Discrete-element-method-based corn threshing process analysis method

A corn threshing and process analysis technology, applied in threshing equipment, agriculture, application, etc., can solve problems such as physical simulation that has not been reported yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

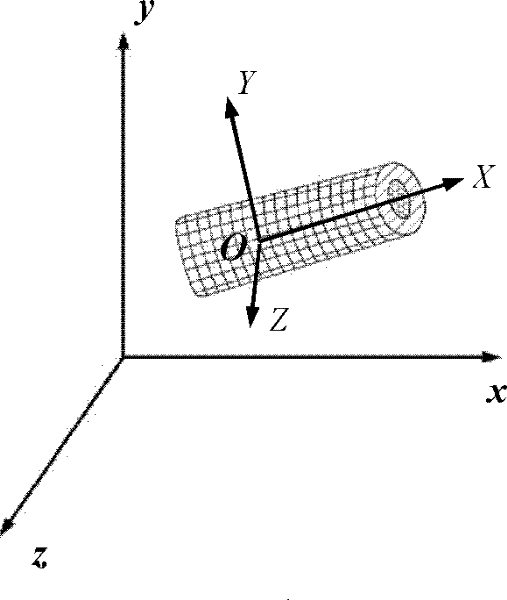

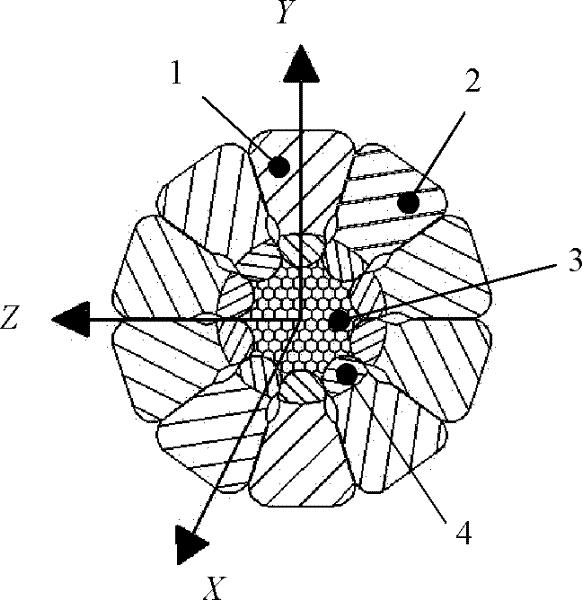

[0040] The specific content and modeling process of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] ①Modeling method of corn thresher

[0042] The modeling method of the thresher is established by adopting the invention patent "Boundary Modeling Method Based on CAD Model" (Patent No. 200510016835.7) obtained by the applicant, that is, the surface of the parts in the thresher in contact with the ear of corn is discretized into primitives, such as a plane , sphere, cylinder, cone, etc., and add motion attributes and material properties, thereby establishing a discrete element method analysis model of the thresher.

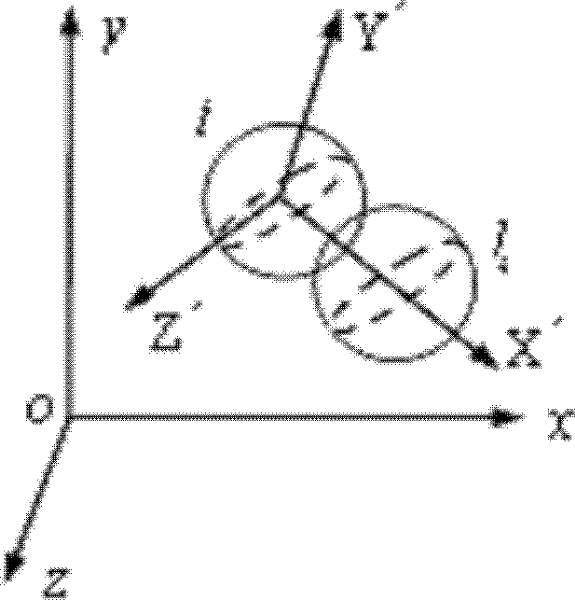

[0043] ②Calculation method of force in threshing process

[0044] It can be seen from observation that the ear of corn consists of two parts: the corn cob and the grain growing on the cob, and usually the ear of corn is in the shape of a truncated cone, while the cross section of the corn kernel is approx...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com