Patents

Literature

144 results about "Discrete element method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A discrete element method (DEM), also called a distinct element method, is any of a family of numerical methods for computing the motion and effect of a large number of small particles. Though DEM is very closely related to molecular dynamics, the method is generally distinguished by its inclusion of rotational degrees-of-freedom as well as stateful contact and often complicated geometries (including polyhedra). With advances in computing power and numerical algorithms for nearest neighbor sorting, it has become possible to numerically simulate millions of particles on a single processor. Today DEM is becoming widely accepted as an effective method of addressing engineering problems in granular and discontinuous materials, especially in granular flows, powder mechanics, and rock mechanics. Recently, the method was expanded into the Extended Discrete Element Method taking thermodynamics and coupling to CFD and FEM into account.

Cosmetic device comprising discrete elements

A cosmetic device comprising a solid or semi-solid cosmetic composition comprising a plurality of discrete elements is provided. The discrete elements each comprise a water soluble core surrounded by an erodible shell. The cosmetic composition may be a cleansing composition. The discrete elements may form a matrix.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

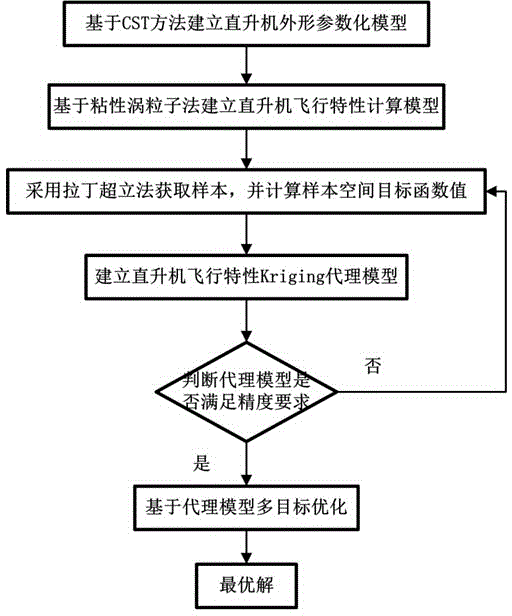

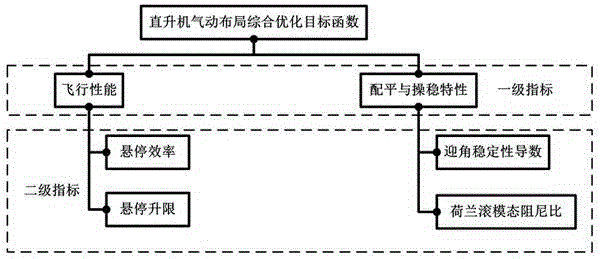

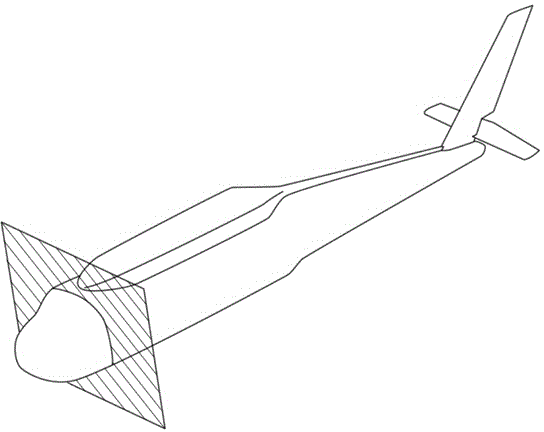

Helicopter aerodynamic layout optimization method capable of reducing adverse effect of aerodynamic interference

ActiveCN104899365AReduced aerodynamic layout optimization methodReduce demandSustainable transportationSpecial data processing applicationsDiscrete element methodEngineering

The present invention discloses a helicopter aerodynamic layout optimization method capable of reducing the adverse effect of aerodynamic interference. According to the method, aiming at the defects of a wind tunnel test and a CFD method and based on a discrete vortex method and a surface element method, a coupled aerodynamic interference high-precision analysis model for a helicopter is set up, so that the influence of aerodynamic interference on the helicopter can be considered only by simulating calculation without carrying out the wind tunnel test; compared with the CFD method, the method has the advantages of greatly reducing the requirements of a simulation model for computing resources and shortening computing time. In order to further reduce calculated amount and a optimization region, a helicopter fuselage shape parameter model is set up by a parametric method and a combined optimization method based on an agent model is adopted, so that the optimal helicopter aerodynamic outline and layout are obtained and the purpose of reducing aerodynamic interference to improve the flight characteristics of the helicopter is achieved. The helicopter aerodynamic layout optimization method can be applied to the conceptual design phase of the helicopter so as to improve the flight characteristics, the balancing characteristic, stability and manoeuvrability of the helicopter.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Bituminous mixture compaction simulation method based on discrete elements

ActiveCN105512436AEasy to operatePracticalSpecial data processing applicationsCAD numerical modellingDiscrete element methodRoad surface

The invention discloses a bituminous mixture compaction simulation method based on discrete elements. The method comprises the steps that a prescribed space region is generated through a 'wall' command in PFC<3D> software, and the space region is randomly filled with a particle system composed of coarse aggregates and bituminous mortar; partial bituminous mortar is randomly deleted; corresponding contact types are given to the interior of the coarse aggregates, the interior of the bituminous mortar and the space between the coarse aggregates and the bituminous mortar in a bituminous mixture; a 'clump', formed by gathering basic unit particles, in the PFC<3D> software is set to serve as a rolling wheel of a road roller, and the static pressure action on the bituminous mixture is achieved through rolling wheels of the road roller under the action of gravity; excitation force is given to the 'clump', the excitation force of a 'clump' system is coupled with the gravity, and vibrating compaction action is simulated; compaction of compaction road rolling wheels to the bituminous mixture is controlled through fish language programming. The method is easy and convenient to use, economical and effective and has certain significance to construction of a bituminous mixture pavement.

Owner:SOUTHEAST UNIV

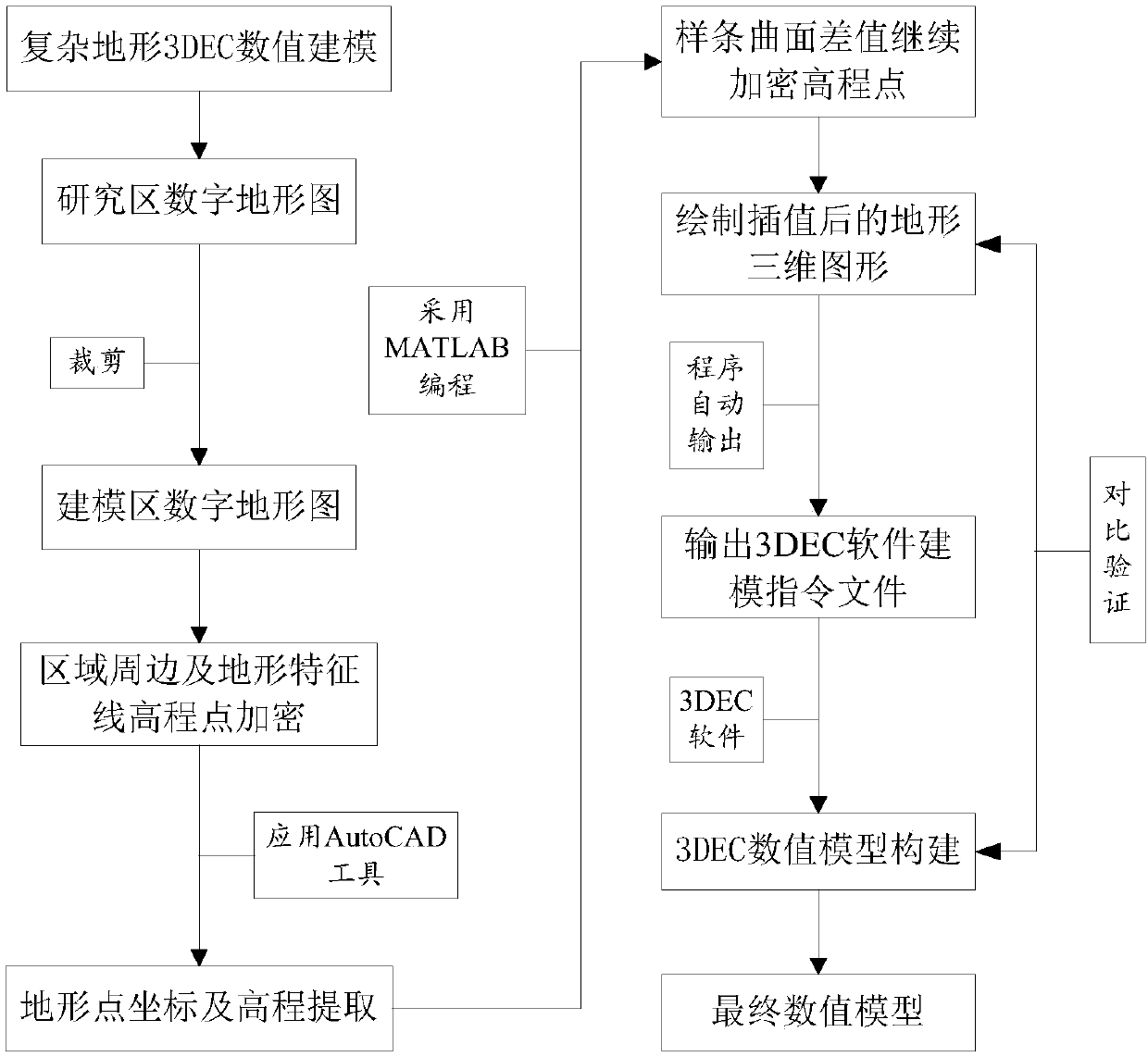

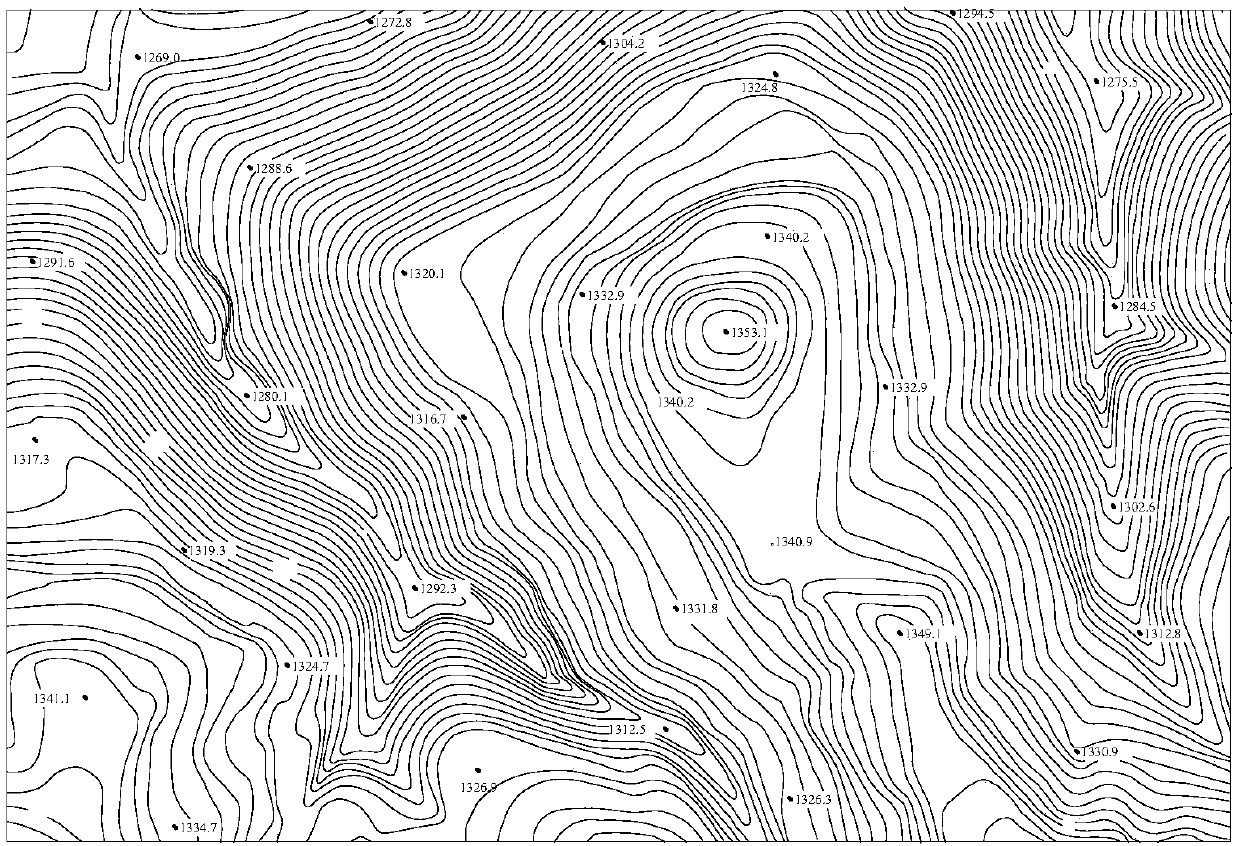

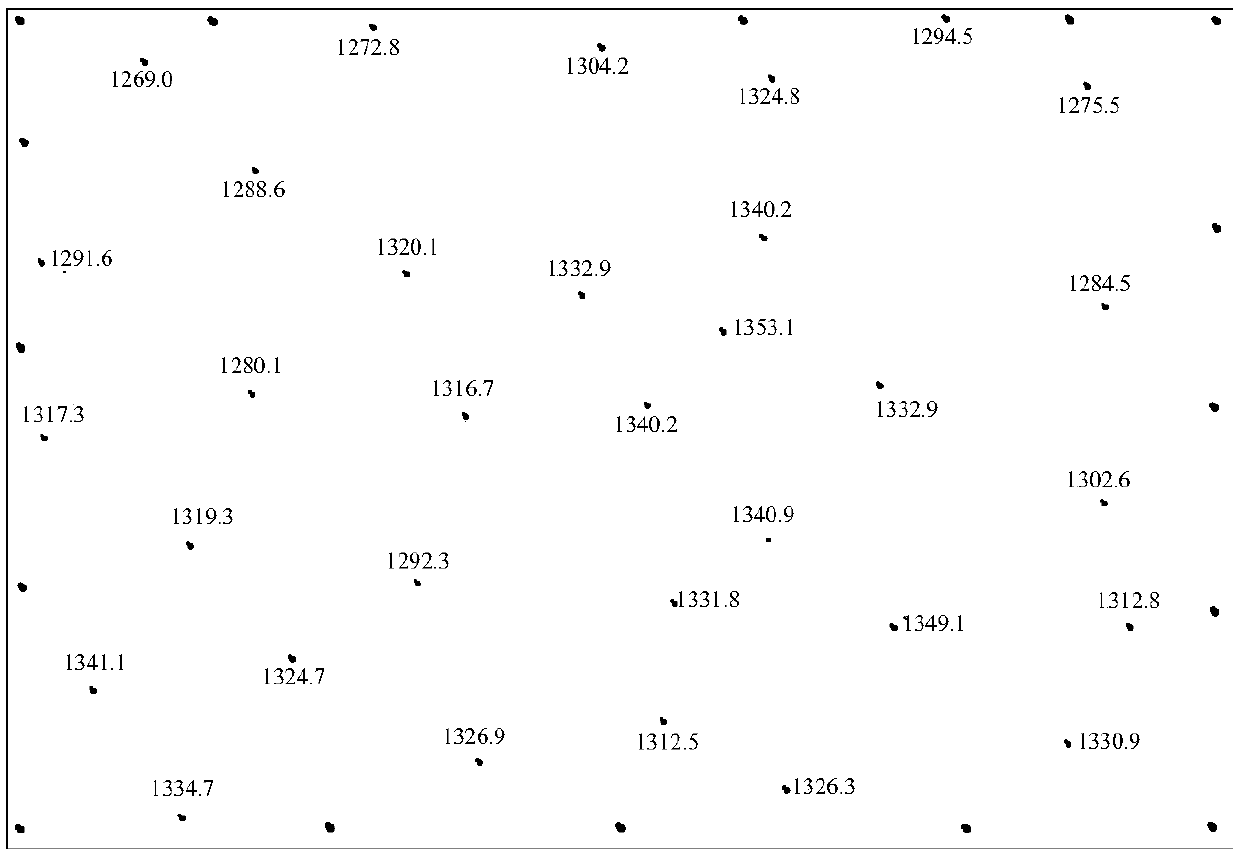

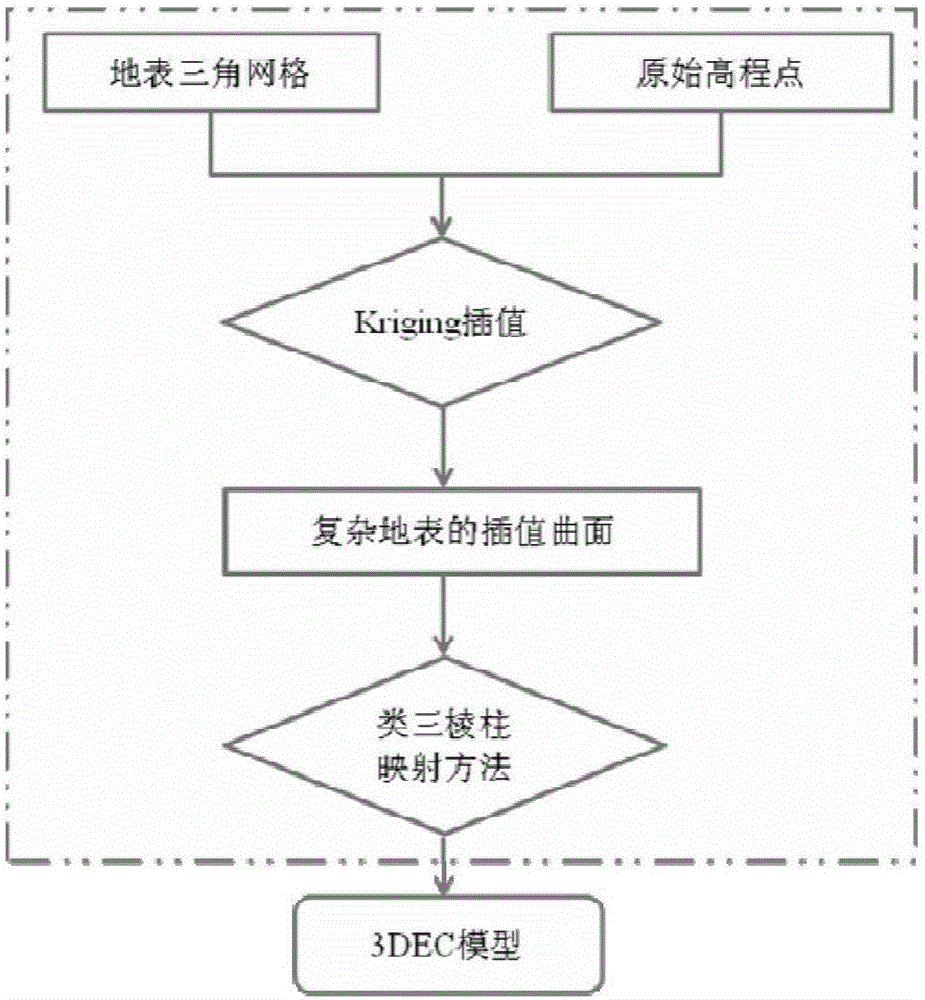

Modeling method for 3D discrete element method numerical model of complicated terrain based on contour line

ActiveCN107562833AHigh degree of intelligenceRealize automatic drawingSpecial data processing applications3D modellingTerrainData file

The present invention provides a modeling method for 3D discrete element method numerical model of complicated terrain based on contour line, and belongs to numerical simulation research fields in geological engineering and mining engineering fields. The method comprises: firstly, acquiring a digital topographic map of a modeling area, encrypting elevation points at a boundary of the area and an area with sparse elevation points and obtaining elevation values of each encrypted elevation point, and extracting 3D spatial information of each elevation point and saving the information; then performing surface spline interpolation on the digital topographic map, and drawing a modeling area surface 3D graphics; inputting the 3D spatial information of all the elevation points after surface splineinterpolation into a final terrain data file, and establishing a 3D numerical model by 3D discrete element method software; and by comparison and verification with the surface 3D graphics, obtaininga final 3D discrete element method numerical model of the modeling area. According to the method, high-precision numerical modeling can be performed on any complicated terrain area, and the established model surface has smaller deviation than the actual terrain surface, and the method has higher application value.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

A method for simulating the catastrophic evolution of overlying karst collapse based on discrete element method is presented

ActiveCN109359391AGeometric CADSpecial data processing applicationsDiscrete element methodGeomorphology

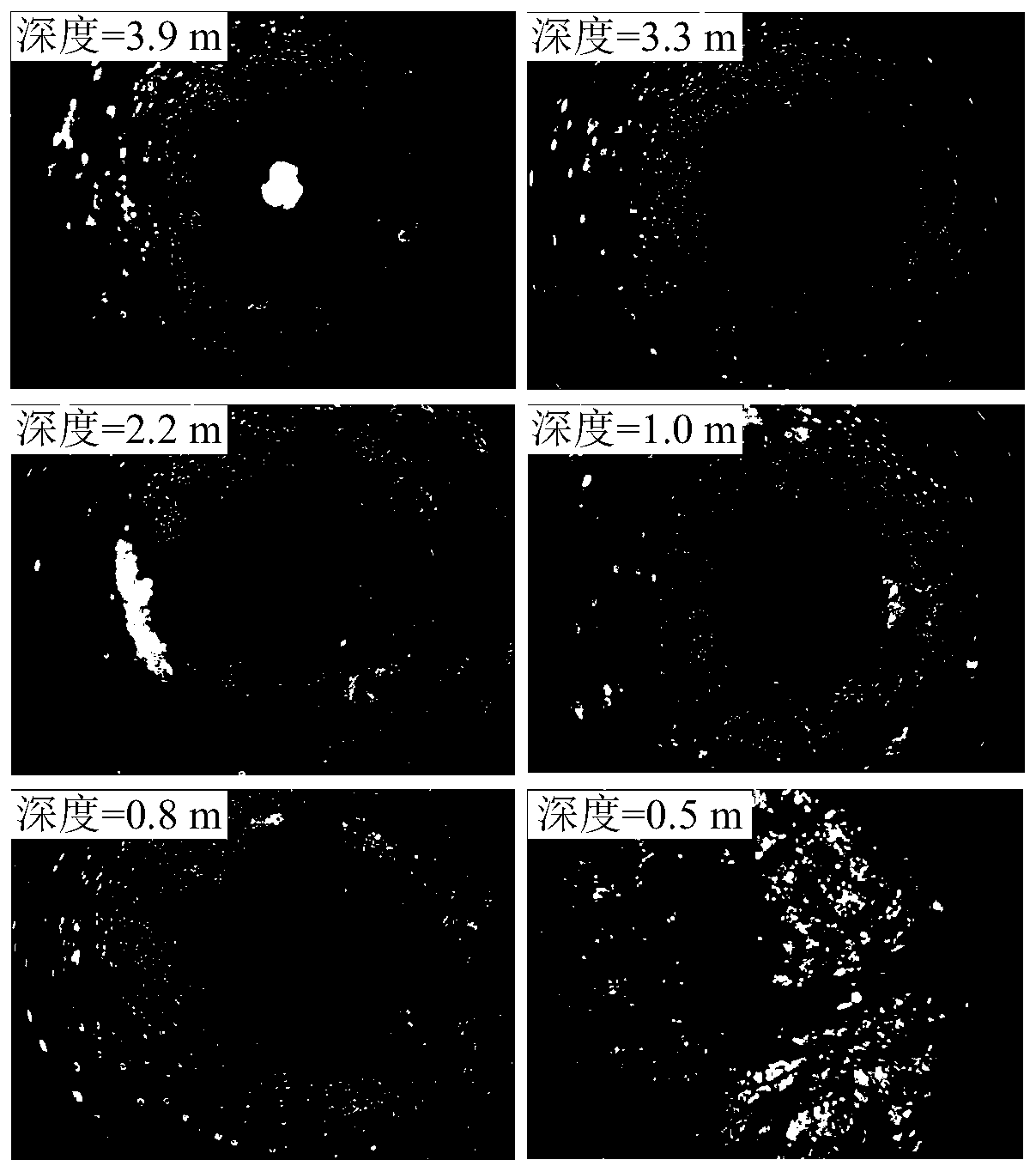

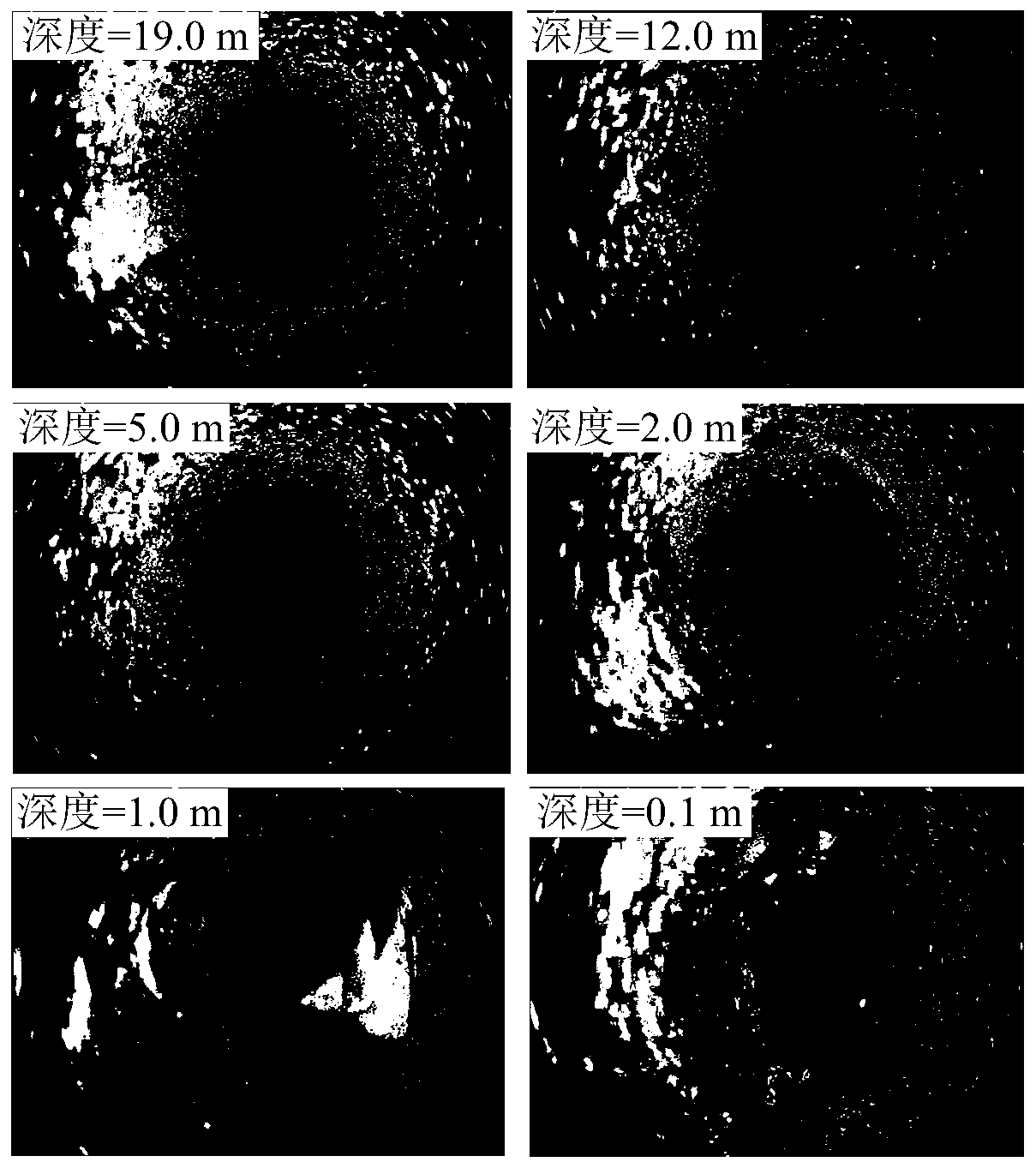

The invention belongs to the research field of geological disaster mechanism, and discloses a method for simulating the catastrophic evolution of overlying karst collapse based on the discrete elementmethod. The mechanism of overlying karst collapse and the catastrophic evolution process are analyzed by using the discrete element method. The whole process of karst collapse is revealed from the microscopic angle, including: crack formation, particle spalling, soil cavity formation, soil cavity expansion, overburden collapse and so on. The displacement of overburden soil particles, the development trend of cracks and the variation of system unbalance force are analyzed in order to truly reflect the multi-field variation characteristics of the catastrophic main body (overburden soil) under the action of external forces. The invention obtains the critical soil hole equilibrium height and the critical groundwater flow velocity formed by the soil hole of the overlying karst collapse by using the discrete element numerical simulation method, and compares with the theoretical result, and the simulation result can provide a reliable basis for the exploration and treatment of the karst collapse geological disaster, the disaster prevention and mitigation work.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

