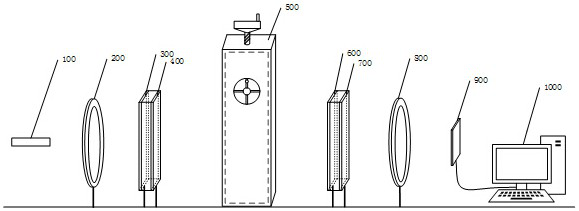

A contact stress visual test loading device for granular materials and using method thereof

A technology of contact stress and loading equipment, which is applied in the direction of analyzing materials, testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, etc. Problems such as heterosexuality and contact stress cannot be directly tested and observed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

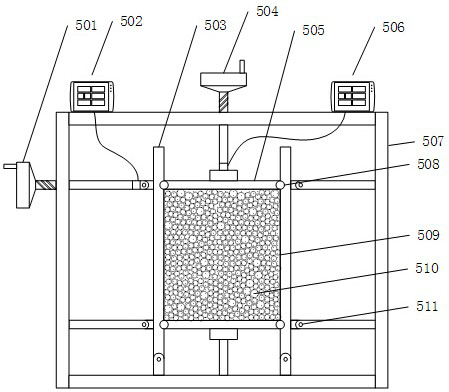

[0059] The steps of pure shear horizontal loading mode are as follows:

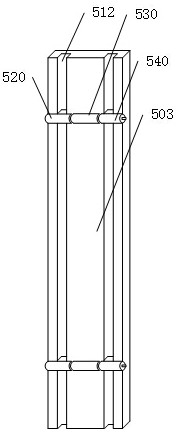

[0060] (1) Make a granular sample 510 according to the size of the sample container, put the granular sample 510 into the experimental container, and fix it on the internal support device of the loading device 500, turn the cross knob 523, and insert the slideway pin 524 into the slideway 512 In the reserved hole, the horizontal baffle 505 cannot move up and down.

[0061] (2) Press the button 544, the horizontal baffle 505 and the vertical baffle 503 can rotate, and adjust the horizontal shear screw head 501 to adjust the sample container to a vertical state, press the button 544 again to make the button pop up, At this time, the horizontal baffle 505 and the vertical baffle 503 cannot rotate, and the horizontal shear screw head 501 is fixed to keep the vertical baffle 503 from being displaced during the axial loading process.

[0062] (3) Rotate the cross knob 523 to make the card pin 524 withdraw from...

Embodiment 2

[0065] The steps for pure shear loading are as follows:

[0066] (1) Make a particle sample 510 according to the size of the sample container, put the sample into the experimental container, and fix it on the internal support device of the loading device 500, turn the cross knob 523, and insert the slideway pin 524 into the pre-set position of the slideway 512. Stay in the hole so that the horizontal baffle 505 cannot move up and down.

[0067] (2) Press the button 544, the horizontal baffle 505 and the vertical baffle 503 can rotate, and adjust the horizontal shear screw head 501 so that the lateral horizontal shear screw head 501 lightly touches the stress-displacement sensor, from the side The reading at this time is zero to the stress displacement meter 502, ensuring that the sample container is adjusted to a vertical state at this time.

[0068] (3) Start loading from the reading zero, record the image state with the photoelastic experimental equipment every certain read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com