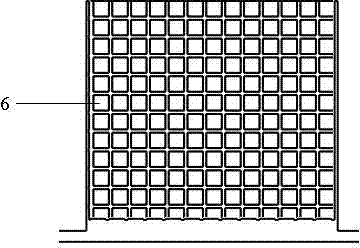

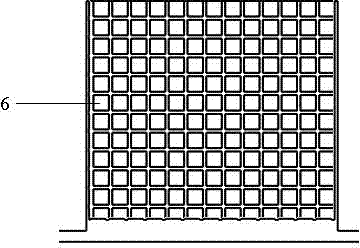

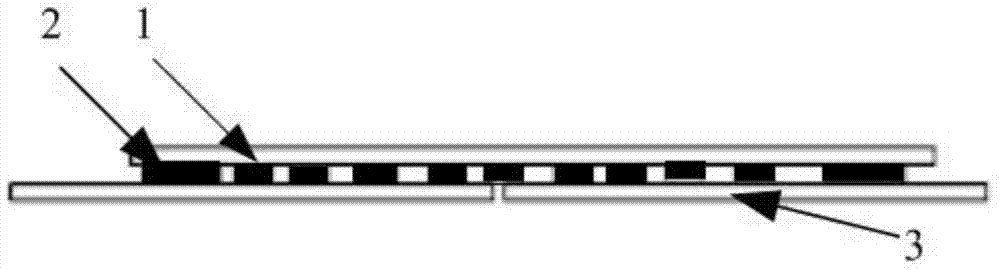

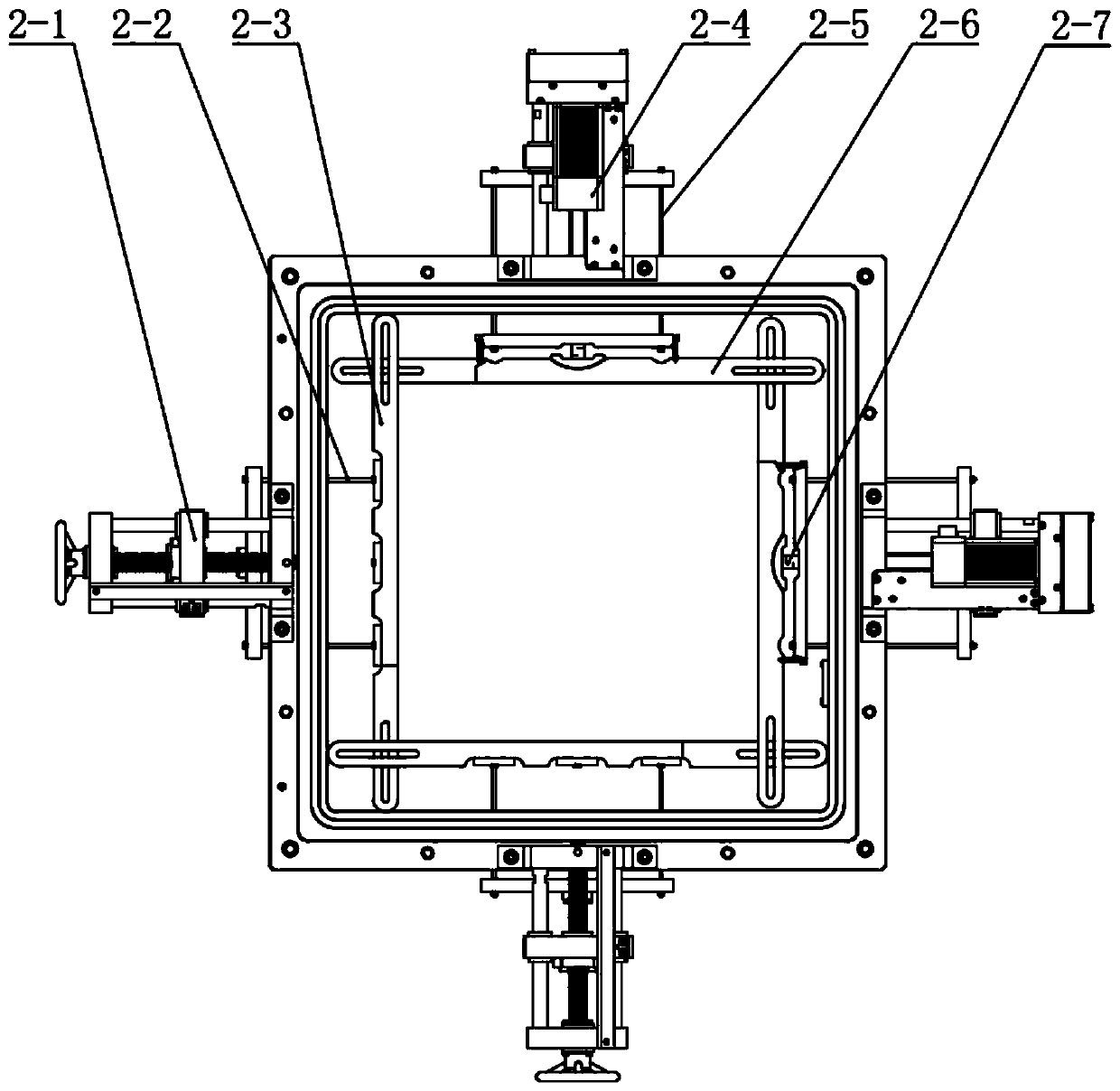

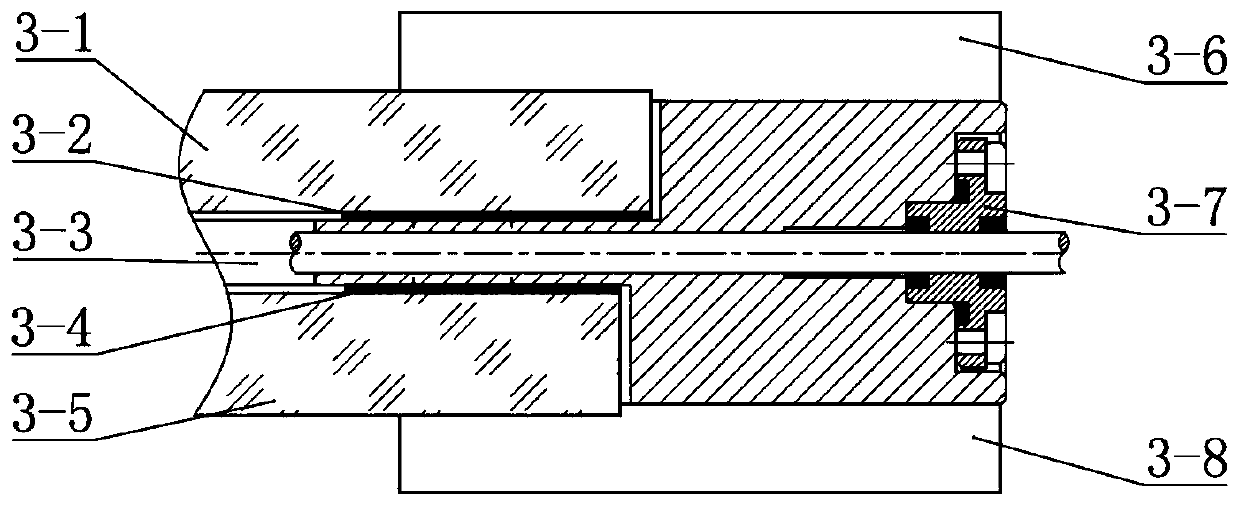

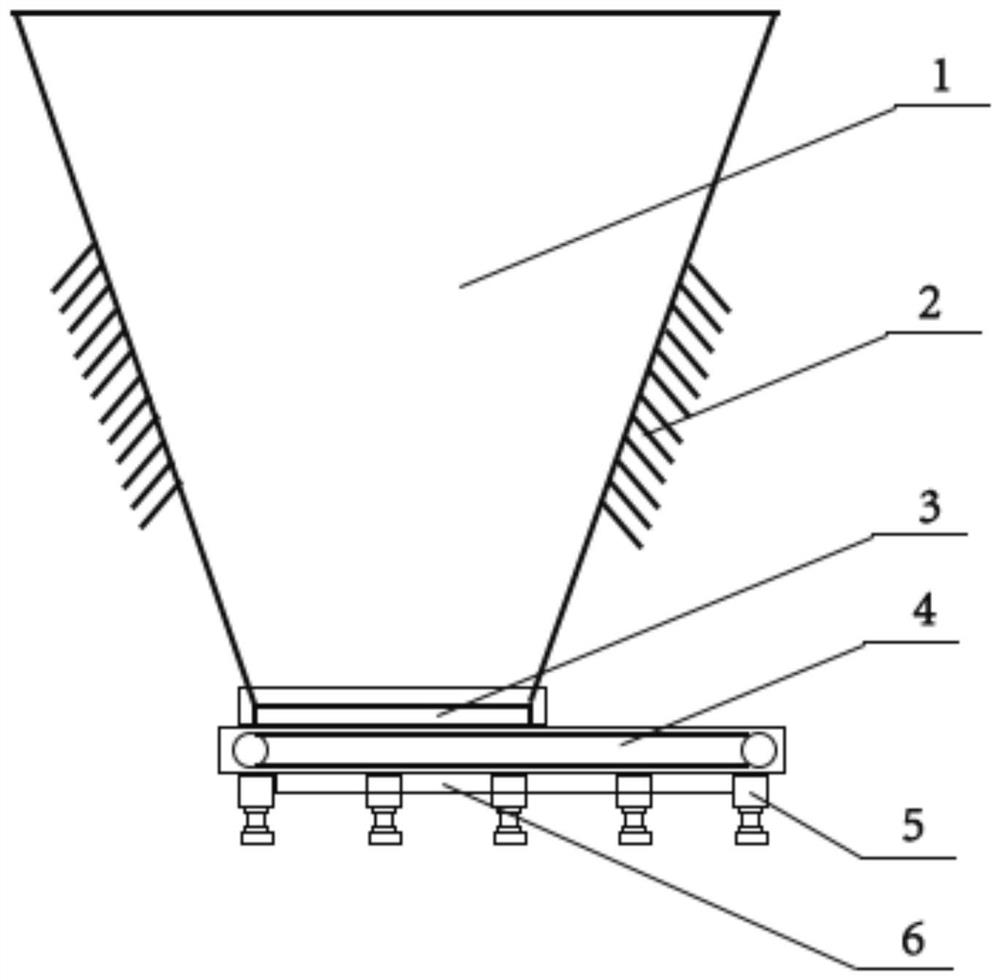

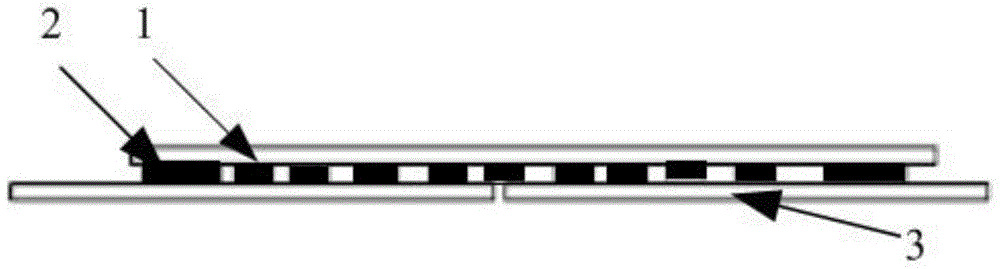

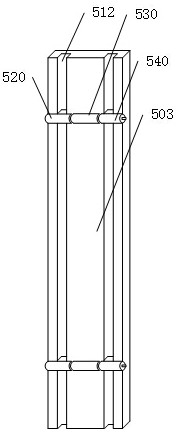

Grinding particle restraining device for observing particle force chain

The invention discloses a grinding particle restraining device for observing a particle force chain. The grinding particle restraining device comprises an upper transparent layer, a lower transparent layer, a middle-layer grinding particle restraining module clamped between the upper transparent layer and the lower transparent layer, a plurality of stress sensors for measuring stress states of grinding particles and a controller, wherein the middle-layer grinding particle restraining module comprises a cavity for containing photoelastic particles, a baffle and a force application mechanism; a gap is formed in the side surface of the cavity; the baffle is mounted at the gap of the cavity; the force application mechanism is arranged at the bottom of the cavity; an extrusion part of the force application mechanism penetrates through a base plate of the cavity and is in contact with the photoelastic particles; the upper transparent plate, the lower transparent plate, the extrusion part of the force application mechanism, the cavity and the baffle form a middle-layer closed containing cavity for containing the photoelastic particles; the middle-layer grinding particle restraining module is provided with the multiple stress sensors; the stress sensors are connected with the signal input end of the controller; the force application mechanism is connected with the signal output end of the controller. The grinding particle restraining device has the beneficial effects that force chain collection aiming at the photoelastic particles is realized, and the shape can be adjusted according to different processing objects.