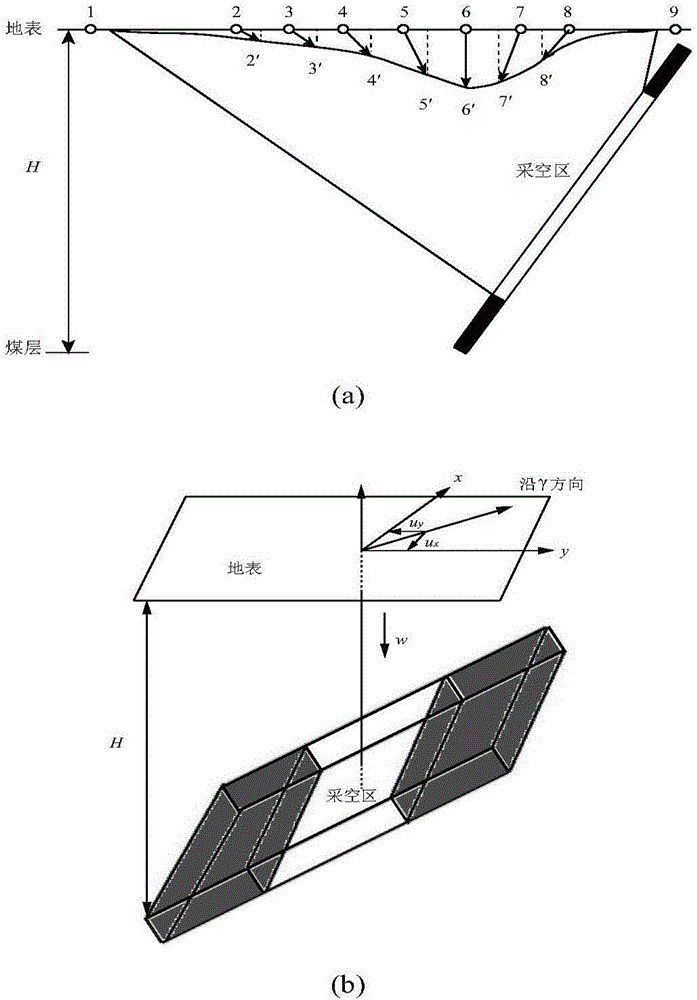

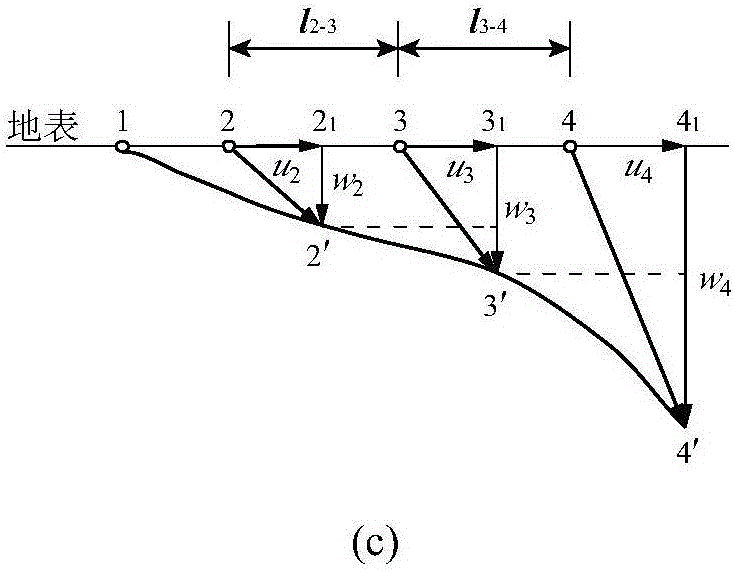

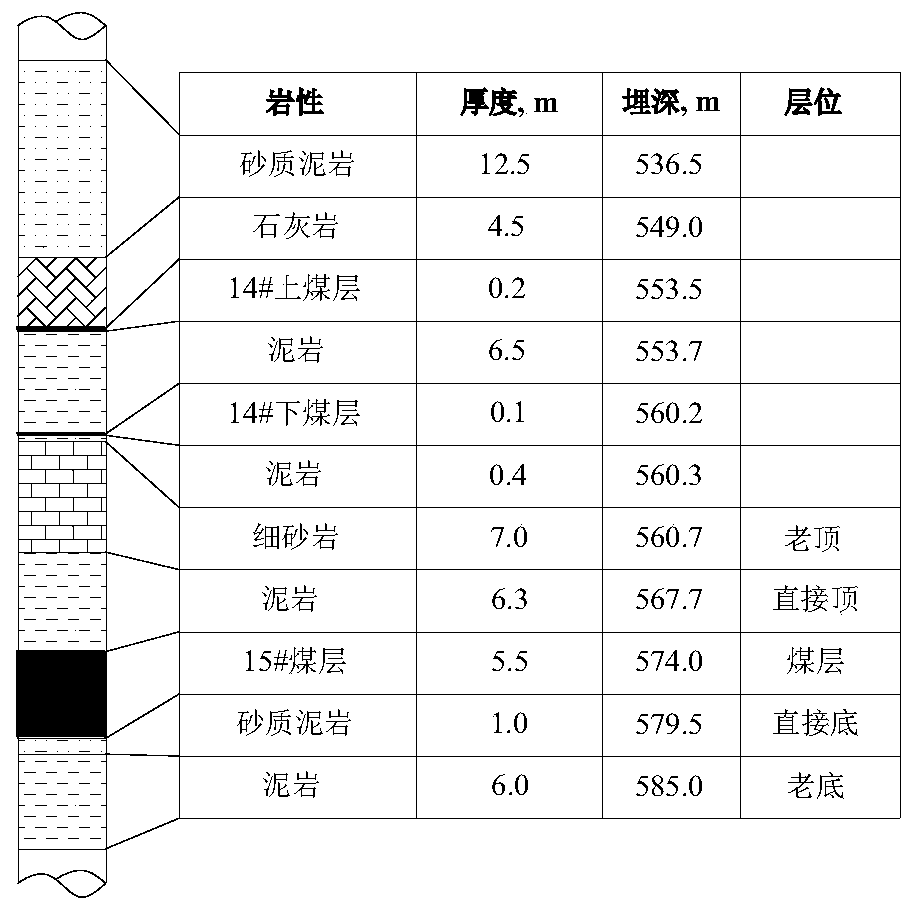

Method for predicting distribution rule of ground surface fissures induced by underground mining of surface mine end slope

ActiveCN106326528ASolving the Crack Prediction ProblemData processing applicationsDesign optimisation/simulationTerrainModel parameters

The invention provides a method for predicting a distribution rule of ground surface fissures induced by underground mining of a surface mine end slope. The method comprises the following steps of collecting terrain and geology data of a surface iron mine; building an underground mining model of the surface iron mine end slope; determining the parameters of the underground mining model of the surface iron mine end slope; numerical simulation of underground mining: utilizing a three-dimensional discrete element method to calculate the numerical simulation of mining of the surface iron mine end slope, so as to obtain a rock layer and ground surface movement rule; predicting the ground surface fissures. The method has the advantages that the problem of predicting of ground surface fissures caused by the end slope mining from the surface iron mine into the underground mine is solved; a three-dimensional geology model of the rock body of the surface iron mine is established by a three-dimensional geology modeling method, and is divided into a discrete block model suitable for the 3DEC calculation; the distribution scope and type of the ground surface fissures in the underground mining process can be predicted, and the support is provided for the safety production of mines.

Owner:ANSTEEL GRP MINING CO LTD

Discrete element method for simulating roadway surrounding rock fracture evolution

ActiveCN110390152AStrong on-site guidanceAuthentic and reliable simulationEarth material testingMaterial strength using tensile/compressive forcesDiscrete element methodFinite element method

The invention discloses a discrete element method for simulating roadway surrounding rock fracture evolution. The discrete element method comprises the steps that on-site coal and rock stratum coringis conducted an RQD value is recorded, roadway deformation is observed, and coal seam fracture distribution characteristics are counted; mechanical parameters of coal rock samples are tested indoors,and the strength of the rock mass is calculated according to the RQD value; a UDEC-Trigon module is used for establishing a numerical model to adjust parameters, and parameters match with rock mass strength to correct model parameters; and a numerical model of the engineering scale is established to adjust the parameters to be matched with field deformation characteristics, and finally roadway surrounding rock fracture evolution is simulated. Accurate basic mechanical parameters are provided for discrete element numerical simulation roadway deformation, and it can be ensured that the simulation result is real and reliable.

Owner:CHINA UNIV OF MINING & TECH +1

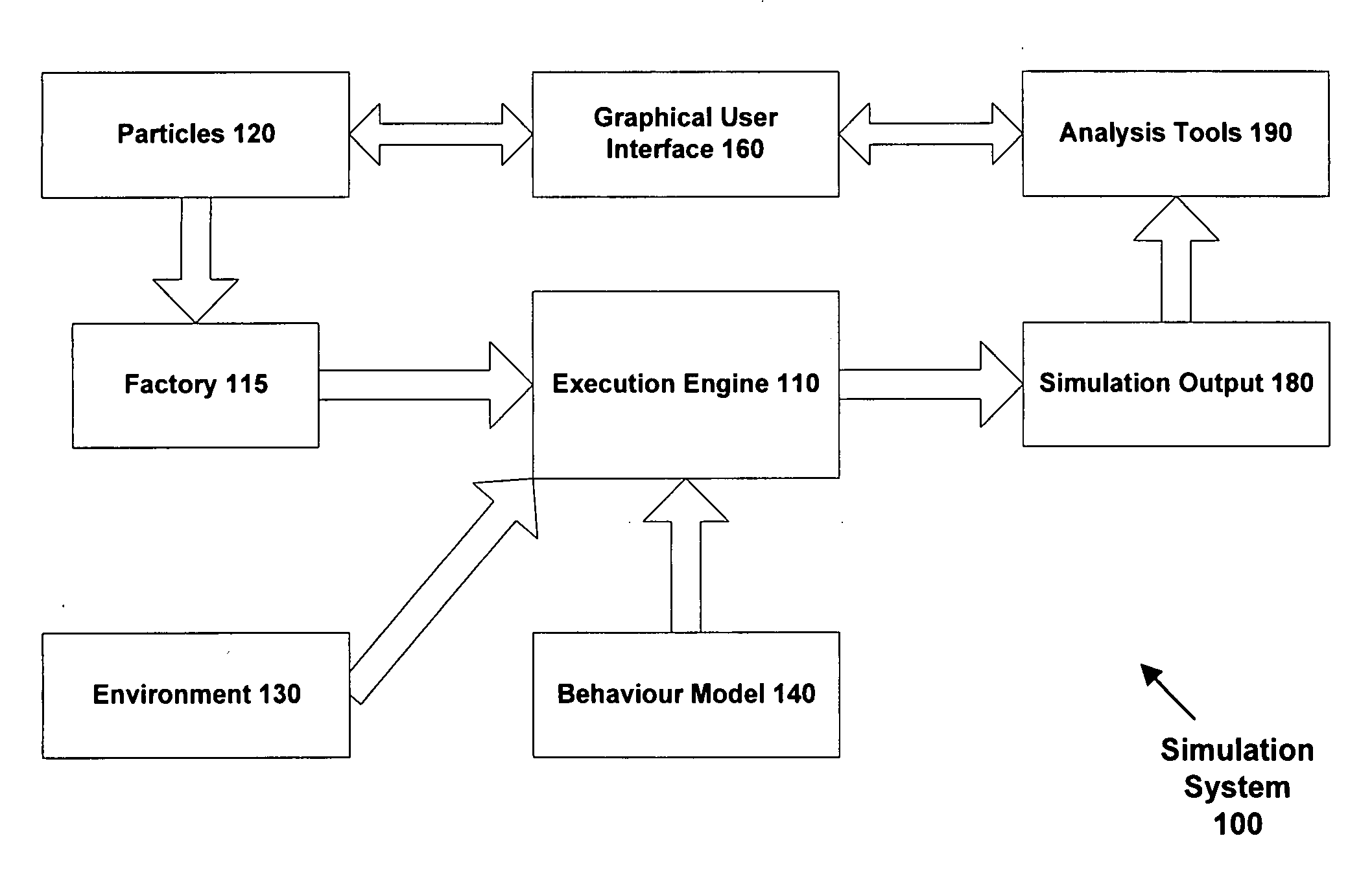

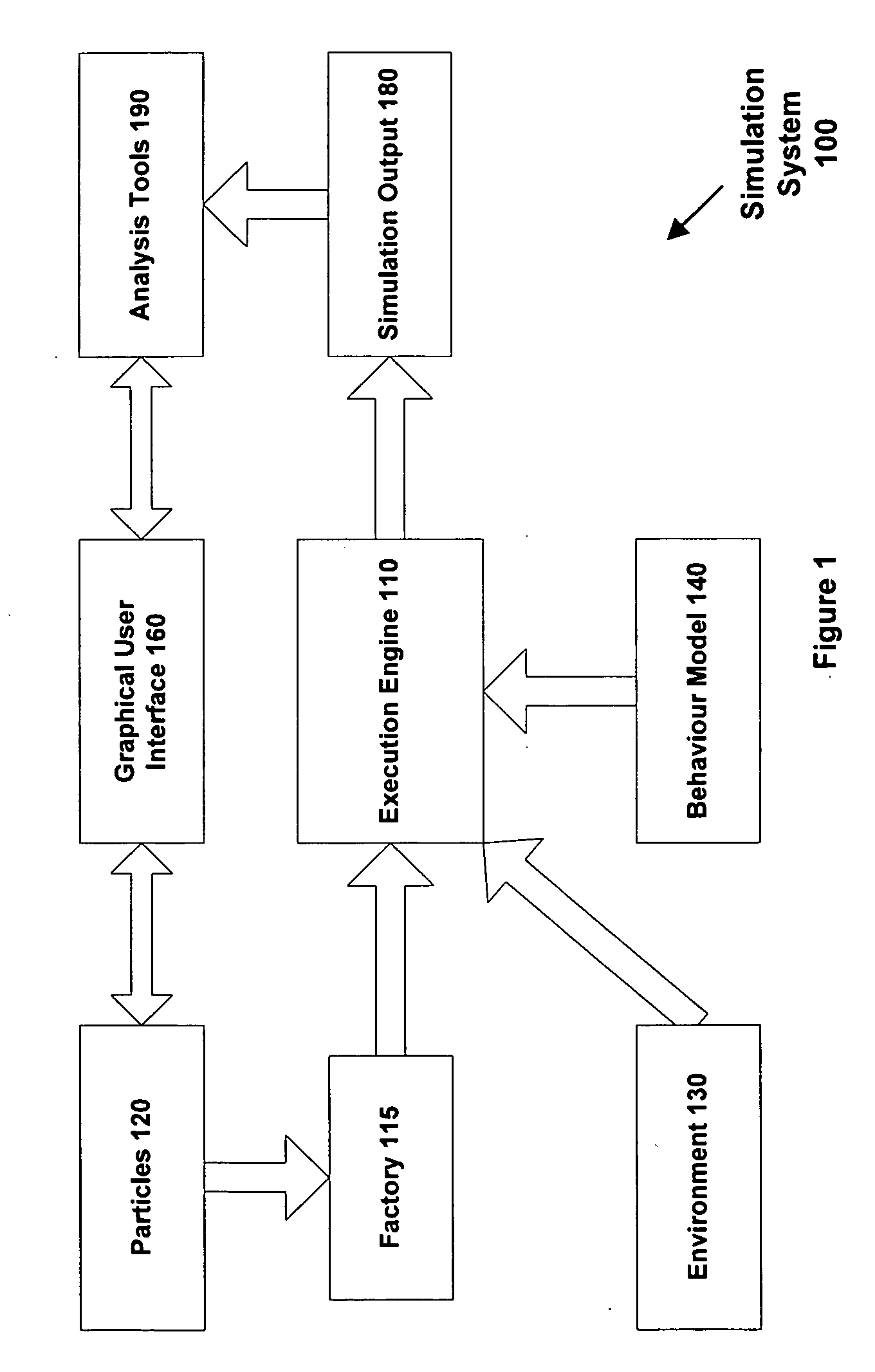

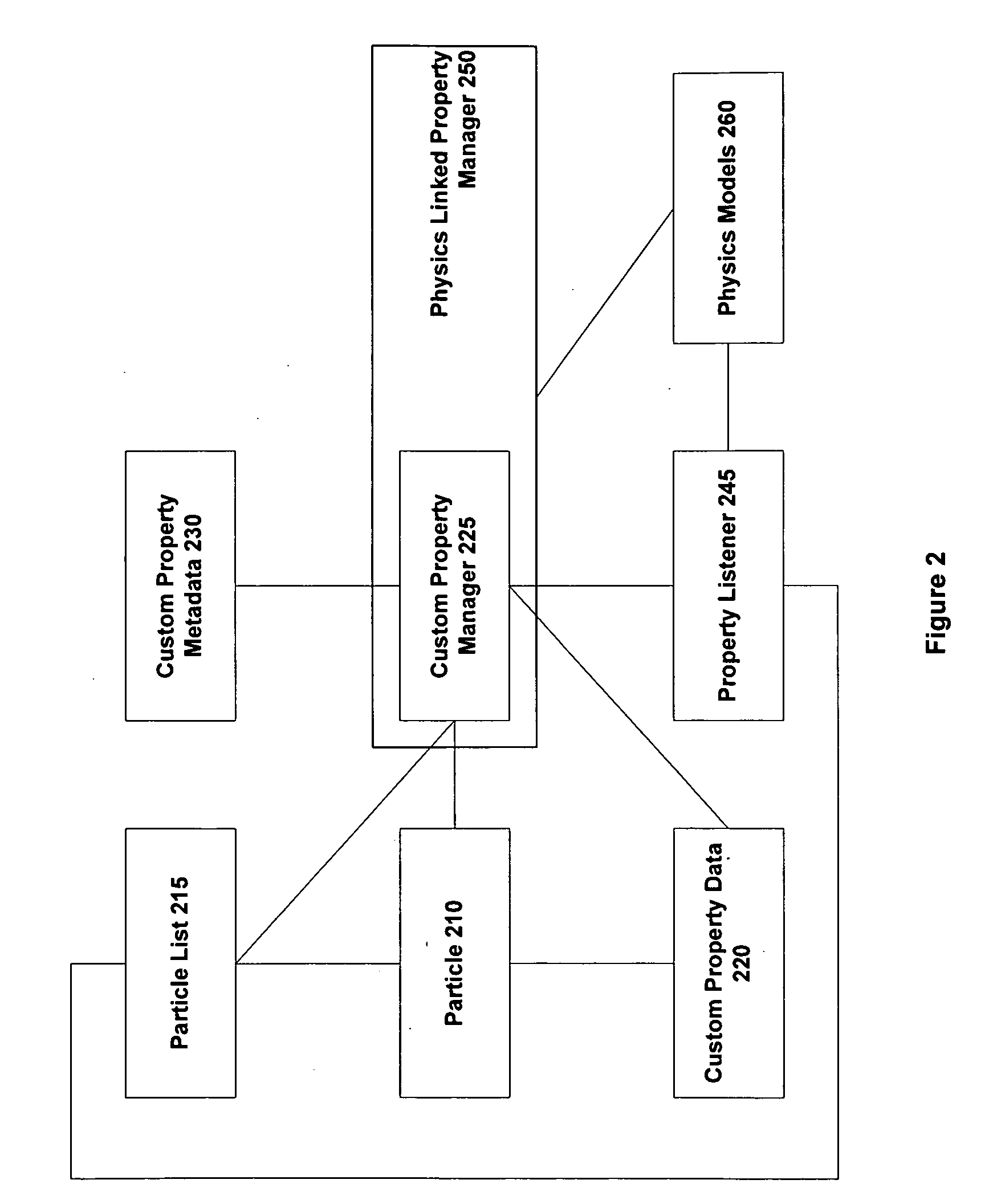

Method and apparatus for simulation by discrete element modeling and supporting customisable particle properties

ActiveUS20100042386A1Increase flexibilityExpand the scope ofDesign optimisation/simulationSpecial data processing applicationsComputational scienceDiscrete element method

One embodiment of the invention provides a computer-implemented simulation system for discrete element modeling. The system comprises discrete elements corresponding to objects or particles, where each particle has a predefined set of properties. The system further has an interface for receiving at least one behaviour model for applying to the particles, and supports receipt from the at least one model of one or more custom properties for the particles. The system is responsive to receipt of the one or more custom properties to extend the discrete elements to contain both the predefined set of properties and the one or more custom properties for the particles. The system is operable to perform a simulation using discrete element modeling by applying the at least one behaviour model to the particles and to update accordingly values of the predefined and custom properties. The values of the custom particle properties are stored with the default (built-in) particle property values and can be analysed and visualised in the same way as the default property values.

