Photoelastic instrument used for observing and recording granular material bearing structure configuration and features

A load-carrying structure, photoelastic instrument technology, applied in the direction of instruments, analysis materials, etc., can solve problems such as difficult operation, large error of test data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

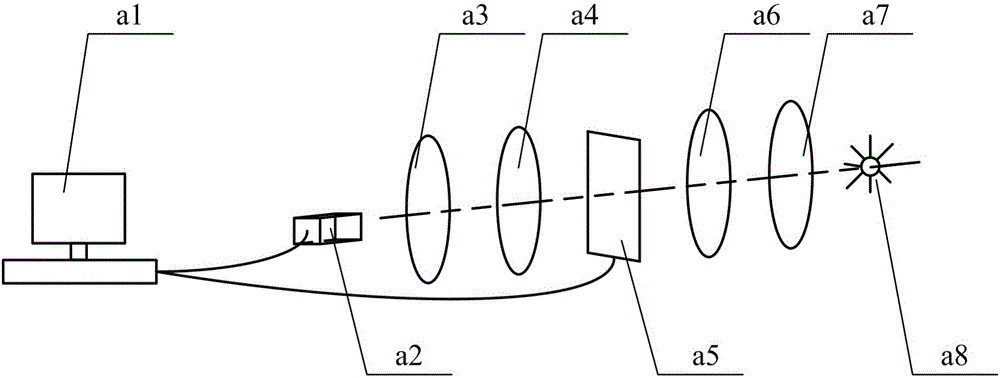

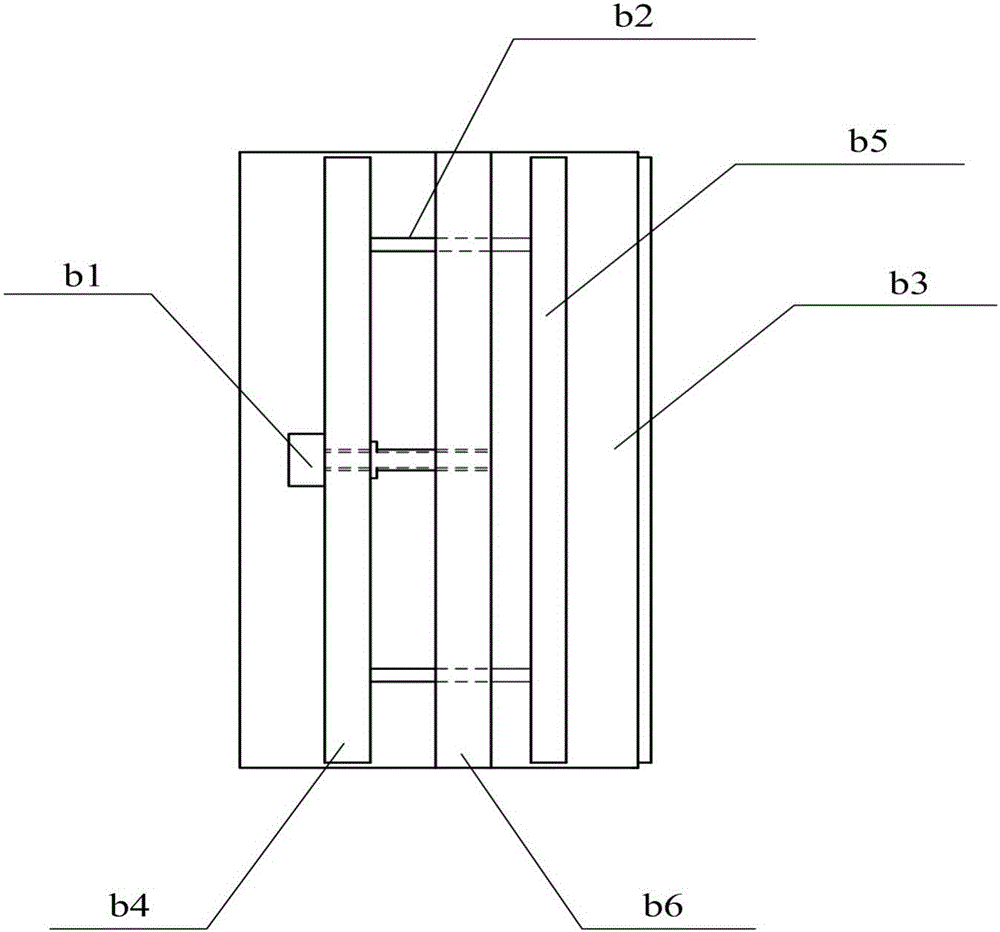

[0029] 1. An instrument based on the birefringence principle of light for real-time observation and recording of the load-bearing structure configuration and characteristics of the internal force chain of the particle system. It is characterized in that it includes photoelastic instruments a3, a4, a6, a7, a8, multi-directional