Structural design finalizing method based on material test and DEM-CFD (discrete element method and computational fluid dynamics) simulation coal transport system

A DEM-CFD and system structure technology, which is applied in the field of structural design and finalization of coal conveying and transfer systems based on material testing and DEM-CFD simulation, can solve the problems of dust overflow in the guide chute, chute wear, economic losses, etc., and improve the operation efficiency. , Improve the service life and reduce the effect of relative motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

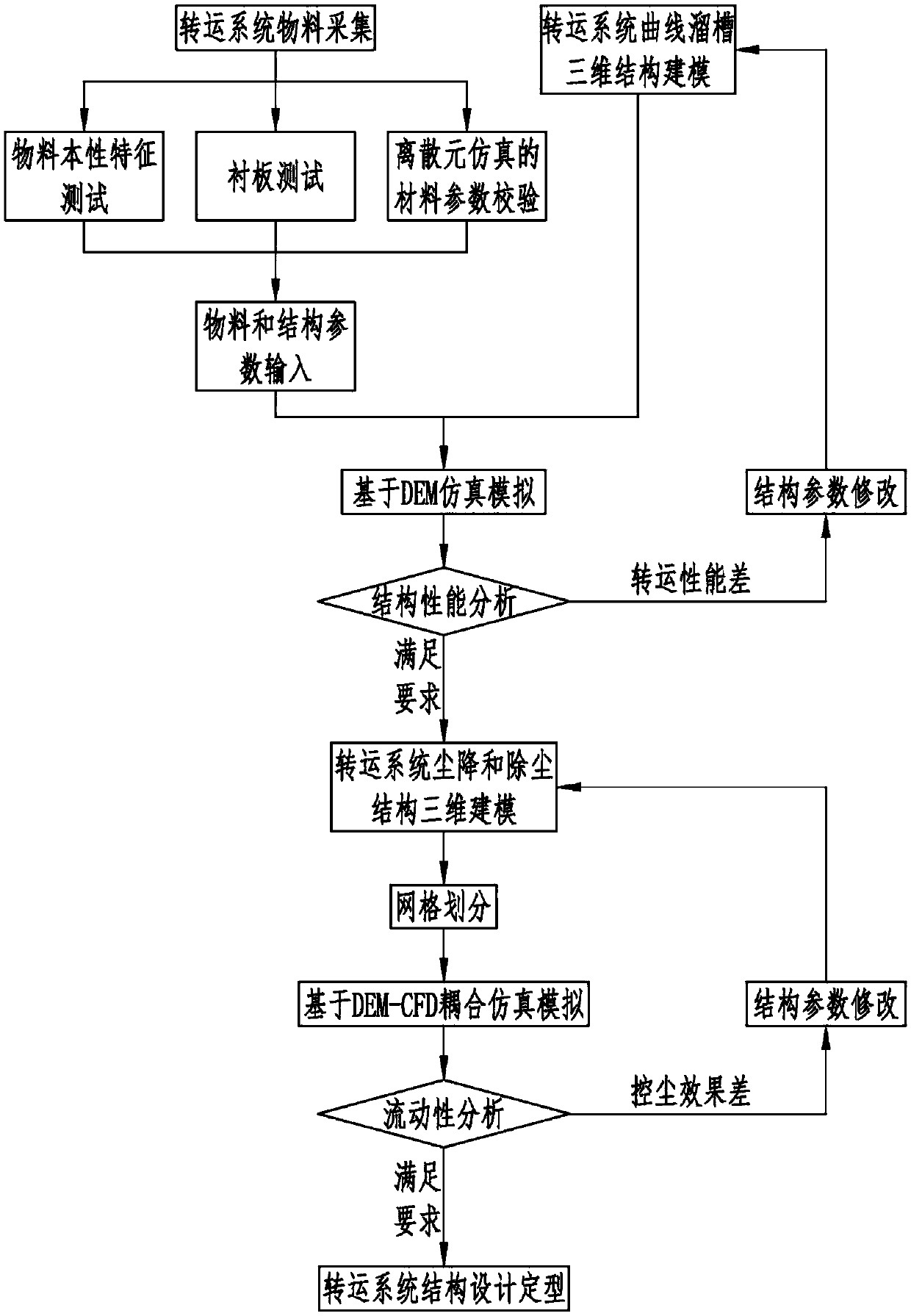

Method used

Image

Examples

Embodiment 1

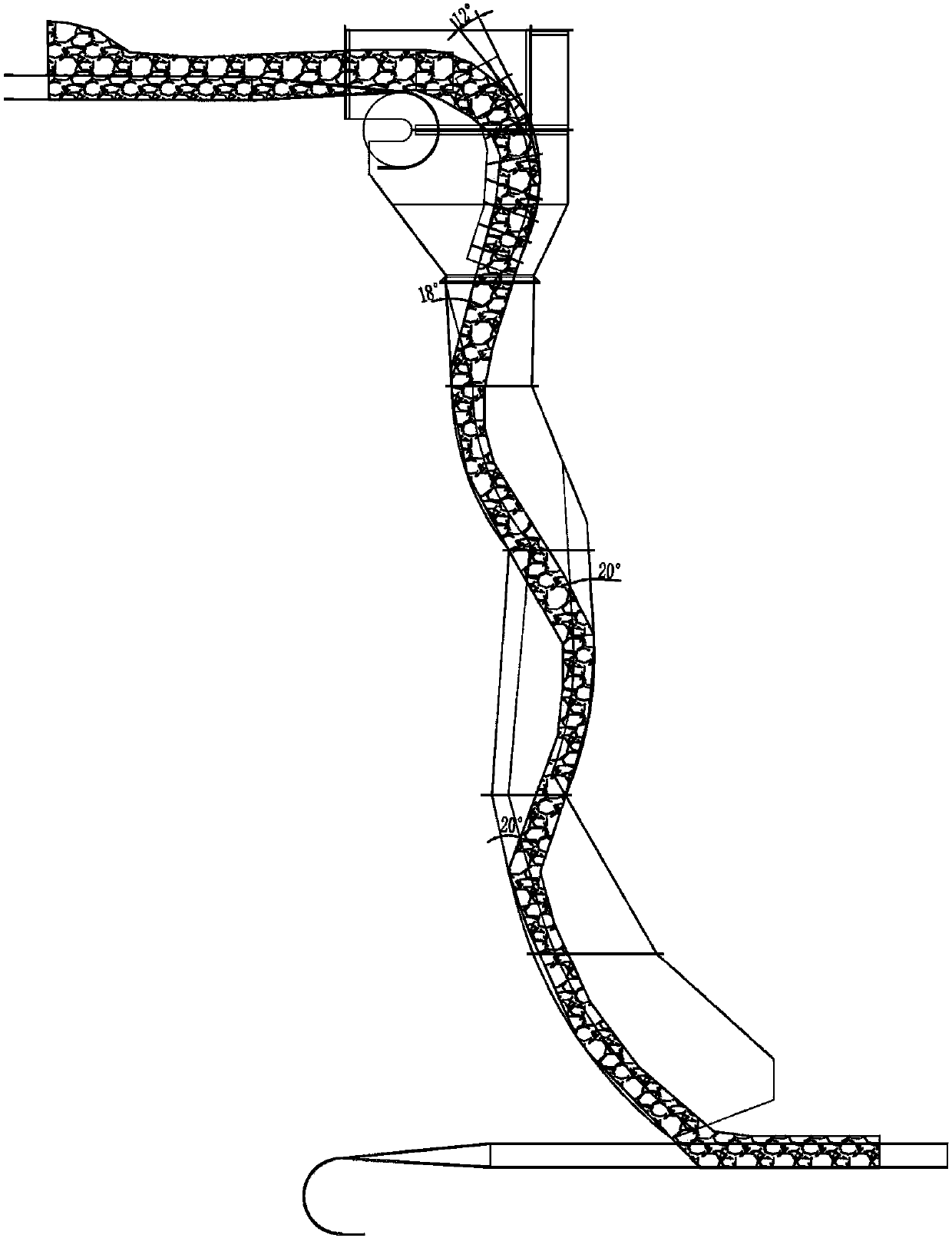

[0150] The specific working conditions are as follows:

[0151] Band width: B=1800mm, blanking point: 1, blanking height: 18m, belt speed: 3.5m / s,

[0152] Rated output: 3000t / h; Maximum output: 3600t / h

[0153] Coal: up to 250mm

[0154] Coal type: (1) Shenfu Dongsheng coal is used as the coal type, and Yitai No. 4 coal is used as the calibration coal type (2) Indonesian lignite

[0155] The shell of the chute is made of 8mm thick Q235B steel plate, the lining of the impact surface of the chute is made of high chromium bimetallic wear-resistant composite steel plate, the total thickness is not less than 24mm (12mm+12mm), the substrate is 12mm thick Q235B steel plate, and the thickness of surfacing welding is not less than 12mm; The hardness is HRC58-60, the carbon content (C) is not less than 4-5%, and the chromium (Cr) content is not less than 30%; the lining of the wear surface of the chute is not less than 25mm thick pure ceramics, AL 2 o 3 Content: more than 92%; Mohs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com