Owner:ALTAIR ENG LTD

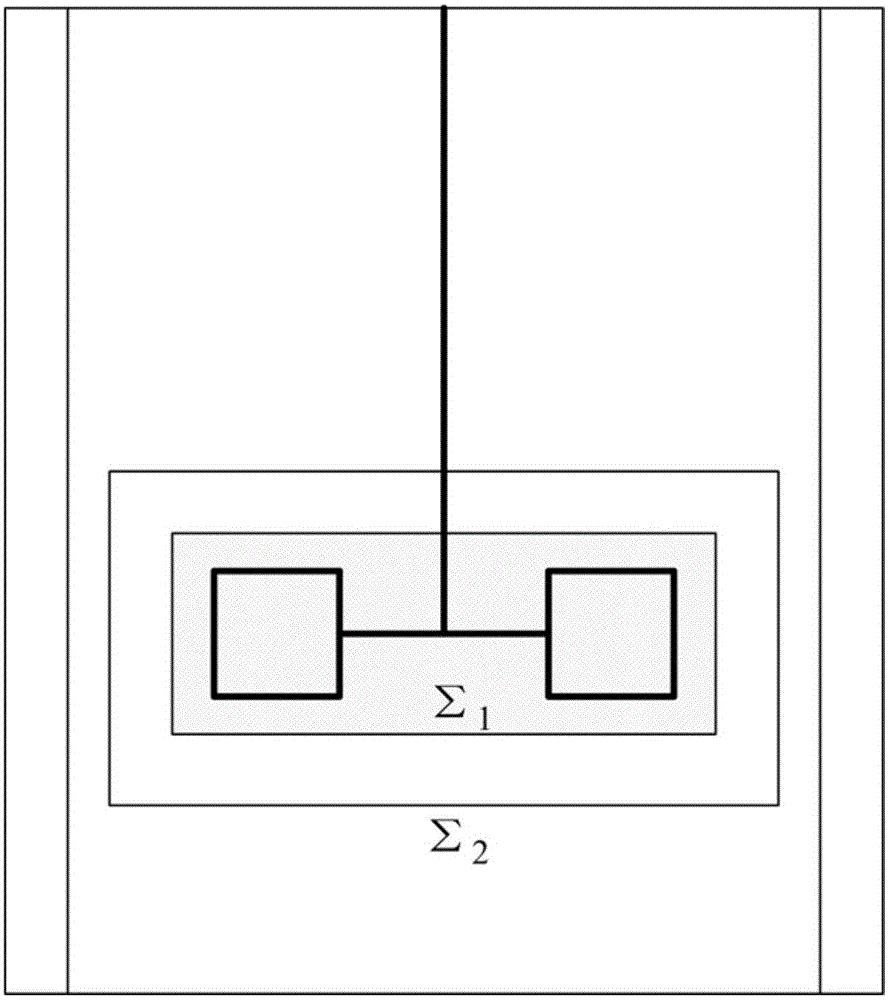

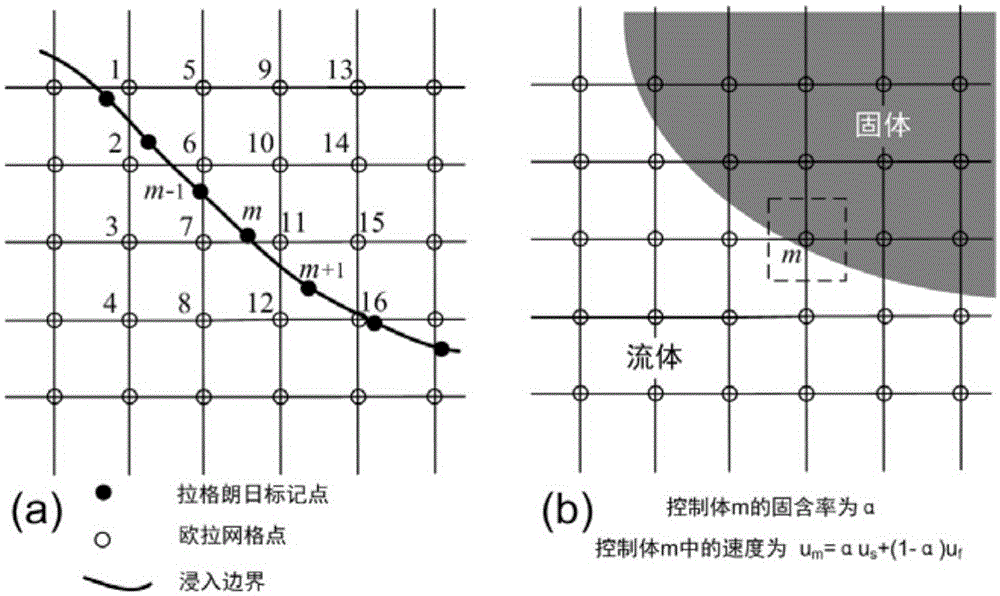

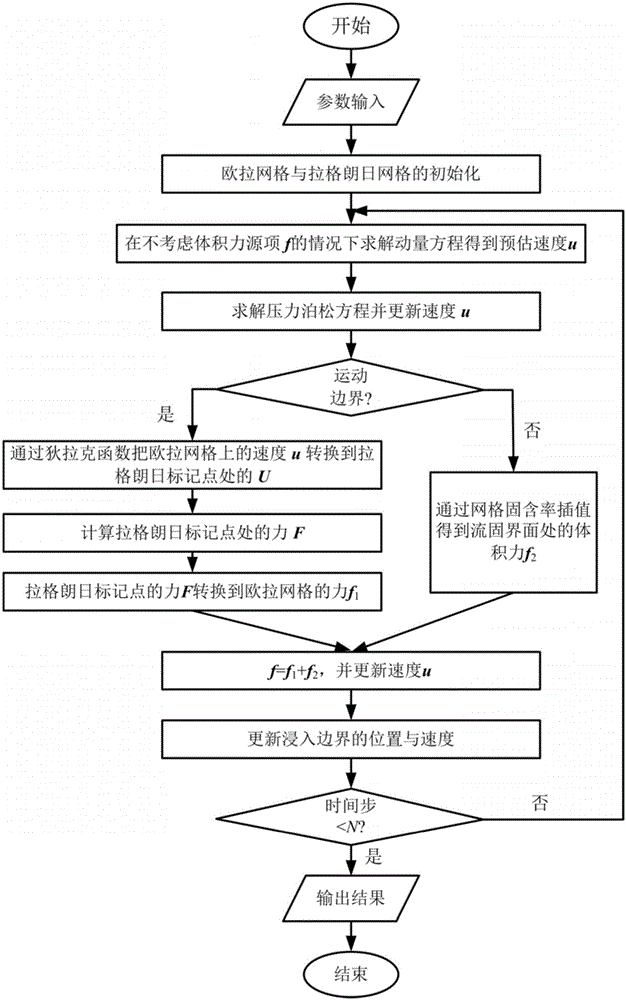

Stirred tank reactor simulation method based on immersed boundary method

ActiveCN105069184APromote generationReduce workloadSpecial data processing applicationsBoundary knot methodSolid particle

The present invention provides a stirred tank reactor simulation method based on an immersed boundary method. The method includes: a preparation phase including determination and setting of calculating parameters, generation of fluid grid files, generation of Lagrange mark point information, and preparation of calculating resources; numerical calculation: setting boundary conditions of computational domains and solving velocity fields and temperature fields based on fluid grids; combining with a discrete element method to achieve an interface analytic simulation of two-phase flow of particle flow, wherein the immersed boundary method is directly employed to apply non-slip boundary conditions to particle surfaces; a post-processing phase, and outputting information of each Euler mesh and information of each particle after a simulation is completed. According to the characteristics of different boundaries, in the calculation, the mixed immersed boundary method is employed to process, and the mass numerical simulation of turbulent flow in the stirred tank reactor is achieved through combination of large eddy simulation and high performance parallel computing technology. The simulation method may be applied to simulation of turbulent flow and simulation of solid particle suspension in the stirred tank reactor and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

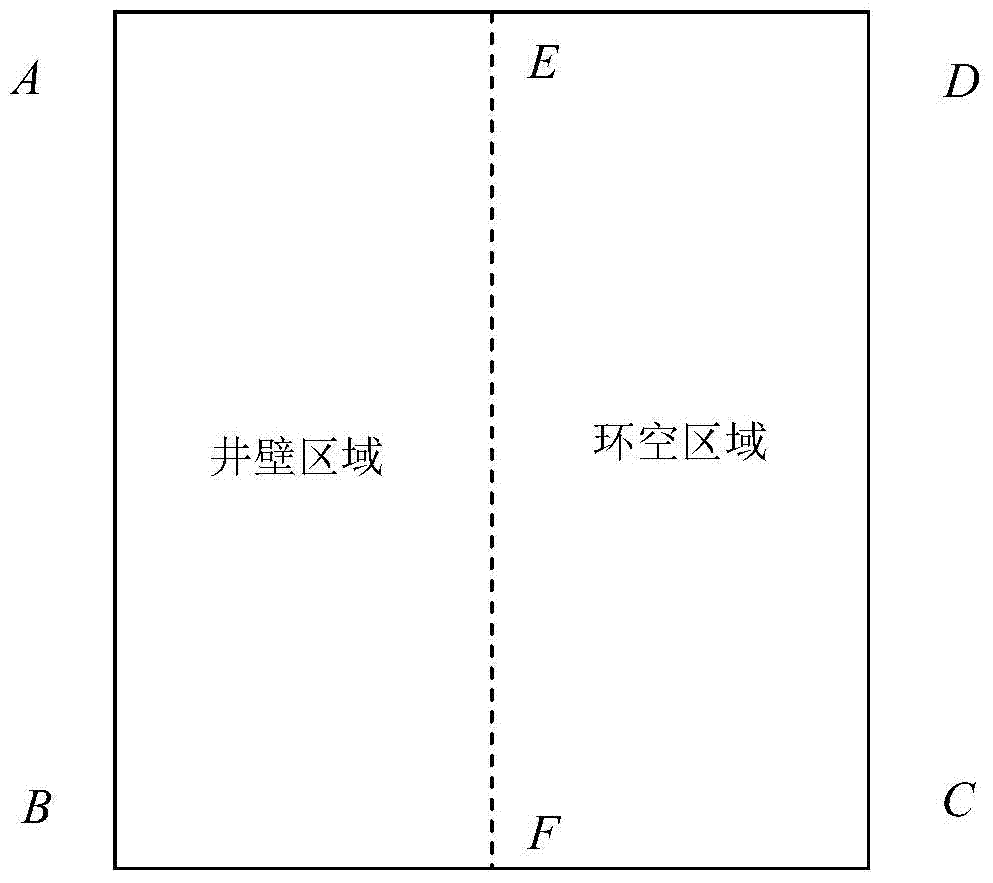

Simulation method of plugging of shale pore-throats by nanoparticles

InactiveCN104504192AAvoid high sealing (above nanoscale) conditionsReflects microscopic pore sizeSpecial data processing applicationsDiscrete element methodThroat

The invention discloses a simulation method of plugging of shale pore-throats by nanoparticles. According to structural features of shale pores, simulation dimensions and boundary conditions of shale are set; initial conditions of stresses and speeds of the nanoparticles in drilling fluid are set; according to features of the nanoparticles and the drilling fluid, a particle contact and motion model is built; a nanoparticle system and the process of contact, collision, deposition and migration with the particles, on the surface of the shale and in the pores of the shale, are solved by the discrete element method; shale pore plugging condition, plugged layer pore structure and the like are simulated; plugging law and plugging micro-process and mechanism are revealed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

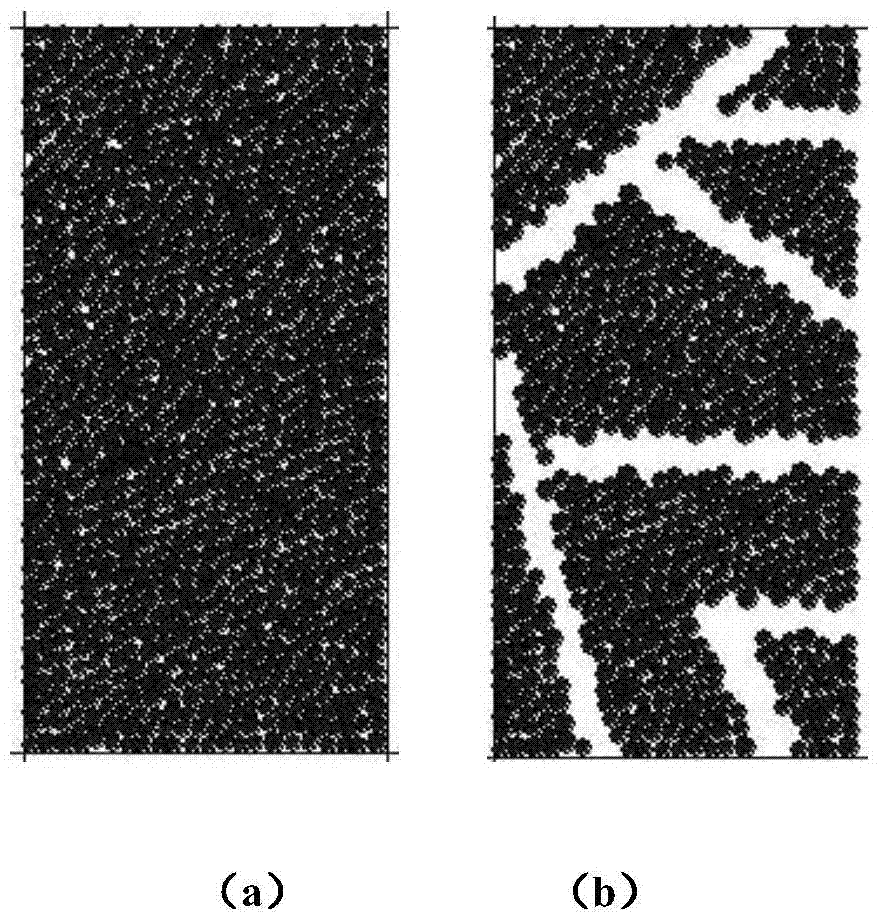

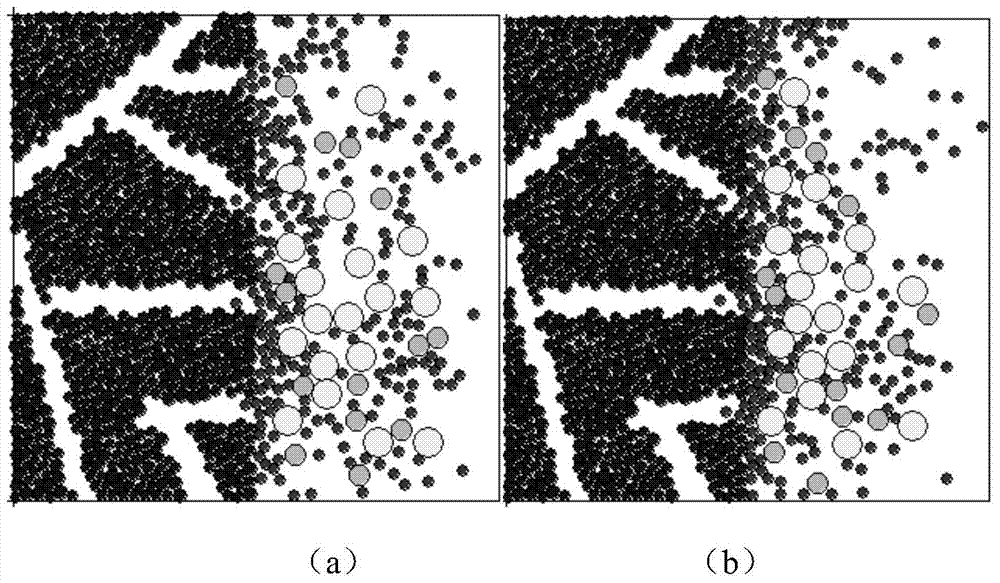

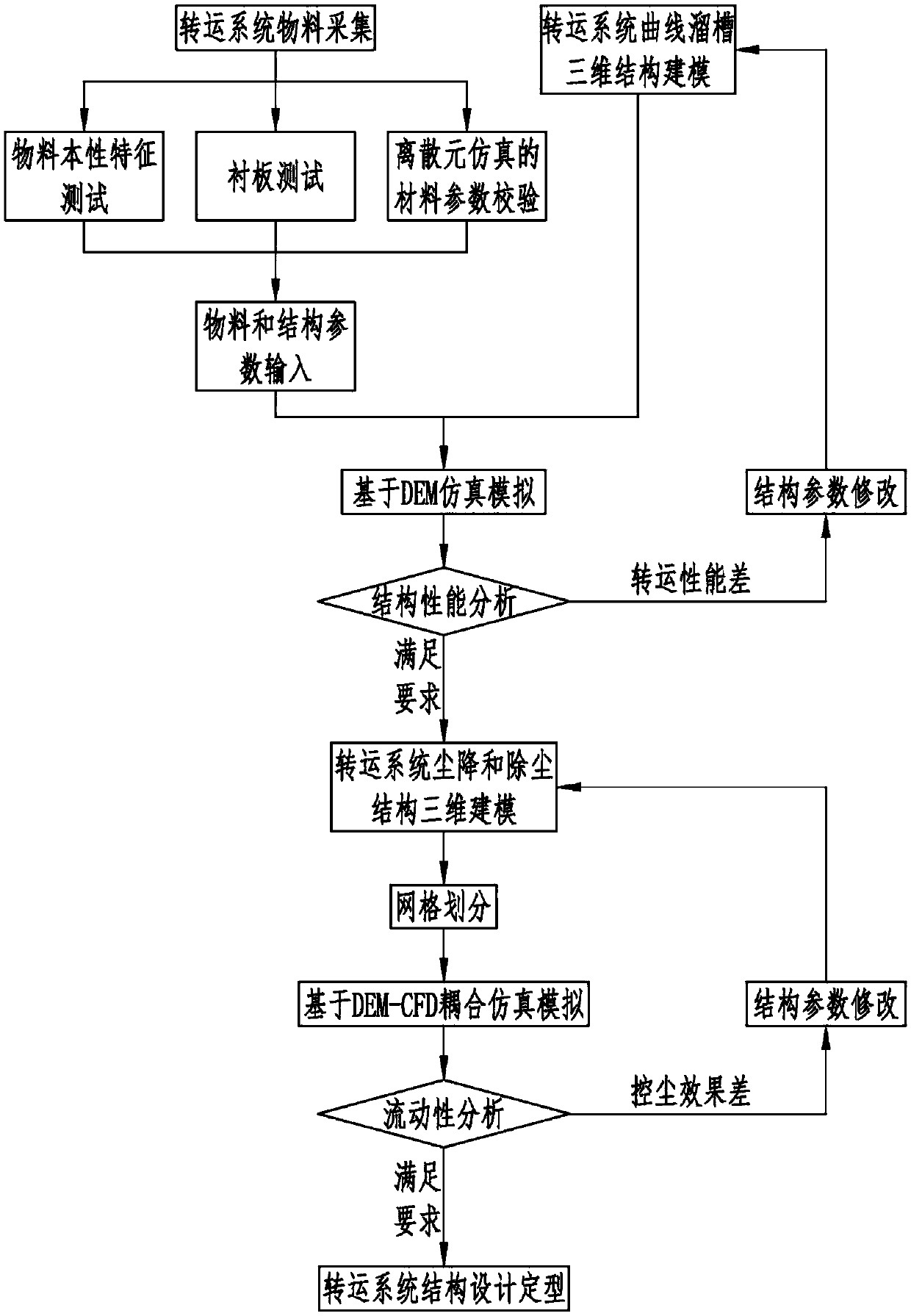

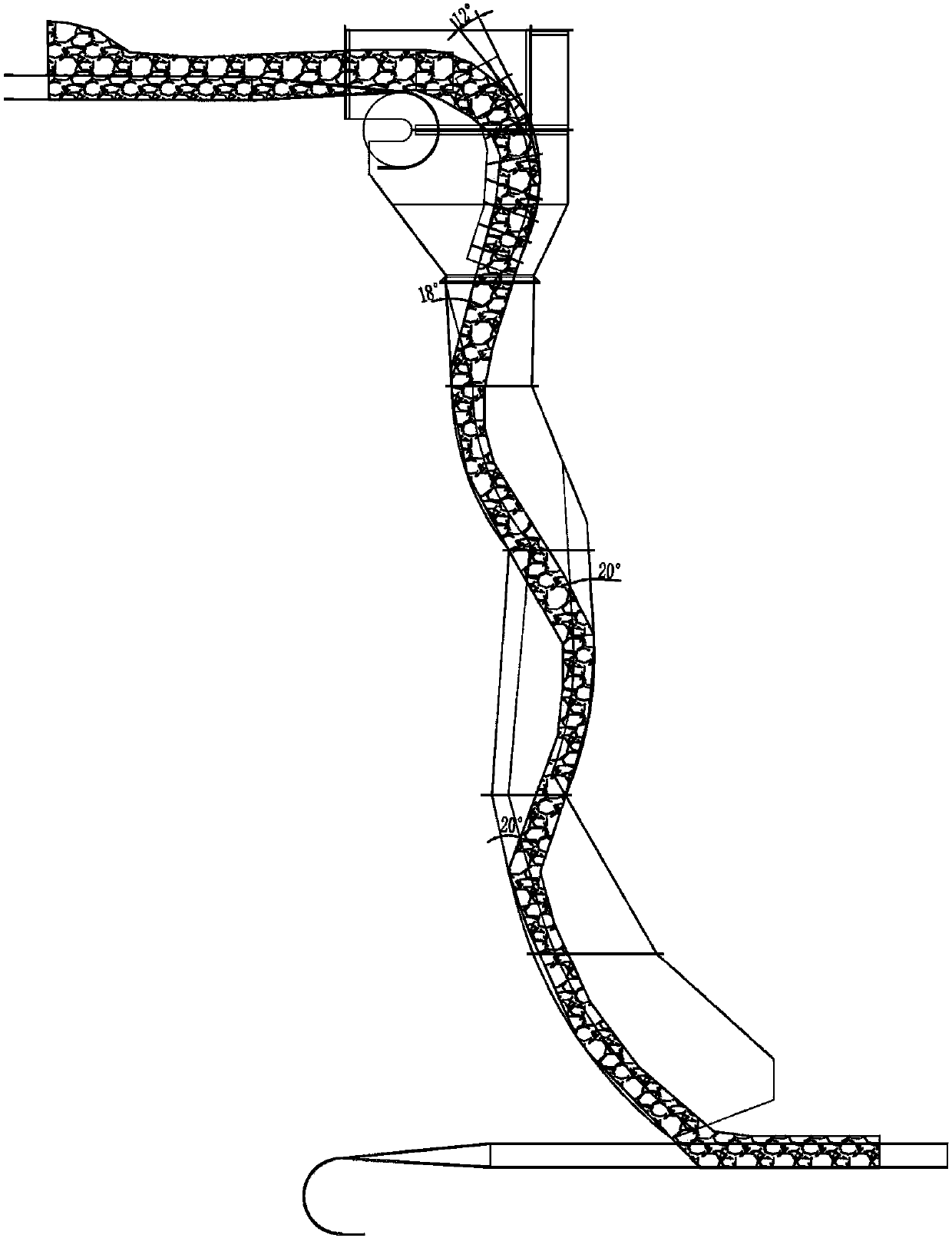

Structural design finalizing method based on material test and DEM-CFD (discrete element method and computational fluid dynamics) simulation coal transport system

ActiveCN108256270ADesign optimisation/simulationSpecial data processing applicationsDiscrete element methodTransport system

A structural design finalizing method based on material test and DEM-CFD (discrete element method and computational fluid dynamics) simulation coal transport system is based on the material test; through DEM and coupled simulation of DEM and CFD, system performance analysis is performed on the structure of the coal transport system before processing and manufacture; verification on design scheme performances helps a designer find potential problems of the system so as to finally determine an optimal design scheme.

