Patents

Literature

55 results about "Particle dynamics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

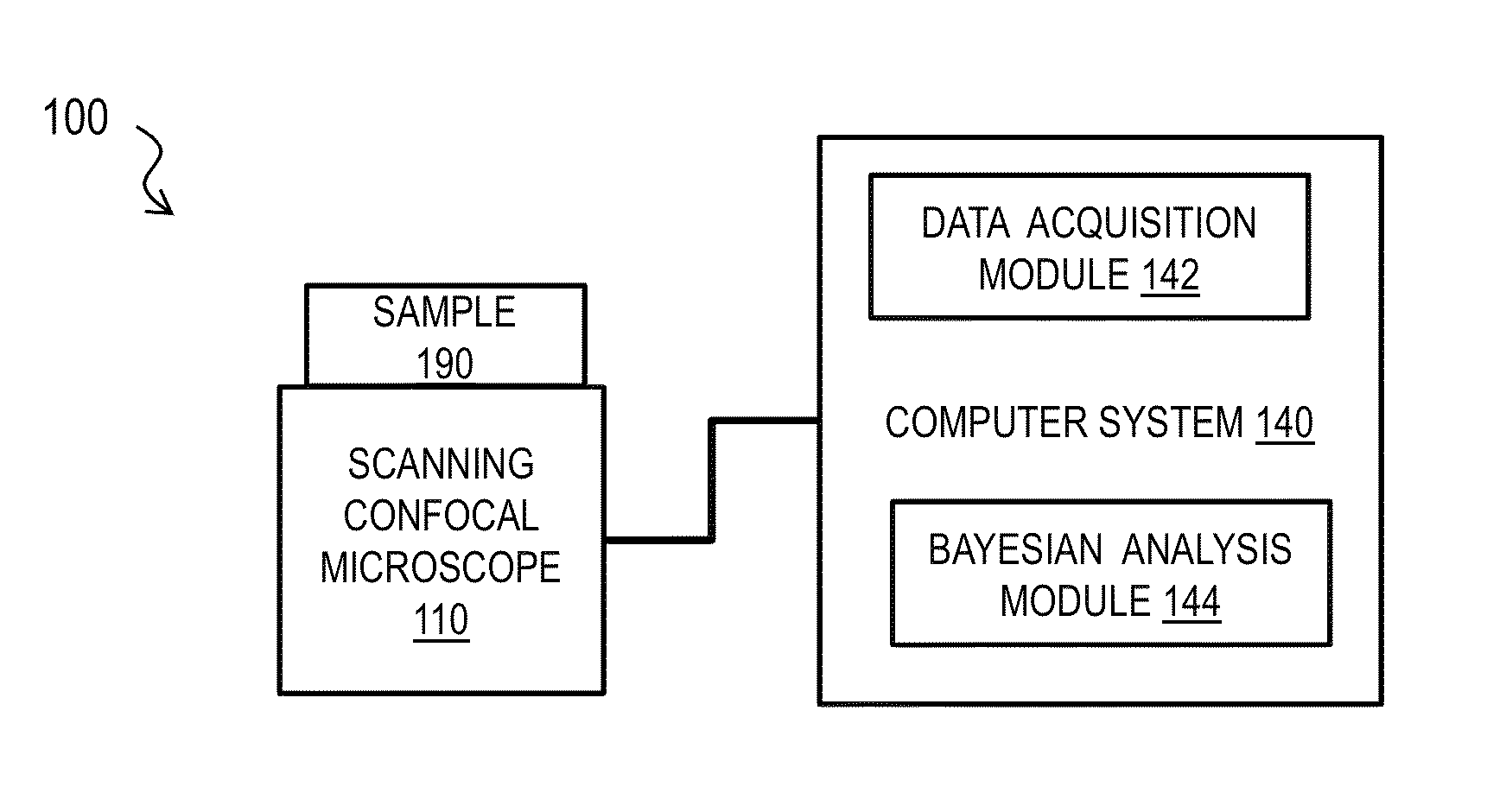

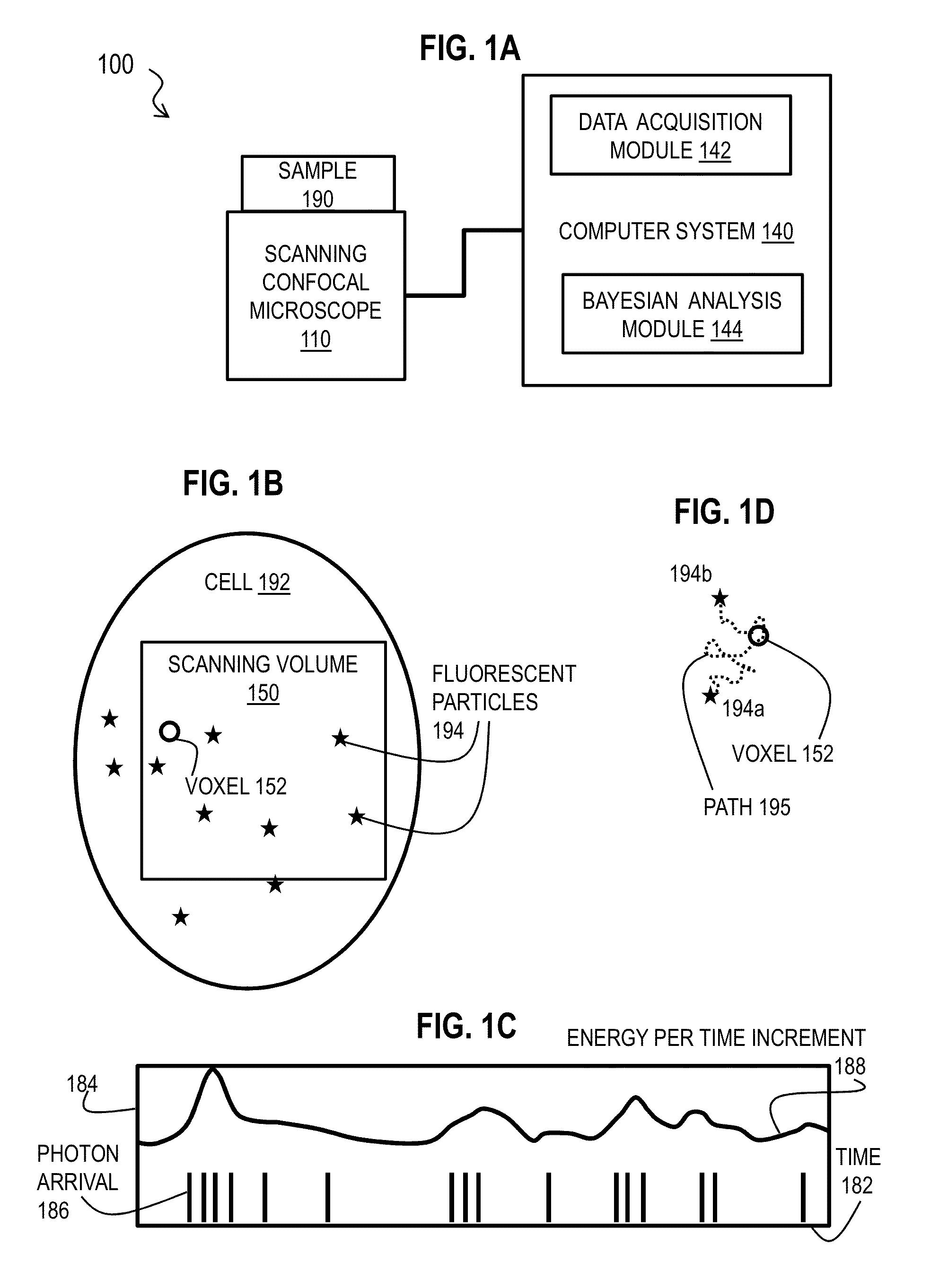

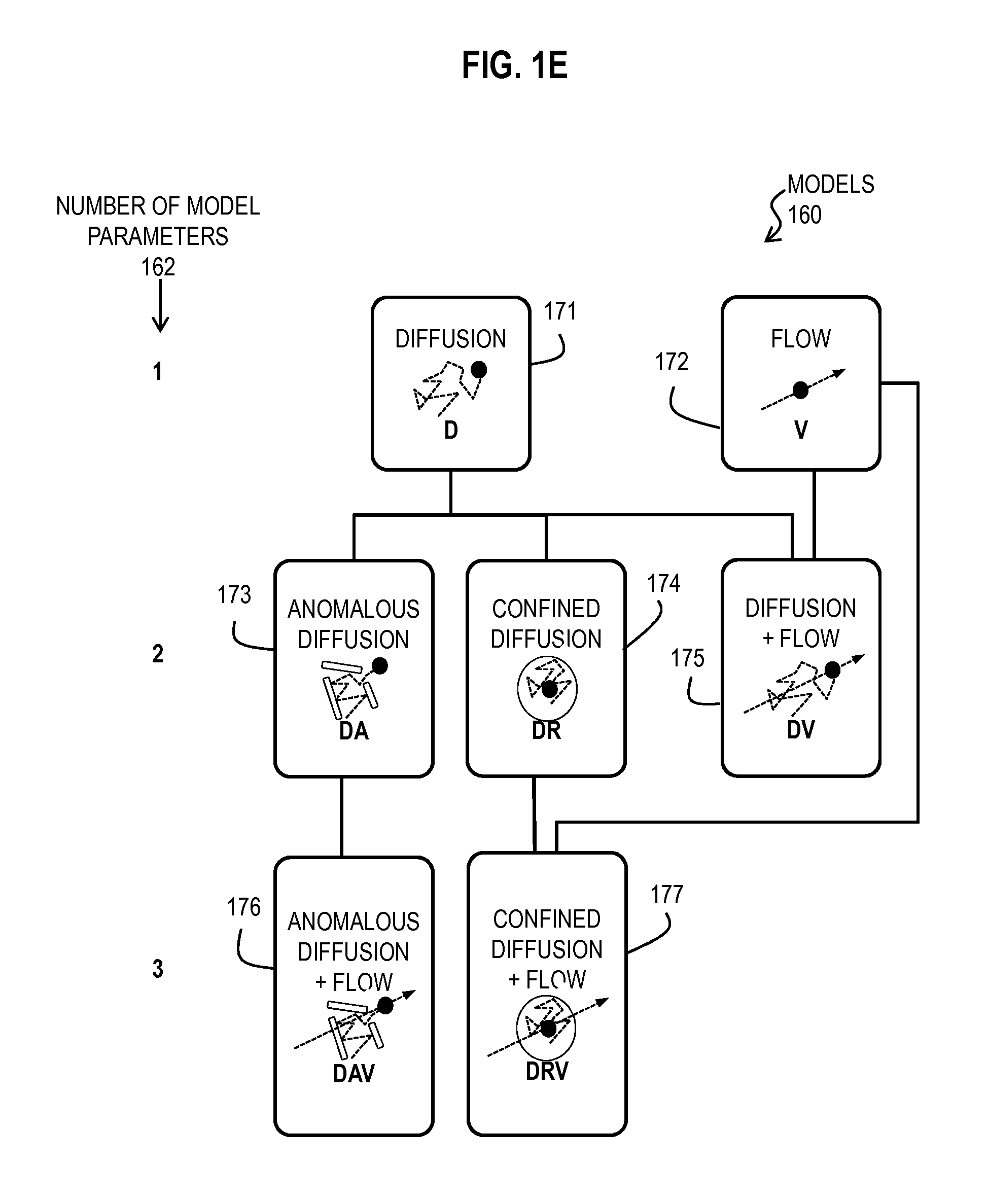

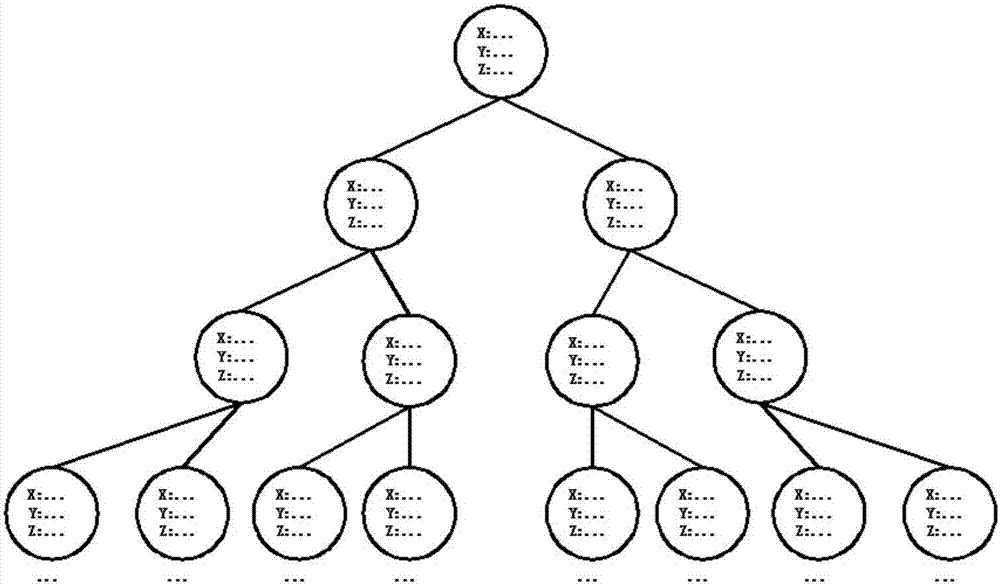

Bayesian Inference of Particle Motion and Dynamics from Single Particle Tracking and Fluorescence Correlation Spectroscopy