Owner:ZHEJIANG UNIV OF TECH

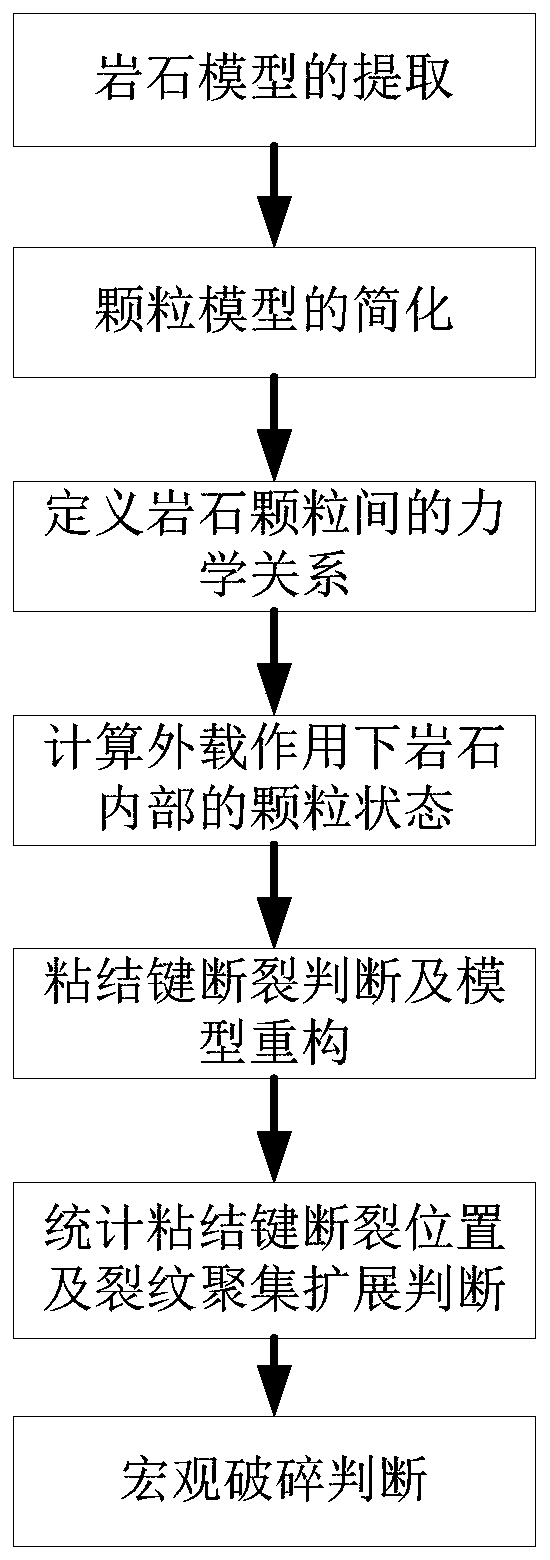

Method for realizing visualization of rock crushing process based on EDEM

ActiveCN111259593ARealize visualizationData processing applicationsSustainable transportationMacroscopic scaleClassical mechanics

The invention discloses a method for realizing visualization of a rock crushing process based on an EDEM. The method comprises the steps of constructing a rock physical model; obtaining rock particleposition information and establishing a force chain network model; defining a mechanical relationship of bonding bonds among particles in the model and acquiring intrinsic mechanical parameters of therock; calculating bond bearing information in the force chain network model under the action of an external load, judging the bond by utilizing a fracture criterion of the bond, judging whether crackaggregation intersection is formed or not, and when two sections of the crack are expanded to the surface of the rock, enabling the rock to form macroscopic fracture. According to the invention, thefracture position information and model reconstruction information of the bonding bond in the whole process are calculated to realize visualization of the rock crushing process; the stress change of the bonding bonds in the crushing process is analyzed from the microcosmic perspective, the fracture sequence of the bonding bonds in the crushing process is analyzed from the microcosmic perspective,the rock crushing characteristics are analyzed from the macroscopic perspective, visualization of the rock crushing process is achieved, and the rock crushing mechanism is conveniently analyzed and researched.

Owner:JIANGXI UNIV OF SCI & TECH

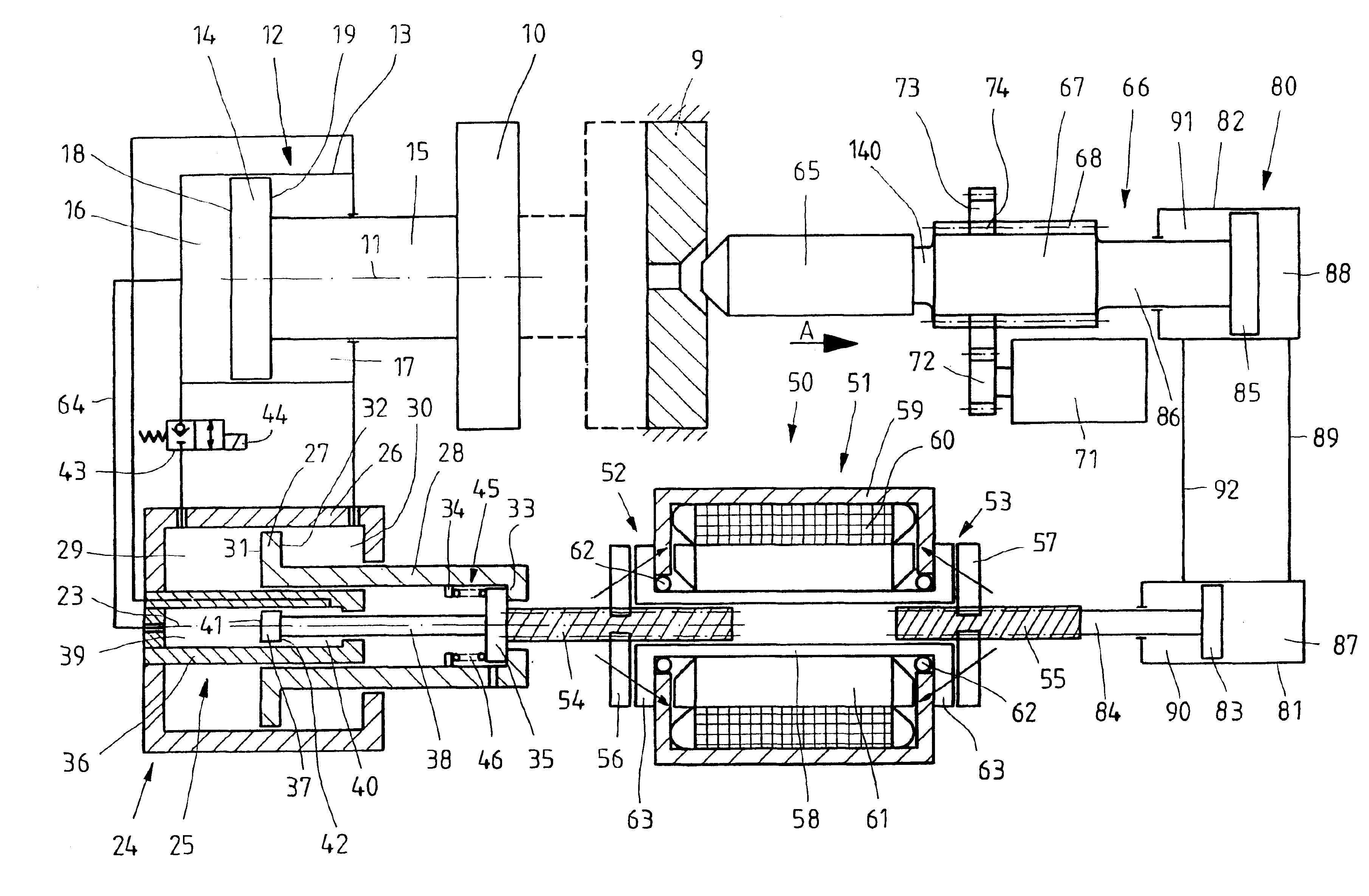

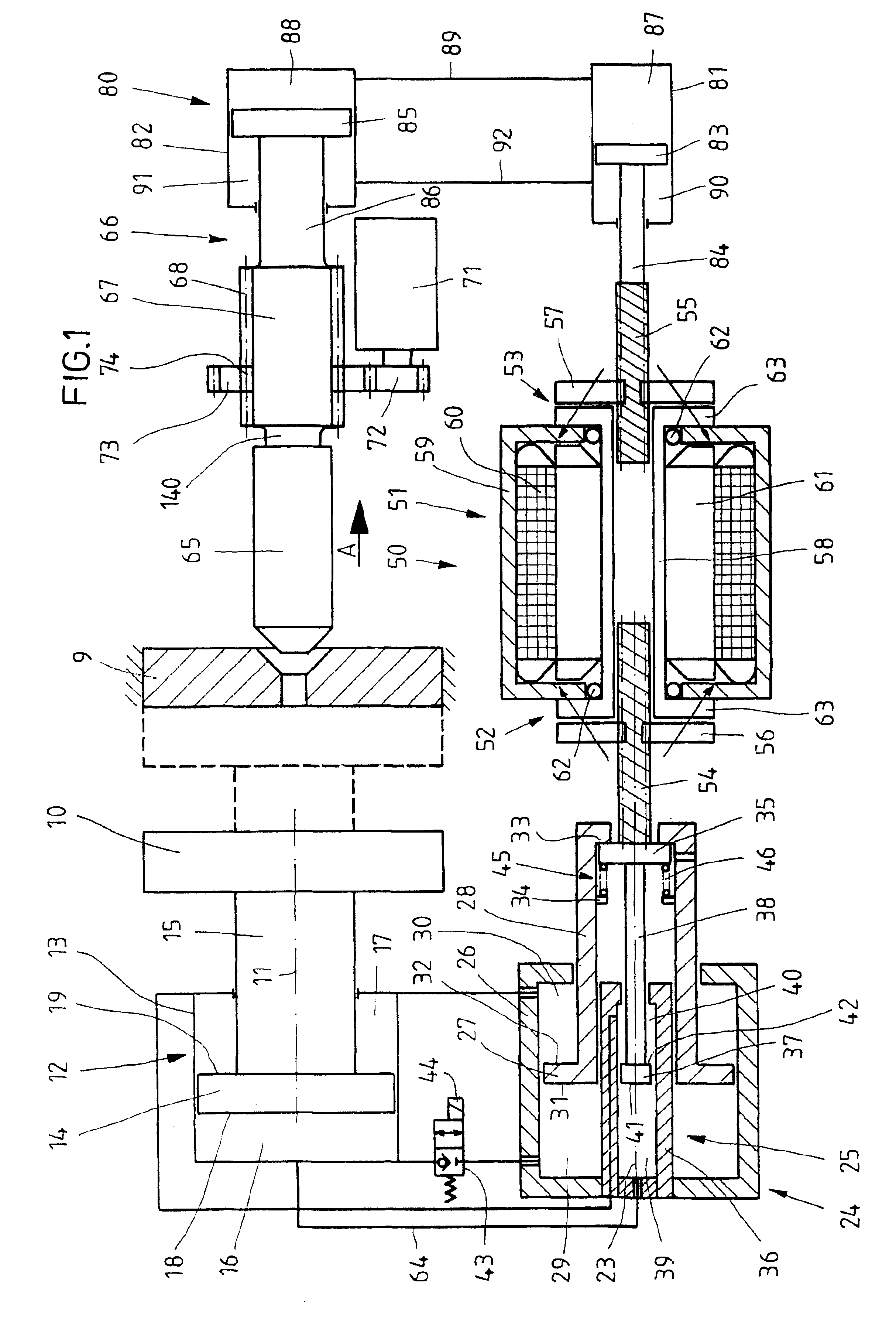

Drive device for displacing two linearly moveable components pertaining to a plastic injection moulding machine

