Abrasive particle constraining device for particle force chain observation

A technology of restraint device and abrasive particles, applied in general control system, program control in sequence/logic controller, instrument and other directions, can solve the problem of reducing the response speed and quality of after-sales service, increasing the mental workload of technicians, affecting the Solve problems such as the efficiency of failure problems, and achieve the effect of avoiding duplication of labor, saving manpower, and improving processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific illustrations.

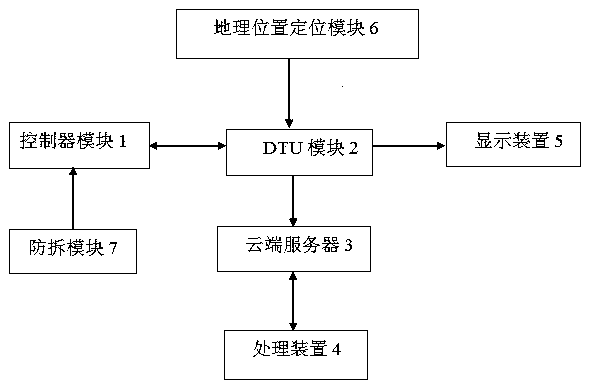

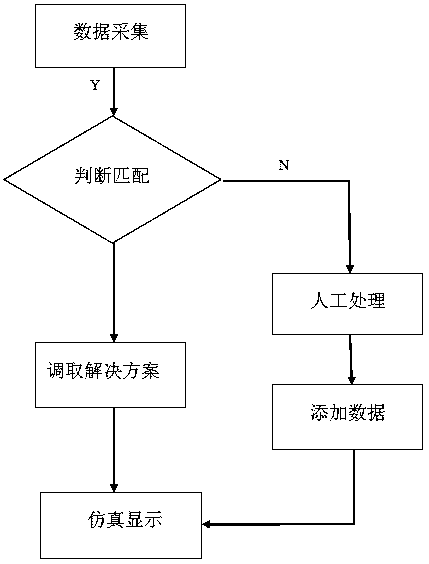

[0030] The abrasive particle restraint device for observing the particle force chain is characterized in that it includes an upper transparent layer, a lower transparent layer, a middle layer abrasive particle restraint module sandwiched between the upper and lower transparent layers, and multiple sensors for measuring the force state of the abrasive particles. Stress sensor and controller module 1, the middle abrasive particle confinement module includes a cavity for accommodating photoelastic particles, a baffle, and a force application mechanism, and the side of the cavity has a gap; the baffle is installed At the gap of the cavity; the bottom of the cavity is equipped with a force applying mechanism for extruding the photoelastic particles, and the extrusion part of the force applying mechanism penetrates the bottom plate of the cavity and connects with the photoelasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com