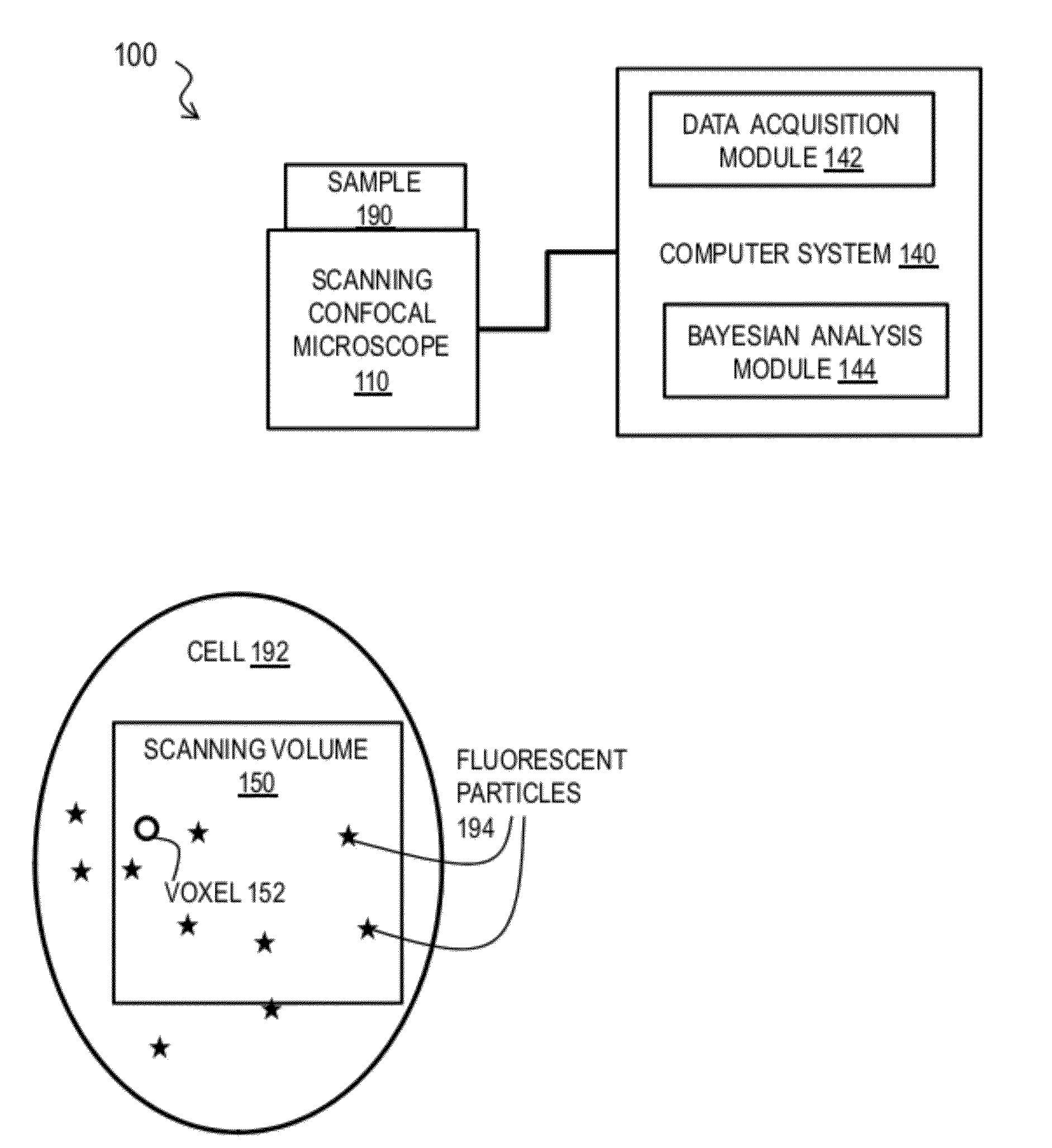

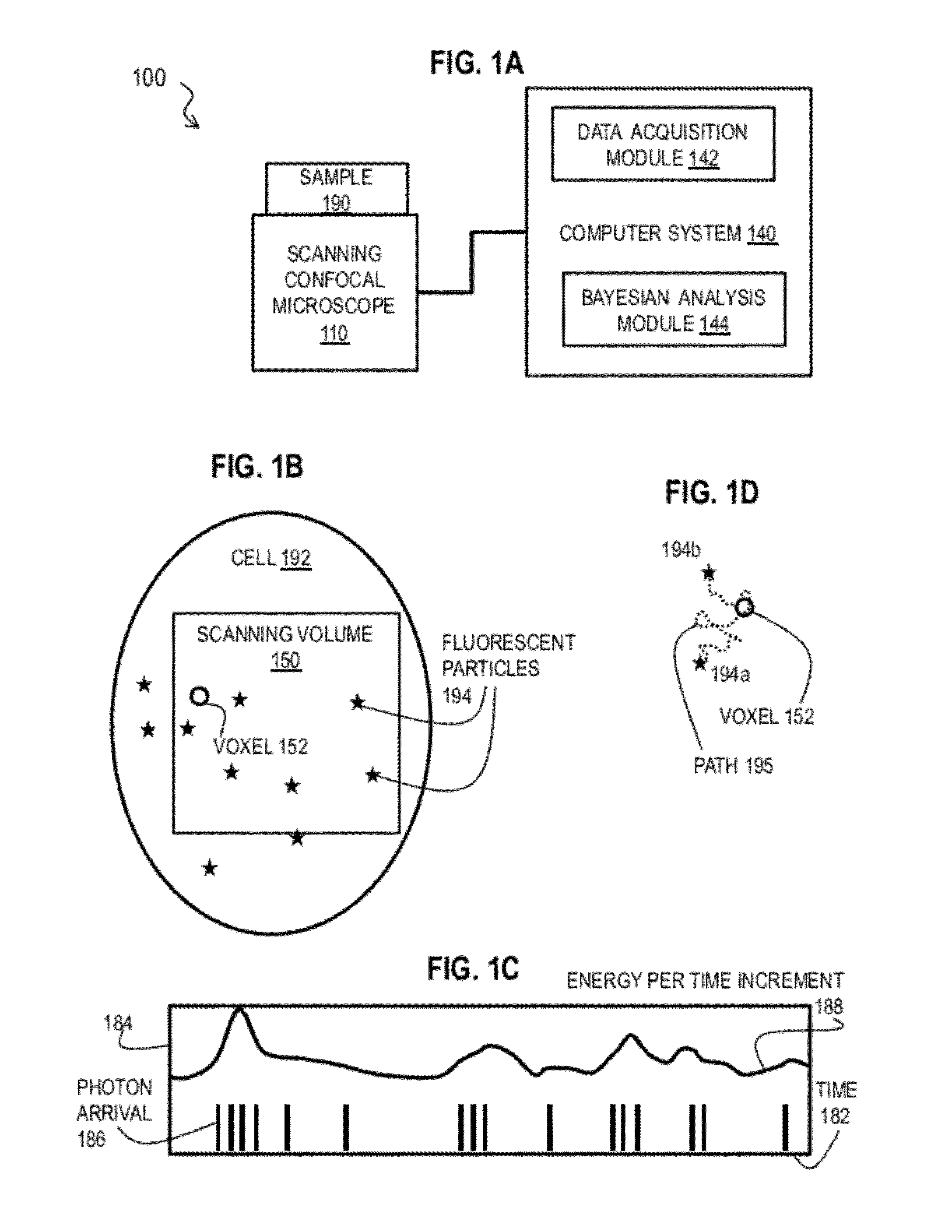

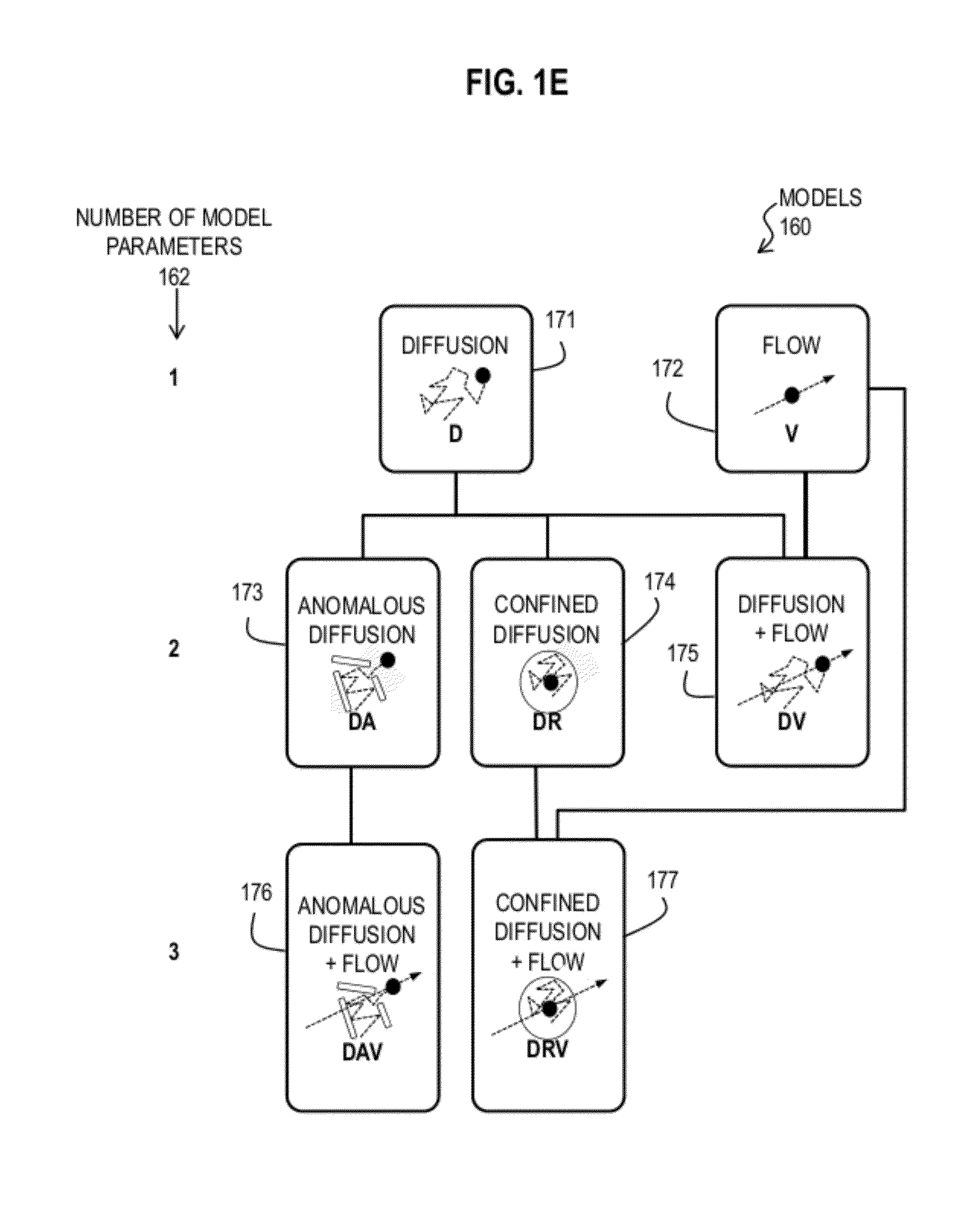

Techniques for inferring particle dynamics from certain data include determining multiple models for motion of particles in a biological sample. Each model includes a corresponding set of one or more parameters. Measured data is obtained based on measurements at one or more voxels of an imaging system sensitive to motion of particles in the biological sample; and, determining noise correlation of the measured data. Based at least in part on the noise correlation, a marginal likelihood is determined of the measured data given each model of the multiple models. A relative probability for each model is determined based on the marginal likelihood. Based at least in part on the relative probability for each model, a value is determined for at least one parameter of the set of one or more parameters corresponding to a selected model of the multiple models.