InactiveUS6913456B2Not easy to wearSimple and low-cost constructionFood shapingLinear motionEngineering

A drive device which is intended for displacing two linearly movable components of a plastics injection-molding machine at least partly at successive times, in particular for displacing the injection unit for bringing the injection nozzle into contact with a mold and for displacing the injection mechanism for injecting polymer into the mold. With a known drive device, arranged downstream of an electric rotating motor are two clutches, by which rotational movements are transmitted on the basis of frictional engagement, and with which wear accordingly occurs. Each clutch is followed by a threaded drive, by which the rotational movement of the output element of a clutch is transformed into the linear movement of the machine component to be displaced. To make the known drive device for a plastics injection-molding machine less susceptible to wear and less costly in a first way the threaded drive is arranged between the electric motor and the two clutches and, for displacing the one movable component, the linearly movable drive output element of the threaded drive is able to be moved beyond the displacement distance necessary for displacing the other movable component. In a second way the electric motor is an electric linear motor with a linearly movable drive output element, arranged downstream of which in the force chains are the two clutches, and for displacing the one movable component, the drive output element is movable beyond the displacement distance necessary for displacing the other movable component.

Owner:BOSCH REXROTH AG

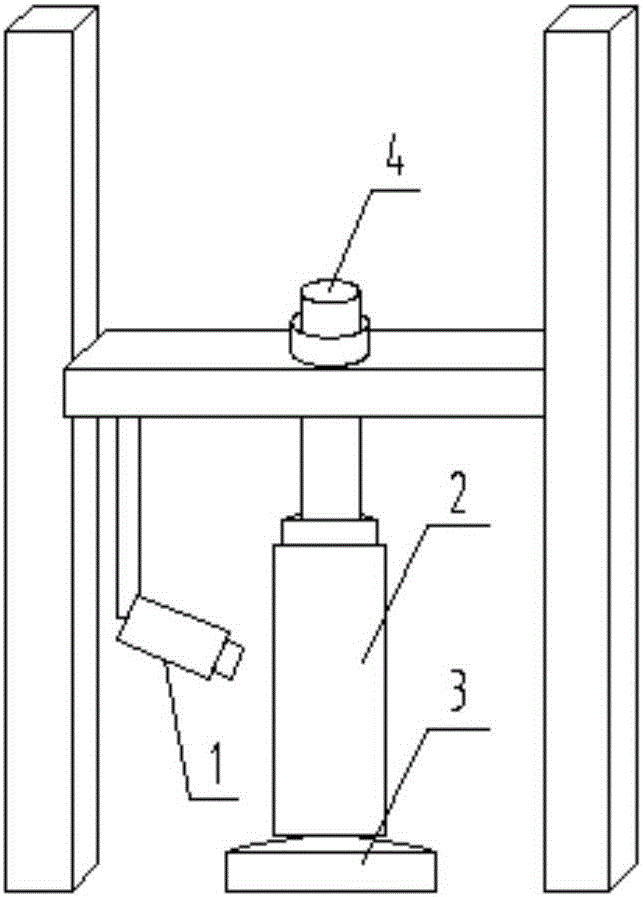

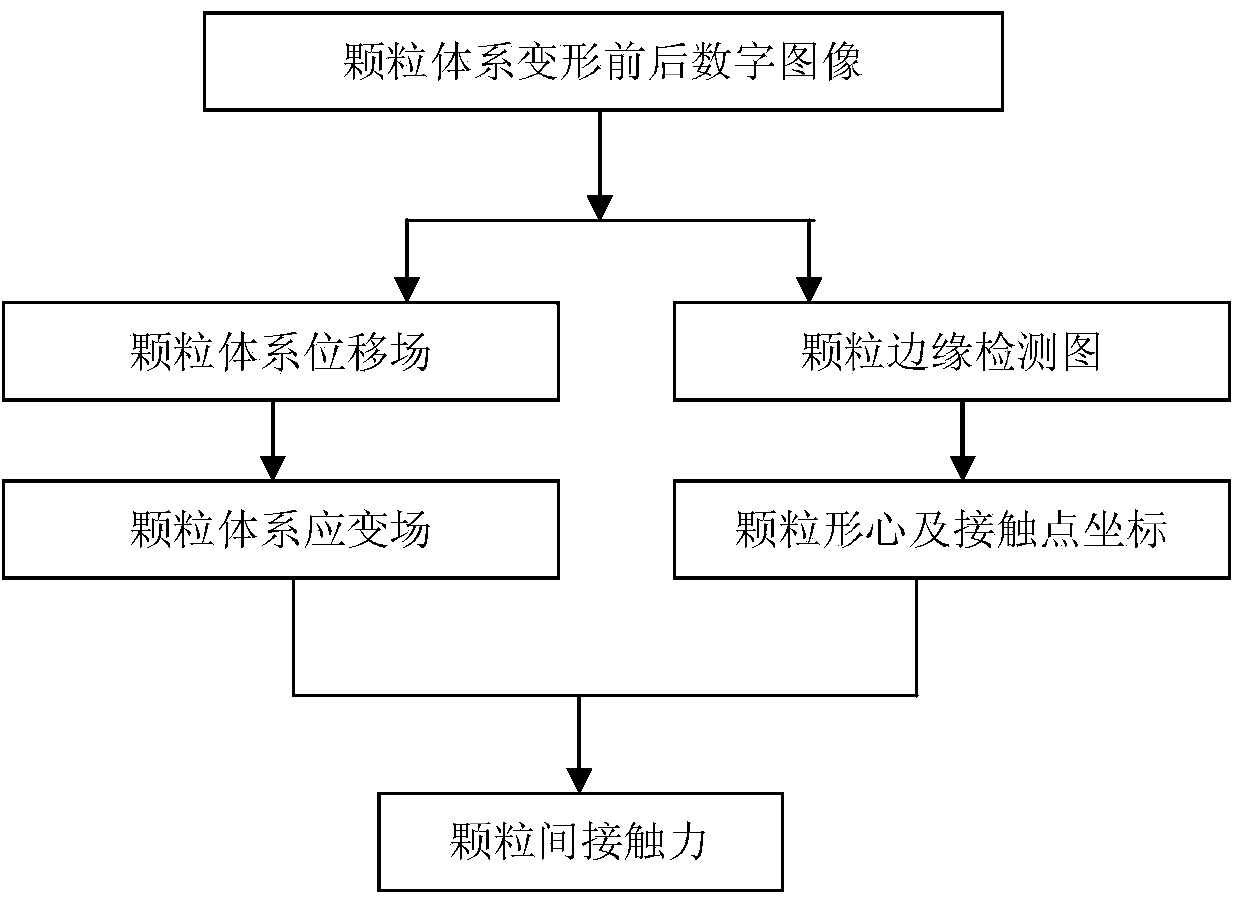

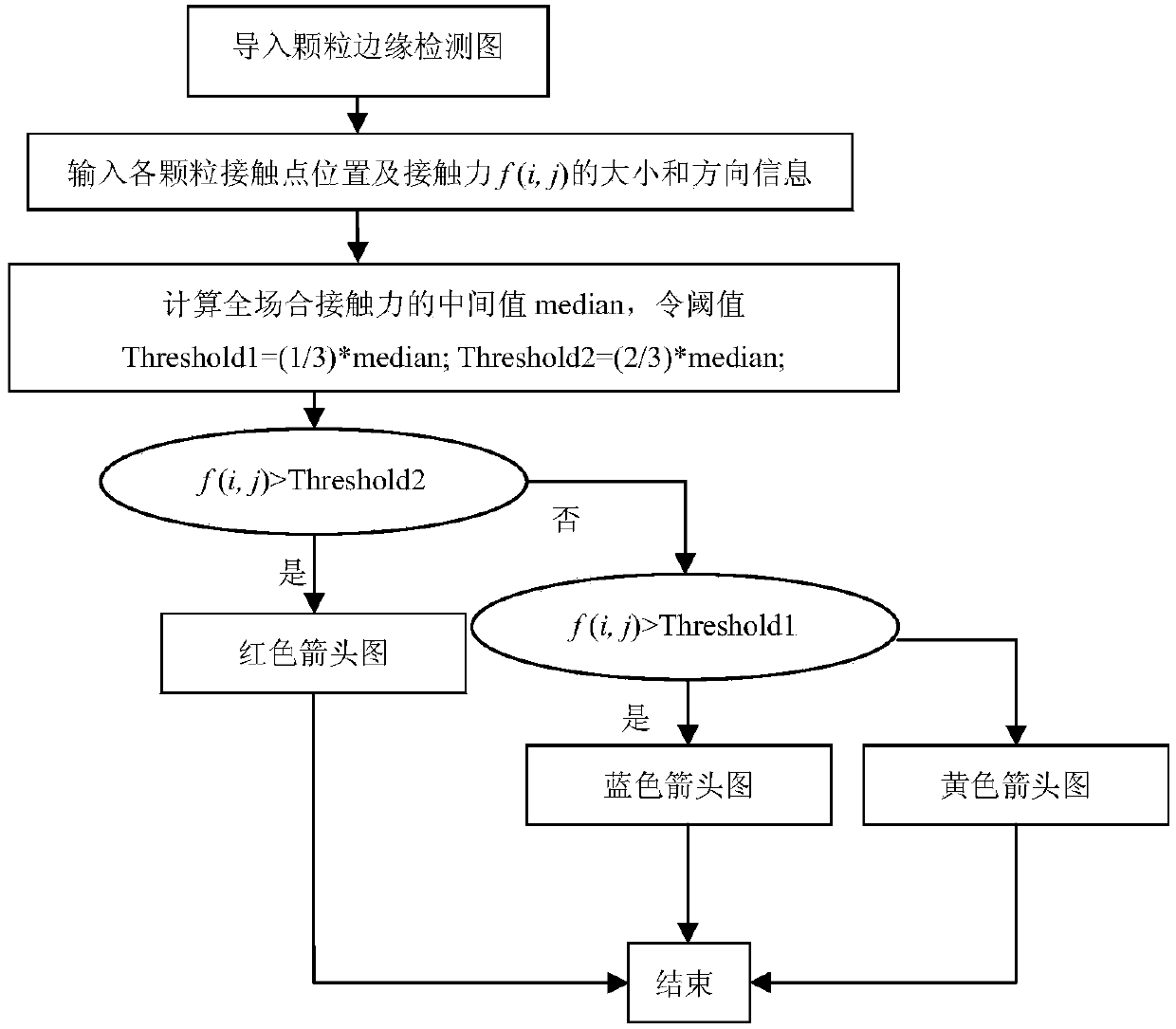

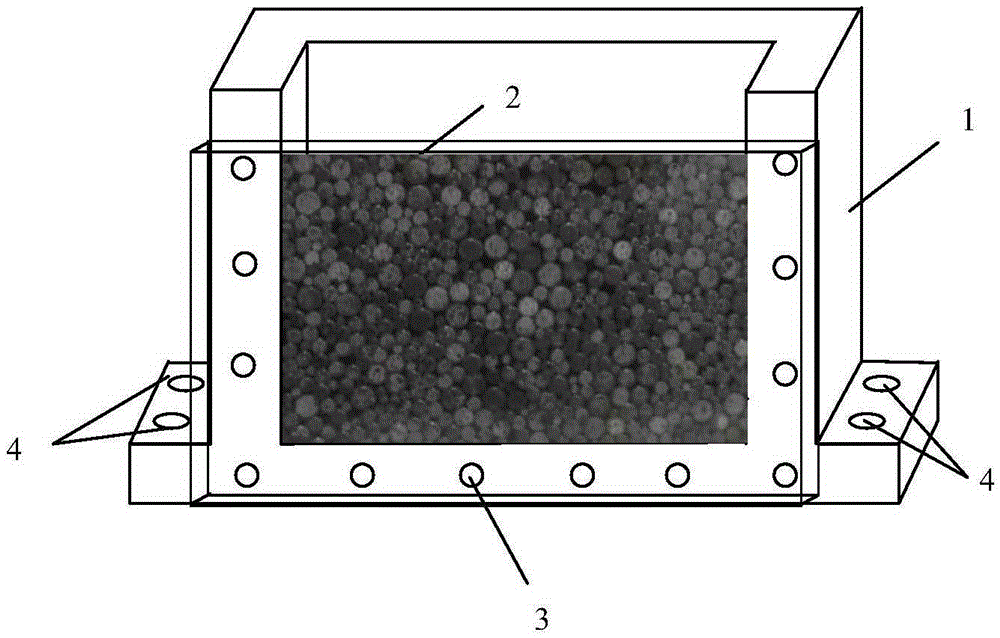