Owner:XIAMEN LIQI ENVIRONMENTAL ENG

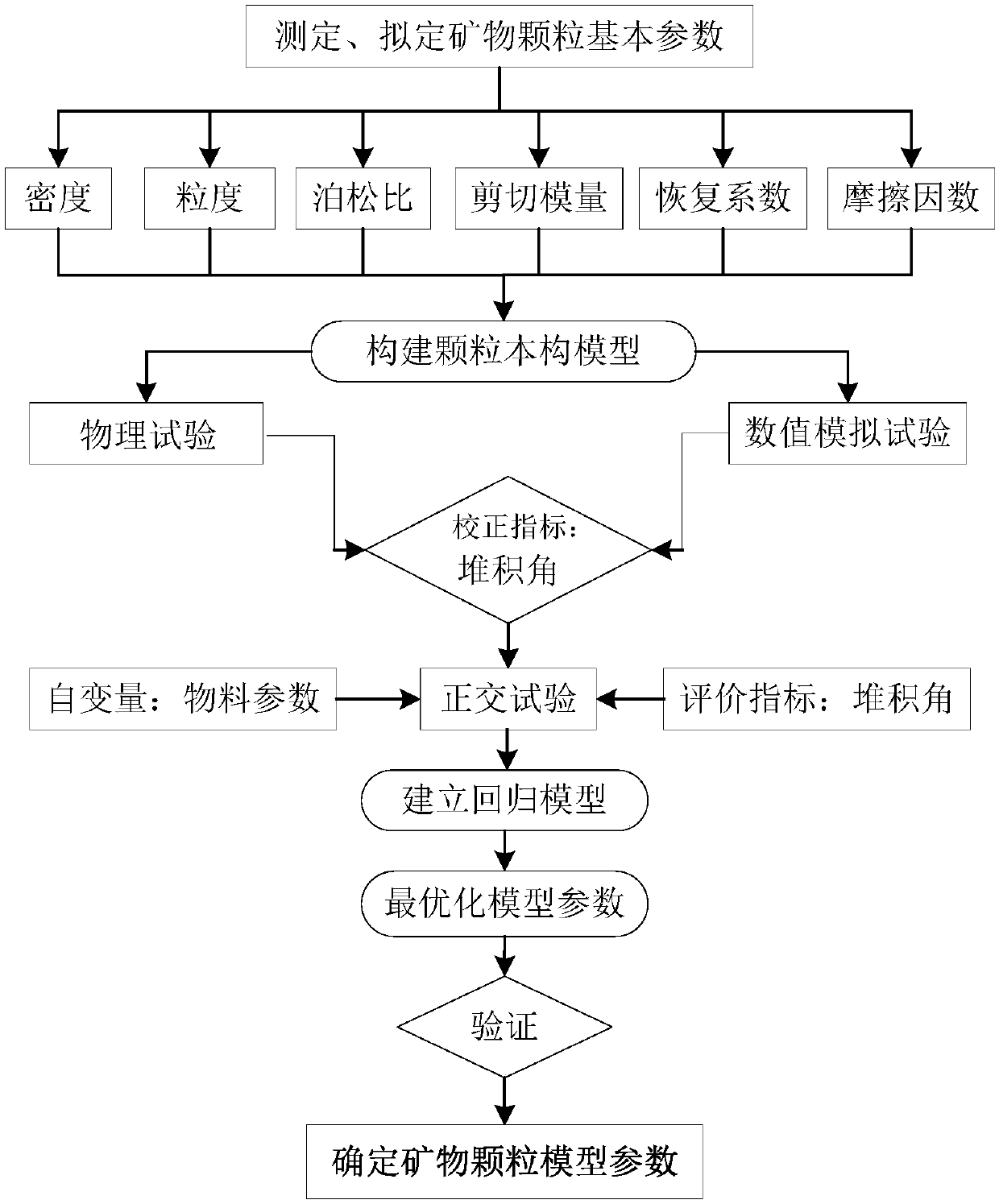

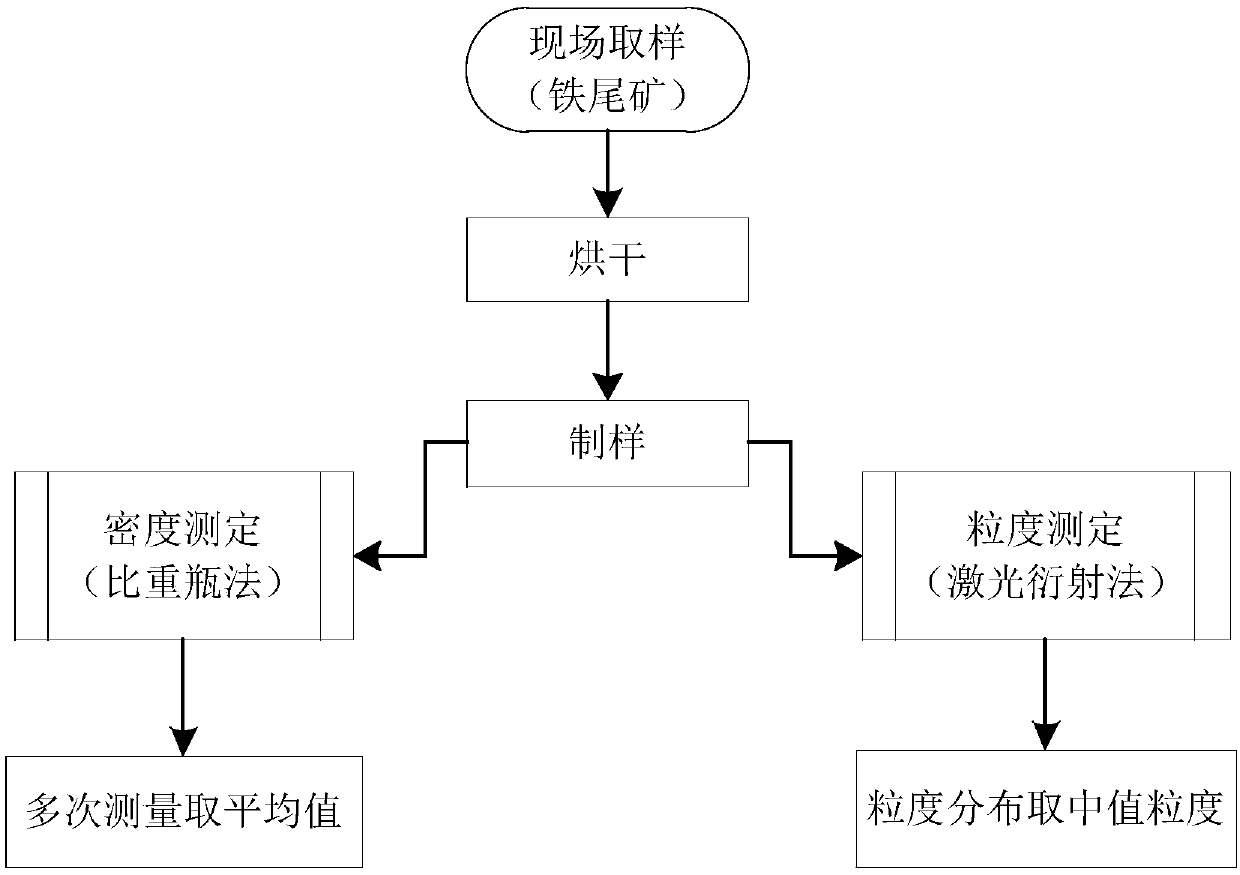

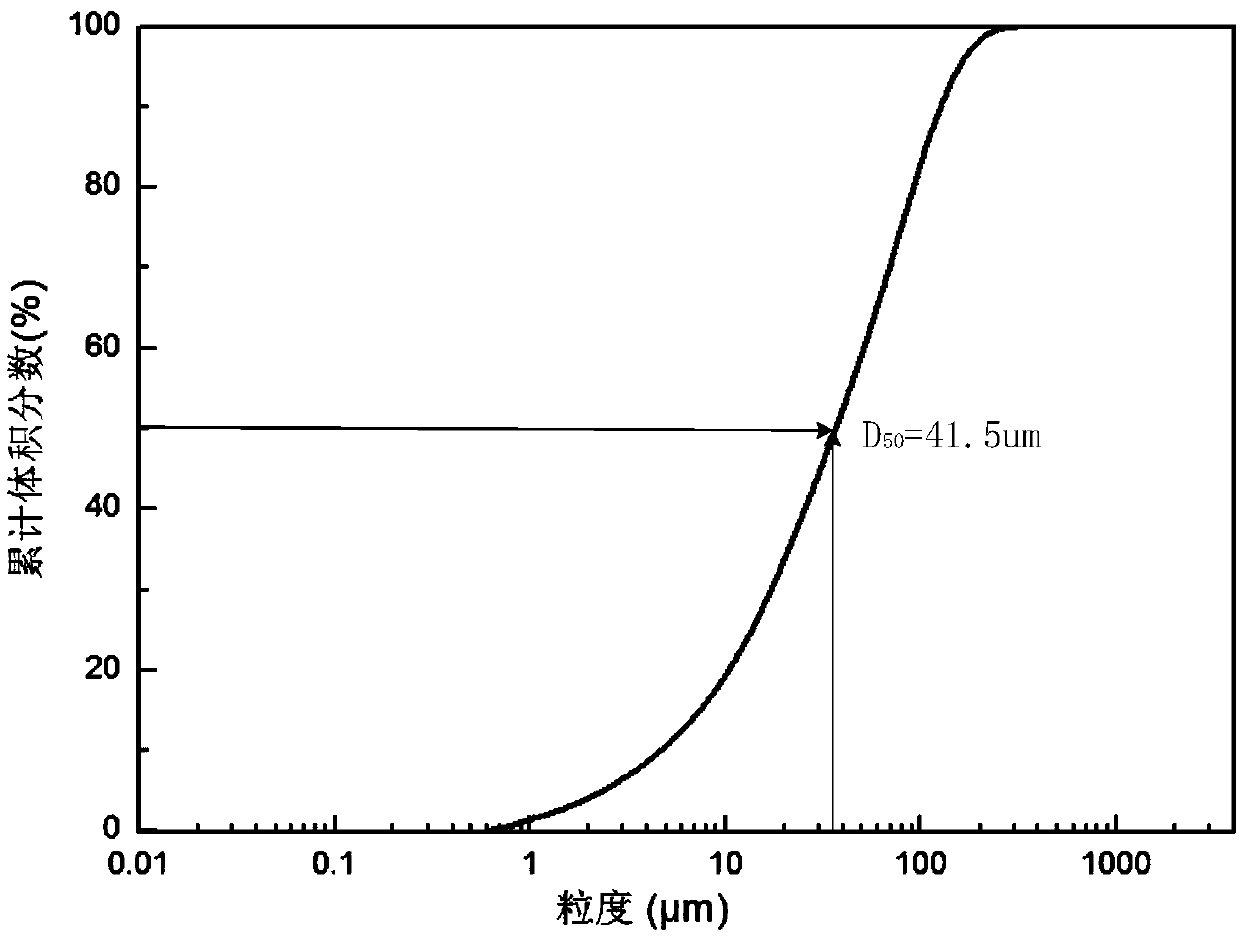

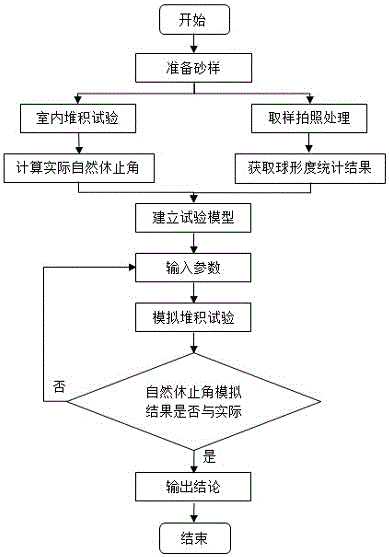

Mineral particle model parameter calibration method based on discrete element method

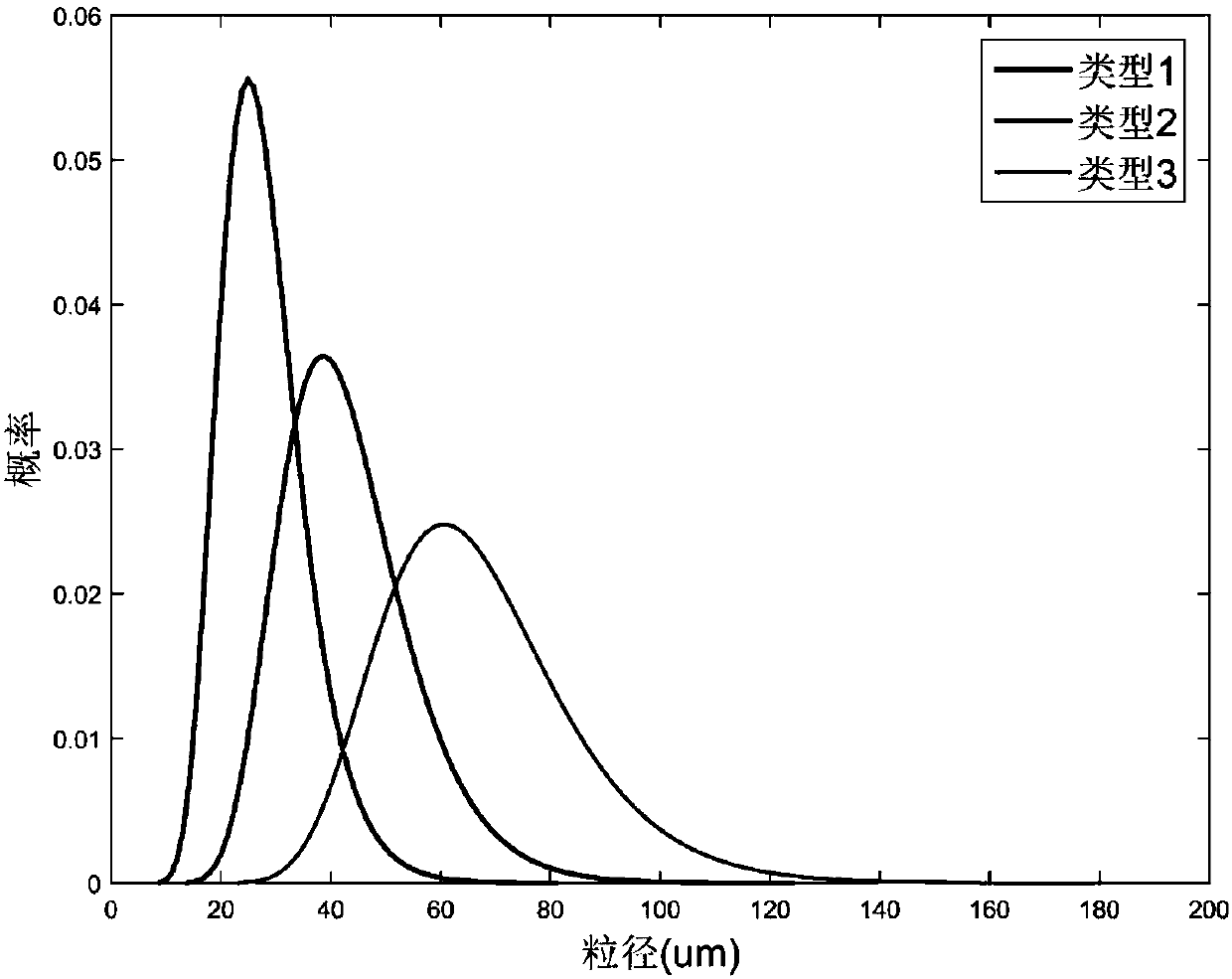

InactiveCN109612885AOvercoming complexityOvercome difficultyMaterial strength using tensile/compressive forcesParticle size analysisRegression analysisMineral particles

The invention provides a mineral particle model parameter calibration method based on a discrete element method. The mineral particle model parameter calibration method comprises the steps that a mineral particle model parameter constitutive model based on the discrete element method is built through physical test determination and a preliminary prepared method, and the constitutive model is usedfor being combined with stacking angle determination to carry out a physical and numerical simulation dual-directional test; on the basis of preliminary verification results, mineral particle model parameters are taken as independent variables to carry out an orthogonal numerical test, a stacking angle determination value is taken as an evaluation index to carry out regression analysis, and stacking angle physical test measurement is taken as a target value to build a regression model and determine a mineral particle model parameter optimal combination; and the determined optimal combination is verified through a numerical test again, and the mineral particle model parameters based on the discrete element method are determined finally. The technical scheme solves the problems of high difficulty in obtaining parameters and low measurement accuracy of an existing mineral particle model, and provides effective technical means for determining parameters of mineral particle numerical simulation tests.

Owner:NORTHEASTERN UNIV

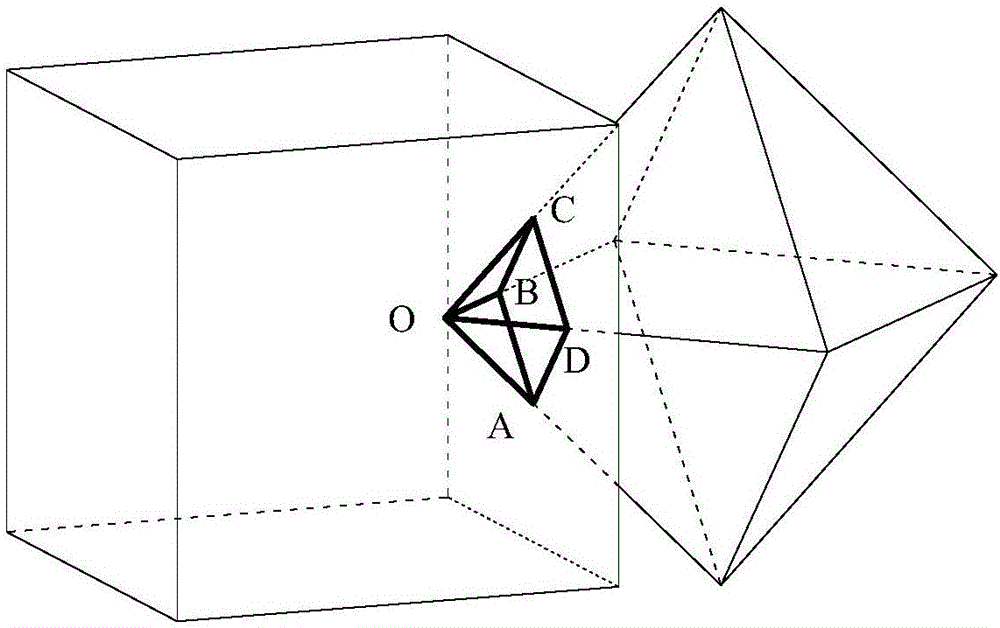

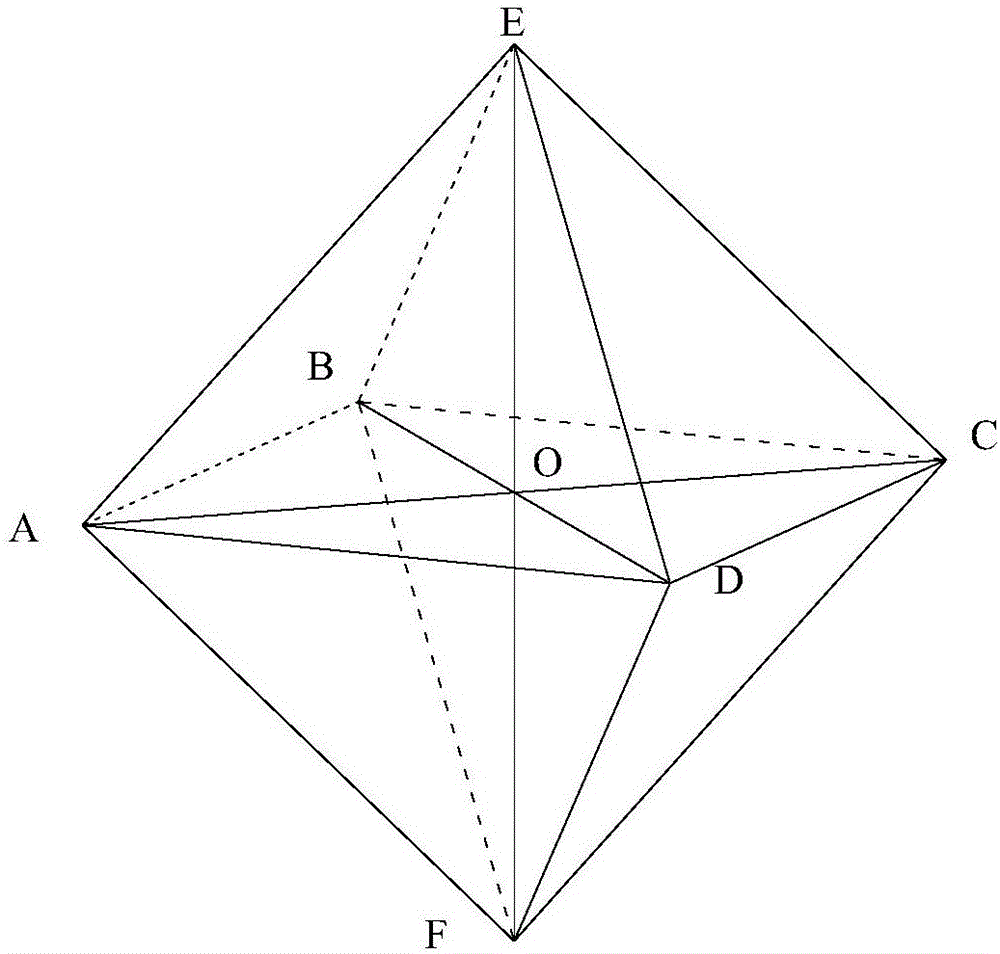

Three-dimensional random convex polygon block discrete element method based on distance potential function

ActiveCN106529146AReduce in quantityImprove accuracyInformaticsSpecial data processing applicationsResearch ObjectContact force

The invention discloses a three-dimensional random convex polygon block discrete element method based on a distance potential function. A research object is discretized into a block element system; carrying out contact detection on all block elements according to a nonuniform block discrete element contact detection method provided by the method; defining the distance potential function and carrying out normal contact force calculation on mutually contacting block elements, thereby obtaining normal contact force acting on each target block element and a torque caused by the normal contact force; on the basis of a tangential contact force direction vector calculation method provided by the method, carrying out calculation to obtain tangential contact force of each block element and the torque caused by the tangential contact force according to increment of tangential relative displacement; solving acceleration and angular acceleration of each block element through a rigid motion equation; and calculating velocity and displacement of each block element through a velocity verlet algorithm and describing deformation and motion state of a whole medium according to motion and relative position of each block element.

Owner:HOHAI UNIV

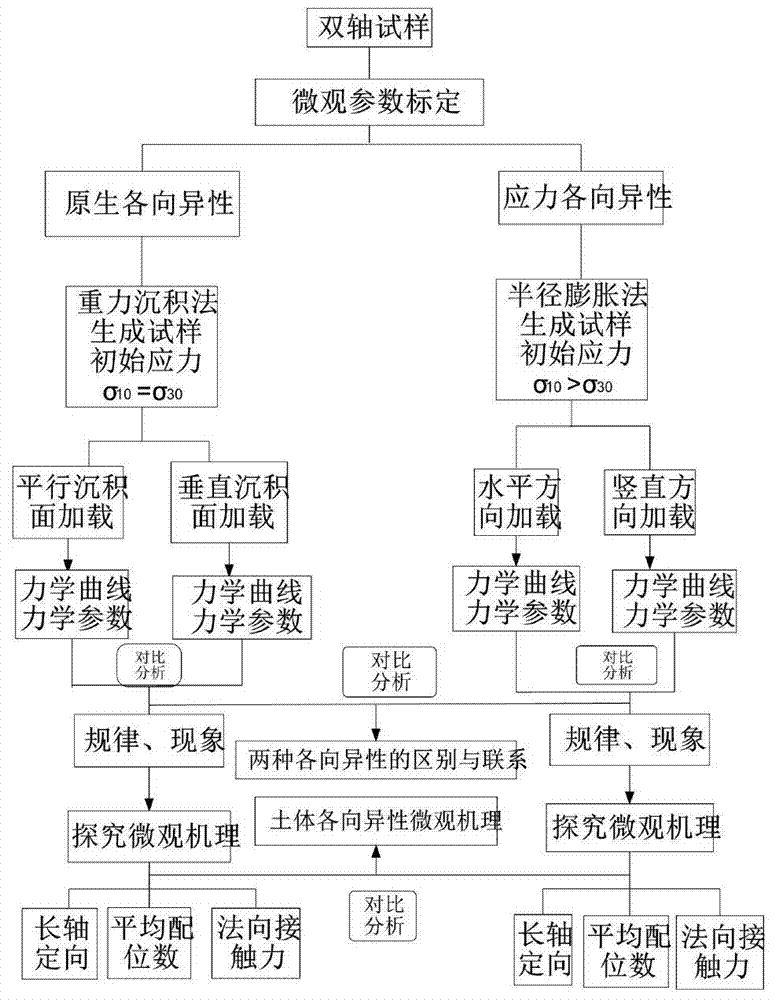

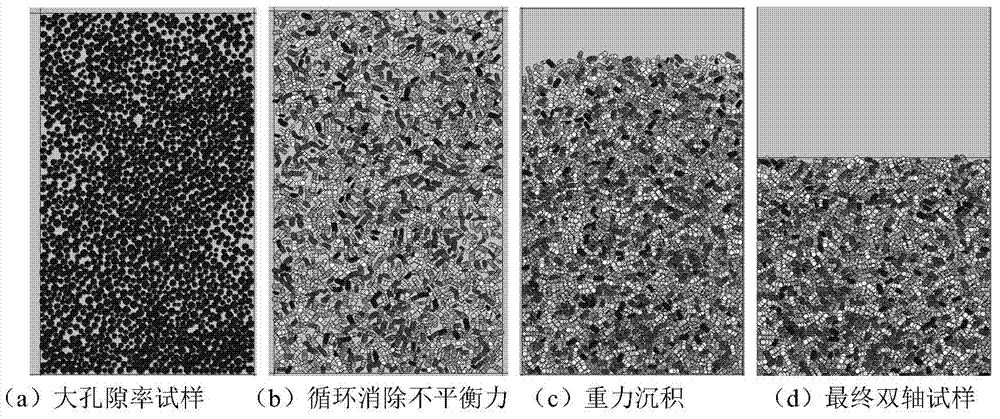

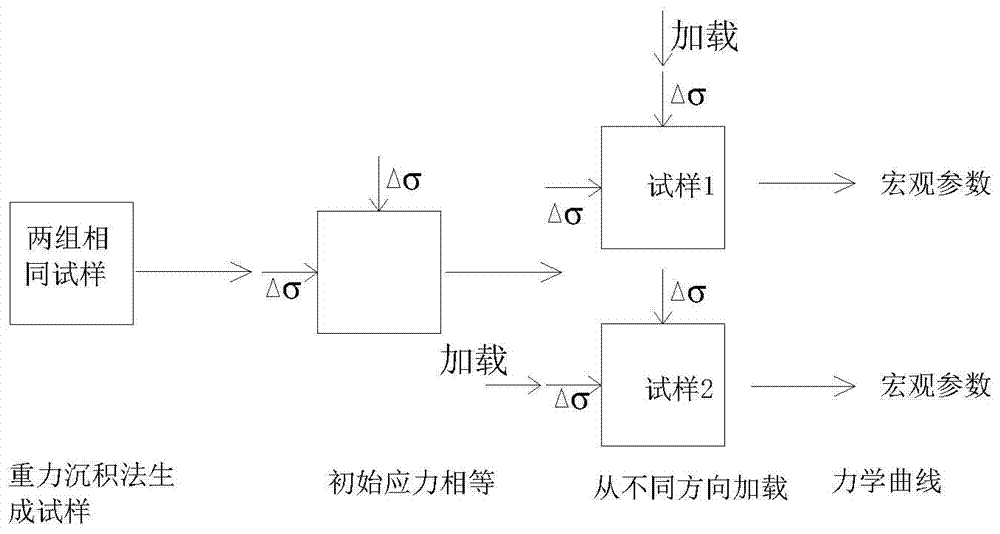

Cohesionless soil anisotropic mechanical property microcosmic mechanism numerical simulation method

ActiveCN104517006AEasy to compareHigh simulationSpecial data processing applicationsStress–strain curveSoil stress

The invention provides a soil anisotropic mechanical property research idea and method from the microscopic point of view by developing a horizontal loading program and a micro-mechanical parameter monitoring program through a particle discrete element unit method. The method includes the steps of (1) obtaining stress-strain curves and related mechanical parameters of cohesionless soil according to laboratory tests; (2) establishing a plane biaxial specimen to simulate soil original anisotropy according to micromechanics parameters determined in a particle flow biaxial test in step (1); (3) establishing a plane biaxial specimen to simulate soil stress anisotropy according to the micromechanics parameters determined in the particle flow biaxial test in step (1); (4) comparing and analyzing expression rules of soil original anisotropy and the soil stress anisotropy to obtain the difference and relation between the two kinds of anisotropy and finding out microscopic mechanisms of the production of the two kinds of soil anisotropy. The soil anisotropic mechanical property research idea and method provides a new idea for the cohesionless soil anisotropic mechanical property numerical simulation by using the advantages of the particle flow discrete element method in the research of the particulate material microstructure.

Owner:HOHAI UNIV

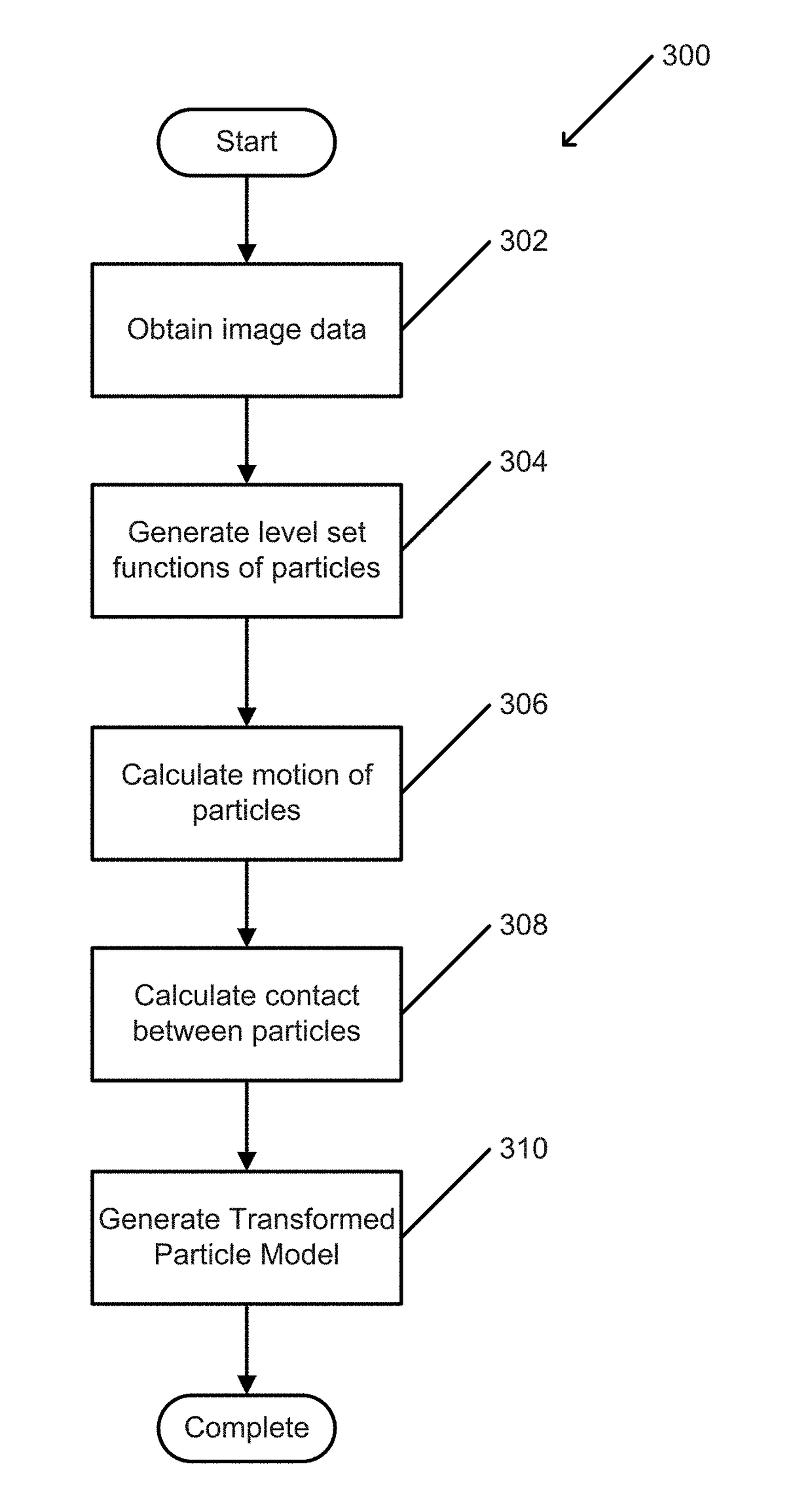

Systems and Methods for Level Set Discrete Element Method Particle Simulation

ActiveUS20180203960A1Design optimisation/simulationSpecial data processing applicationsDiscrete element methodComputer science

Systems and methods for level set discrete element method particle simulation in accordance with embodiments of the invention are disclosed. In one embodiment, a particle simulation device includes a processor and a memory storing a particle analysis application, wherein the processor, on reading the particle analysis application obtains image data describing a plurality of particles, models a plurality of grains based on the image data, where each modeled grains includes a level set function corresponding to one of the plurality of particles, calculates the motion of each of the plurality of grains based on a force applied to the plurality of grains, and generates a transformed particle model based on the plurality of grains and the calculated motion.