Owner:MASSACHUSETTS INST OF TECH

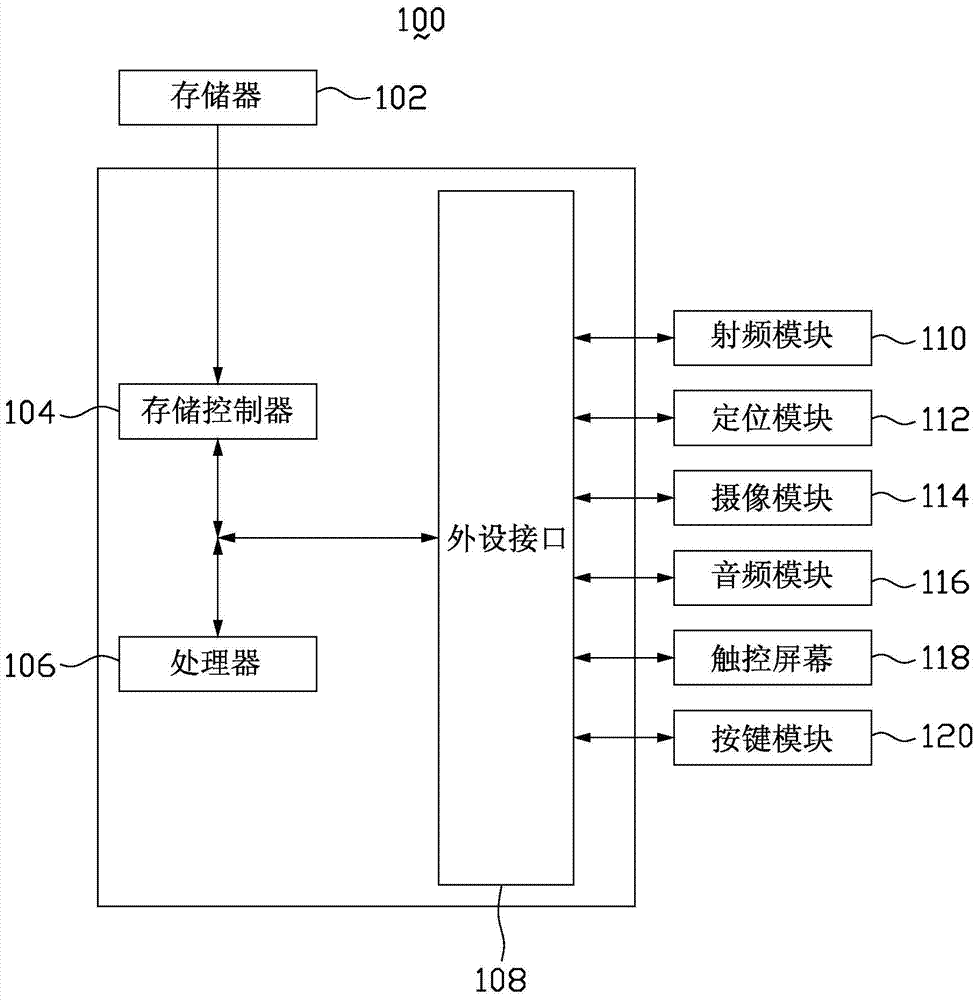

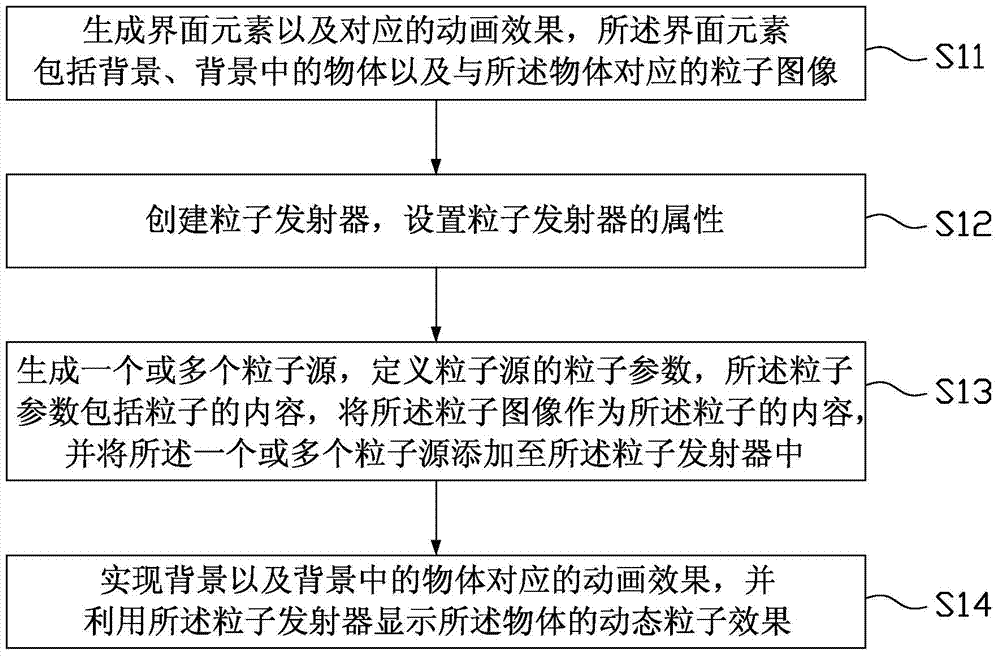

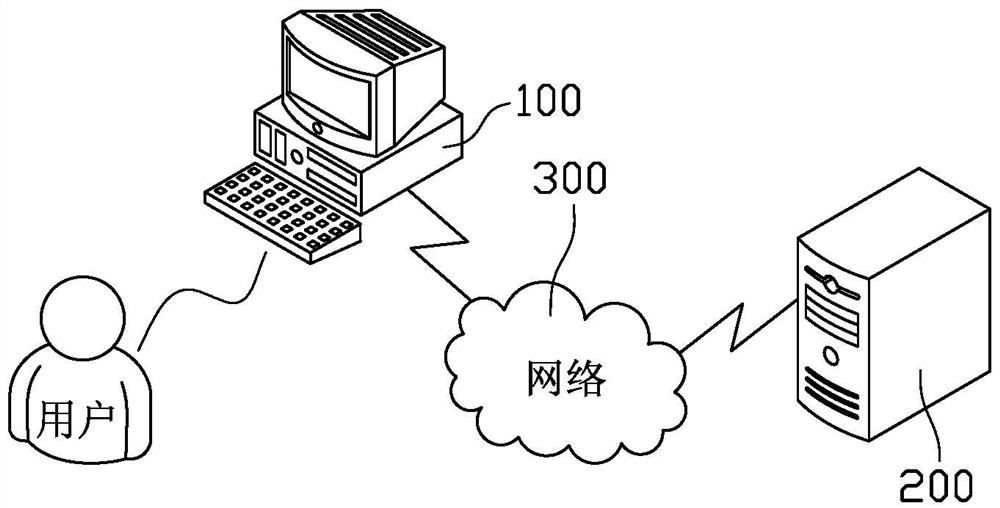

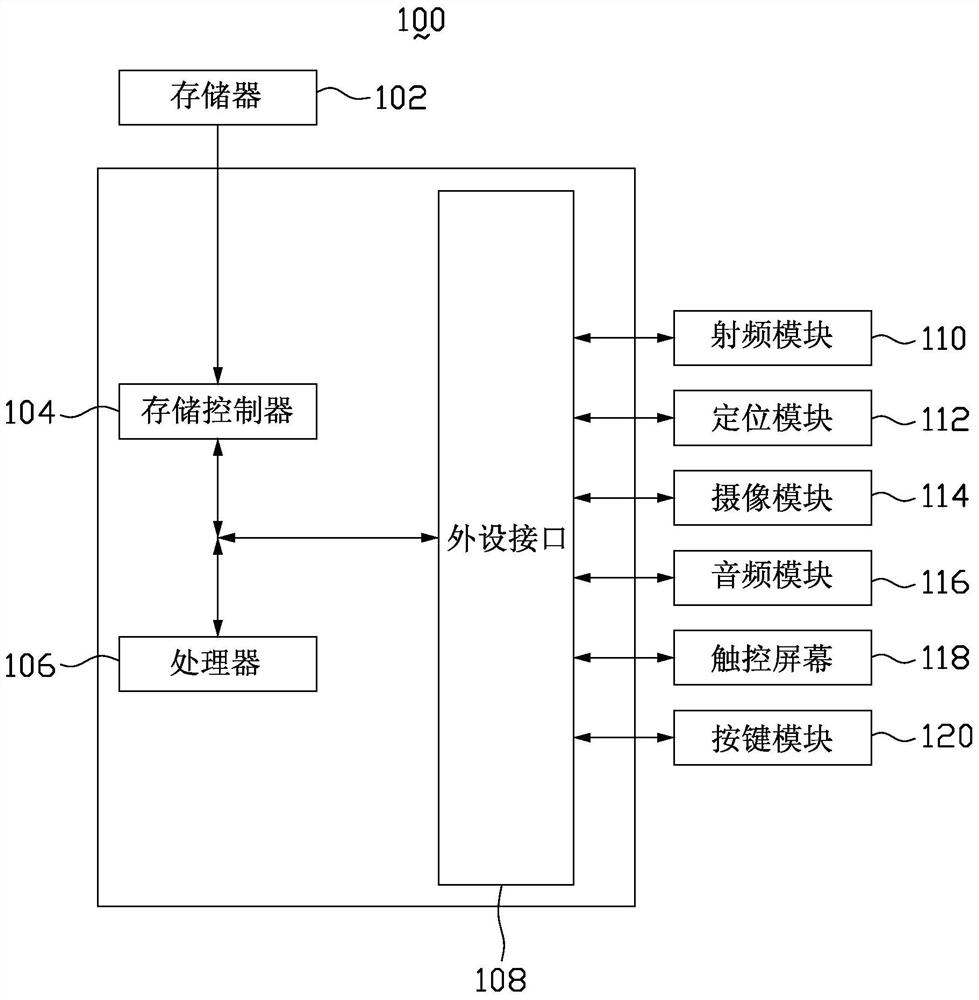

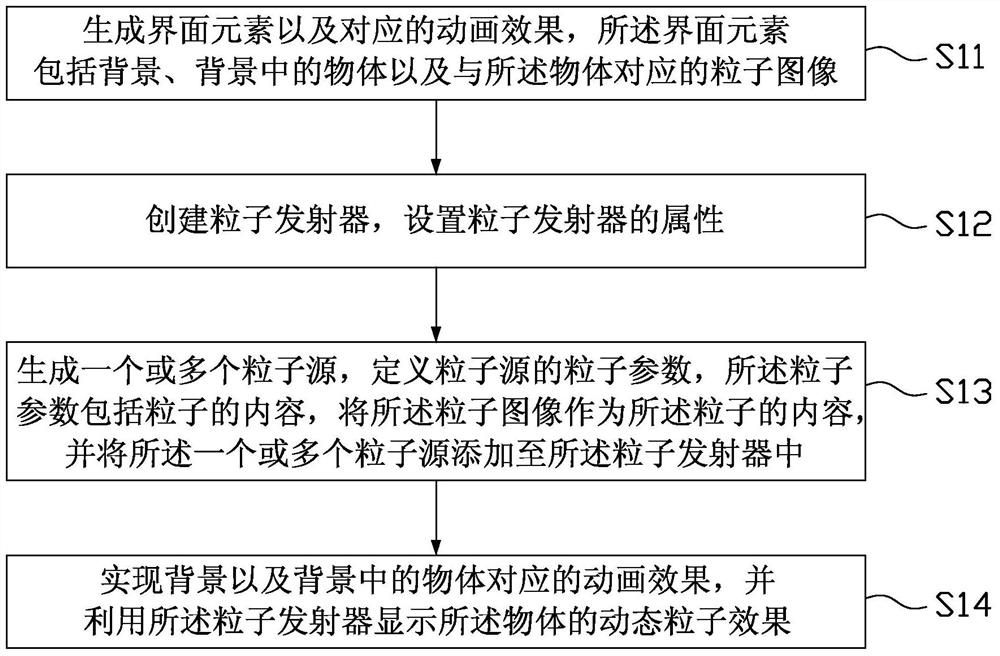

Method and apparatus for implementing dynamic interface

ActiveCN104850389AWith particle dynamic effectImprove realismAnimationSpecific program execution arrangementsParticle dynamicsAnimation

The embodiment of the invention provides a method and apparatus for implementing a dynamic interface. The method comprises steps of generating interface elements and a corresponding animation effect, wherein the interface element includes a background, objects in the background and particle images corresponding to the objects; establishing a particle emitter and setting the attribute of the particle emitter; generating one or more particle sources, and defining particle parameters of the particle sources, wherein the particle parameters includes contents which are particle images of the particles; adding the one or more particle sources in the particle emitter; and implementing the background and the animation effect corresponding to the objects in the background, and displaying a dynamic particle effect of the objects using the particle emitter. According to the method and apparatus for implementing the dynamic interface provided by the embodiment of the invention, a particle dynamic effect can be displayed on the interface, tracks and special effects of motions of the true-life objects can be simulated at high order, and the third dimension effect and the interest of the interface can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Bayesian inference of particle motion and dynamics from single particle tracking and fluorescence correlation spectroscopy

Techniques for inferring particle dynamics from certain data include determining multiple models for motion of particles in a biological sample. Each model includes a corresponding set of one or more parameters. Measured data is obtained based on measurements at one or more voxels of an imaging system sensitive to motion of particles in the biological sample; and, determining noise correlation of the measured data. Based at least in part on the noise correlation, a marginal likelihood is determined of the measured data given each model of the multiple models. A relative probability for each model is determined based on the marginal likelihood. Based at least in part on the relative probability for each model, a value is determined for at least one parameter of the set of one or more parameters corresponding to a selected model of the multiple models.