loading system a5, data collection and display system a1, industrial camera a2, particle placement device ( figure 2 );

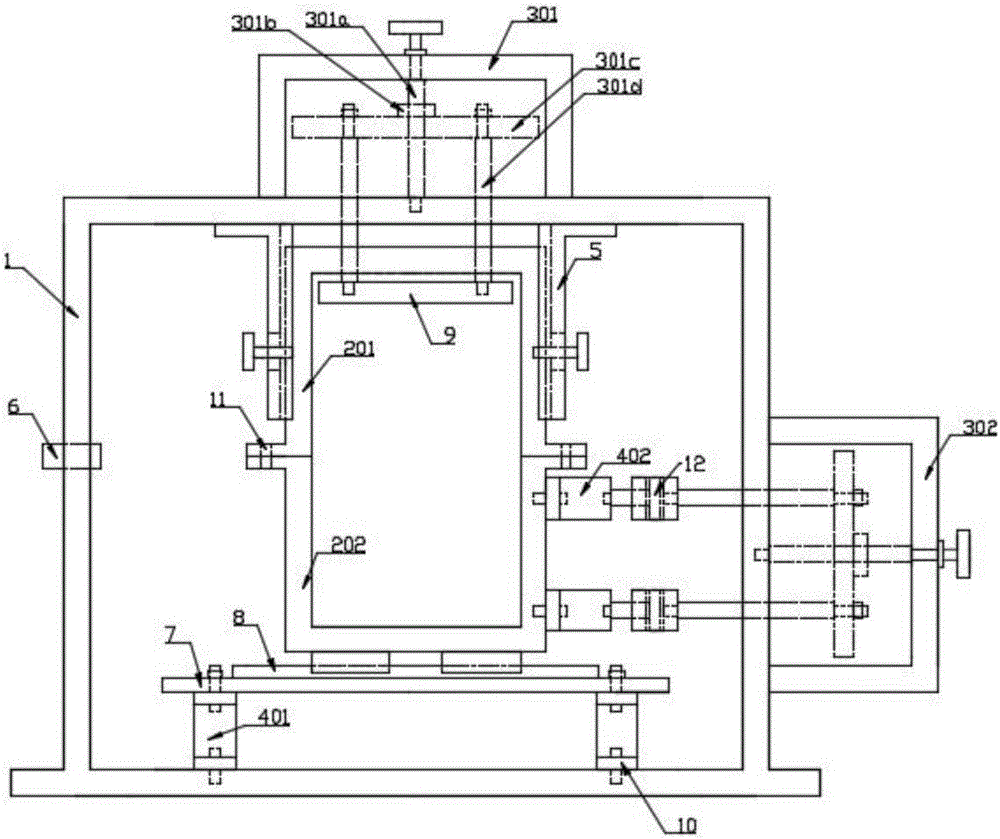

[0030] Among them, the multi-directional loading system ( image 3 ) is located between the front 1 / 4 wave plate a4 and the back 1 / 4 wave plate a6 of the photoelasticometer, and its multidirectional loading system ( image 3 ) coincides with the central axis of the geometric centers of the polarizers a4 and a6.

[0031] 2. An instrument for real-time observation and recording of the load-bearing structure configuration and characteristics of the internal force chain of the particle system based on the principle of light-based biref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com