Owner:CALIFORNIA INST OF TECH

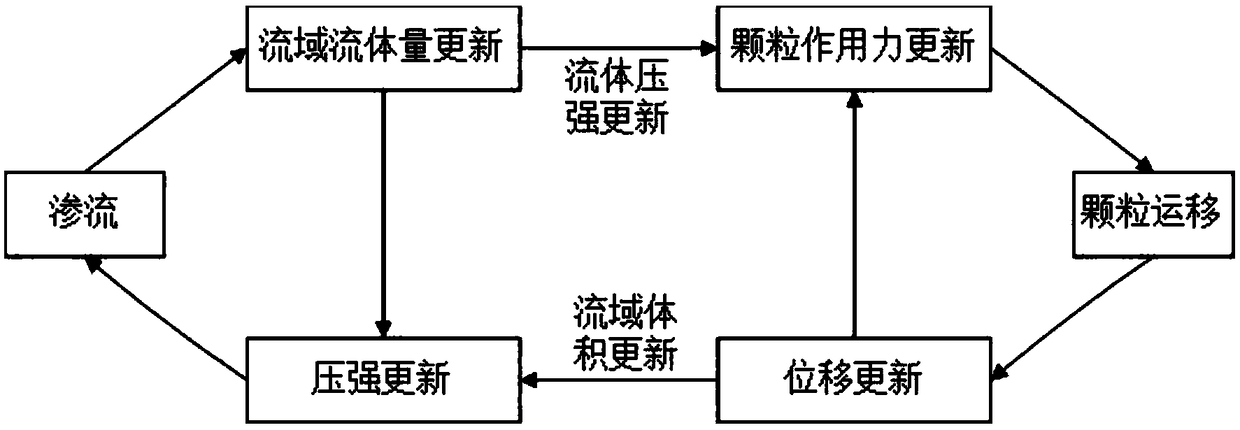

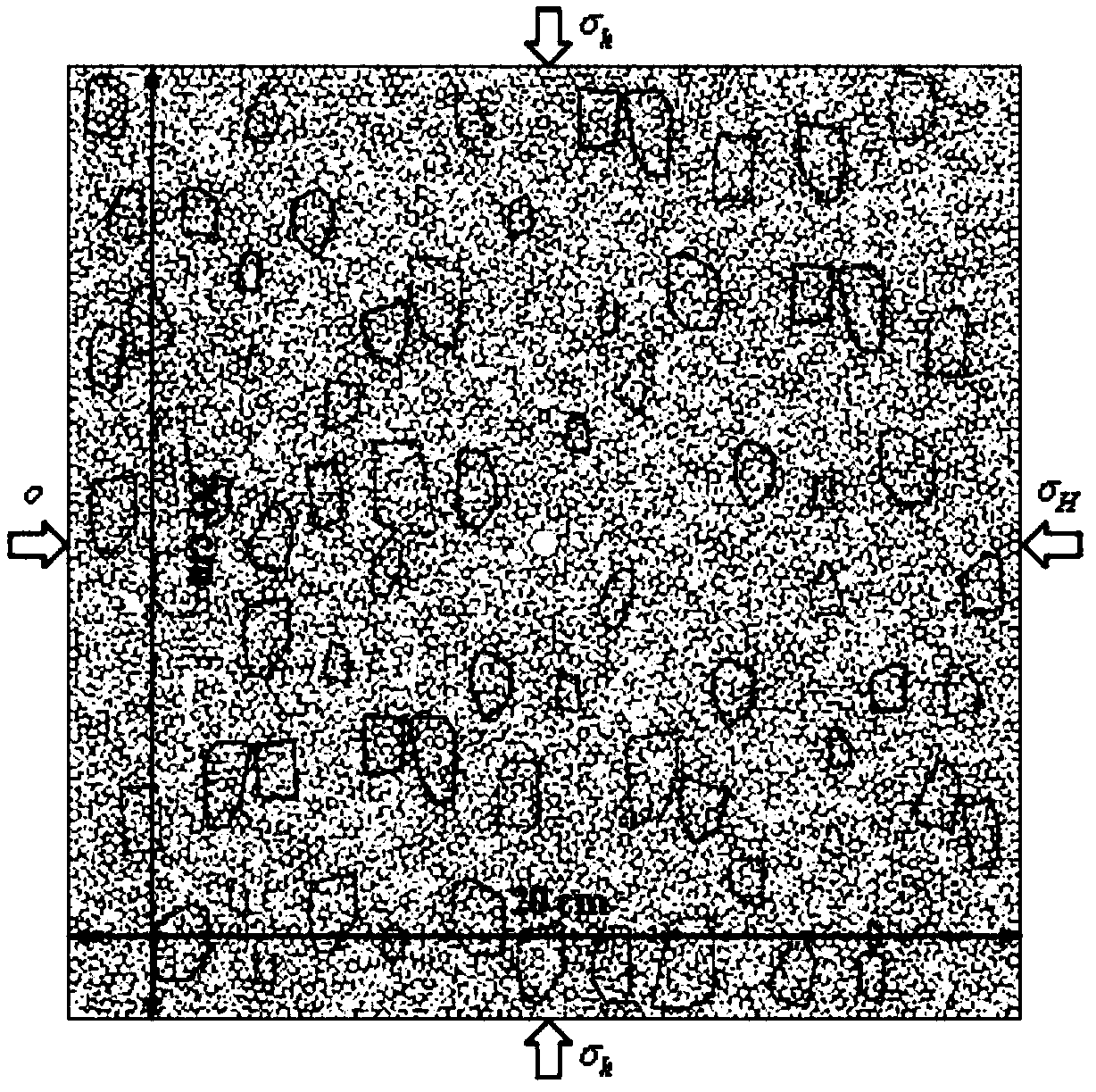

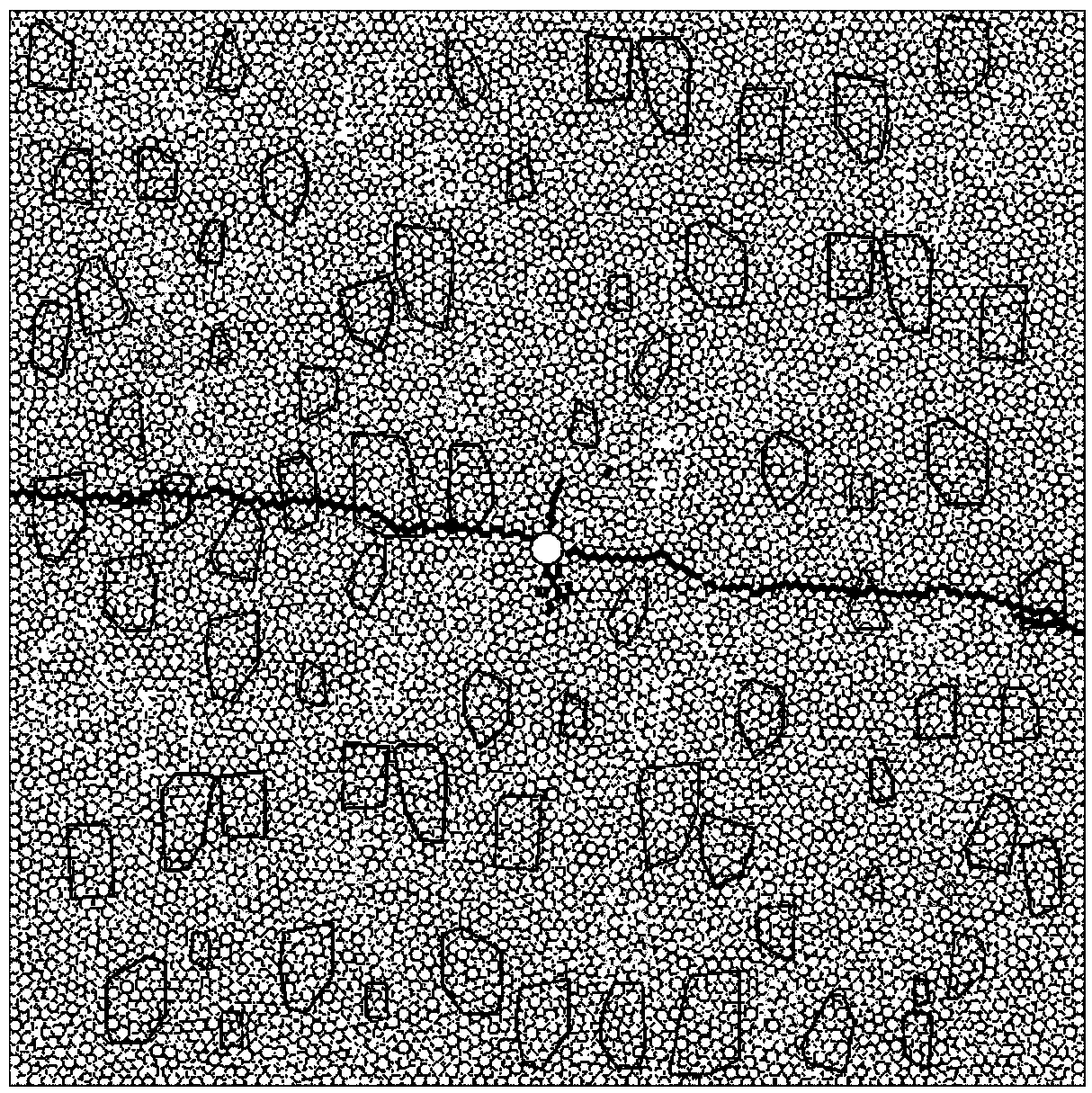

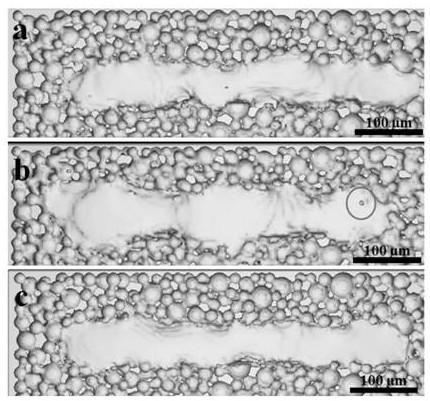

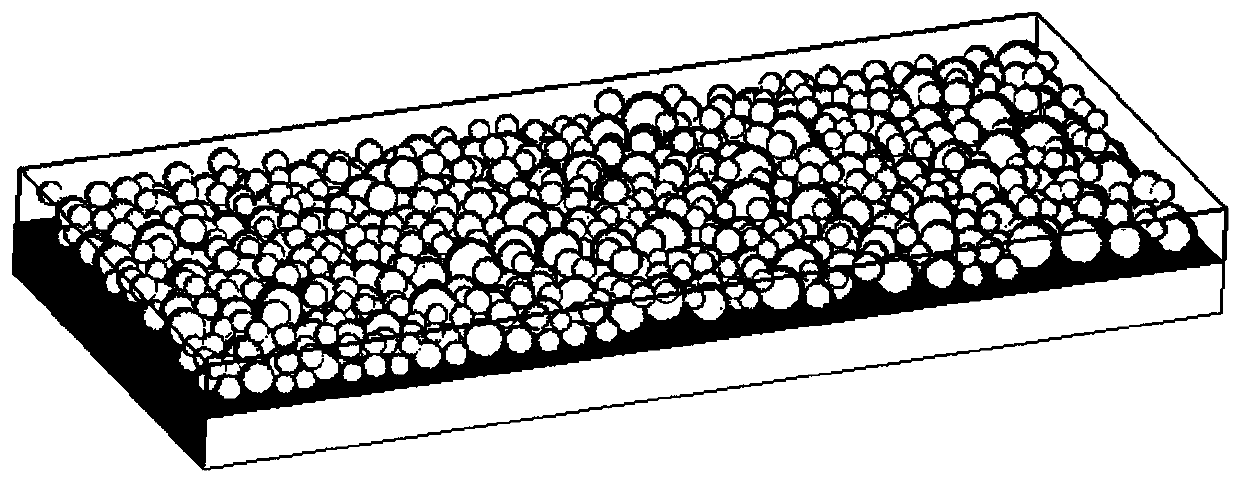

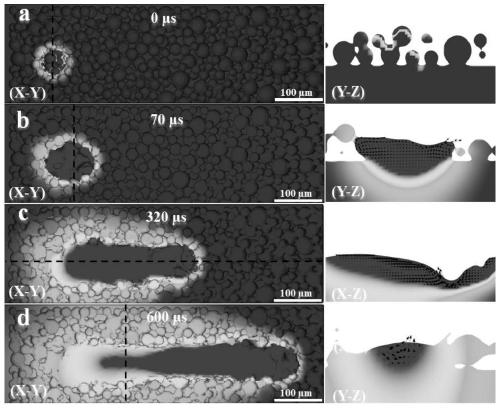

Glutenite hydrofracture simulation method based on discrete element

ActiveCN109374867AAccurate captureAccurately reproduce interactionsEarth material testingDiscrete element methodHydraulic fracturing

The invention relates to a glutinite hydrofracture simulation method based on a discrete element. The method comprises the following steps of: S1, constructing a wall and a well bore, generating particles according to a size grading curve, and performing initial balance calculation, S2, dividing the particles into a matrix and gravel by a cutting method, endowing the matrix and the gravel with different cementing parameters, S3, adding a seepage field and endowing a corresponding flow parameter, S4, applying confining pressure on the external wall based on a servo system, setting a fluid injection speed, S5, monitoring cementing states of the particles in real time, and judging whether micro cracks are generated according to the cementing states, and S6, continuing simulation till penetration of hydraulic cracks occurs. The glutinite hydrofracture simulation method based on the discrete element can characterize crack initiation and expansion mechanisms of the hydraulic cracks preciselyfrom a microscale, and accurately capture a macro distribution morphology of the hydraulic cracks, so that the understanding of a field engineer on an expansion rule of the hydraulic cracks of a glutinite reservoir is enhanced; and a fracture design is improved.

Owner:QINGDAO UNIV OF SCI & TECH

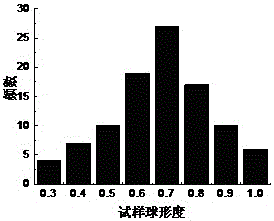

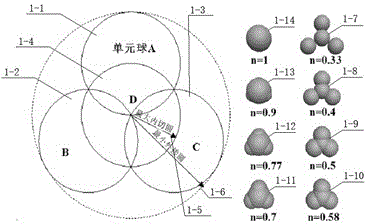

Discrete element combined particle and discrete element stacking test simulation method thereof

ActiveCN106290082AApproximate mechanical propertiesAvoid the defect of not being able to realistically simulate sand and soil bitePermeability/surface area analysisParticle and sedimentation analysisDiscrete element methodEngineering

The invention relates to a discrete element combined particle and a discrete element stacking test simulation method thereof. The discrete element combined particle comprises Clump particles at various degrees of sphericity; each Clump particle is composed of a unit ball A, a unit ball B, a unit ball C and a unit ball D; the unit ball A, the unit ball B and the unit ball C are in equal radius; the unit ball A, the unit ball B and the unit ball C are arrayed on the periphery of the unit ball D in a circumferential distribution form; the unit ball A, the unit ball B and the unit ball C are all tangent or intersected with the unit ball D; and the value n of the degree of sphericity of the Clump particles is more than or equal to 0.33 but less than or equal to 1. According to the invention, a discrete element method is adopted for developing the Clump particles and performing the stacking test simulation; a friction coefficient of the practical particle is directly utilized to simulate the mechanical characteristics of the sand particles according to the statistical result of the degree of sphericity of the particles; the defect of the traditional ball particle adopting a bigger friction coefficient is avoided; and the mechanical property is more approximate to the mechanical property of the practical sand soil.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

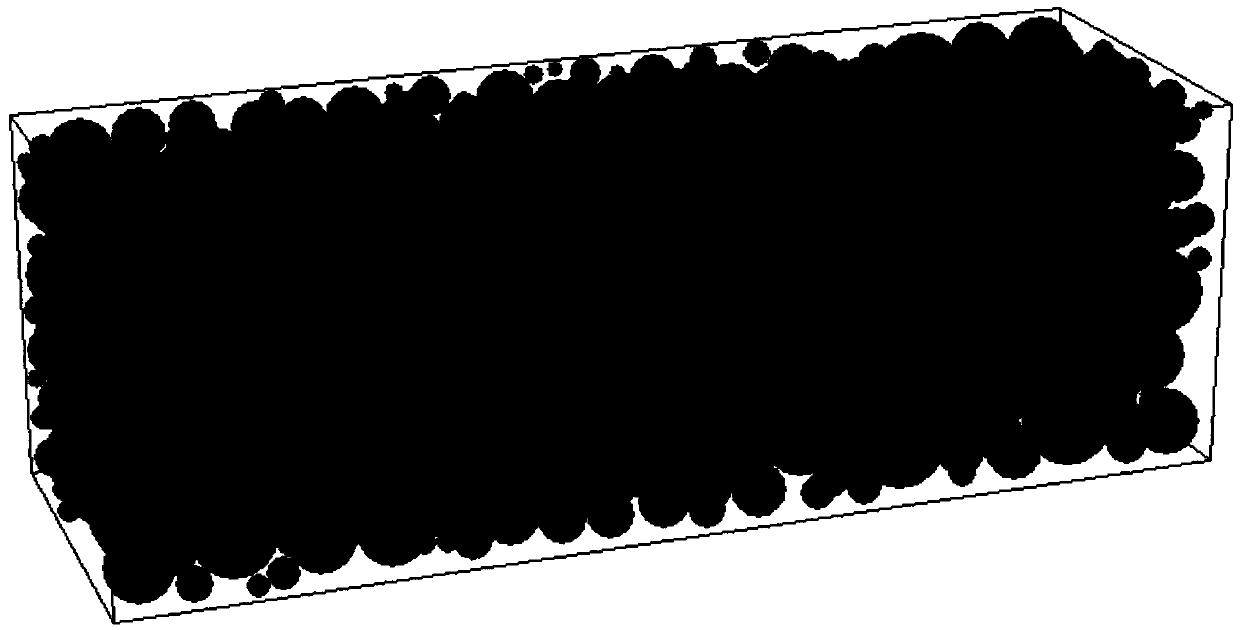

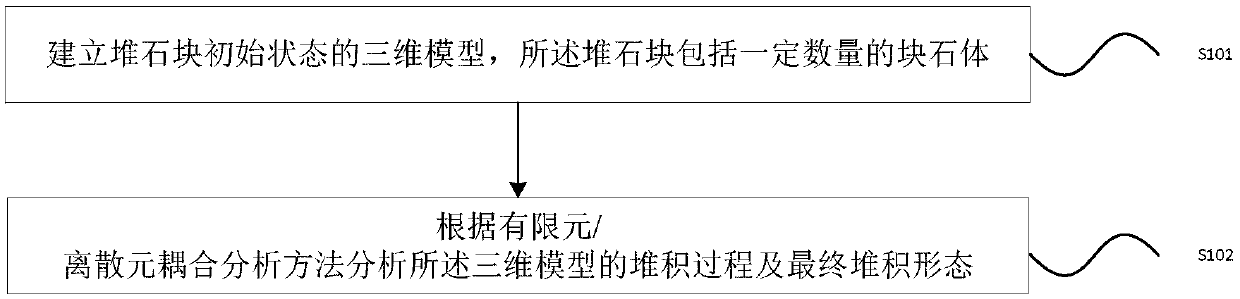

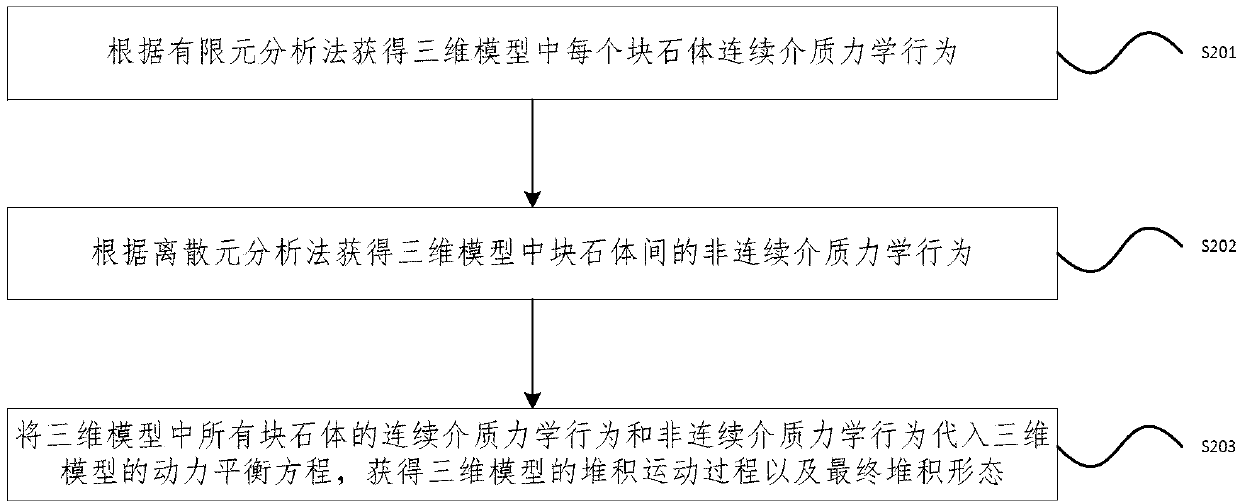

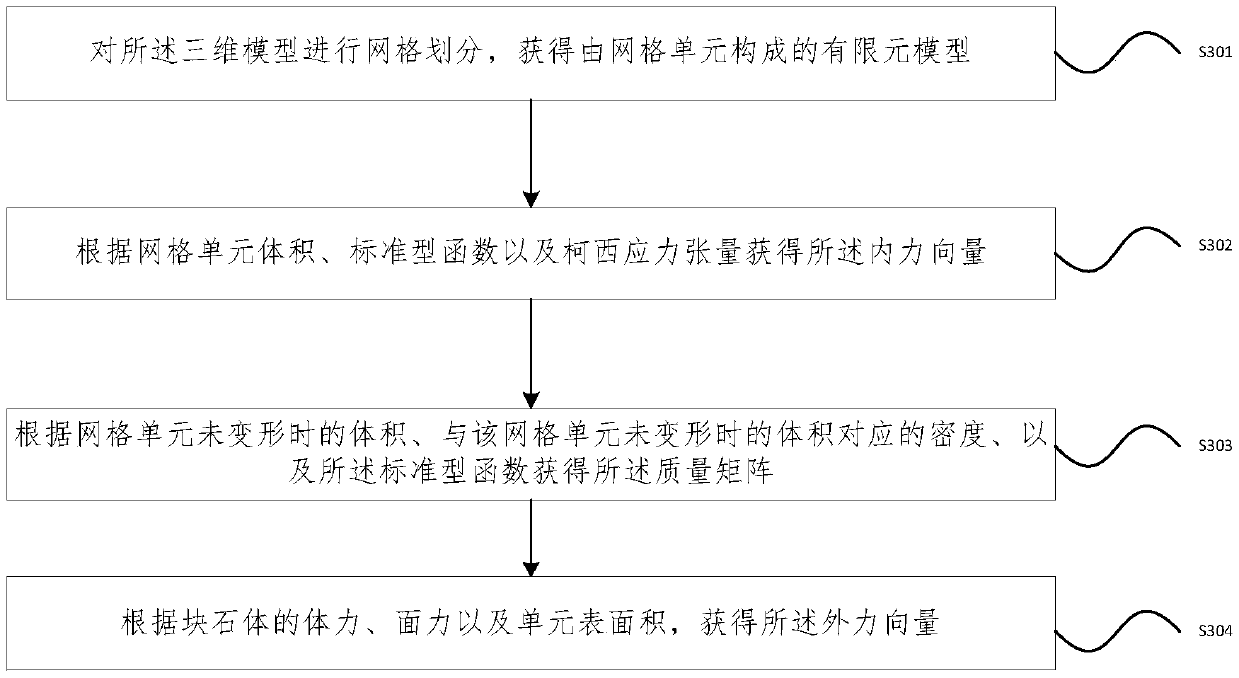

Calculation method and system of rockfill concrete rockfill pile-up process

InactiveCN108984829ASolving Multibody Kinematics ProblemsSolve the mechanical propertiesDesign optimisation/simulationSpecial data processing applicationsDiscrete element methodKinematics

The invention provides a calculation method and system for a rockfill concrete rockfill pile-up process. The method includes: establishing a three-dimensional model of an initial state of a rockfill block, wherein the rockfill block comprises a certain number of block rockfill bodies; analyzing the accumulation process and the final accumulation form of the three-dimensional model according to thefinite element / discrete element coupling analysis method. The finite element / discrete element coupled analysis method, which combines the finite element method to simulate structural stress and deformation with the discrete element method to track block motion, is called finite element / discrete element coupled analysis method. The method retains the advantages of finite element method and discrete element method, which can solve the kinematics and failure mechanics problems of multi-body. In the process of calculating the final accumulation form of the rockfill concrete rockfill block, thereare the characteristics of a large number of block rockfill bodies, complex stress and deformation of the rockfill body with the change of the stress. The mechanical analysis of the invention can completely depict the progressive accumulation process of the rockfill block under the action of the stress, and the calculation result is more accurate.