Owner:MASSACHUSETTS INST OF TECH

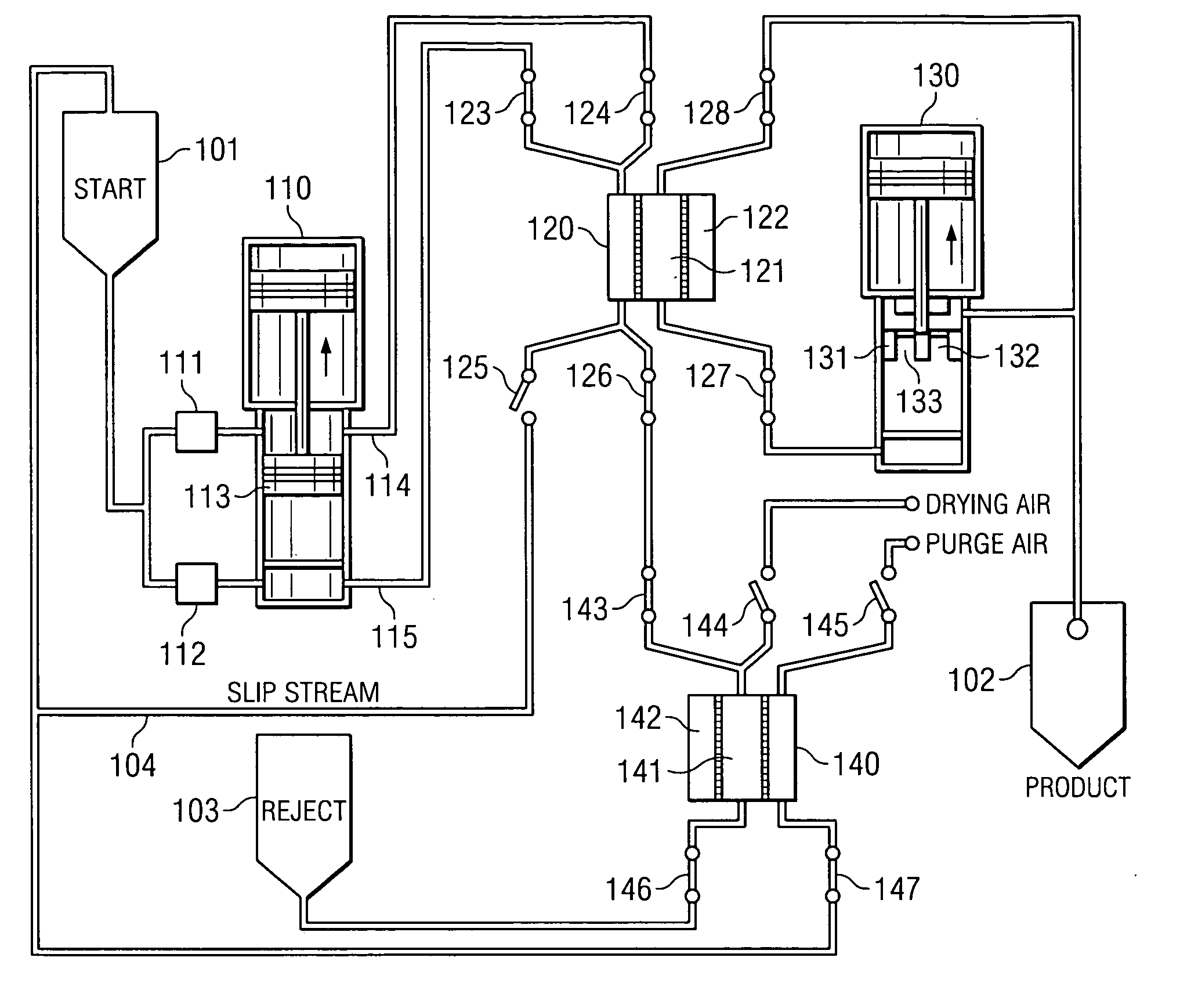

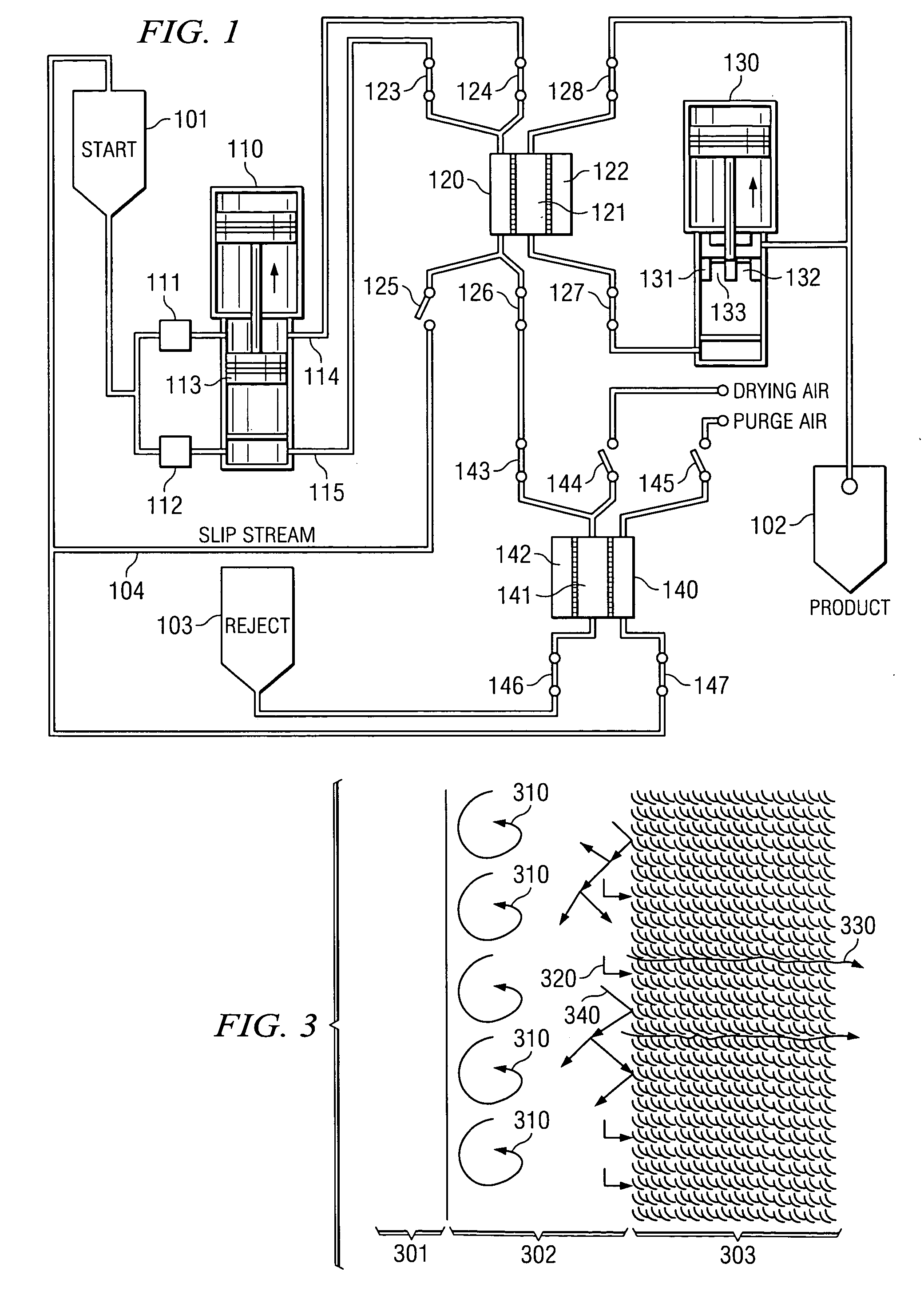

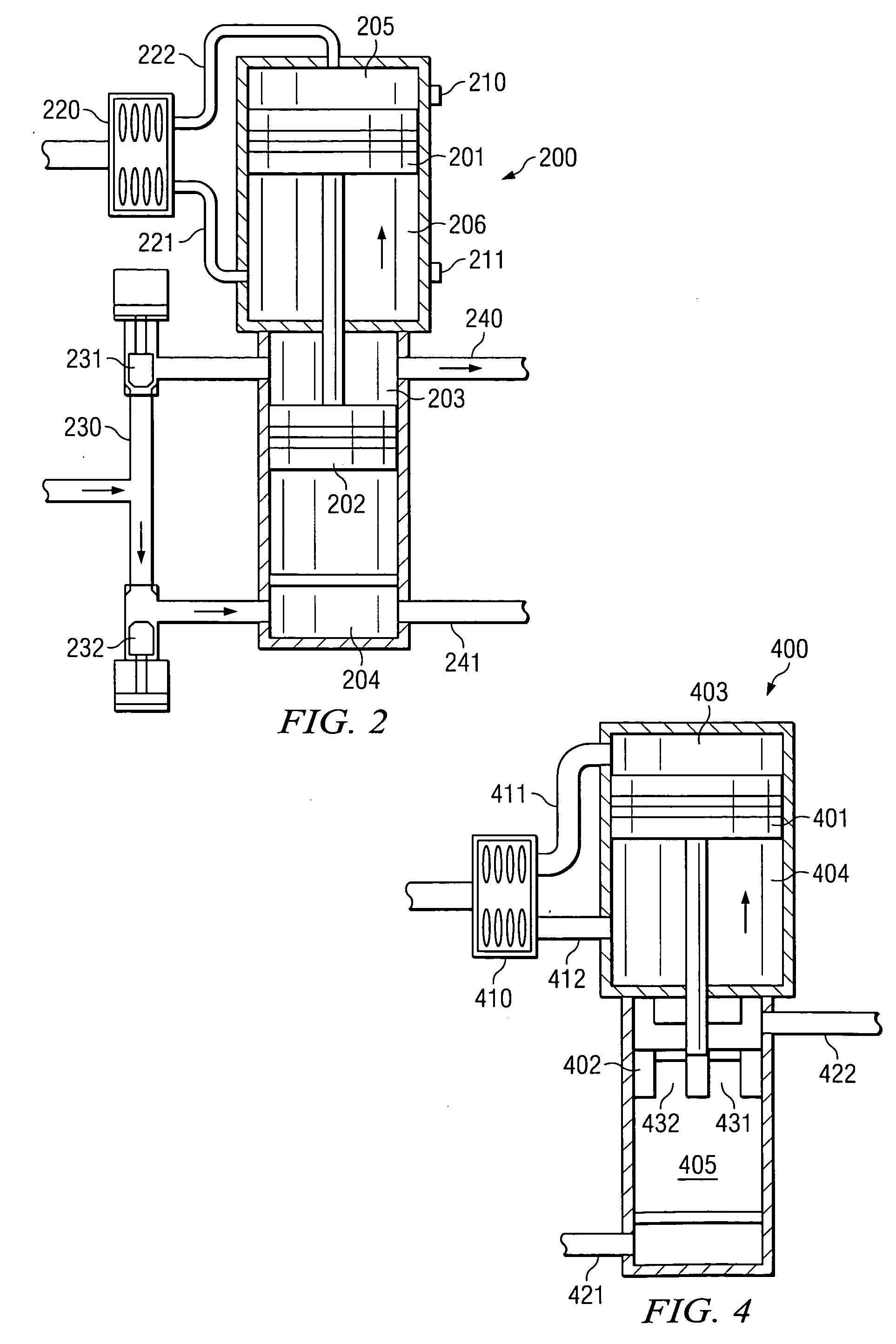

Molecular separator

ActiveUS20050170492A1Improve filtration efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsParticulatesCavitation