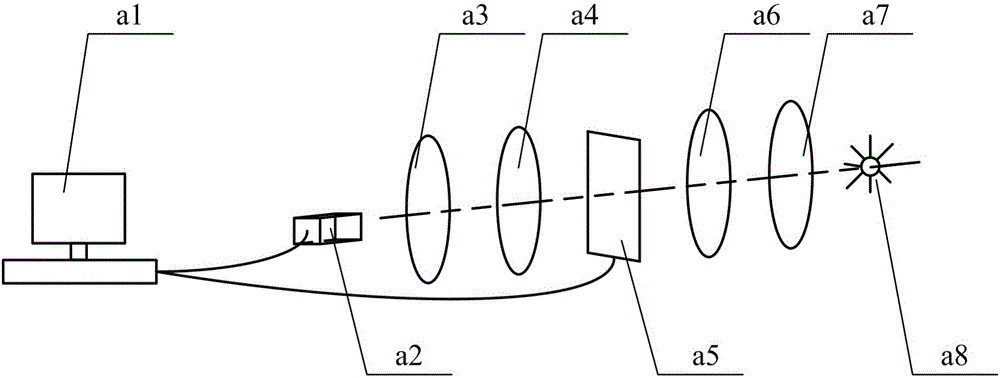

Method for identifying granular system power transmission chain

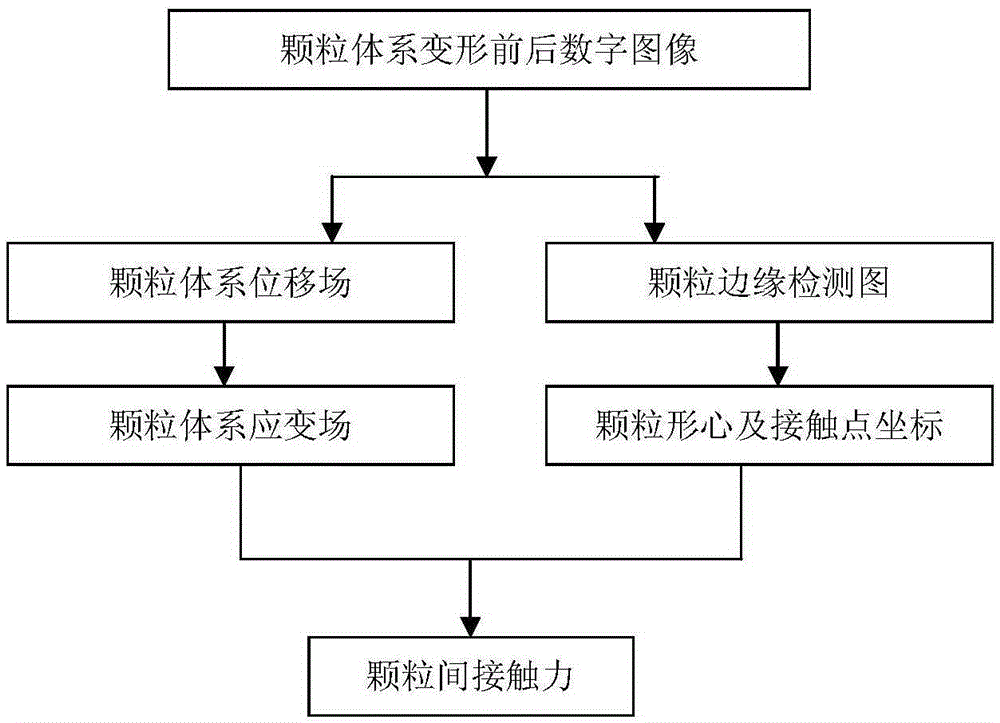

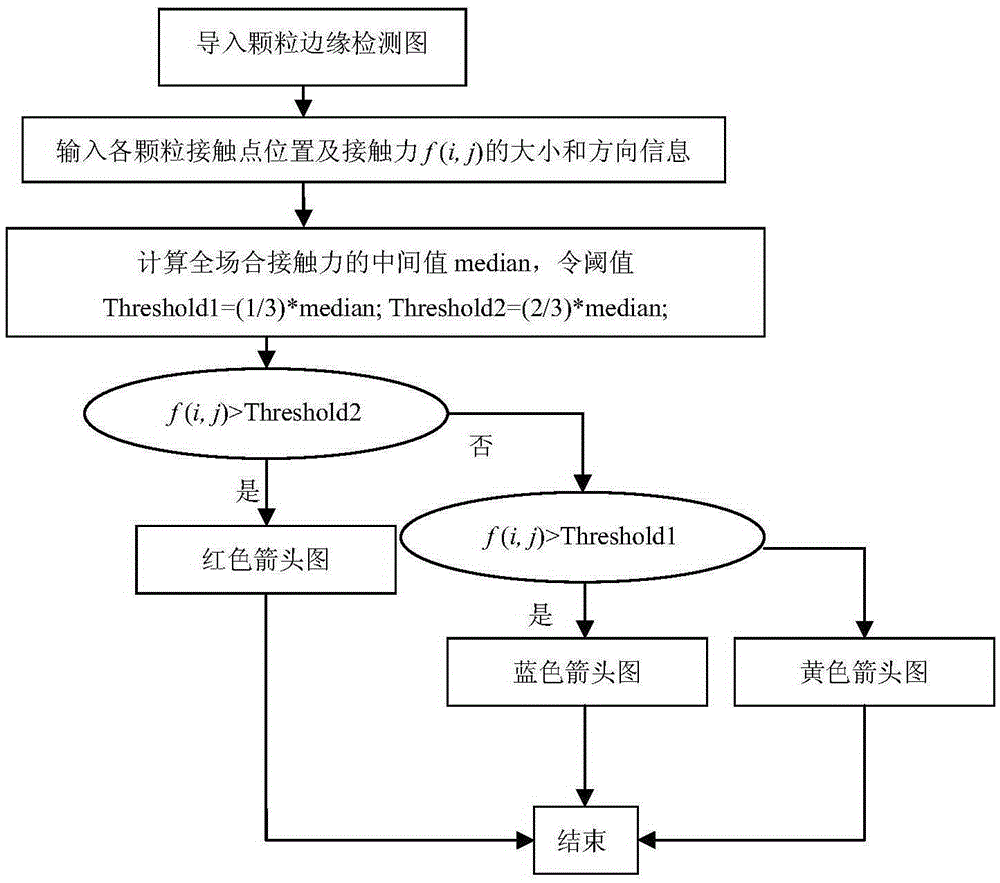

ActiveCN104007047APromote research progressSimple methodImage analysisSpecial data processing applicationsForce equilibriumGraphics

The invention belongs to the technical field of granular system power transmission chain identification, and relates to a method for identifying a granular system power transmission chain. The method includes the steps that firstly, a granular system is loaded, and granular system images before and after deformation are collected to be used as an original image and a target image respectively; then, the original image and the target image are analyzed, and after a displacement field and a strain field in the granular system surface of the target image at the corresponding moment are obtained, the stress of each point is obtained according to the strain of each point in the strain field; afterwards, image edge detection is conducted on the target image, granular centroids are identified, the coordinates of the granular centroids and the position coordinates of contact points of all granules are read, a force equilibrium and torque equilibrium equation is established for each granule, and the size and orientation of contact force at different contact points on all the granules are acquired through calculation; at last, the contact force of each granule is drawn, and the graph which is continuously represented by the contact force between adjacent granules is the path of the power transmission chain. The method is simple, scientific in principle, convenient and flexible to use, high in practicability, large in development prospect and wide in applied range.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