Owner:CHINA AGRI UNIV

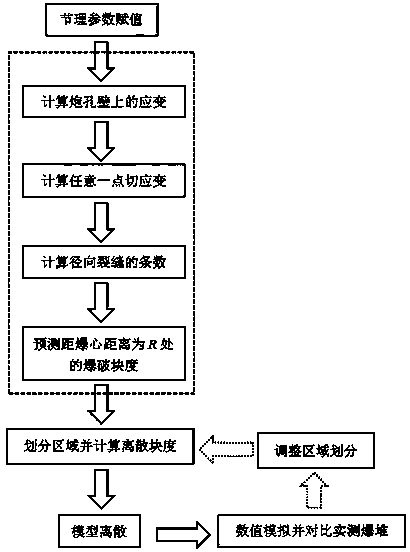

Method for simulating discrete element muck pile form

InactiveCN104239637AHigh precisionIn line with engineering practiceSpecial data processing applicationsBlastingDiscrete element methodShear modulus

The invention discloses a method for simulating a discrete element muck pile form. The method comprises the steps of step 1, respectively giving a bulk modulus and a shear modulus of an integrated rock mass to normal lumpiness and shear lumpiness of an artificial joint; step 2, forecasting forecasted blasting lumpiness of all points in positions which are away from the center of a blast hole in different distances by adopting a Harries blasting model aiming at an integrated rock mass model; step 3, zoning the integrated rock mass model, and taking an average value of the forecasted blasting lumpiness of all points in all zones as preset lumpiness of discrete blocks in the all zones; step 4, setting the artificial joint according to the preset lumpiness of the discrete blocks in the all zones, setting the artificial joint in an oblique and orthogonal way, and dispersing the integrated rock mass model by adopting a discrete element method; step 5, carrying out muck pile form simulation on the dispersed integrated rock mass model by adopting the discrete element method. The method disclosed by the invention has the advantages that the operation is simple, the efficiency and the accuracy of muck pile form simulation can be obviously increased, the discrete element muck pile form is more accordant with engineering practice, and the application prospect is wide.

Owner:WUHAN UNIV

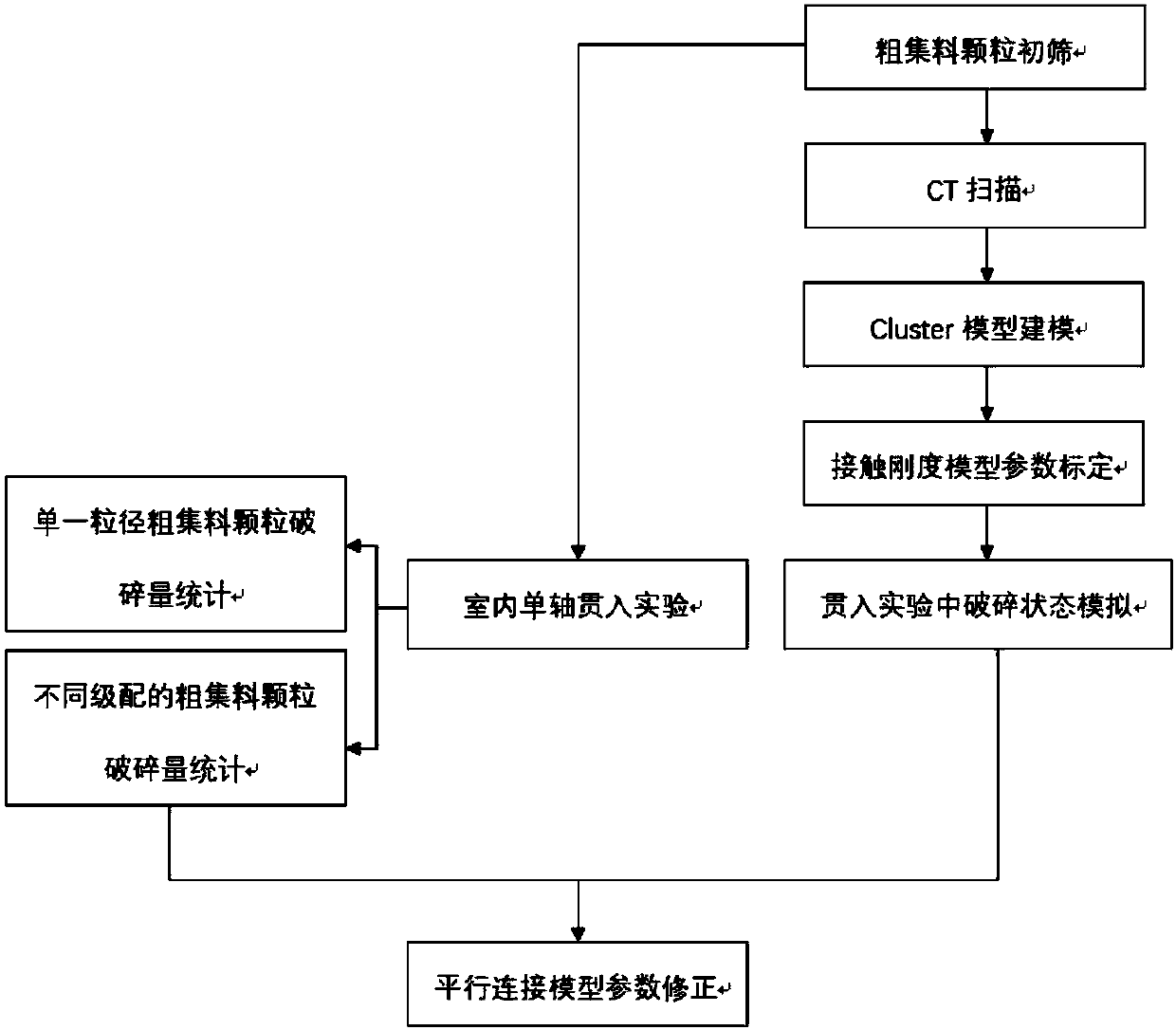

Smashed-state coarse aggregate discrete element method

ActiveCN107657128ARealize broken state simulationGeometric CADDesign optimisation/simulationDiscrete element methodRoad engineering

The invention discloses a smashed-state coarse aggregate discrete element method. The smashed-state coarse aggregate discrete element method comprises the following steps: (1) performing initial screening of coarse aggregate particles; (2) performing CT scanning; (3) performing PFC2D modeling of discrete element software; (4) calibrating parameters of a single-particle-size coarse aggregate particle contact rigidity model; (5) performing statistics to obtain the smashing amount of single-particle-size coarse aggregate particle under penetration resistance; (6) performing statistics to obtain the smashing amount of different grades of coarse aggregate particles under penetration resistance; and (7) correcting parallel connection model parameters based on the coarse aggregate particle smashing amount. Through adoption of the smashed-state coarse aggregate discrete element method, the problem that virtual coarse aggregate particles cannot be smashed in a road engineering discrete elementsimulation process is solved. Micro model parameters of particles of different particle sizes are determined by a Cluster model in discrete element software in conjunction with statistics of the smashing amount in an indoor penetration resistance test in order to simulate a smashing process of a particle material under the action of external resistance, and the virtual coarse aggregate particle shape rebuilding accuracy is ensured by image scanning.

Owner:SOUTHEAST UNIV

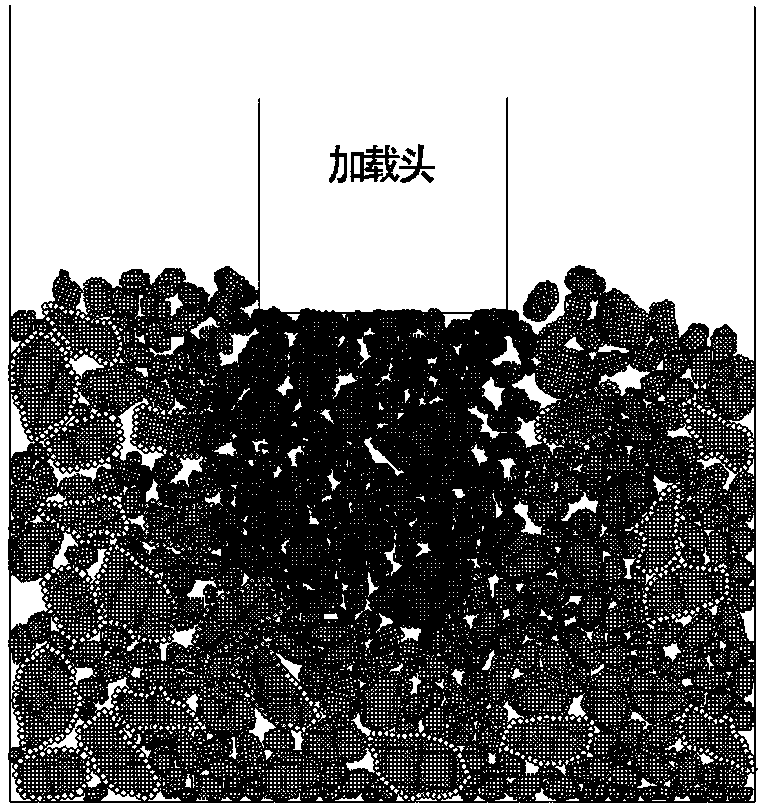

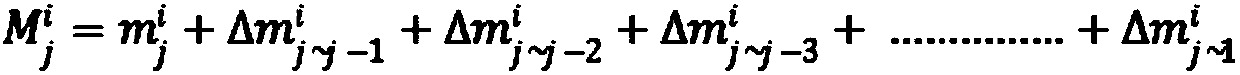

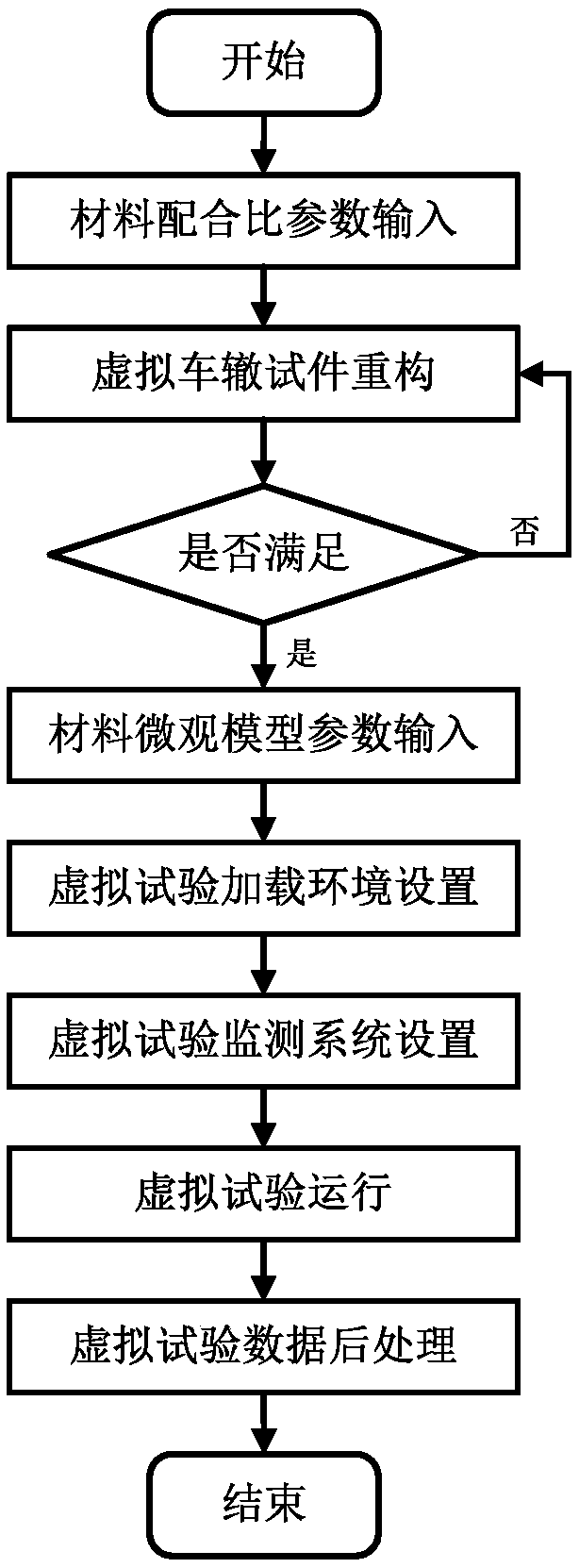

High-temperature performance virtual track test method for asphalt mixture

InactiveCN108982213AOvercome the macroOvercoming the Insufficiency of External Information ChangesMaterial strength using tensile/compressive forcesMaterial testing goodsModel parametersHigh heat

The invention discloses a high-temperature performance virtual track test method for an asphalt mixture. The method comprises the following steps: inputting material mix proportion parameters; reconstructing a virtual track test piece; inputting parameters of a material micromodel; setting a virtual test loading environment; setting a virtual test monitoring system; operating a virtual test; and post-processing virtual test data. A discrete element method adopted by the high-temperature performance virtual track test method for the asphalt mixture is suitable for analyzing large deformation ofa discontinuous medium material and a particle material, in particular analyzing and evaluating high-temperature performance of the asphalt mixture. The test result is reliable, the test period can be shortened greatly, the test cost is lowered, and the problem that the test is limited by site and time is solved. Meanwhile, the test process can be replayed, repeated and reproduced, so that the scientific research and teaching efficiency is improved greatly.

Owner:NANJING INST OF TECH

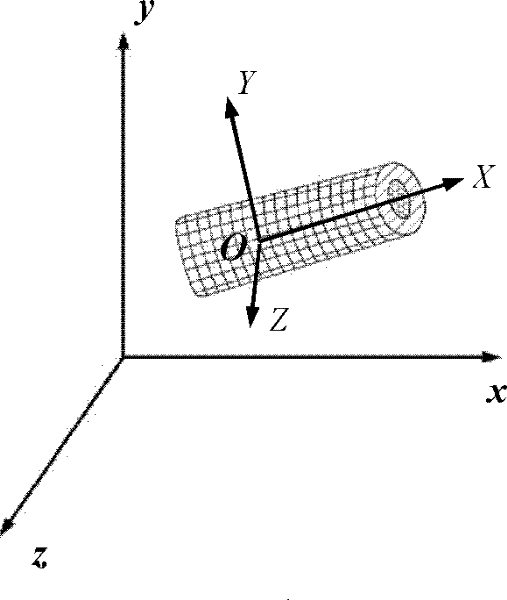

Discrete-element-method-based corn threshing process analysis method

ActiveCN102415243AAchieve integrationImprove performanceThreshersDiscrete element methodAnalysis method

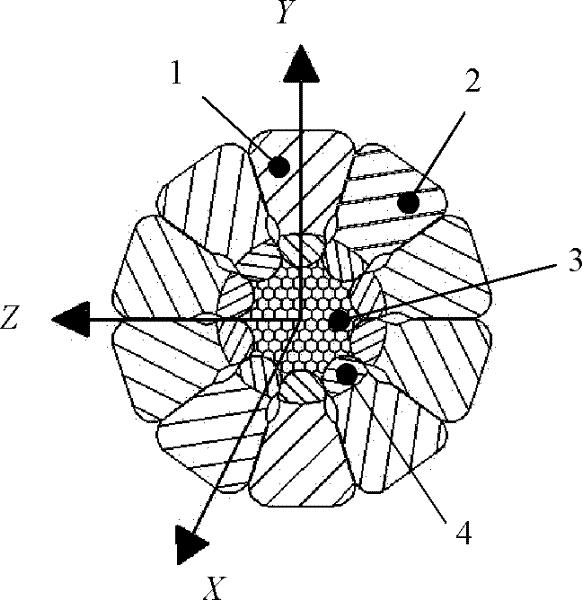

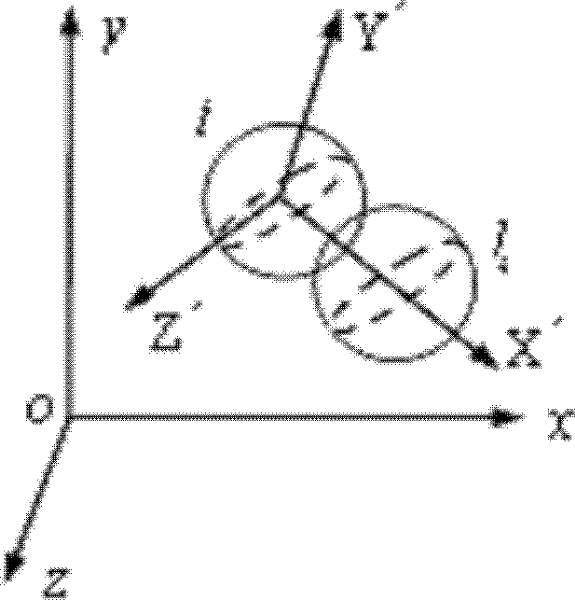

The invention relates to a discrete-element-method-based corn threshing process analysis method. The method is used for researching the corn threshing process. The method comprises the following steps of: establishing a global coordinate system x-y-z and a first local coordinate system X-Y-Z; establishing a discrete element method analysis model of corn ears and corncobs by a spherical particle polymerization method, wherein a connection line of the spherical center of a certain sphere i which is used for forming a corn grain or a corncob and the spherical center of another composed sphere j which is contacted with the corn grain or the corncob is taken as an X' axis, and a Y' axis and a Z' axis meet a right-hand screw rule; transforming contact action repulsion of all composed spheres of each grain which is calculated in the previous step to a third local coordinate system X''-Y''-Z'', and solving resultant force; and when the corn grain is not separated from the corncob if the connection force is less than the connection force determined by the test, evaluating the new position of the remained grain relative to the corncob and updating the position of the corn grain in the third local coordinate system X''-Y''-Z''.

Owner:JILIN UNIV

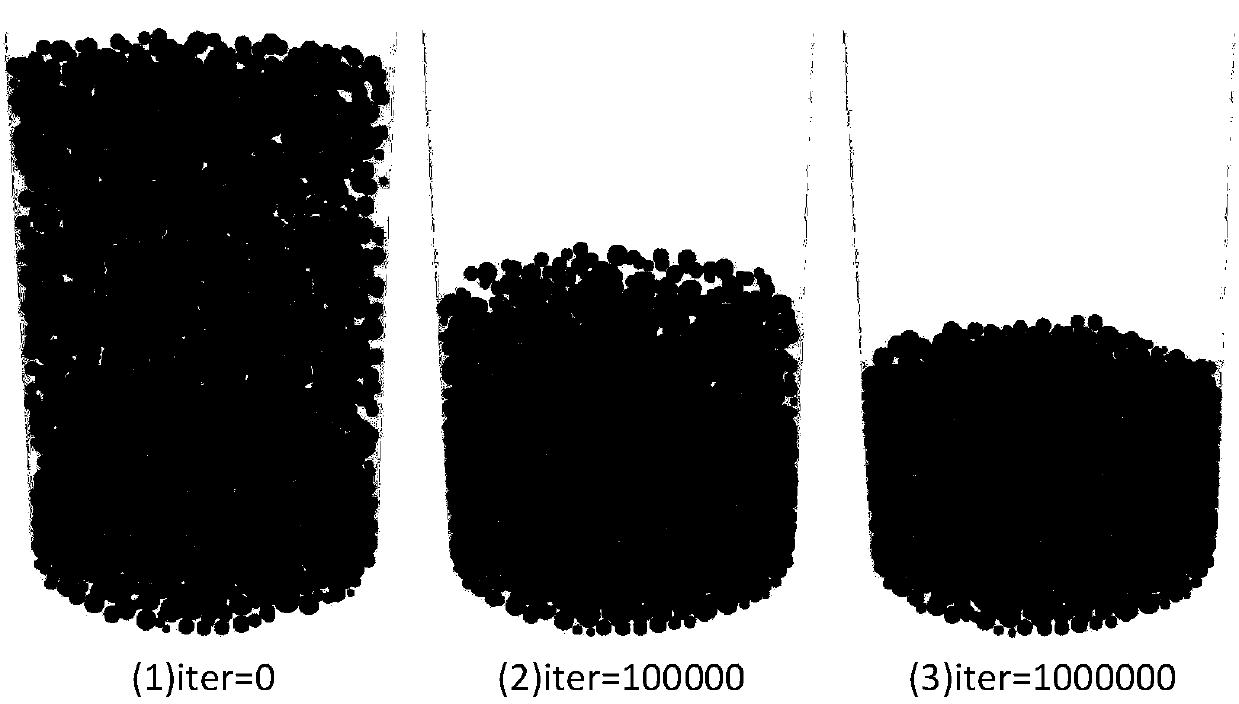

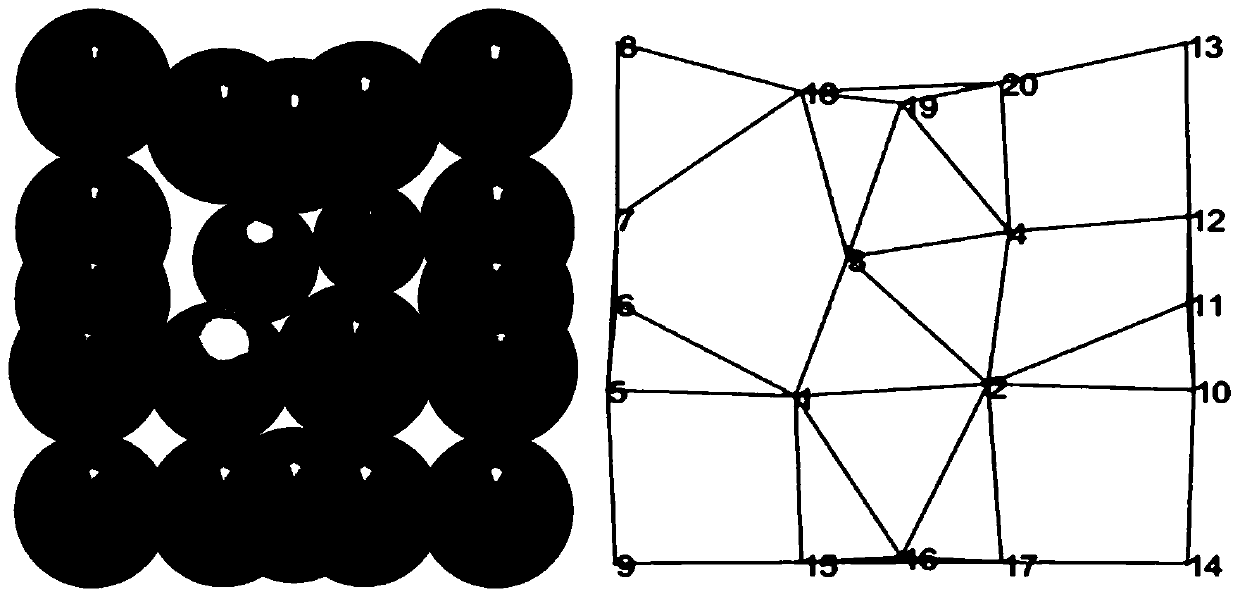

Method for quickly determining representative element volume size of porous medium

ActiveCN107680131AQuick size determinationImage analysis3D modellingDiscrete element methodGeneration process

The invention relates to a method for quickly determining the size of representative element volume of a porous medium 3D reconstruction model, which belongs to the field of porous medium parameter research. Spherical particles following specific particle size distribution are randomly stacked through a discrete element method according to the generation process of a porous medium to get a porousmedium reconstruction model. A large enough volume element is selected, different resolutions are selected to sample the reconstruction model and calculate the permeability, an appropriate resolutionis determined, and a 3D digital image based on the reconstruction model is obtained. The porosity, the specific surface area, the permeability and the change of the variation coefficient of each parameter along with the size of the volume element are calculated, a change relation curve is obtained, the representative element volume of the reconstruction model is determined, and the relation between the representative element volume size and the average particle size is determined using the least squares method. The method can be used to quickly determine the size of representative element volume of the porous medium 3D reconstruction model.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

