Visual test device for damaged form of pile-soil contact surface of specially-shaped pile and use method

A test device and a technology for special-shaped piles, which are applied in the field of model tests, can solve the problems that there is no application or research on the contact surface between structures and soil, and the contact form cannot be completely truthfully reflected, and achieves simple structure, convenient operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

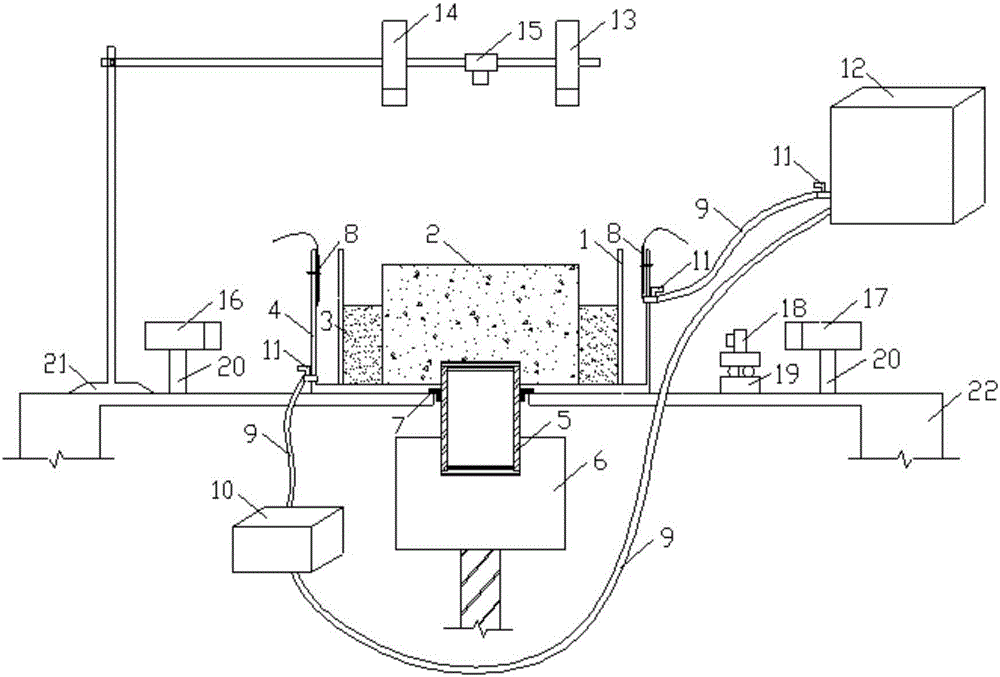

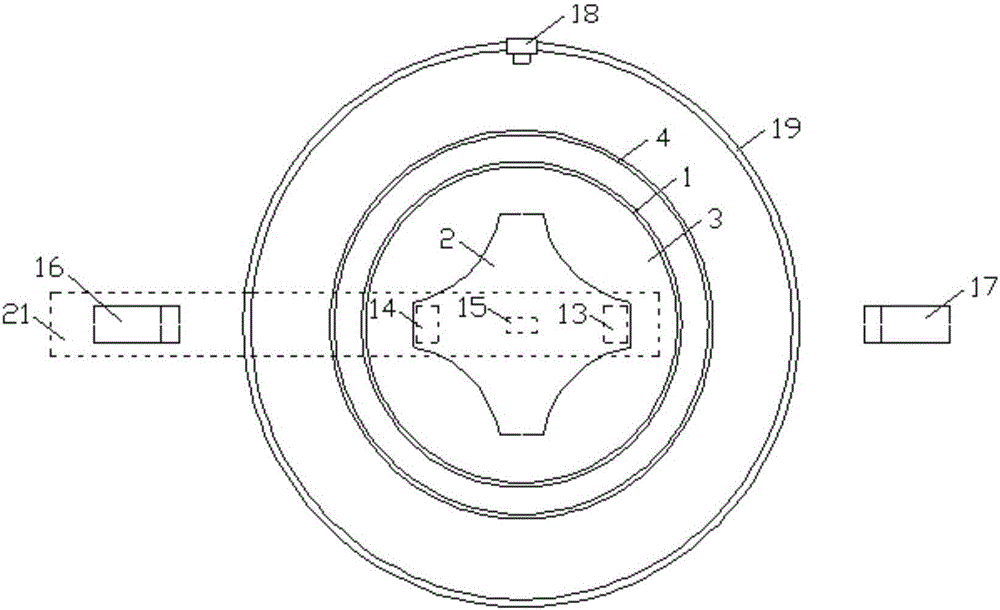

[0037] The visual test device for the failure mode of the pile-soil contact surface of special-shaped piles, the structure is as follows Figure 1-2 As shown, it includes a platform 22, a model pile 2, a model tank 1, a water bath 4, a temperature control system, a laser source and a digital camera.

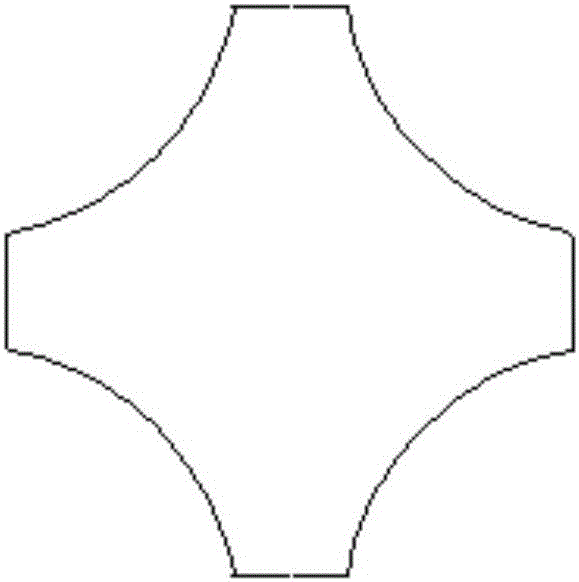

[0038] Model pile 2 is a model pile that simulates the actual full scale of the special-shaped pile on site. The pile body can be made of concrete or PC (polycarbonate) or plexiglass materials, such as Figure 3-5 As shown, the cross-sectional shape of the model pile 2 can be X-shaped, Y-shaped, H-shaped or circular, and the equivalent diameter is 400 ~ 600mm (the model pile of this embodiment is an X-shaped equivalent diameter of 400mm, made of concrete production). The surface of the model pile 2 can be smooth or rough.

[0039] The model pile 2 is set in the model tank 1, surrounded by transparent soil 3, the model tank 1 is set in the water bath 4, both the model tank 1 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com