Smashed-state coarse aggregate discrete element method

A particle discrete element and coarse aggregate technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of difficult simulation of particle crushing state, large differences, and inability to describe the real state of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

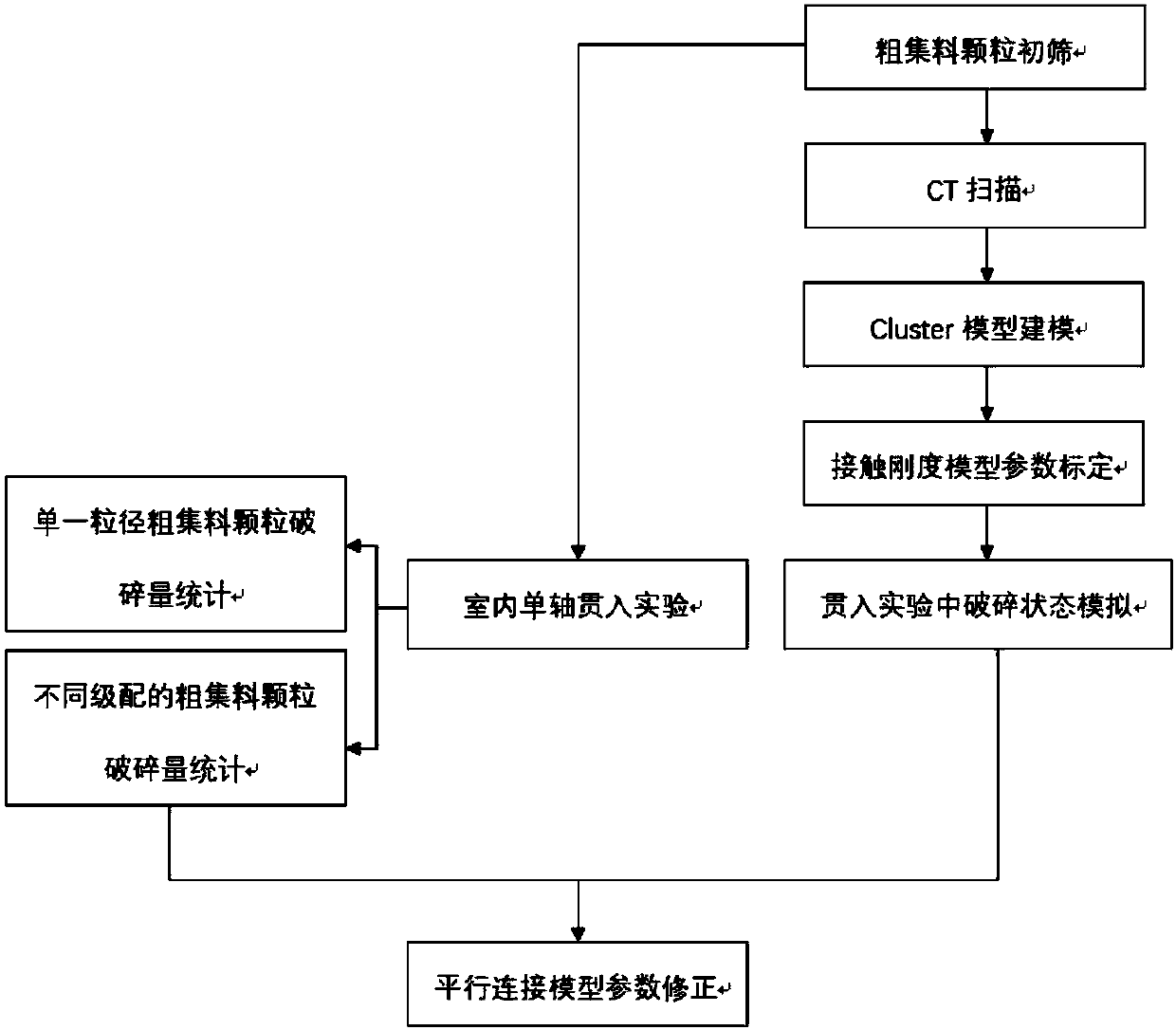

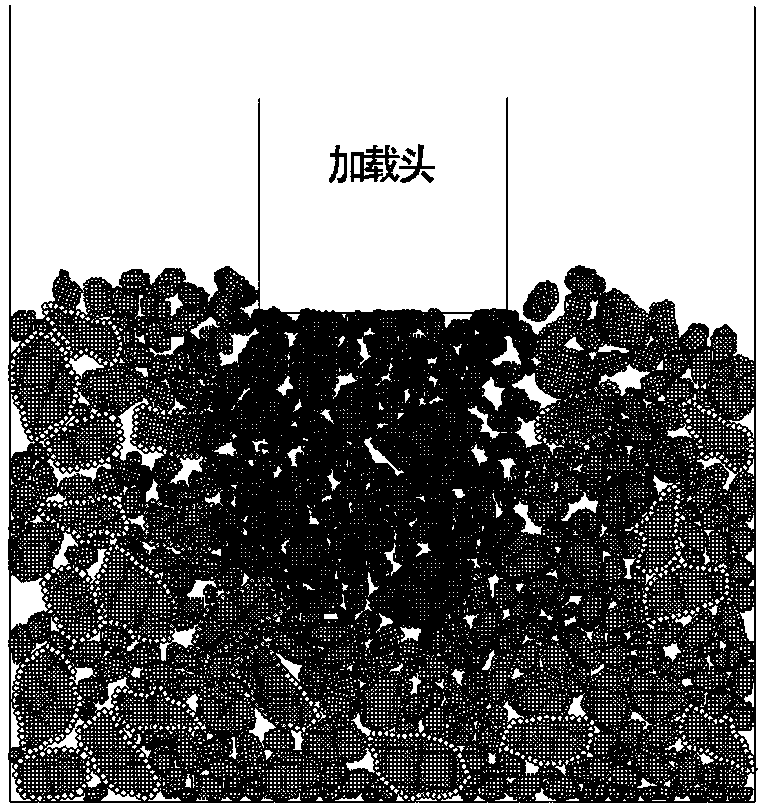

[0023] Such as figure 1 Shown, the present invention comprises the following steps:

[0024] (1) Primary screening of coarse aggregate particles: sieve coarse aggregate particles through a standard sieve, and divide them into 4.75-9.5mm, 9.5-13.2mm, 13.2-16mm, 16-19mm, 19-26.5mm according to particle size , 26.5-31.5mm, the amount of coarse aggregate particles screened out should be sufficient; after the coarse aggregate is screened, use a cylindrical iron container to hold the coarse aggregate particles, and the width of the cylindrical iron container is 12cm , with a height of 15cm, the sieved quantity of each grade of coarse aggregate particles should ensure enough to fill 3 cylindrical containers of the selected size.

[0025] (2) CT scanning: CT scanning is performed on each grade of coarse aggregate particles screened out to obtain the morphological profile ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com