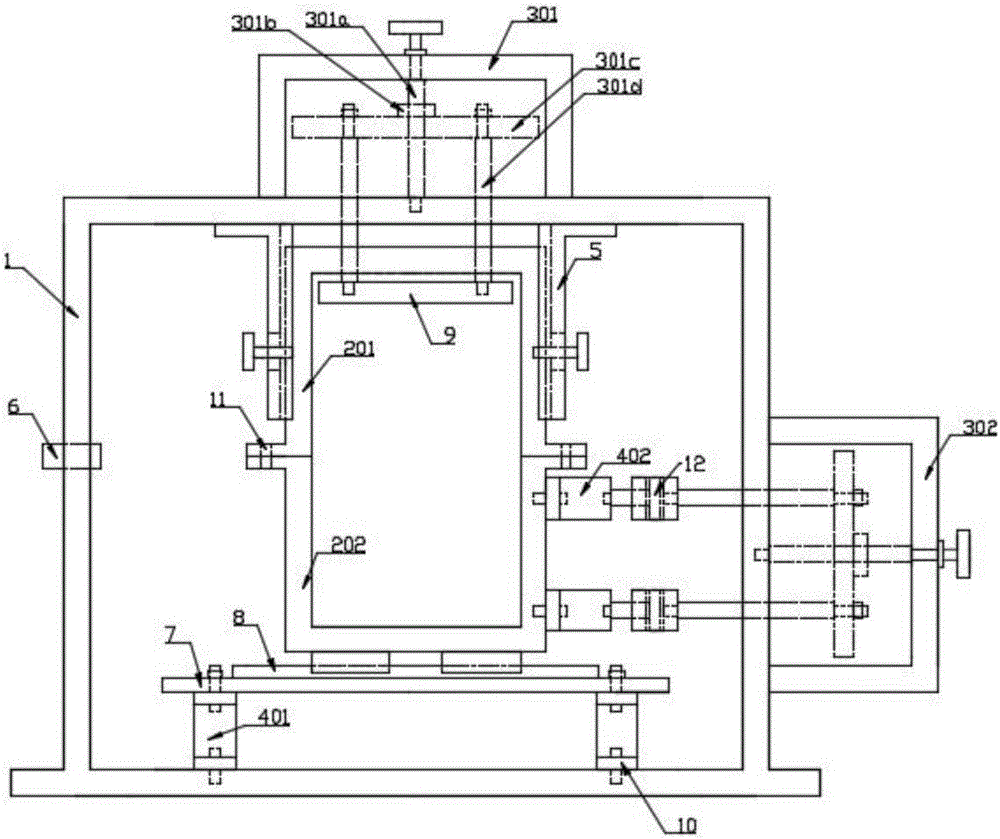

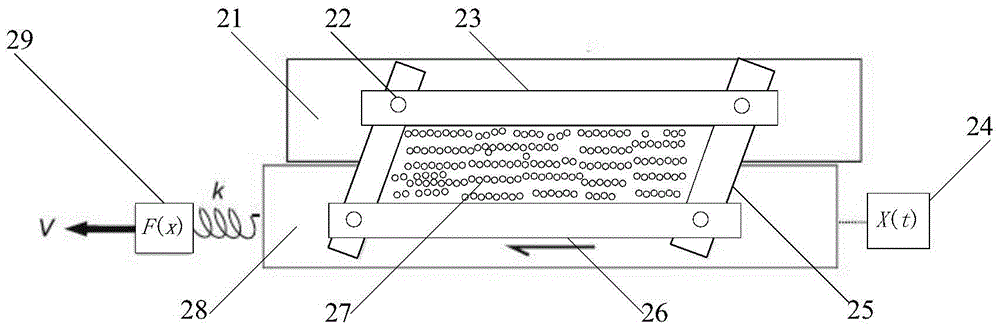

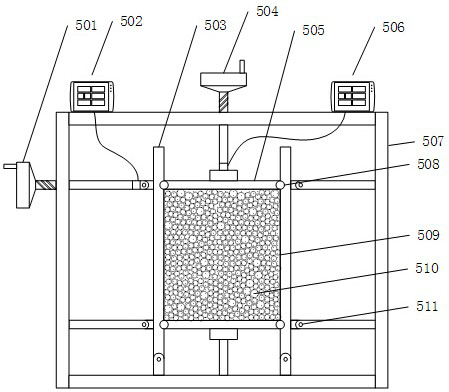

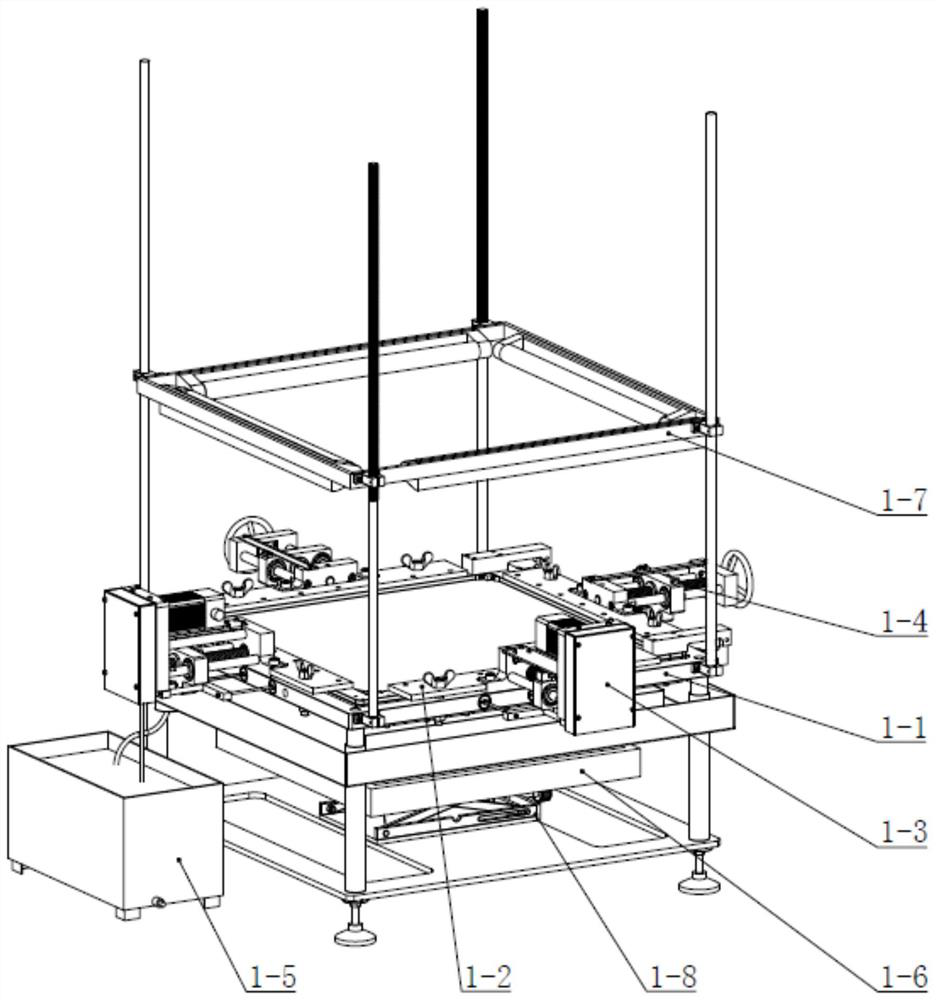

Particle material contact stress visualization test loading device and using method thereof

ActiveCN110208080AMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesStress distributionParticle mechanics

The invention, which relates to the technical field of photoelasticity and particle mechanics, discloses a particle material contact stress visualization test loading device comprising a photo-elasticexperiment device and a loading device that work independently. The loading device includes a rectangular frame; a horizontal baffle is connected to the middle part of the upper end of the rectangular frame by a vertical axial spiral head and a vertical baffle is connected to the middle of the front side of the rectangular frame by a horizontal shearing spiral head. In addition, the invention also discloses a using method of the device. A particle sample is loaded by the loading device; the dynamic stress change of the particle sample is dynamically captured by using the photo-elastic experiment device; and then the stress change image is analyzed by a computer. According to the invention, the contact stress state of the particle material can be studied deeply by three kinds of loading modes of the loading device; the visual image displaying of the stress distribution (force chain) of the particle material can be provided by using the photo-elastic experiment device; and the image isanalyzed by using computer software to obtain the stress distribution of all positions.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Pull rod lock mode hydraulic tyre vulcanizer

The invention discloses a hydraulic tire curing press with a pull rod locking module. The invention consists of a frame consisting of a lower beam and a supporting part, an upper beam, an upper and lower thermal plate, an opening and closing die cylinder, a central structure and a pressurized structure. The upper beam is driven by the opening and closing die cylinder and has freedom of moving fromthe top to the bottom. An upper die and a lower die are directly arranged between the upper thermal plate and the lower thermal plate and are respectively fixed connected with the upper beam and thelower beam. The pressurized structure consists of a pulling rod, a pressurized splint and a pressurized cylinder. The pulling rod is evenly arranged corresponding to the axle wire of in the tire module. The upper terminal of each pulling rod is fixedly connected with the upper beam and the lower terminal of each pulling rod is fixedly connected with the pressurized plate traveling through the lower beam; the pressurized cylinder is fixed on the bottom of the lower beam and the piston terminal of the cylinder is fixedly connected with the pressurized plate; the pulling rod is arranged with a locking die structure and an adjusting die structure. The invention increases the working precision and reducing the manufacturing cost, at the same time, the invention also has the advantages of avoiding the problem of oil leaking and contamination, being convenient for the cylinder maintenance, simplifying the forcing chain of the locking die force and reducing the manufacturing cost of the curingpress.

Owner:SINO ARP TIRES EQUIP TECH (SUZHOU) CO LTD

Mechanism for converting mechanical energy for wind powered energy systems

InactiveUS20050225092A1Improve efficiencyHigh energyEnergy industryWind motor combinationsPower cycleMechanical energy

An improved drive mechanism for a windmill has: (a) a drive chain driven into movement by a wind wheel shaft driven into rotation by wind movement against a wind wheel; (b) a drive chain sprocket driven by the drive chain and coupled to a force chain sprocket to correspondingly drive a force chain; (c) a chain pin coupled at one position to the force chain and also coupled to a captive slide; and (d) a pump rod connected to the slide and driven an equal distance in each direction by the driven slide in order to convert full mechanical force equally on both the full upstroke and the full downstroke of the pump rod. The improved drive mechanism improves the efficiency of the power cycle by transitioning to the full upstroke with only a minimal dwell on either end of the stroke for transition to movement in the opposite direction. Full mechanical force can thus be applied equally on both the full upstroke and the full downstroke. A high reliability oil bucket chain link lubrication system is used to flood the entire chain mechanism with abundant oil to avoid the problems in traditional pumps of loss of priming, seal wear, etc.

Owner:CONLON THOMAS R

A Method for Identifying Kinetic Chain of Granular System

ActiveCN104007047BPromote research progressSimple methodImage analysisSpecial data processing applicationsForce equilibriumContact force

The invention belongs to the technical field of granular system power transmission chain identification, and relates to a method for identifying a granular system power transmission chain. The method includes the steps that firstly, a granular system is loaded, and granular system images before and after deformation are collected to be used as an original image and a target image respectively; then, the original image and the target image are analyzed, and after a displacement field and a strain field in the granular system surface of the target image at the corresponding moment are obtained, the stress of each point is obtained according to the strain of each point in the strain field; afterwards, image edge detection is conducted on the target image, granular centroids are identified, the coordinates of the granular centroids and the position coordinates of contact points of all granules are read, a force equilibrium and torque equilibrium equation is established for each granule, and the size and orientation of contact force at different contact points on all the granules are acquired through calculation; at last, the contact force of each granule is drawn, and the graph which is continuously represented by the contact force between adjacent granules is the path of the power transmission chain. The method is simple, scientific in principle, convenient and flexible to use, high in practicability, large in development prospect and wide in applied range.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