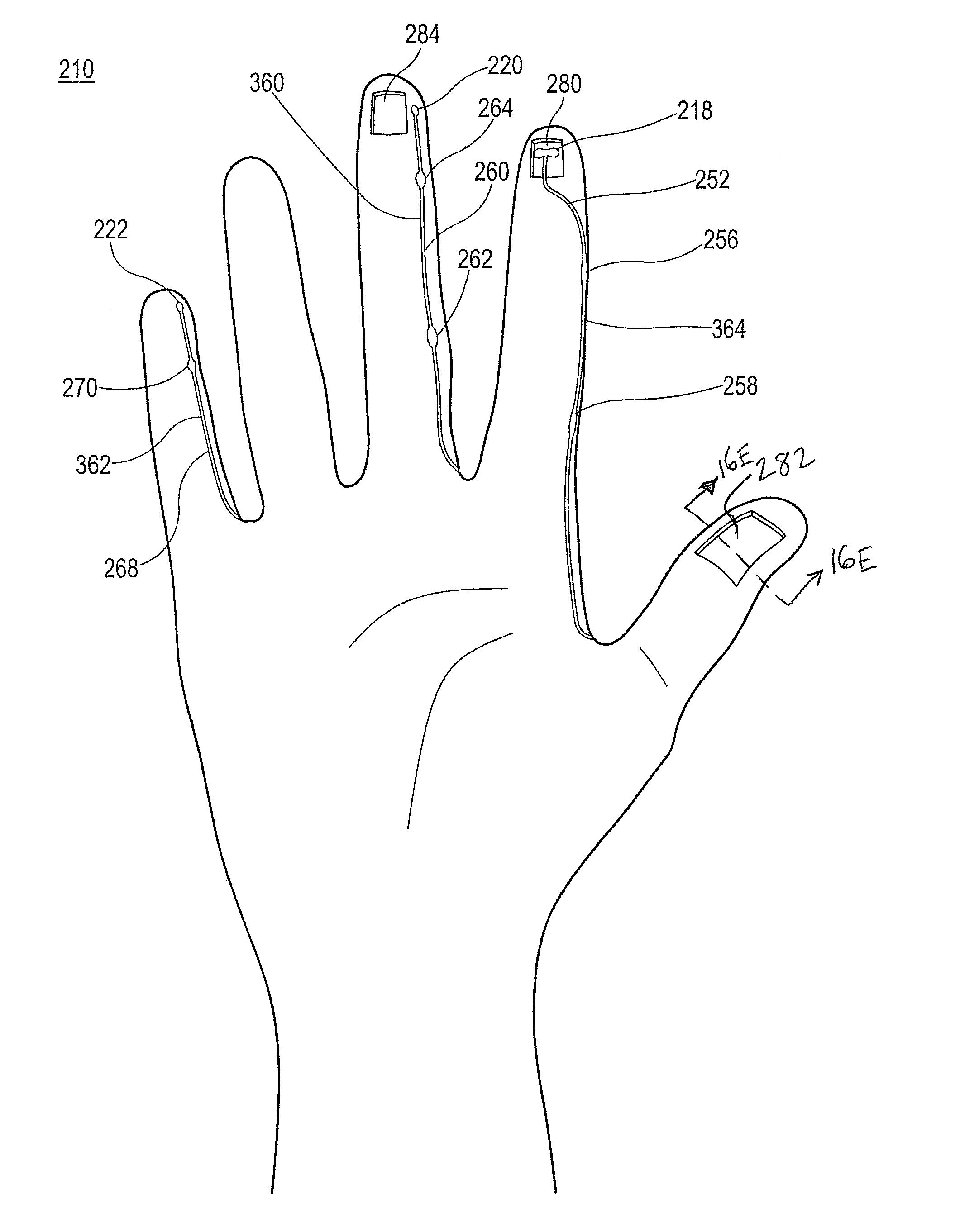

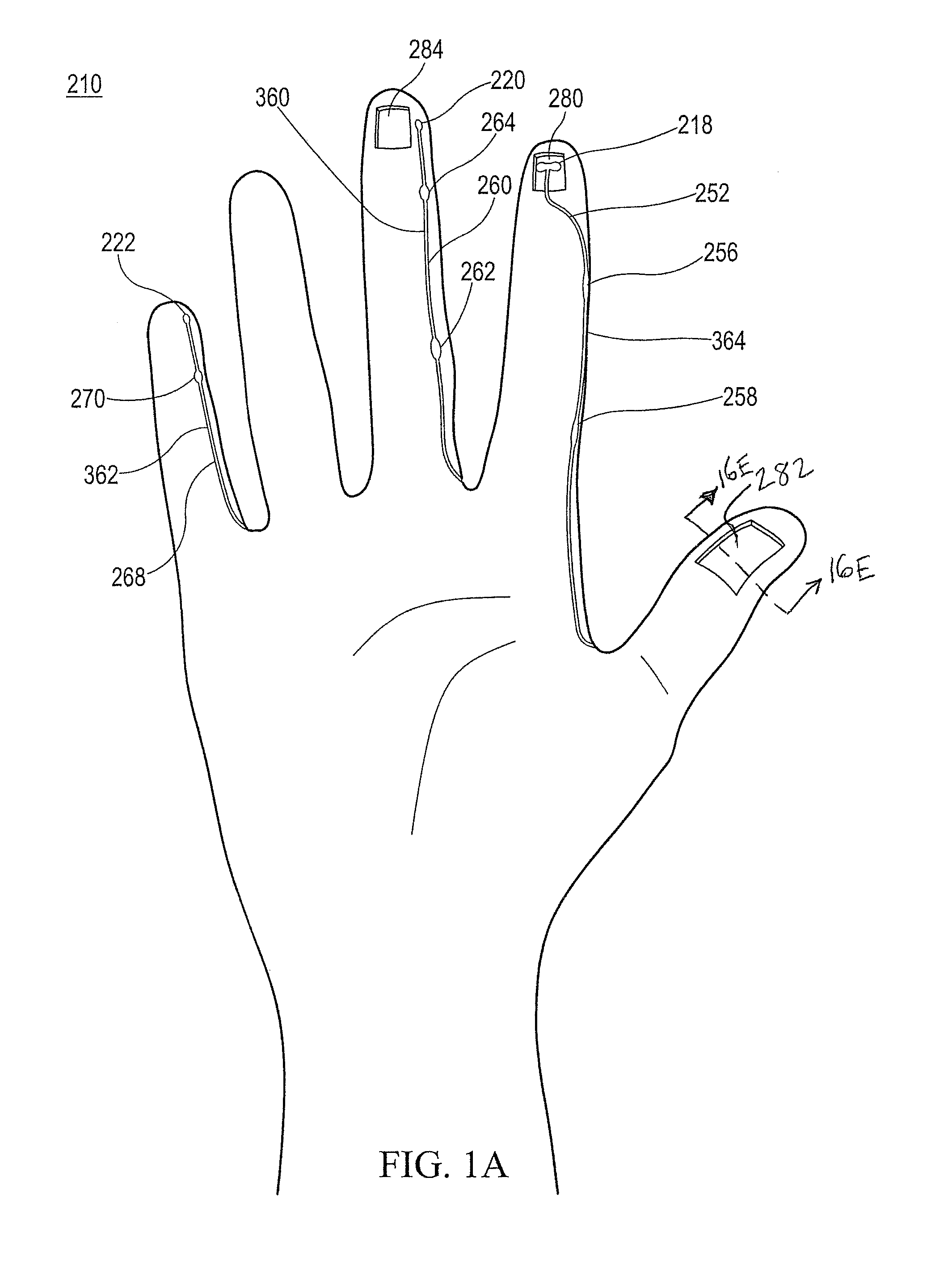

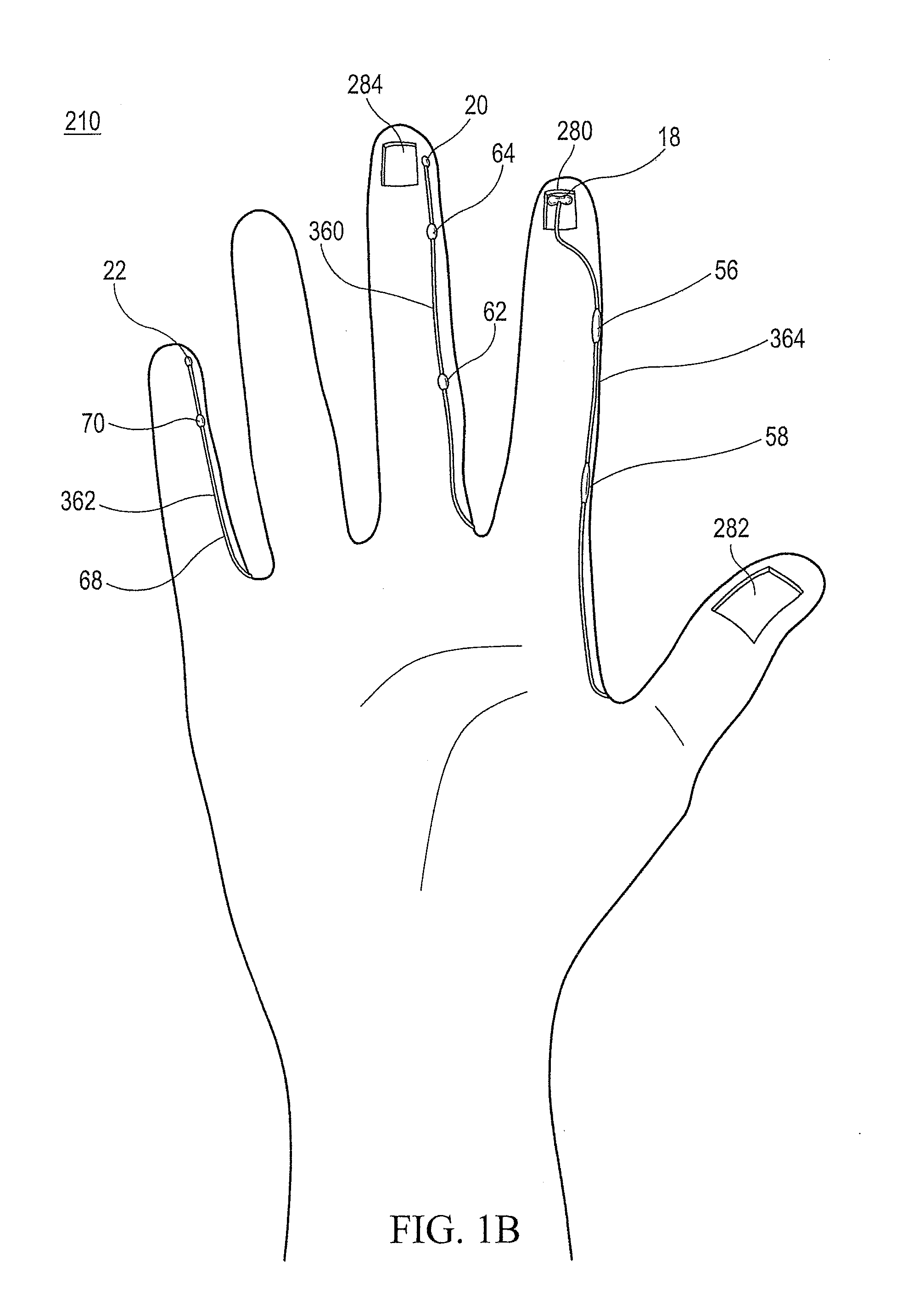

Method of making polymeric gloves having embedded surgical support systems and discrete elements

ActiveUS20160354068A1Avoid accidental switchingGlovesSurgical glovesInterference fitDiscrete element method

A method of manufacturing a glove that includes discrete elements and component systems, such as, but not limited to, lights, electrical cautery, suction, and irrigation, attached to the surgical glove. The gloves produced by this method can be used as surgical gloves or for other industrial applications. In a particular application, the method includes providing a former comprising a hand-shaped portion and a first surgical system comprising a first surgical instrument, and a first switch for controlling the first surgical system. The former includes a first depression for receiving the first surgical system. The first depression is adapted to produce an interference fit with at least a portion of the first surgical system. The first surgical system can be loaded into the first depression and a polymer coating can be applied over the loaded former to form a surgical glove.

Owner:SCHNEIDER ANDREW I DR

Numerical simulation method for predicting selective laser melting single-melt-channel forming defect

PendingCN111222256AAdditive manufacturingIncreasing energy efficiencySelective laser meltingDiscrete element method

The invention provides a numerical simulation method for predicting a selective laser melting single-melt-channel forming defect. The method comprises the steps that S1, establishing a powder bed particle model through EDEM software; s2, selecting a powder bed particle material, and gridding the powder bed particle model; s3, establishing a multi-physical-field model for simulating required heat transfer and molten pool driving force; and S4, selecting laser power and scanning speed as objects to respectively simulate multiple groups of different process parameters. The invention provides a numerical simulation method for predicting the selective laser melting single-melt-channel forming defect, the powder bed model is established through a discrete element method, a heat transfer and molten pool driving force multi-physical-field model is constructed, and numerical simulation is carried out on single-melt-channel forming to obtain a final morphology result; and the formed single meltchannel is evaluated, the defect phenomenon is analyzed, and reference is provided for optimization of technological parameters.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

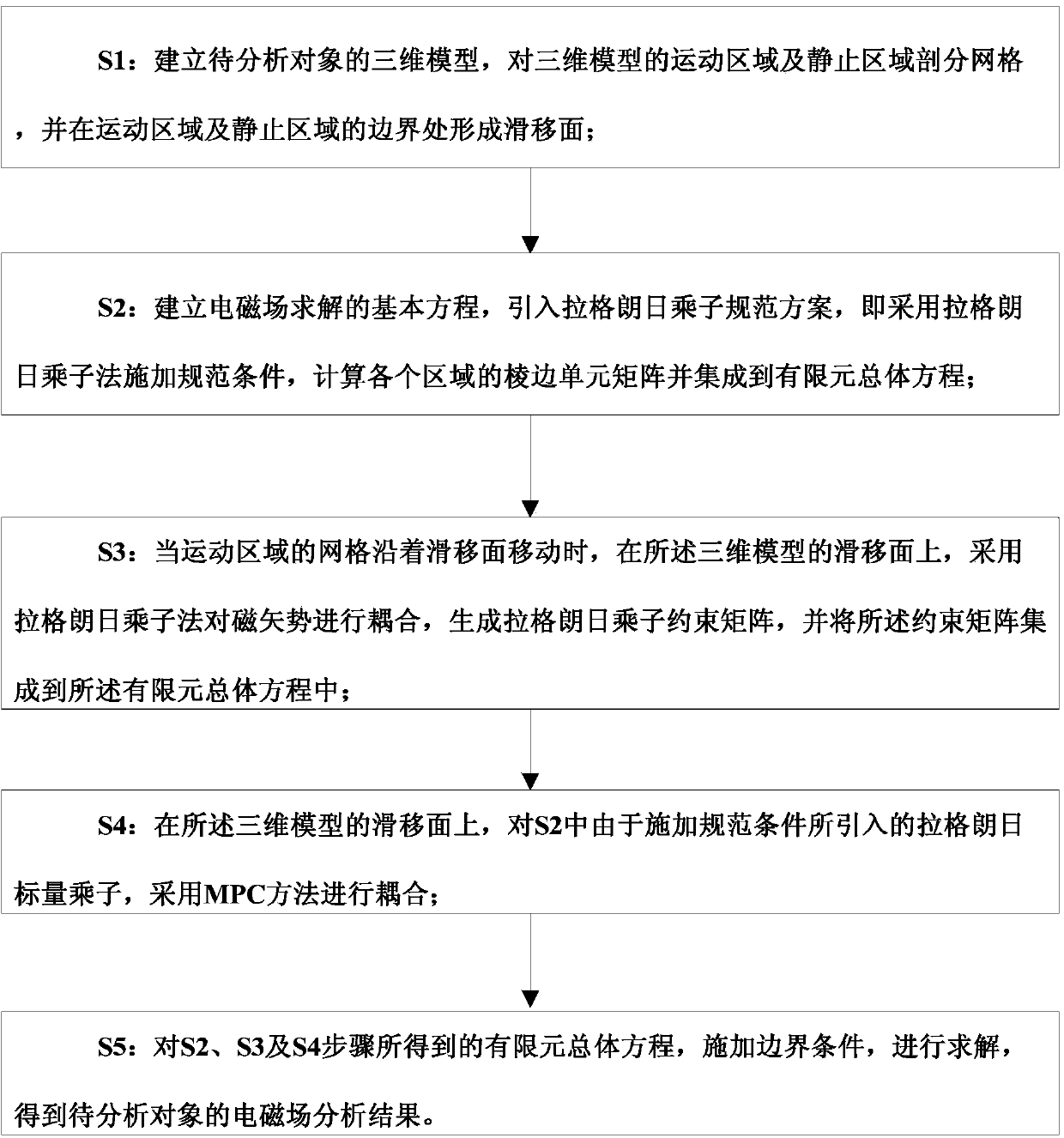

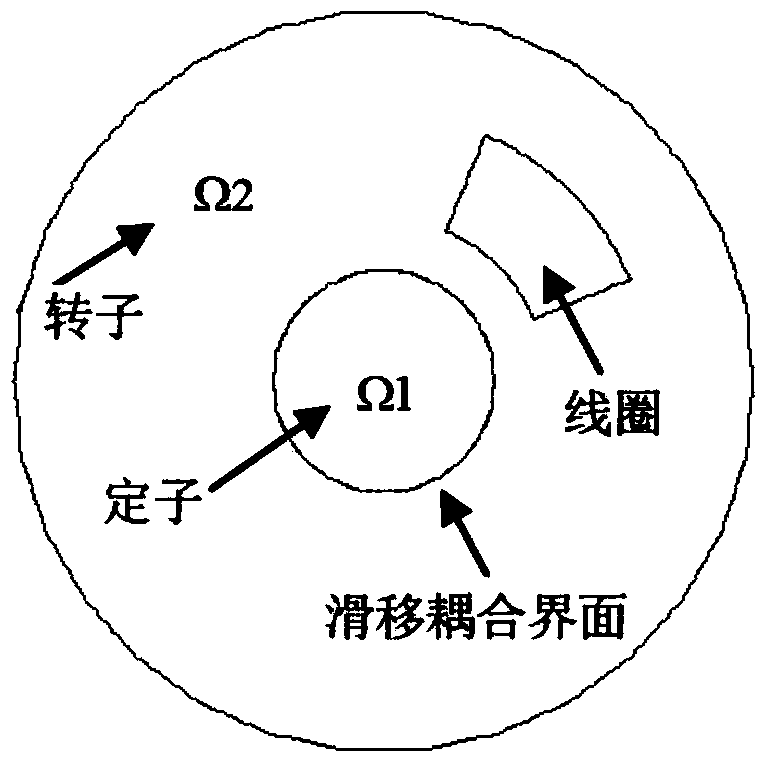

Coupling method for processing moving boundary problems in electromagnetic field based on edge element method

ActiveCN103699752AGood mannersAccurate and reliableSpecial data processing applicationsEngineeringElectromagnetic field

The invention discloses a coupling method for processing moving boundary problems in an electromagnetic field based on an edge element method. The method includes: establishing a three-dimensional model, generating meshes of a moving region and a stationary region of the model, and forming a slip plane at a boundary of the two regions; establishing a basic equation for solving the electromagnetic field, adopting a Lagrangian multiplier method to apply standard conditions, calculating an edge element matrix of each region and integrating the edge element matrixes; when the meshes in the moving region move along the slip plane, adopting the Lagrangian multiplier method to couple degree of freedom of magnetic vector potential on the slip plane, generating a Lagrangian multiplier constraint matrix, and integrating the constraint matrix; on the slip plane, standardizing an introduced Lagrangian scalar multiplier, and coupling by adopting an MPC (multi-point constraint) method; applying boundary conditions to a finite element population equation obtained through the above steps and solving to obtain an electromagnetic field analysis result of a to-be-analyzed object. A finite element matrix obtained by the method is good in behavior, and computed results are accurate and reliable.

Owner:INTESIM DALIAN

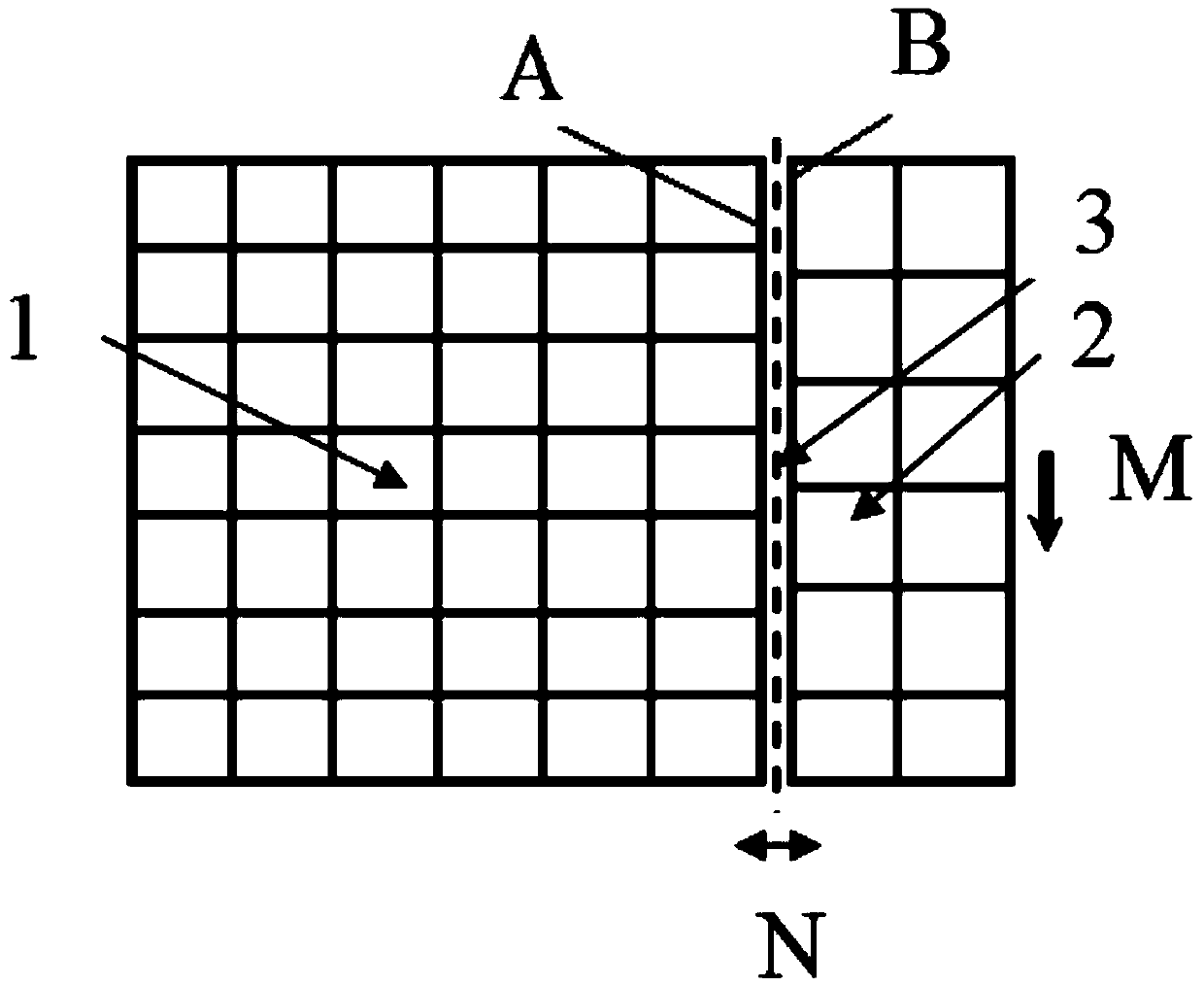

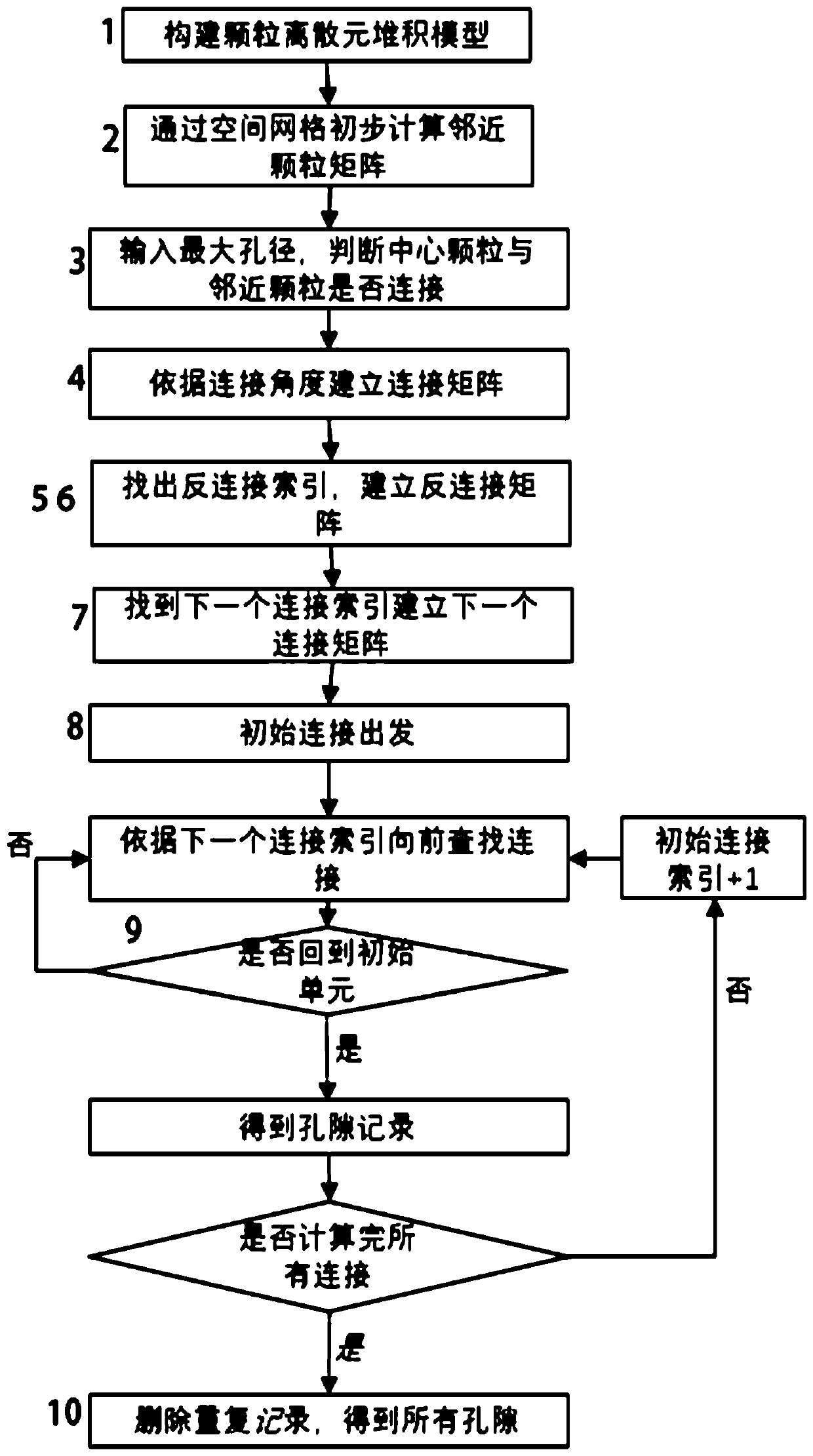

Rapid search method for discrete element pore system based on GPU matrix calculation

PendingCN109977505AImprove the efficiency of search calculationsSolve the problem of difficult to search poresDesign optimisation/simulationSpecial data processing applicationsDiscrete element methodArray data structure

The invention discloses a rapid search method for a discrete element pore system based on GPU matrix calculation. The method comprises the following steps of: establishing a grid number matrix; a preliminary adjacent particle array is established, each particle being centered relative to its adjacent particle; first, a neighbor matrix N is obtained in discrete element calculation; and sorting theN matrixes in the row direction according to the connection angles, and converting the N matrixes into a connection matrix C; and using a connection matrix control search algorithm to find out a reverse connection index matrix CI of the connection matrix C and a next connection index matrix CN; and then, starting from the initial connection, a next connected index matrix CN is used for searching nodes forwards until the nodes return to the original point, and all pores of the accumulation body are obtained through the method. According to the method, the speed of a discrete element numerical method is remarkably increased, a rapid and simple method is provided for finding all holes in the fluid-solid coupling process, and dynamic simulation of a large-scale fluid-solid coupling system canbe achieved.