The present invention discloses a method and apparatus for separating particles and dissolved matter from a fluid stream. Specifically, the present invention includes a first pressure source which transports untreated fluid into a separator annulus with a filter element disposed therein. The untreated fluid is placed under appropriate pressure sufficient to produce turbulent flow, increased particle kinetics and / or cavitation physics allowing the desired fluid to penetrate and pass into and through the filter media. The filtered fluid is then transported to a collection tank. The contaminant particulate matter retained on the exterior of the filter media may be removed by the instantenous reverse pressurization of the separator annulus by a second pressure source thereby removing the contaminant particles away from contact with the filter media, and which may then be transported to a waste collection tank or a concentrator for further treatment.

Owner:TERVITA +1

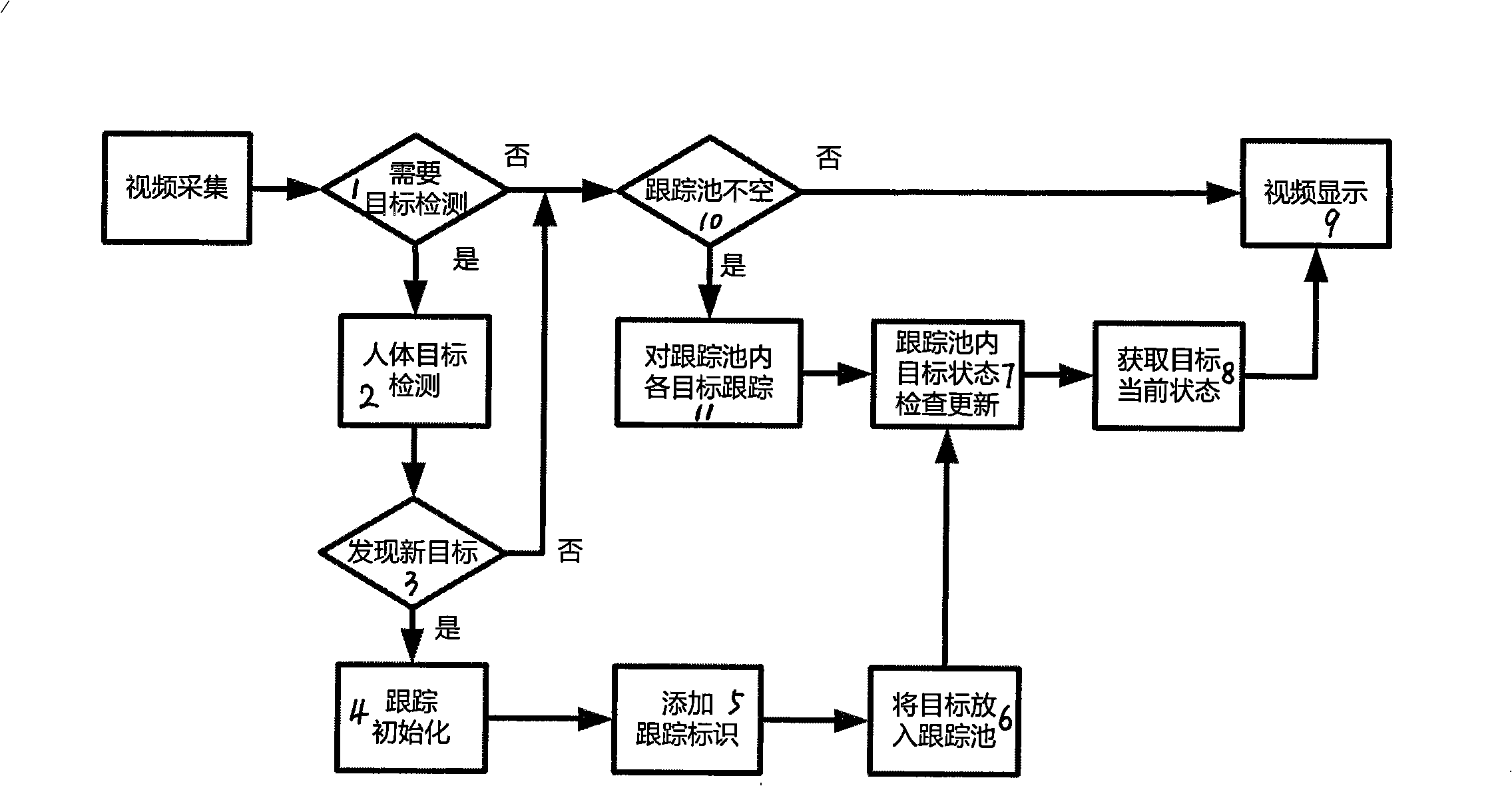

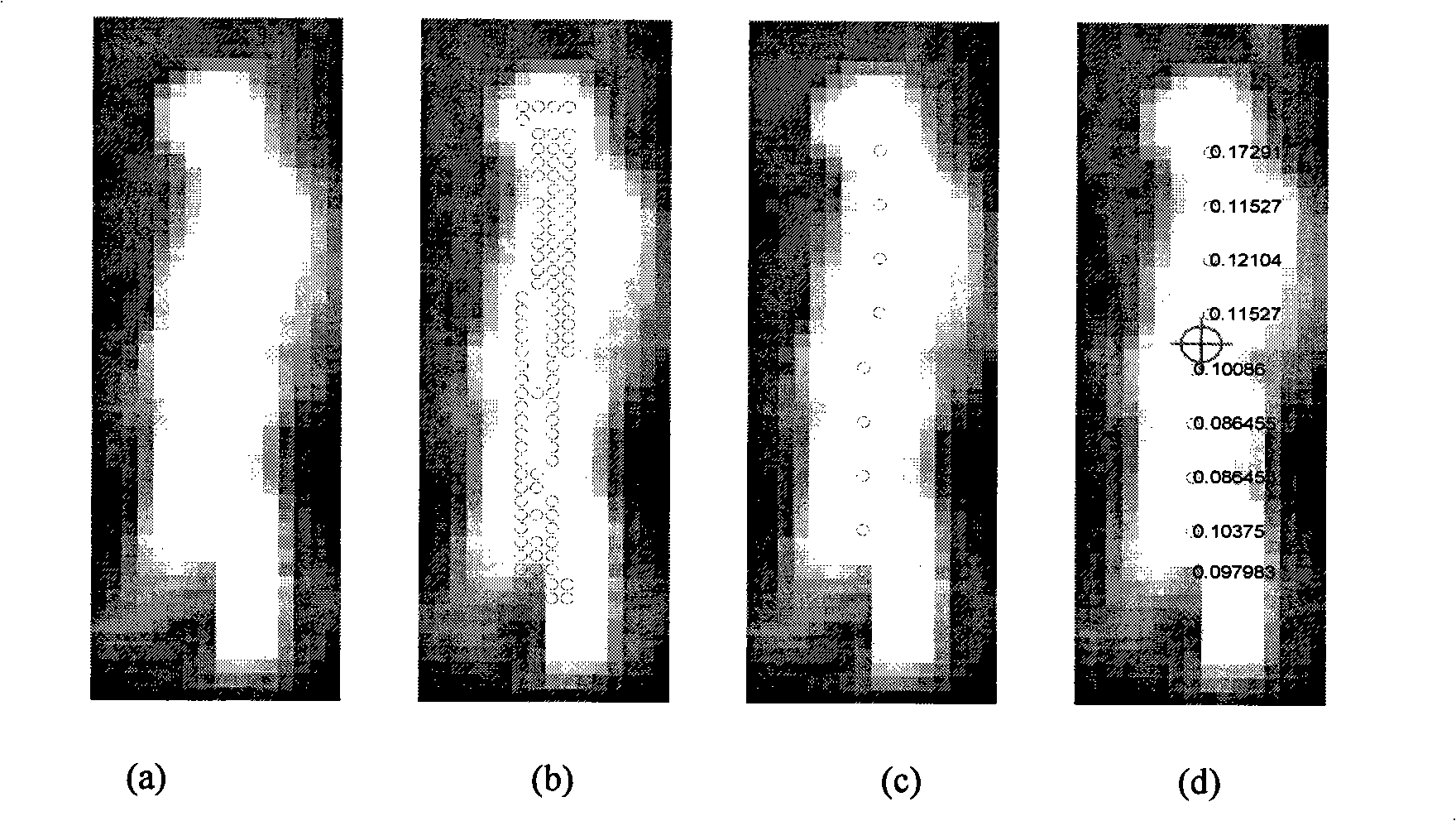

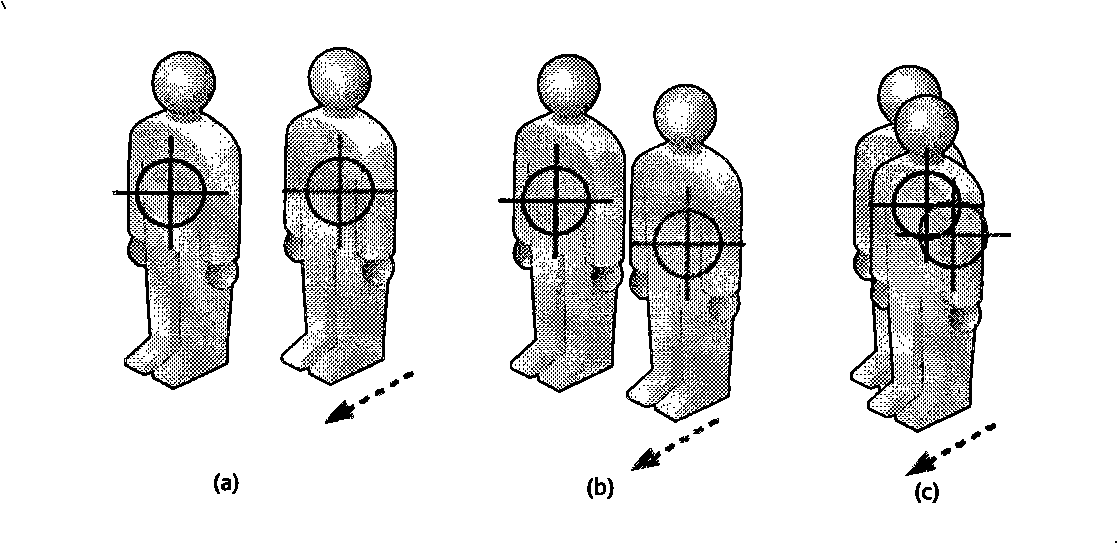

System for tracking infrared human body target based on corpuscle dynamic sampling model

InactiveCN101303726AReliable trackingSmall amount of calculationCharacter and pattern recognitionHuman bodyData stream

The invention provides an infrared human target tracking system based on a particle dynamic sampling model. The system includes a thermal infrared imager, an image collection device, a CPU and a video display device. The image collection device collects and transmits the video data flow of the thermal infrared imager to the CPU; the CPU combines the infrared video data into a continuous image sequence and carries out tracking on the image sequence. A tracking method is realized by random particle sampling and transfer control, which includes: taking an individual target as an object, regenerating a random sampling particle according to the observing particles of each target and removing the redundant particles according to the set judging rule of an ineffective sampling particle; carrying out