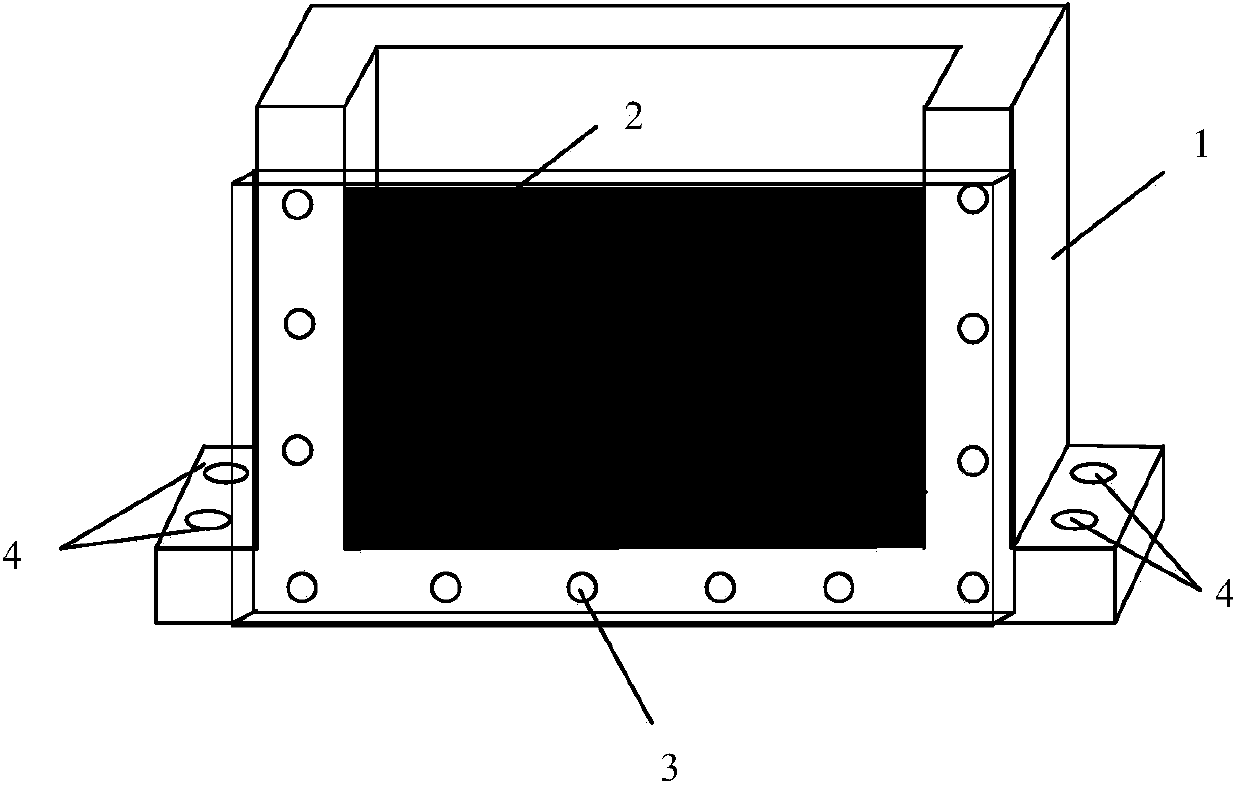

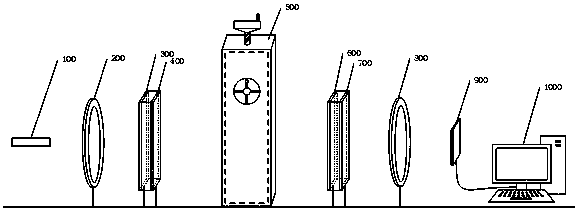

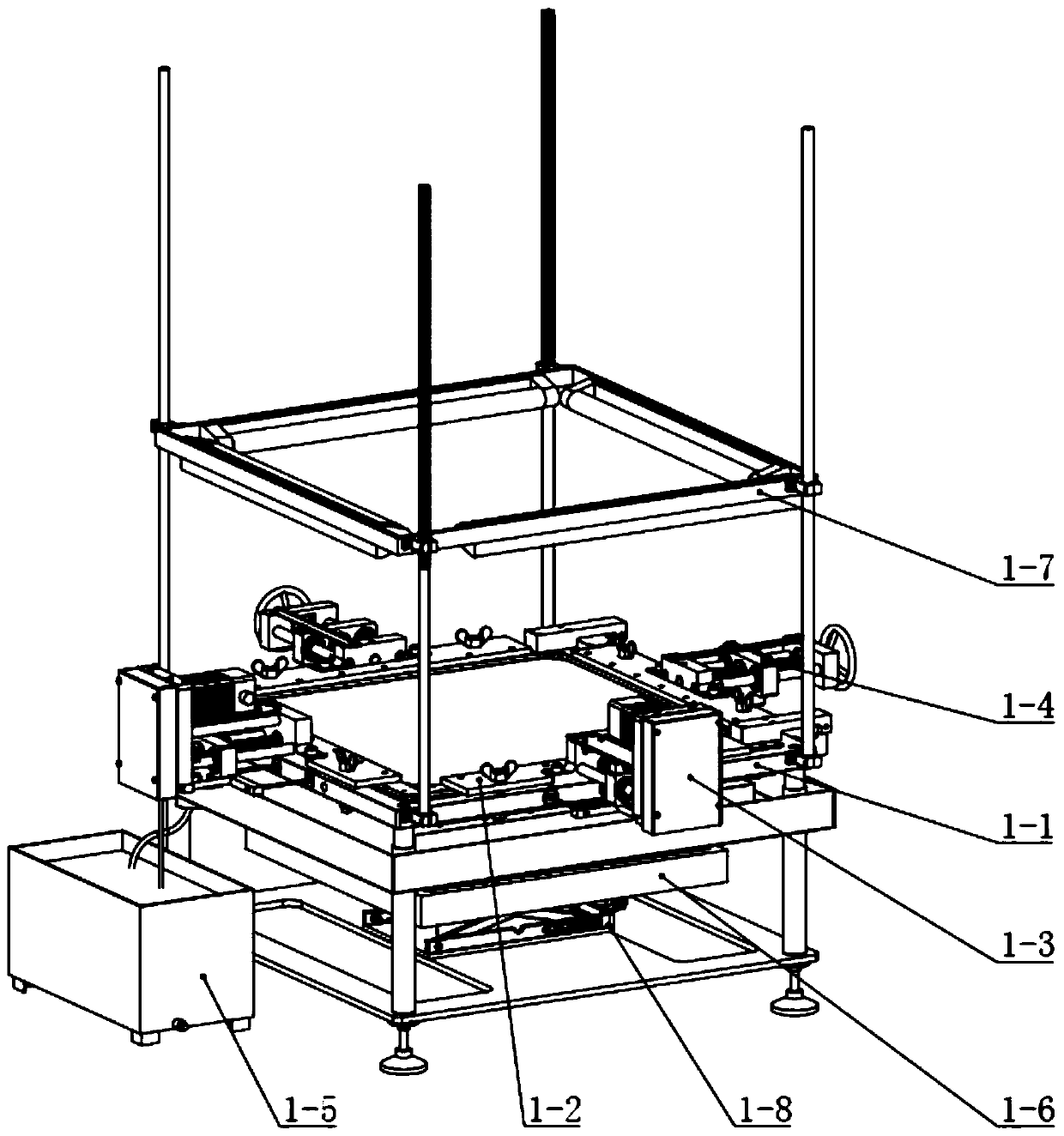

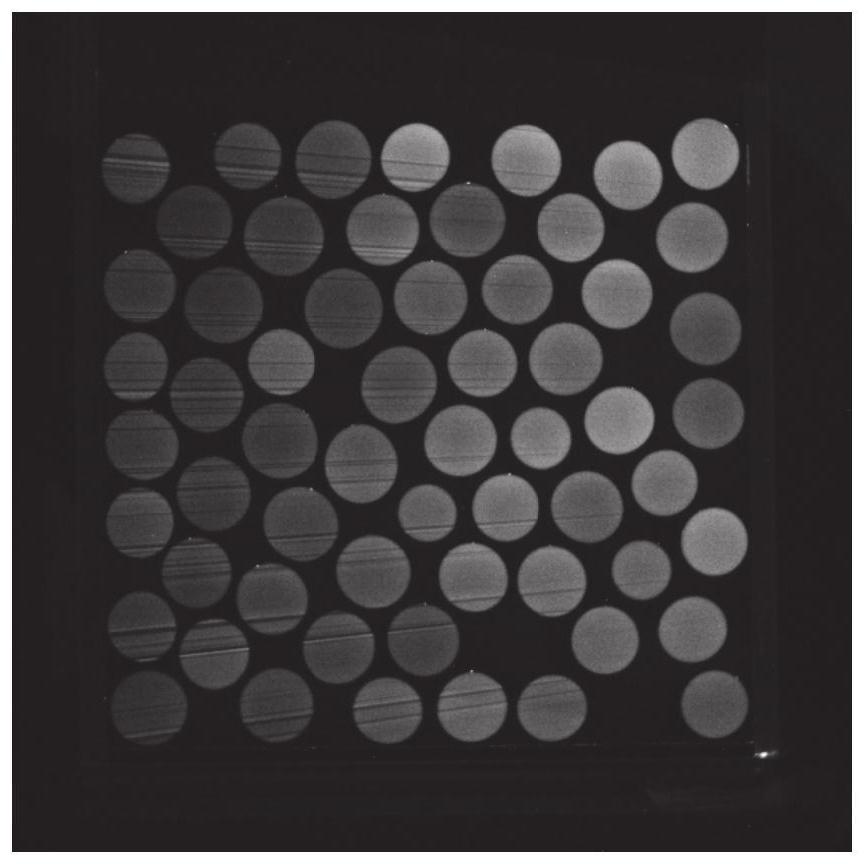

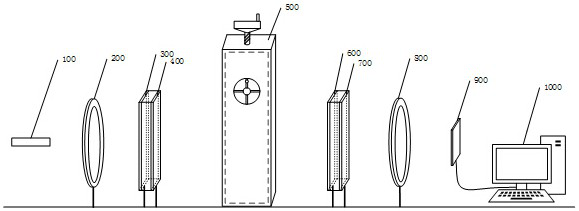

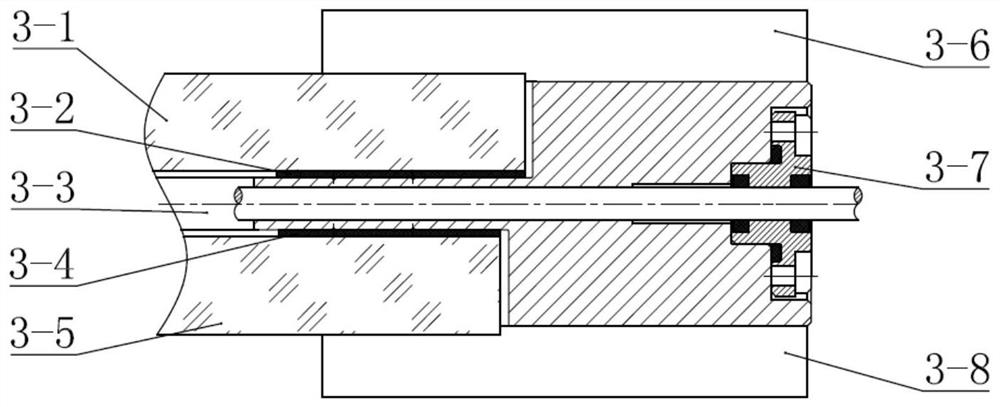

Photoelastic instrument used for observing and recording granular material bearing structure configuration and features

The invention relates to the field of precision measurement, in particular to a photic double refraction principle based instrument used for observing and recording bearing structure configuration and features of a force chain in a granular system in real time. Functions of a photoelastic device, a multi-way loading system, a data collection display system, an industrial camera and a granular placement instrument are integrated, compressing and shearing of granular materials can be observed, and the features of the contact force chain can be visually observed. The photoelastic instrument is simple in operation, multiple in loading mode, and the comprehensive function of visualizing and integrating displacement, force and photoelastic images is achieved.