Owner:NANJING UNIV

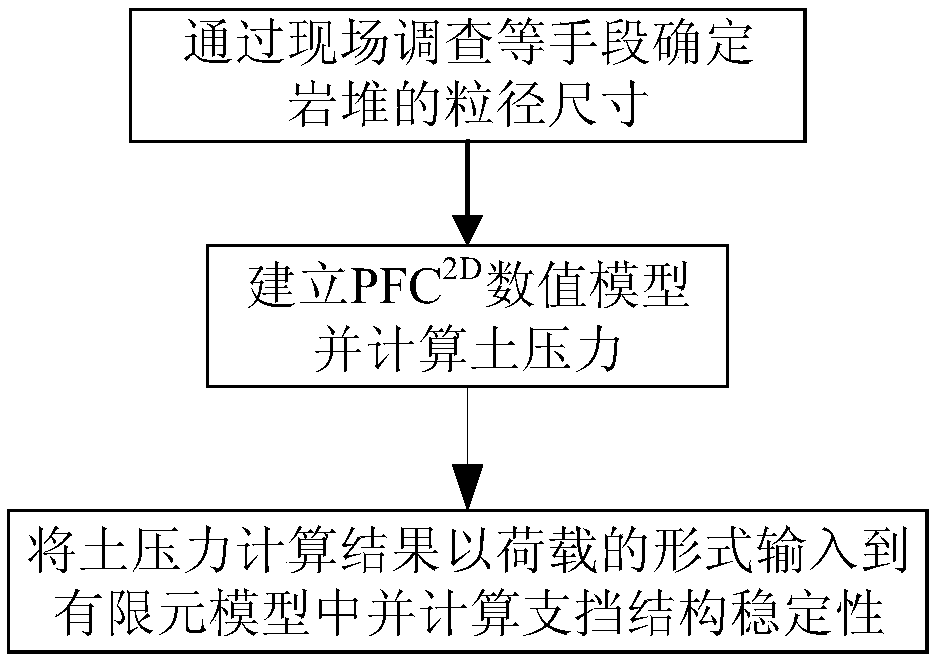

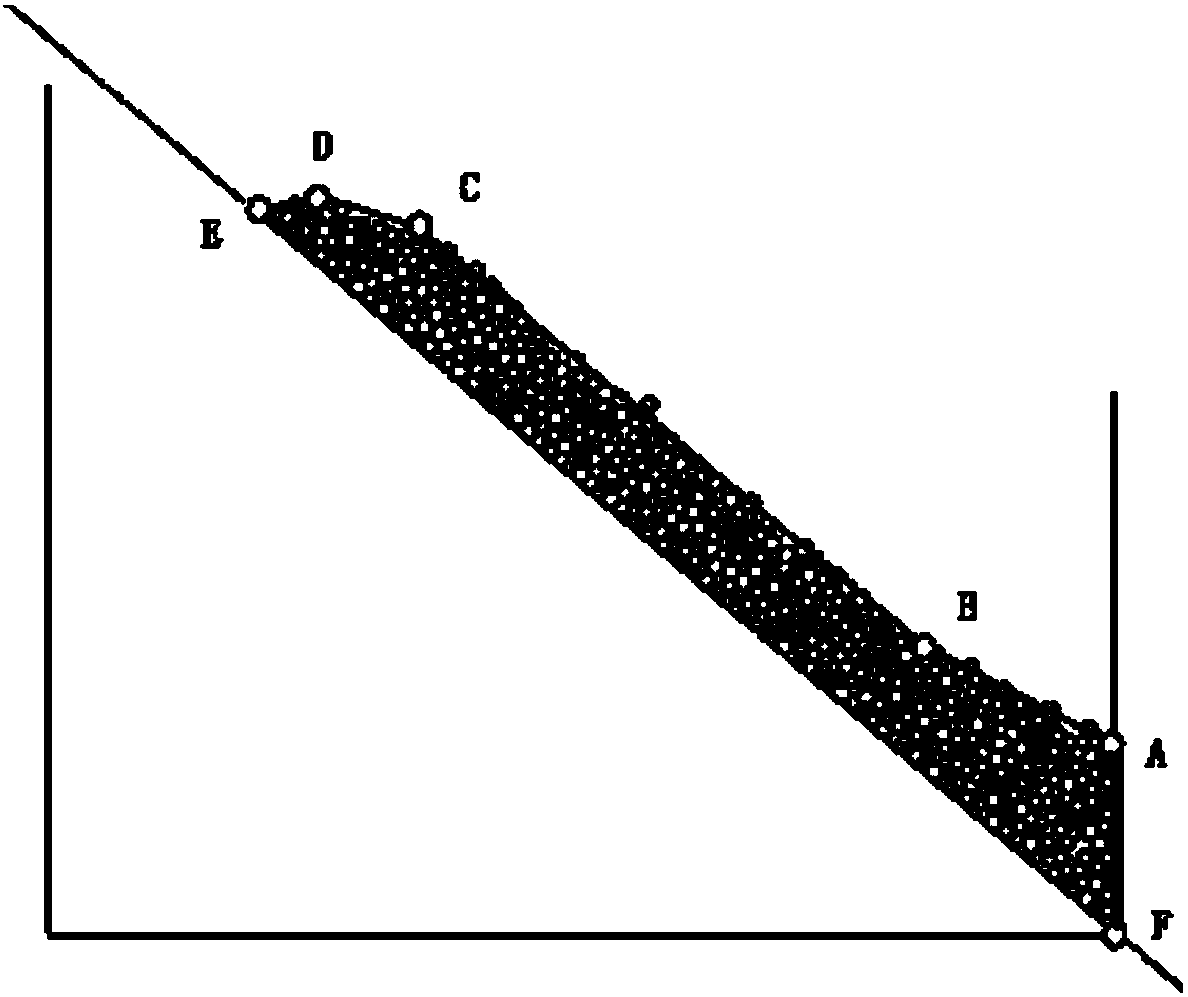

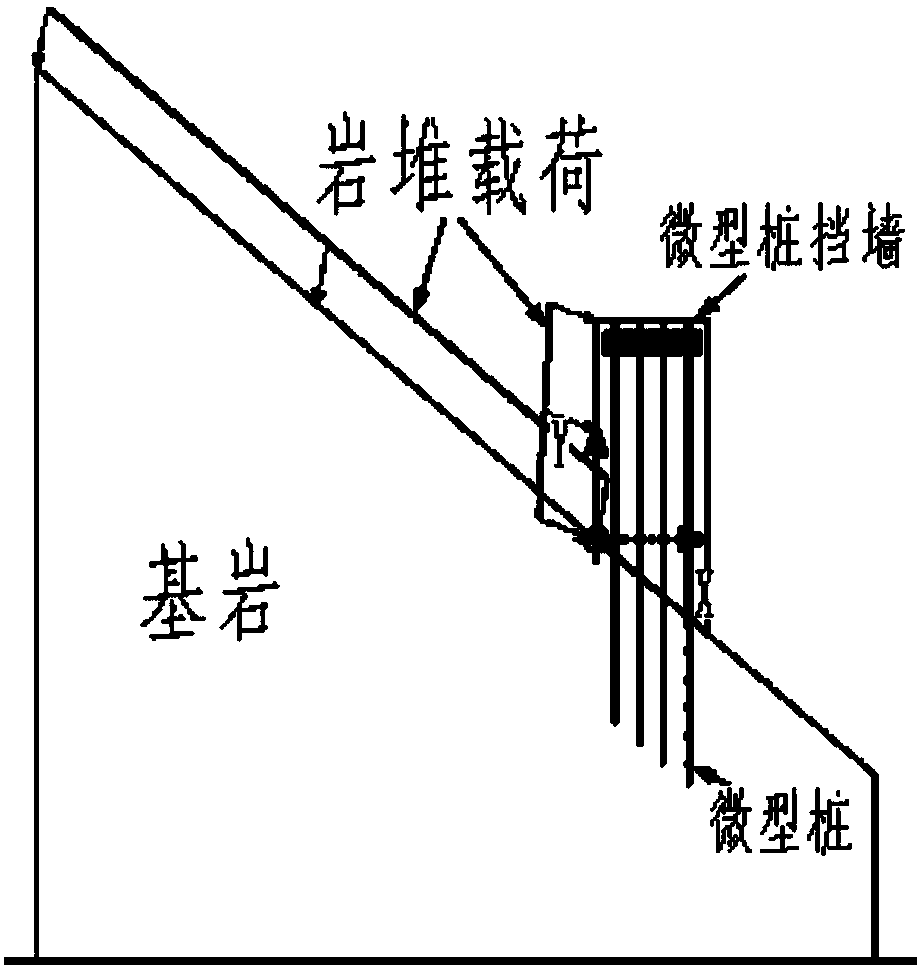

Discrete element method-finite element method combined analysis method for talus retaining structure

InactiveCN107818229ADesign optimisation/simulationSpecial data processing applicationsDiscrete element methodElement model

The invention discloses a discrete element method-finite element method combined analysis method for a talus retaining structure. The combined analysis method comprises the steps of firstly carrying out field investigation so as to determine the particle size of a talus, establishing a discrete element program PFC2D numerical model according to practical engineering, calculating a soil pressure, inputting a soil pressure result calculated by virtue of the discrete element program PFC2D numerical model into a finite element model, and carrying out stability analysis on the talus retaining structure. A discrete element has relatively strong advantages in the aspect of calculating the soil pressure of a macadam accumulation body, and the soil pressure result is used as a load boundary condition of a finite element model for carrying out stability analysis on the talus retaining structure, so that the advantages of both sides can be exerted, and a novel solution is provided for engineeringproblems.

Owner:TSINGHUA UNIV +1

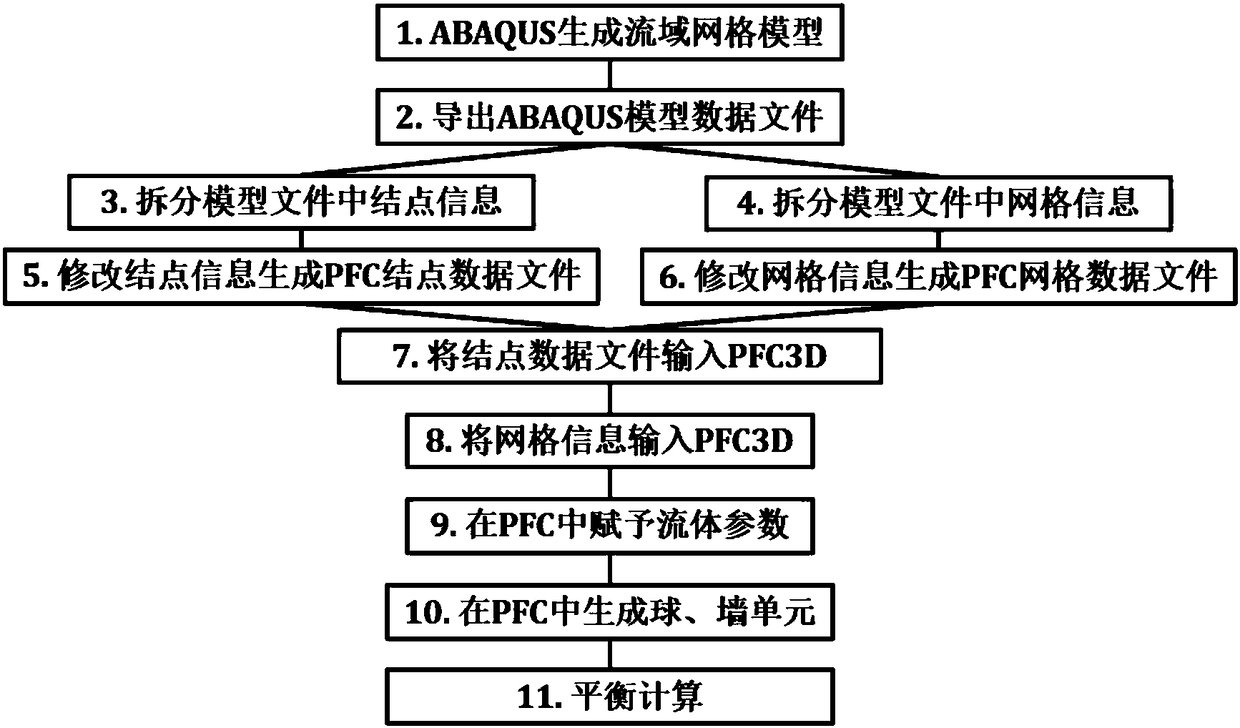

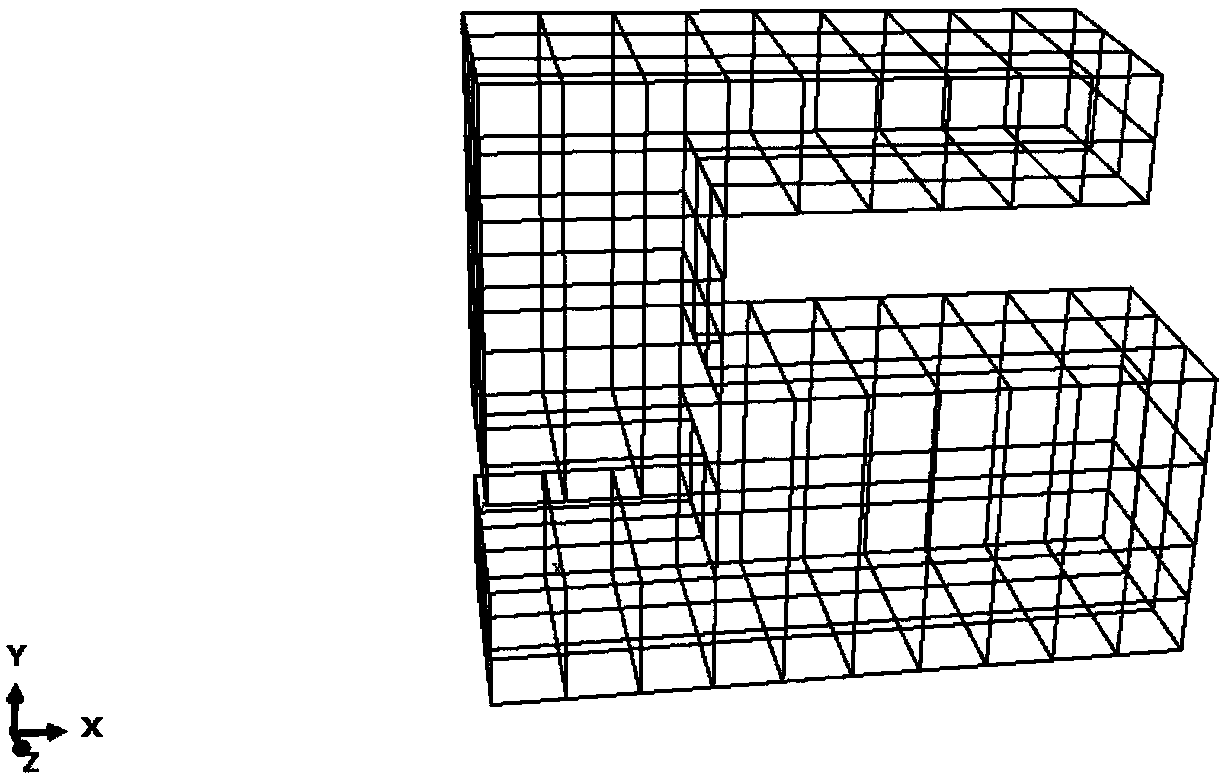

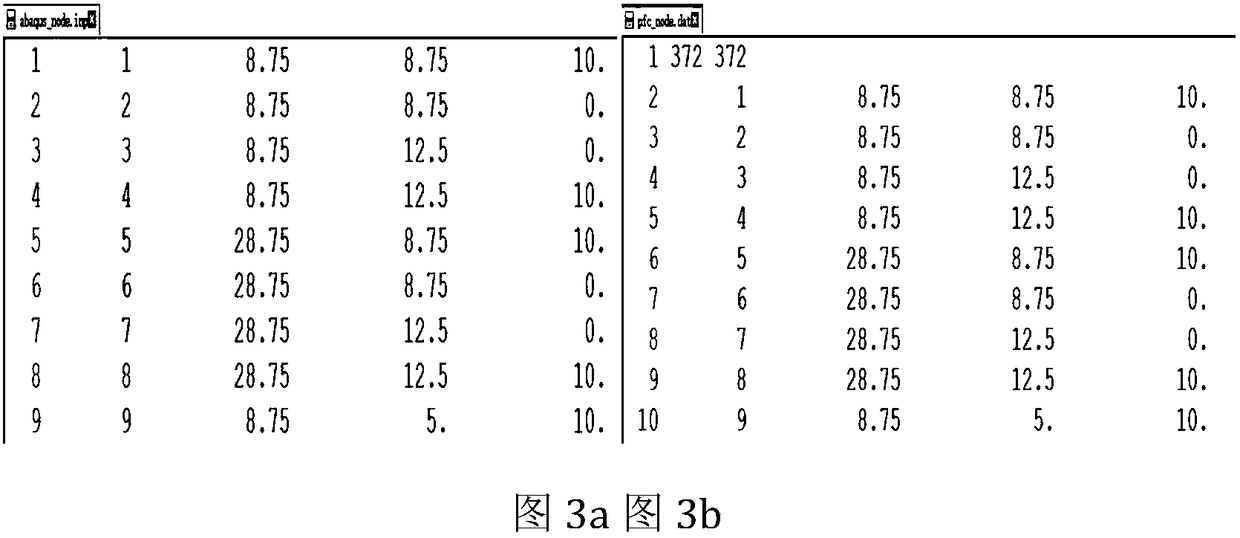

Modeling method of discrete element fluid-solid coupling grid model based on ABAQUS-PFC3D

ActiveCN108536928AQuality improvementEasy to set upDesign optimisation/simulationSpecial data processing applicationsDiscrete element methodModel method

The invention discloses a modeling method of a discrete element fluid-solid coupling grid model based on ABAQUS-PFC3D. The method comprises the following steps: building a pretreatment grid-junction model with ABAQUS, rewriting information of the model so as to determine unit and junction information and geometric characteristics imported into a PFC flow domain grid model, importing a fluid grid into a PFC3D simulation platform, and endowing the fluid grid with hydrodynamic parameters; building sphere and wall elements, endowing with micro-parameters and initial conditions, and performing iterative operation of fluid-solid coupling analysis till balance.

Owner:SHANDONG UNIV

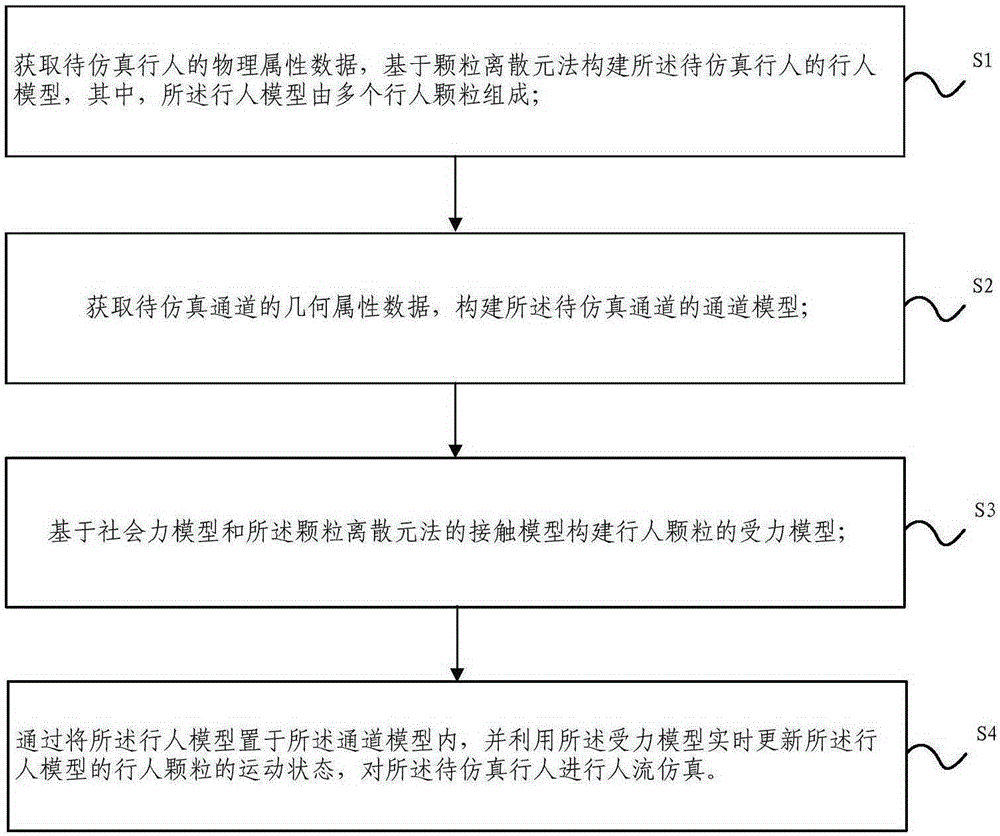

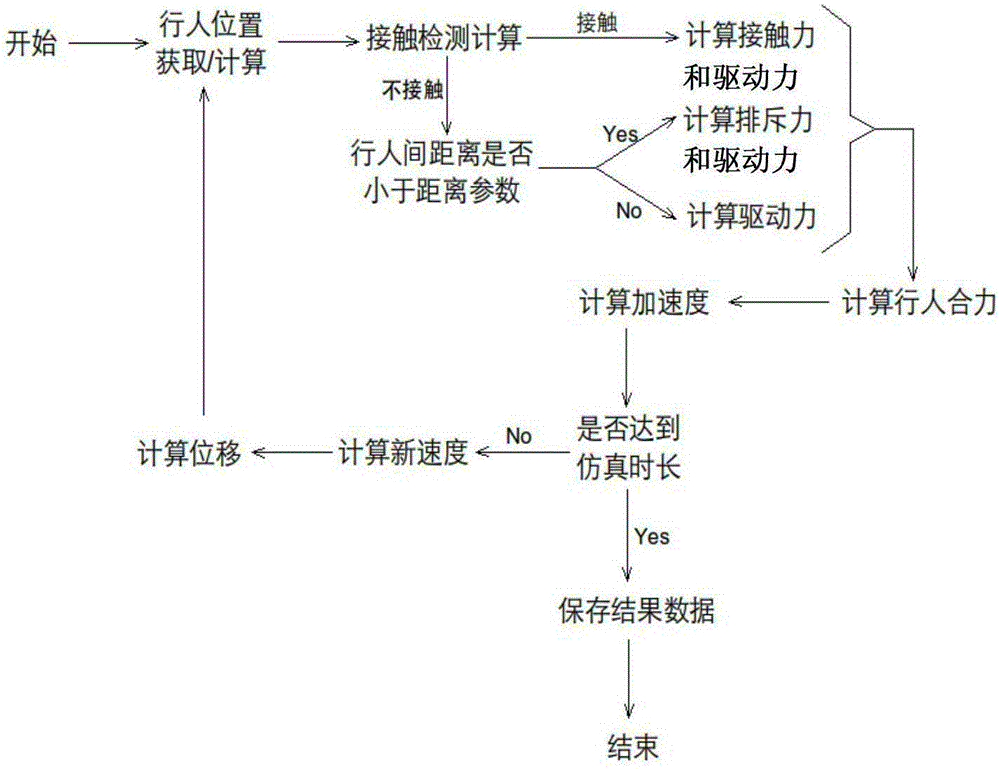

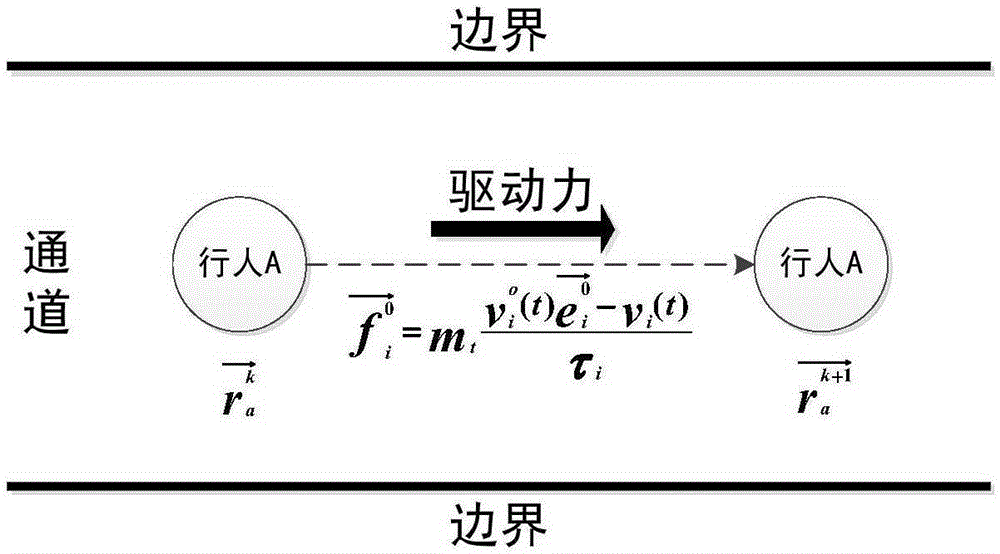

Cross-domain simulation method and device for large-scale pedestrian motion in hub

InactiveCN105205216AIncrease the input levelImprove computing efficiencySpecial data processing applicationsDiscrete element methodGeometric property

The invention discloses a cross-domain simulation method and a cross-domain simulation device for large-scale pedestrian motion in a hub. A cross-domain granular discrete element method is introduced into pedestrian simulation, so that the input magnitude and the calculation efficiency are improved on the basis of keeping the simulation precision, and simulation of the large-scale pedestrian motion in the traffic hub is realized. The method comprises the following steps: S1, acquiring physical property data of pedestrians to be simulated, and constructing a pedestrian model of the pedestrians to be simulated based on the granular discrete element method; S2, acquiring geometric property data of a channel to be simulated, and constructing a channel model of the channel to be simulated; S3, constructing a stress model of pedestrian granules based on a social force model and a contact model of the granular discrete element method; and S4, putting the pedestrian model into the channel model, updating motion states of the pedestrian granules of the pedestrian model in real time by adopting the stress model, and performing pedestrian simulation on the pedestrians to be simulated.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com