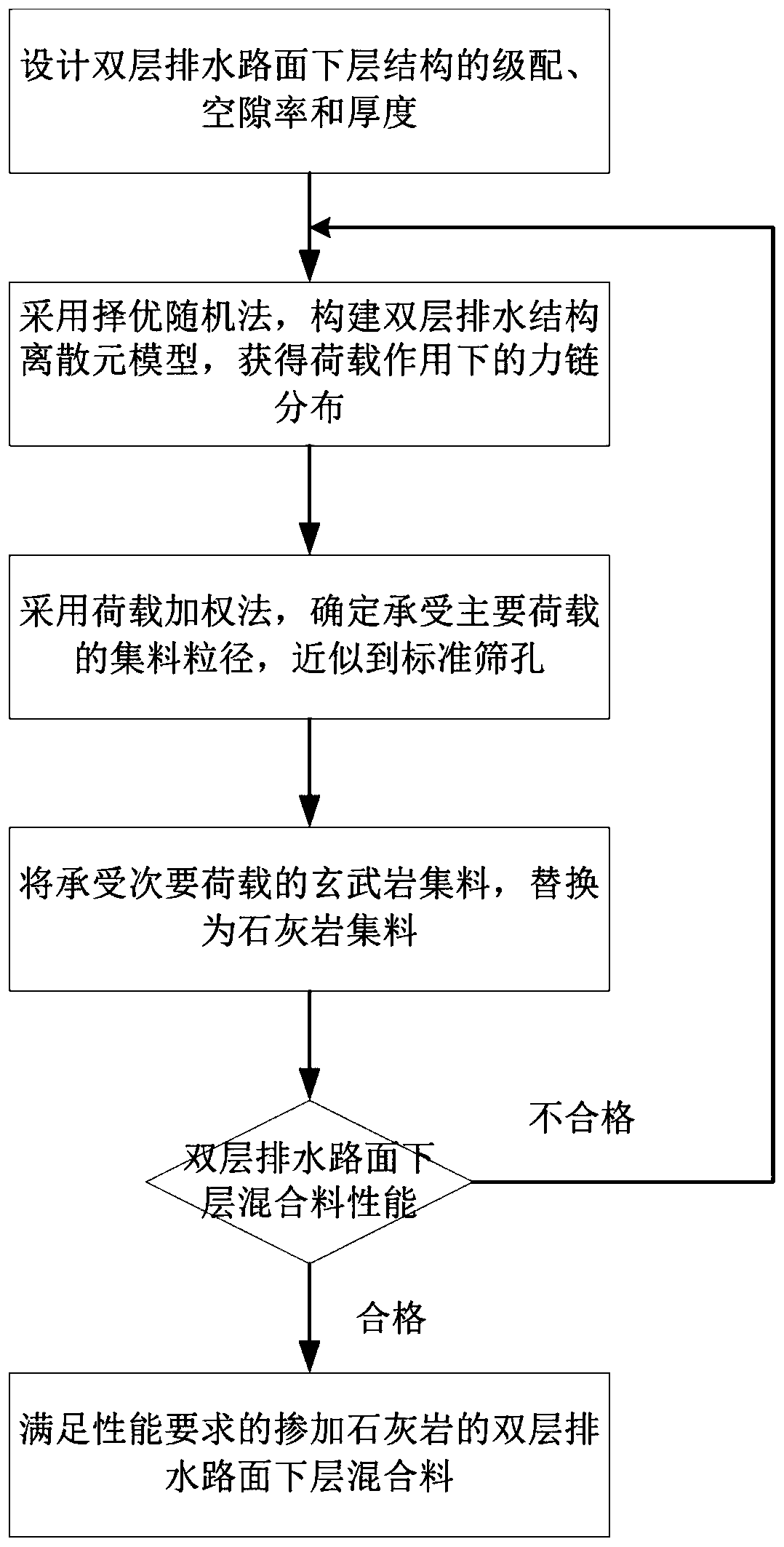

Method of applying limestone to lower-layer structure of double-layer drainage pavement

A pavement structure and limestone technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of performance degradation of the mixture, failure to effectively reduce construction costs, and low replacement rate, and achieve the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

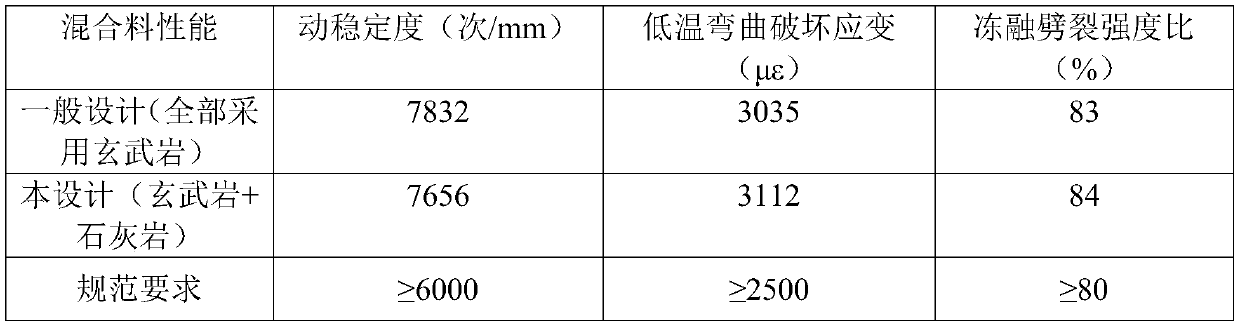

Examples

Embodiment

[0058] Step 1: Use 25mm PAC-10+40mm PAC-16 double-layer drainage pavement structure (where PAC-16 is used as the lower layer 2 of the double-layer drainage pavement structure), and the porosity of the upper and lower layers 1 and 2 are both 20%.

[0059] Step 2: According to the gradation of PAC-10 and PAC-16 mixture, the discrete element method is used to construct multiple sets of discrete element digital models of the double-deck drainage pavement structure, and determine the aggregate, mortar material parameters and related contact parameters.

[0060] Step 3: Apply boundary conditions (the bottom displacement is all zero, and the horizontal displacement on both sides is zero) and vertical load 4 to the above discrete element digital model, and obtain the load 4 in the PAC-16 of the double-deck drainage pavement substructure 2 Force chain 3 distribution ( figure 2 ).

[0061] Step 4: Use the load weighting method to calculate and determine that the average particle size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com