Owner:BEIHANG UNIV

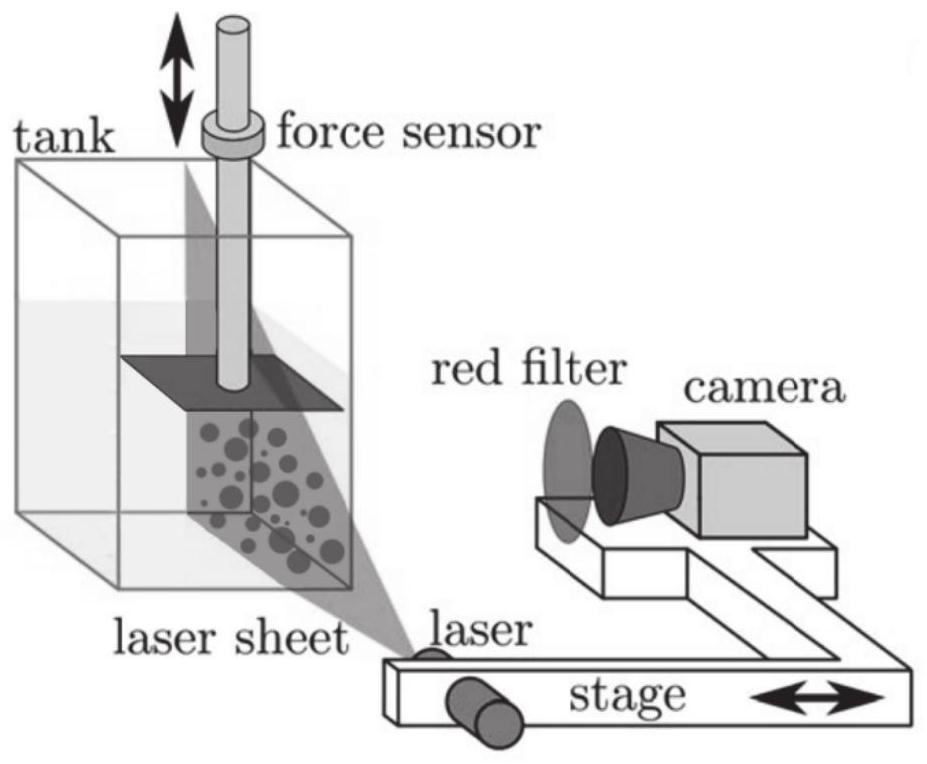

Particulate matter fluid-solid coupling photoelastic experiment device and using method thereof

The invention relates to a particulate matter fluid-solid coupling photoelastic experiment device and a using method thereof, and belongs to the technical field of photoelastic experiments. The deviceis mainly composed of a bearing frame, a sealed container, a loading system, a water pressure supply system and a light source system. The device is applied to research on force chain structure evolution and action of the discrete particles in a specific water pressure environment, and the force chain evolution condition in a discrete particle system under the fluid-solid coupling condition can be observed very conveniently. In combination with extraction and analysis of digital images in the later period, spatial physical parameters such as displacement and rotation and mechanical parameterssuch as inter-particle contact normal and tangential force are calculated from the particle scale, and force chain strength distribution and configuration composition are obtained on the mesoscopic scale. within combination with a stress-strain relationship directly obtained by an experiment, multi-scale mechanical behavior research on the loose geologic body can be carried out deeply, a disaster-causing mechanism of the water environment on the loose geologic body is revealed, and an experiment basis is provided for constructing an engineering geologic safety control theoretical system in China.

Owner:UNIV OF SCI & TECH BEIJING +1

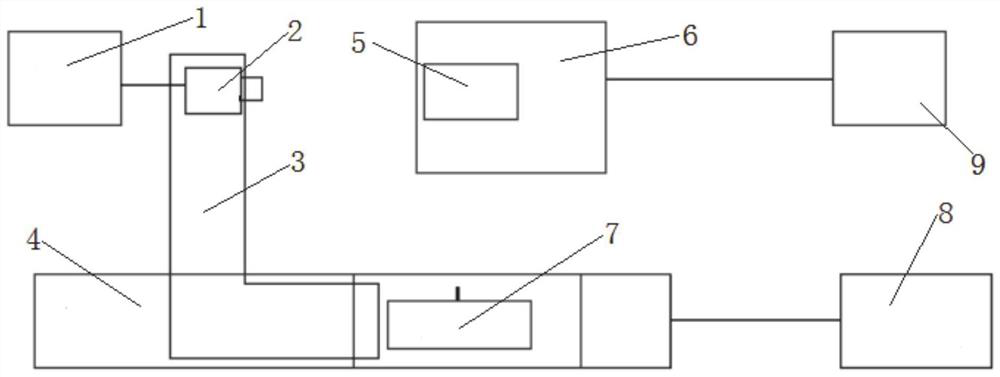

Device and method for identifying internal force chain of three-dimensional particle system

PendingCN114216820AAccurate identificationSimple structurePhase-affecting property measurementsEngineeringComputational physics

The invention provides a device and a method for identifying an internal force chain of a three-dimensional particle system. The device comprises a gradienter used for placing an experiment box; the laser is arranged on the gradienter and is used for turning on laser before the camera shoots, so that a laser surface is overlapped with the inner wall of the experiment box; the pressure testing machine is arranged on one side of the gradienter and is used for applying sequentially increased pressure or sequentially reduced pressure to the particles in the experiment box; the camera is connected with the gradienter and used for shooting images of the particles; the gradienter, the laser, the pressure testing machine and the camera are all connected with the computer; and the computer is used for obtaining the three-dimensional form of the particle system according to the image shot by the camera so as to identify the force chain.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

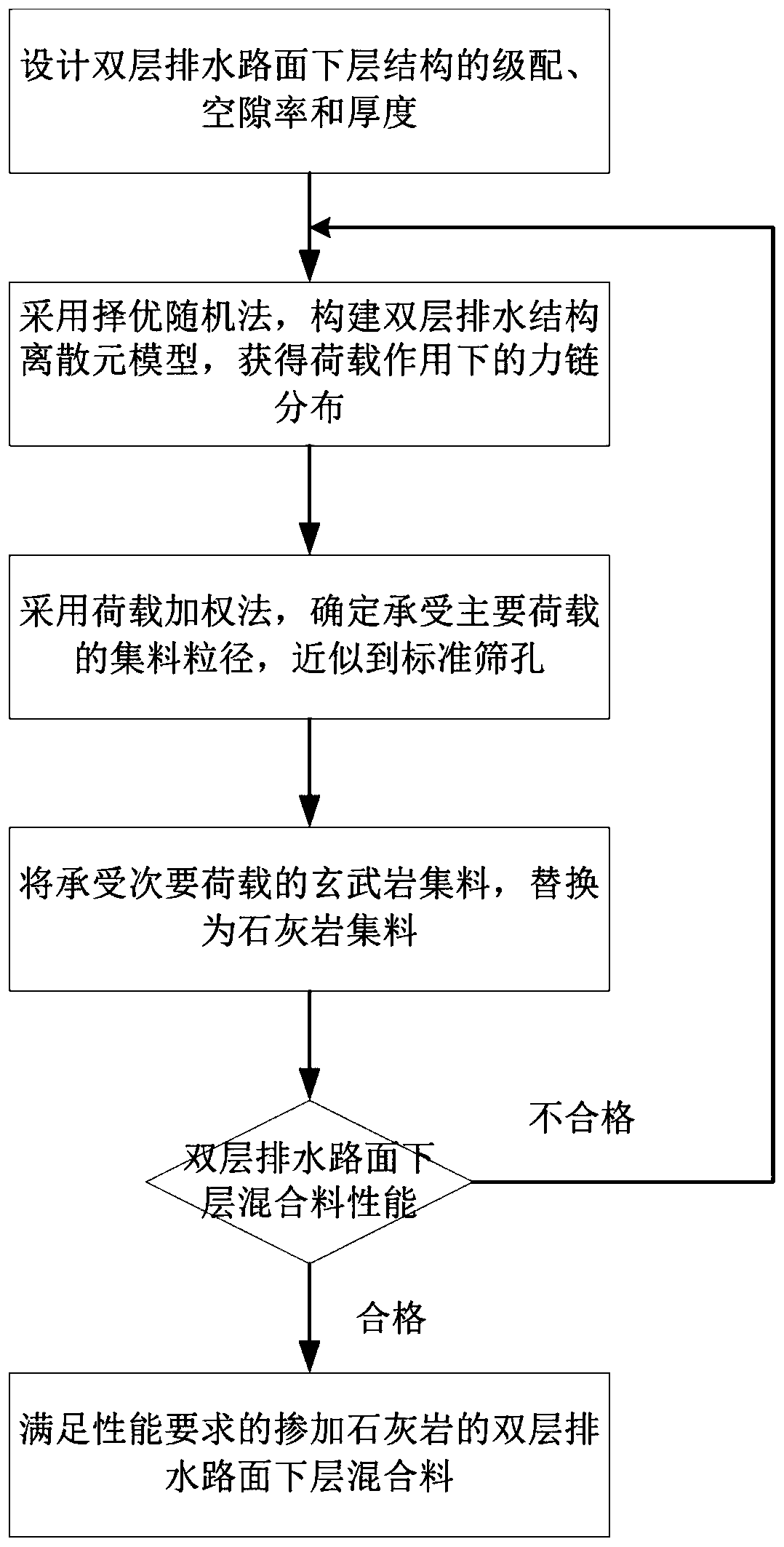

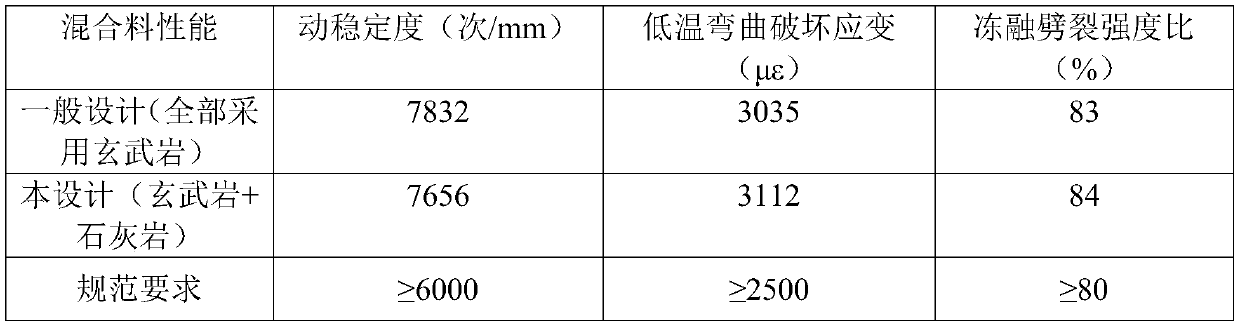

Method of applying limestone to lower-layer structure of double-layer drainage pavement

ActiveCN110331632AReduce construction costsIn situ pavingsPaving gutters/kerbsPorosityRoad engineering

The invention discloses a method of applying limestone to a lower-layer structure of a double-layer drainage pavement and belongs to the technical field of road engineering. The method comprises the following steps: the aggregate grading, the porosity and the thickness of the lower-layer structure of the double-layer drainage pavement are designed; multiple groups of discrete element digital models of the double-layer drainage pavement structure are constructed, and a load is applied to obtain force chain distribution of the load in the lower-layer structure of the double-layer drainage pavement; the average particle size of aggregates, bearing the main load along a force chain path, in the mixture is determined and corresponds to the closest standard sieve mesh interval; the aggregates between the sieve mesh intervals are made of basalt or dolerite, and the aggregates in a size of other sieve meshes are limestone; and the performance of an asphalt mixture of two stone materials is verified. According to the method in the invention, the aggregates which bear the main load are made of basalt or dolerite, and the other aggregates are limestone, the stress characteristics of the two kinds of aggregates are fully utilized, and the cost of the lower-layer structure of the double-layer drainage pavement is effectively reduced while the performance of the asphalt mixture is ensured.