state judging on the targets in a tracking pool; the tracking result processed by the CPU is fed into the video display device to carry out display; the technology facing to the object is adopted to carry out sealing on the complex target states of the human; the problem that the traditional tracking method can not realize the reliable tracking to the human target in the infrared image sequence is overcome.

Owner:CHONGQING UNIV

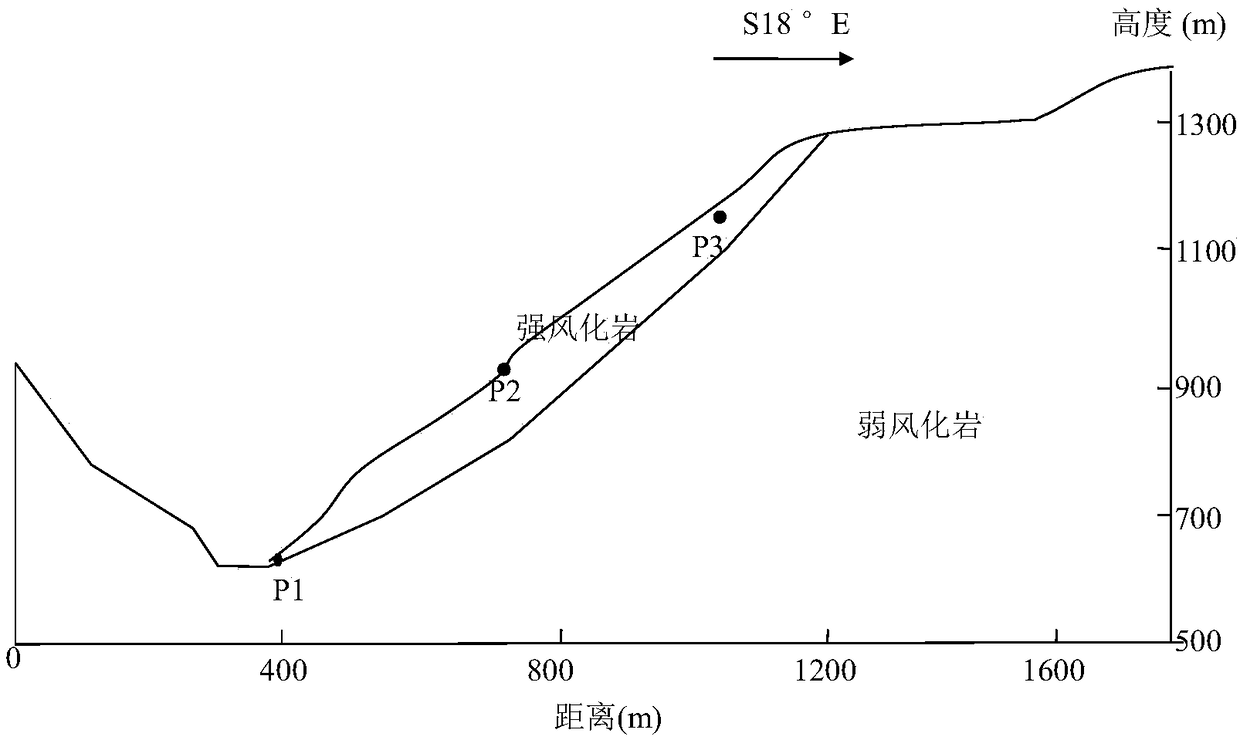

A method for simulating progressive failure, like solid-liquid phase transformation behavior of rock and soil media

InactiveCN109284523AAccurate predictionReasonable assessment of hazardsGeometric CADDesign optimisation/simulationStart upNewtonian fluid

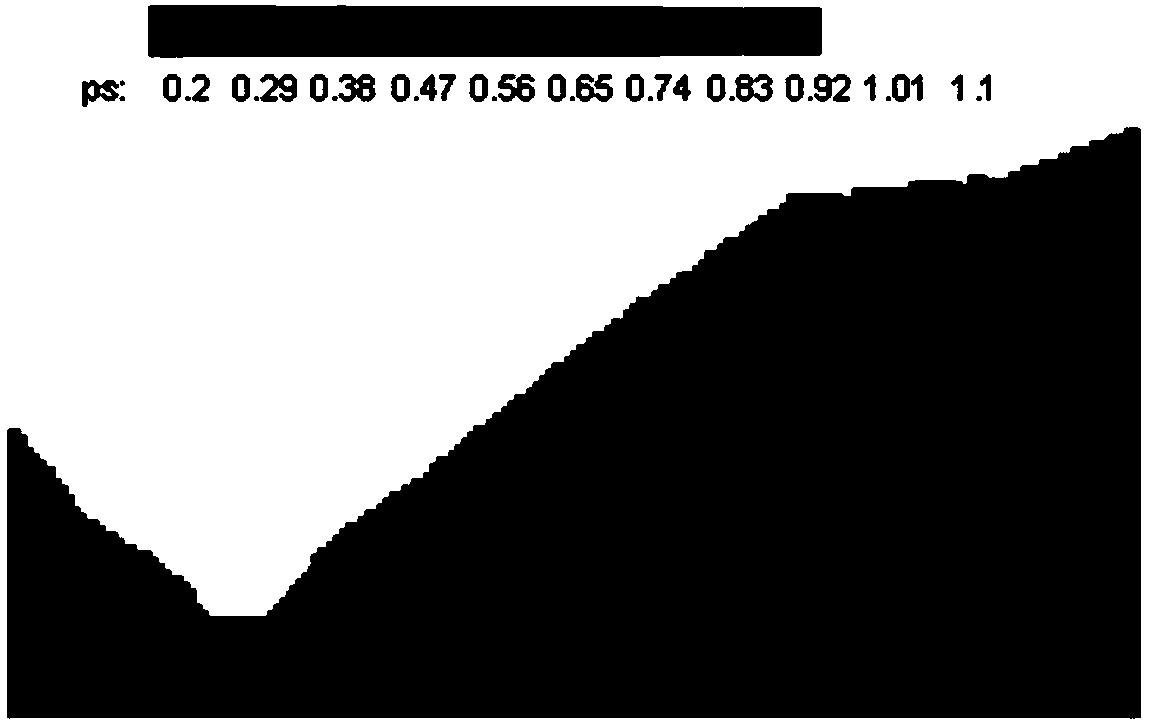

The invention relates to a rock-soil medium progressive failure, solid-like. The smooth particle dynamics (SPH) method is improved from three aspects: boundary condition, constitutive relation and artificial stress, so that the SPH can reproduce the progressive failure of rock and soil media under strong earthquake dynamic condition, solid-like-liquid phase change behavior, constructing slip-freeboundary modified by seismic wave velocity to apply seismic wave, creating free-field boundary to prevent seismic wave reflection, using particle rheology for reference, combining Drucker-Prager constitutive model and Newtonian fluid constitutive model construct a new unified constitutive model, which can describe the phase from sliding (solid-like) to flowing (liquid-like) in geotechnical media.The invention effectively reproduces the kinematic characteristics of the start-up, high-speed flow and accumulation process of the landslide, analyzes the progressive failure of the rock and soil medium and the penetration process of the sliding surface under the action of the strong earthquake, thereby accurately predicting the sliding distance, and reasonably assesses the earthquake-triggered landslide. The hazard caused by debris flow provides scientific basis for the planning and design of earthquake prevention and disaster reduction.

