Contact force measurement test apparatus of granular material force chain structure, and application method thereof

A particle material and test device technology, applied in the field of particle material mechanics research, can solve the problems of limited sample material, complex particle material system, long time, etc., and achieve the effects of accurate and reliable measurement results, promotion of research, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

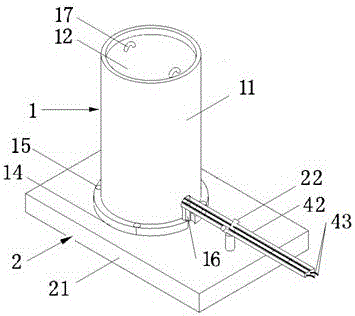

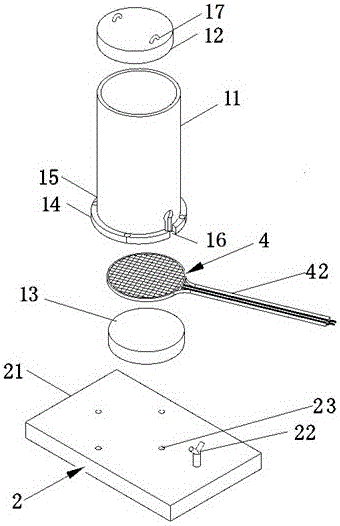

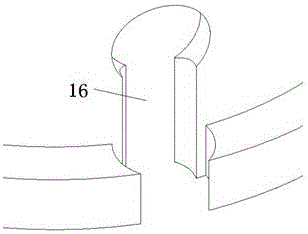

[0049] Such as Figure 1 to Figure 4 As shown, the present invention provides a kind of contact force measuring test device of granular material force chain structure, comprises cylinder container 1, fixing device 2, power loading device, film pressure sensor 4 and data calibration and acquisition system 5; Said cylinder The container 1 includes a cylinder 11, an upper piston 12 and a lower piston 13. The cylinder 11 is used to hold the granular material that needs to measure the contact force; the upper piston 12 is used to cover the upper opening of the cylinder 11, and the lower piston 13 is used to cover The bottom end of the cylinder 11 is open; the fixing device 2 is used to fix the cylinder 11; the power loading device 3 is an air pressure applying device, which is arranged above the cylinder container 1 and directly acts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com