Owner:SOUTHEAST UNIV

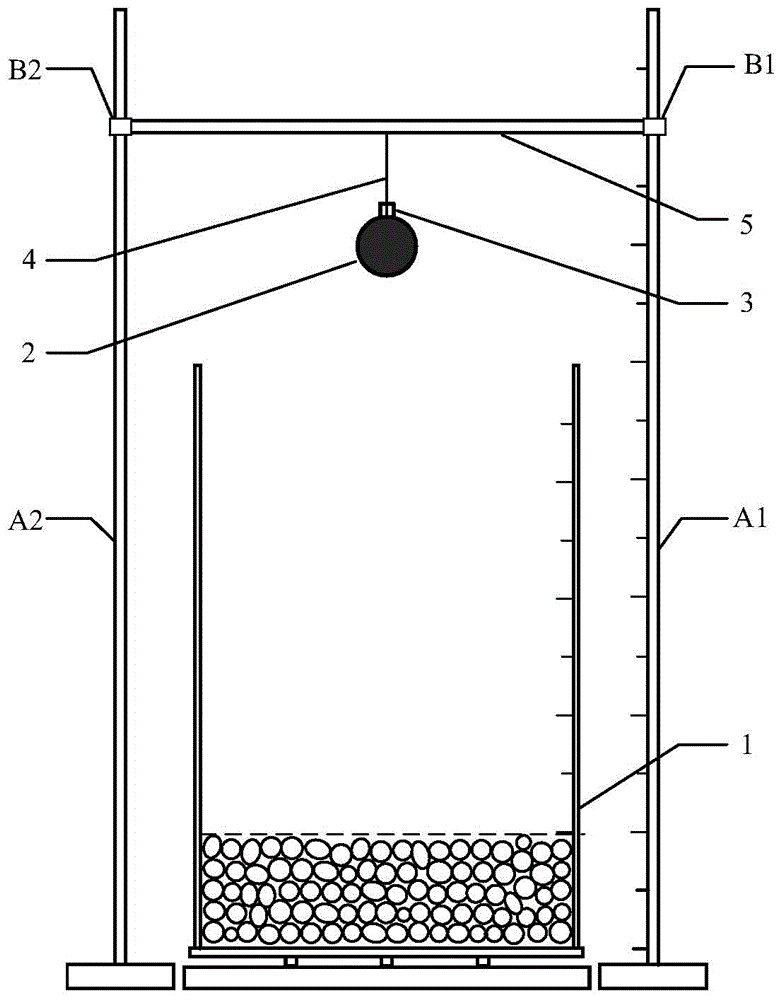

Granular material buffer performance measuring system

InactiveCN104964901ARealize impactAccurate measurementMaterial analysisImpact systemInelastic collision

The invention provides a granular material buffer performance measuring system. A granular substance is a rapid energy dissipating system, and energy is consumed mainly through intergranular non-elastic collision and sliding friction, and an intergranular force chain structure can increase the action area and the action time of external load, so impact load is certainly buffered, and destroys brought by the impact are reduced. The measuring system is composed of a fixed support, a granule impact system, a mechanical response measuring system and an image acquisition system, so vertical impact to the granular substance is realized, the acceleration of an impact substance and the impact force born by a baseboard can be accurately measured, the change of the surface form of the granule and the movement of the impact substance in the impact process is recorded, and a reliable device is provided for accurately measuring the buffer performance of the granular substance. The device can realize control and adjustment of the thickness of a granule layer and the impact height, and the influences of the thickness of the granule layer and the impact height on the buffer characteristic of the granule layer are researched.

Owner:DALIAN UNIV OF TECH

Dynamic Force Chain Observation Device of Abrasive Group in Flexible Polishing

ActiveCN104316231BIdeal control parametersRealize simulationForce measurement by measuring optical property variationImaging processingWear particle

The invention provides a dynamic force chain observation device of a flexible polishing wear particle group. The dynamic force chain observation device comprises an image processing device and a particle control device. The image processing device comprises a light source generator, a light source collector and a data analyzer. The light source generator is located at the bottommost end of an observation region. The light source transmitted by the light source generator penetrates through a lower polarized light device and points to a particle control device in the observation region composed of the lower polarized light device and an upper polarized light device. The upper surface of the particle control device is covered with a transparent baffle. The light source collector is located over the upper polarized light device. The light source collection view of the light source collector covers the light source transmitted out by the upper polarized light device. The data input end of the data analyzer is connected with the data output end of the light source collector. The data signal output end of the data analyzer is connected with a display screen of the data analyzer. The dynamic force chain observation device has the advantages that the external applying parameters of photoelastic particles can be detected in real time, the motion state of the photoelastic particles can be adjusted through sliding blocks, and simulation of the flexible polishing machining test is achieved.

Owner:菏泽建数智能科技有限公司

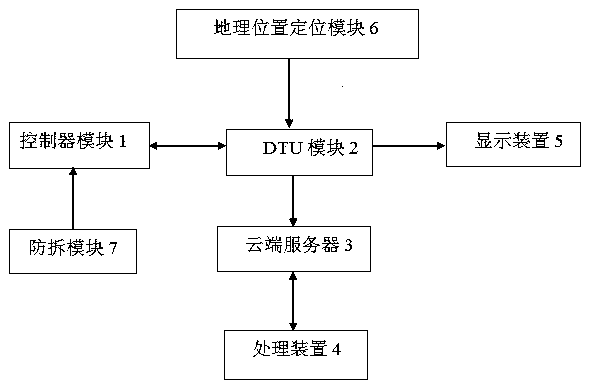

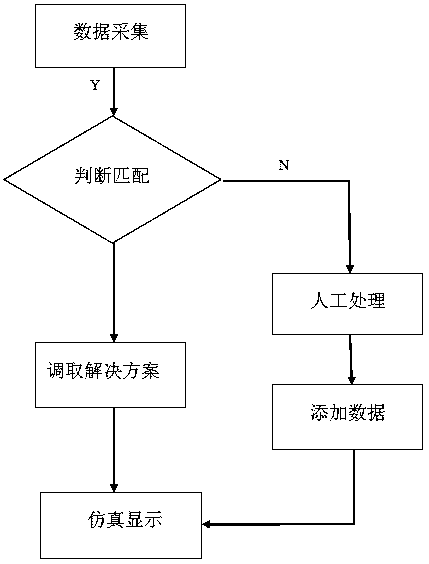

Abrasive particle constraining device for particle force chain observation

InactiveCN108693814ARealize remote maintenance functionAvoid duplication of effortProgramme control in sequence/logic controllersThe InternetEngineering

The invention relates to an abrasive particle constraining device for particle force chain observation, which comprises an upper transparent layer, a lower transparent layer and a controller module, and is characterized by further comprising a DTU module and a cloud server, wherein the controller module is connected with the DTU module, and the DTU module is wirelessly connected with the cloud server. The cloud server is internally provided with a virtual reality diagnosis and maintenance module, wherein the virtual reality diagnosis and maintenance module includes a fault database stored withfault information and an expert experience database stored with solutions corresponding to the fault information. Due to adoption of the technical scheme, the technicians need not to go to the site of the abrasive particle constraining device for particle force chain observation personally for troubleshooting in the case that there is no available network interface or Internet around for the abrasive particle constraining device for particle force chain observation, thereby realizing a function of remote maintenance for the abrasive particle constraining device for particle force chain observation.

Owner:上海前孟计算机科技有限公司

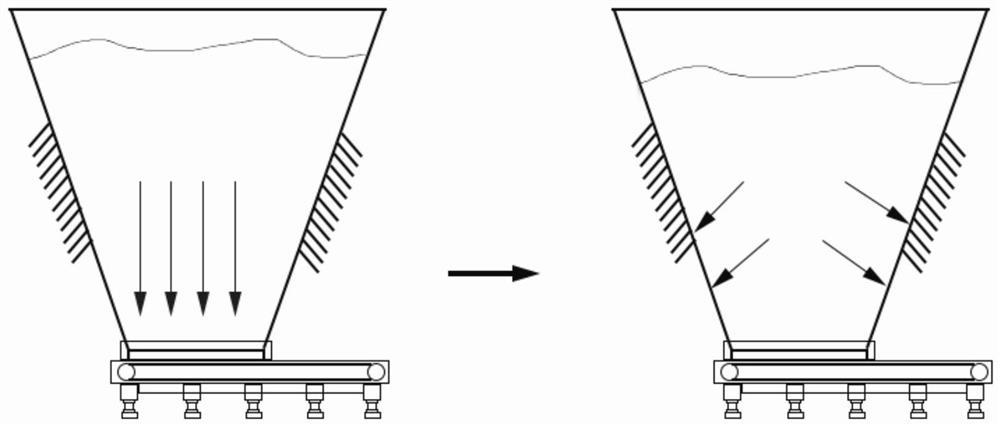

Method for reducing initial pressure of bottom of large material bin

The invention discloses a method for reducing the initial pressure of the bottom of a large material bin. The material bin, a material bin fixing device, a connecting device, a feeding device, a reinforcing bracket and lifting devices are included. A gap between the material bin and the feeding device is connected through the connecting device, the connecting device plays a role in material blocking and sealing, and material leakage and dust overflow are prevented. The material bin is fixed to the ground through the material bin fixing device, the feeding device is located below the material bin and used for conveying materials, and the lifting devices are installed below the reinforcing bracket and used for supporting the feeding device. By means of the lifting devices, the feeding device can rise or fall by a certain height. When the materials are contained in the material bin and the feeding device is ready to start to convey the materials, the lifting devices fall from the high position point by 20-120 mm. At the moment, the structure of a material force chain in the material bin is changed, the bin pressure is reduced, and the torque provided by a motor required for restarting the feeding device is reduced. When the materials in the material bin are completely discharged, the lifting devices rise and reset to the high position point.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Wear Particle Constraint Device for Particle Force Chain Observation

Owner:ZHEJIANG UNIV OF TECH

A contact stress visual test loading device for granular materials and using method thereof

ActiveCN110208080BMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesVisual testParticle mechanics

The invention relates to the technical fields of photoelasticity and particle mechanics, and discloses a loading device for a granular material contact stress visualization test, which includes an independently working photoelastic experimental device and a loading device. The loading device includes a rectangular frame, and the middle part of the upper end of the rectangular frame passes through a vertical axis. A horizontal baffle is connected to the screw head, and a vertical baffle is connected to the middle of the front side of the rectangular frame through a horizontal shearing screw head; a method of using it is also disclosed, wherein the particle sample is loaded by a loading device, and the photoelastic test equipment is used to load the sample. The dynamic stress change of the granular sample is dynamically captured, and finally the image of the stress change is analyzed by the computer. In the present invention, through the three loading modes of the loading device, in-depth research on the contact stress state of the granular material can be made, and the photoelastic experimental equipment can provide the most intuitive image display for the stress distribution (force chain) of the granular material, and Computer software is used to analyze the image to obtain the stress distribution at each position.

Owner:EAST CHINA JIAOTONG UNIVERSITY

A fluid-solid coupling photoelastic experimental device for particulate matter and method of using the same

The invention relates to a particulate matter fluid-solid coupling photoelastic experiment device and a using method thereof, and belongs to the technical field of photoelastic experiments. The deviceis mainly composed of a bearing frame, a sealed container, a loading system, a water pressure supply system and a light source system. The device is applied to research on force chain structure evolution and action of the discrete particles in a specific water pressure environment, and the force chain evolution condition in a discrete particle system under the fluid-solid coupling condition can be observed very conveniently. In combination with extraction and analysis of digital images in the later period, spatial physical parameters such as displacement and rotation and mechanical parameterssuch as inter-particle contact normal and tangential force are calculated from the particle scale, and force chain strength distribution and configuration composition are obtained on the mesoscopic scale. within combination with a stress-strain relationship directly obtained by an experiment, multi-scale mechanical behavior research on the loose geologic body can be carried out deeply, a disaster-causing mechanism of the water environment on the loose geologic body is revealed, and an experiment basis is provided for constructing an engineering geologic safety control theoretical system in China.

Owner:UNIV OF SCI & TECH BEIJING +1

A Calculation Method of Interparticle Contact Force and Recognition of Force Chain in 3D Granular System

ActiveCN106769436BPromote research progressImprove practicalityMaterial strength using tensile/compressive forcesForce chainContact force

The invention belongs to the technical field of particle system force chain recognition and relates to a contact force calculating and force chain recognizing method for particles in a three-dimensional particle system. The method comprises the steps of putting balls into a rigid container to form the three-dimensional particle system, utilizing a loading pressure head to pressurize the three-dimensional particle system, collecting an original sequence image and a target sequence image through an XCT scanner, utilizing a digital body related method to analyze the obtained original sequence image and the target sequence image to obtain stress of all points, then performing image edge detection on a target image, recognizing a particle centroid, reading coordinates of the particle centroid and position coordinates of contact points of all particles, establishing an equation set according to balance conditions of all the particles and solving the equation set to obtain magnitude and direction of contact force fi of all the contact point positions on each particle. The method has a simple principle, is convenient and flexible to use and has strong practicability, application environment friendliness and wide market prospect; in addition, required equipment is simple and easy to obtain, and measurement results are accurate.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com