Owner:TONGJI UNIV

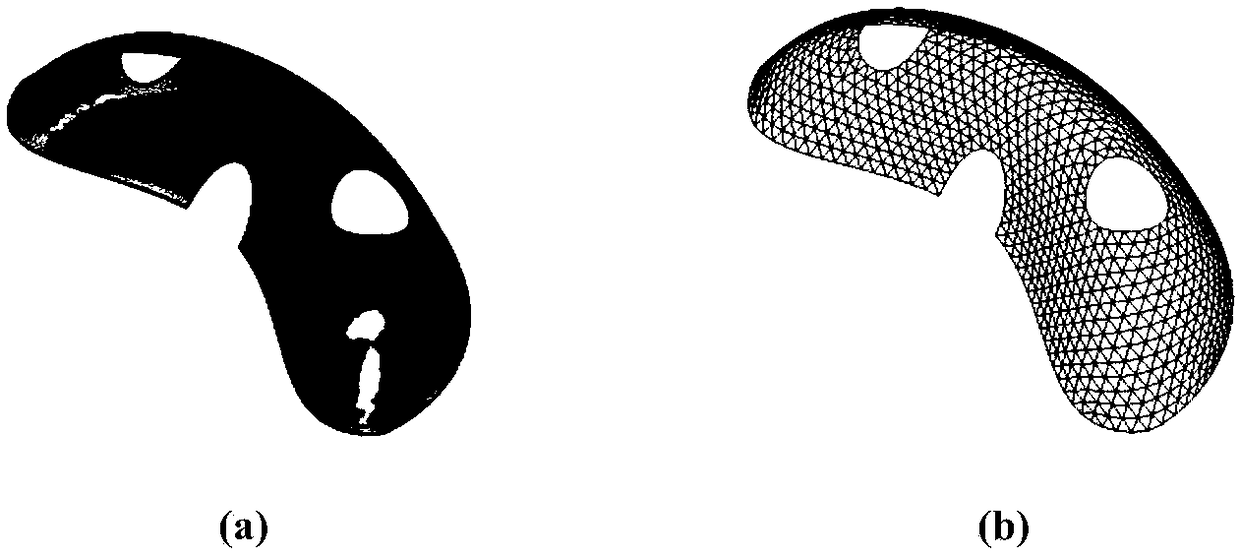

A multi-curved surface building mesh generation method based on discretization

InactiveCN109035410AImprove uniformityGeometric CADSpecial data processing applicationsFree formTopology optimization

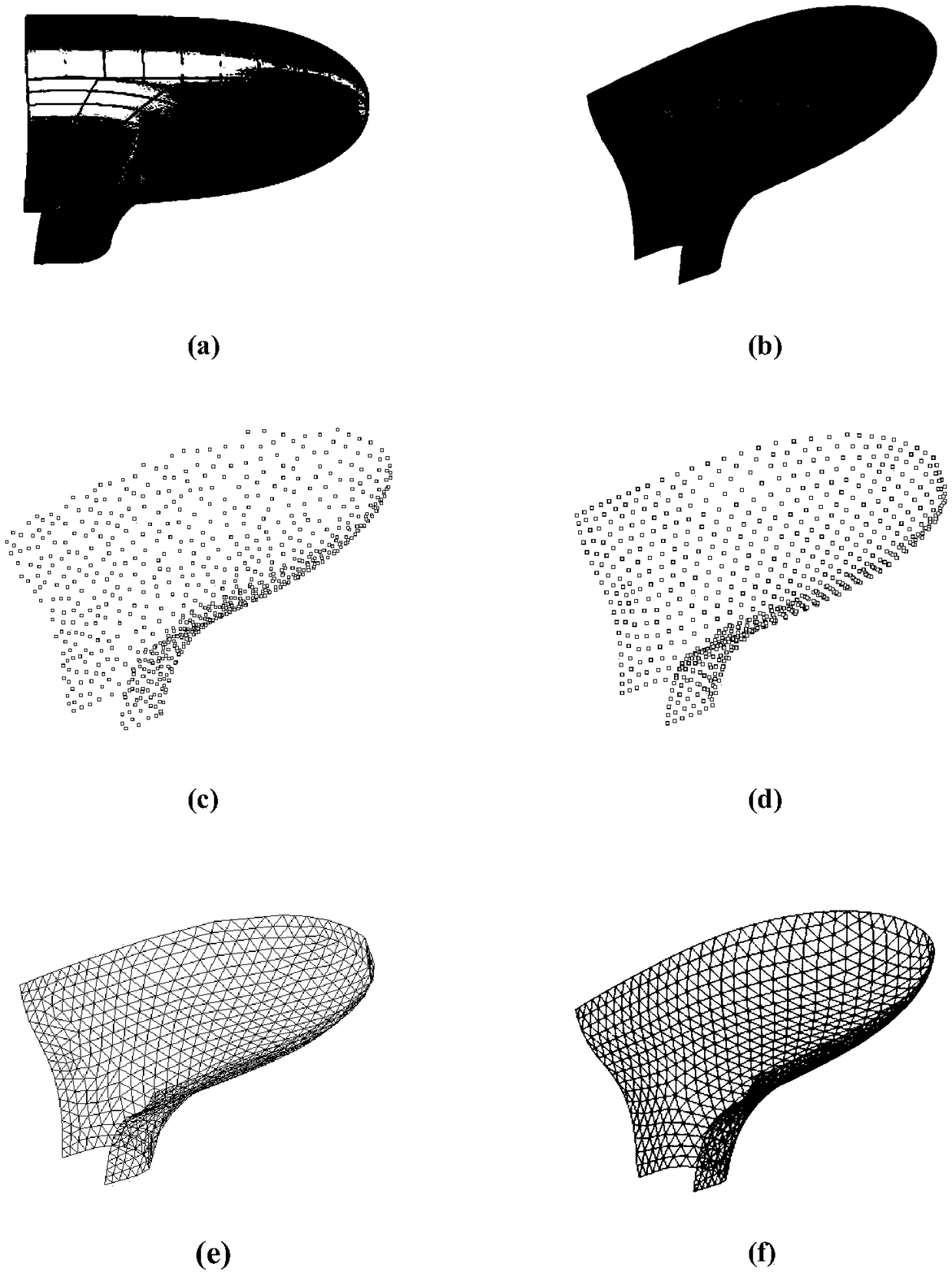

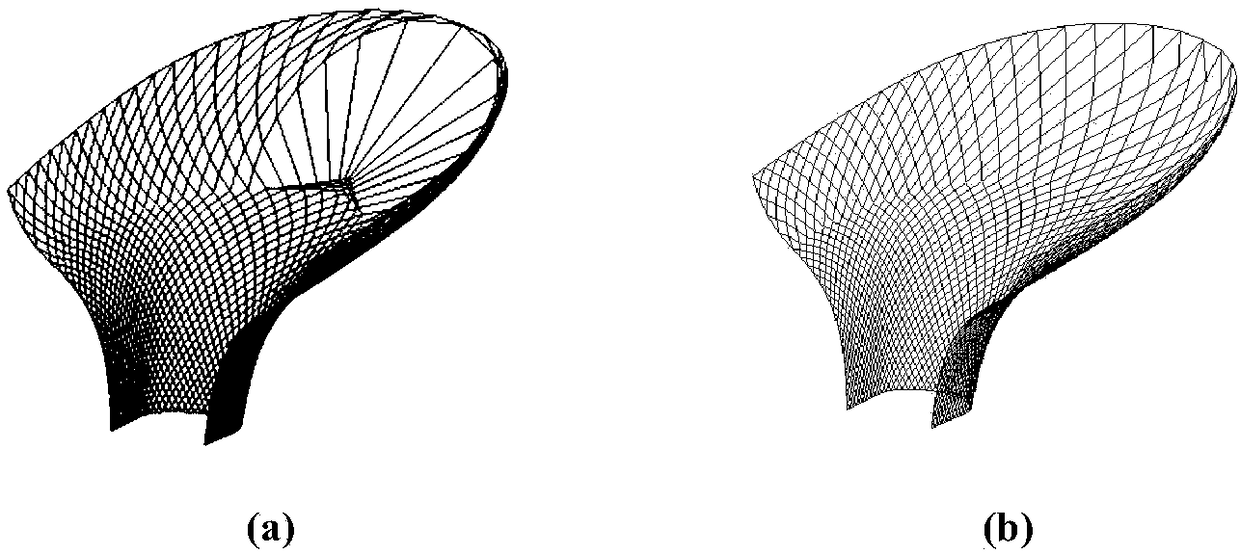

The invention discloses a multi-free-form surface building mesh generation method based on discretization, belonging to the field of building mesh generation. The method is used for building mesh generation of multi-free-form surfaces with cuts and holes. The method comprises the steps of separately discreting a multi-curved surface and stitching the blocks to form a discrete curved surface composed of a large number of small triangular patches; secondly, using the improved error diffusion algorithm, and arranging the initial points on the discretized surface surface according to a certain density. Then, the particle dynamic relaxation algorithm of spatial distance is used to homogenize the point cloud, and the k-means algorithm of the curved surface distance is used to homogenize the point cloud again. Then, triangular meshes are obtained for uniform point clouds. Finally, topology optimization and fairing optimization are carried out. The algorithm of the invention can effectively process multi-free-form surfaces with cuts and holes, and obtain a uniform smooth triangular mesh.

Owner:ZHEJIANG UNIV

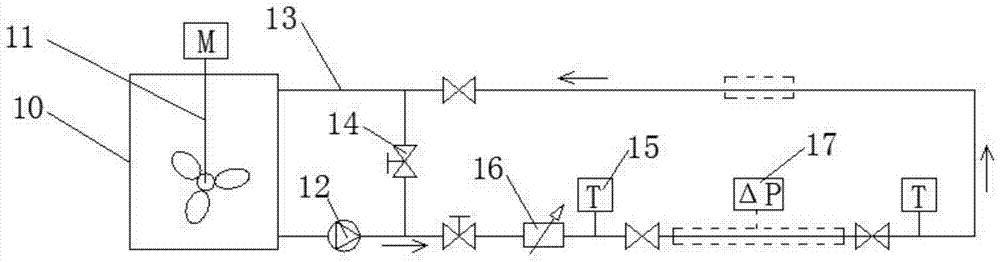

Phase change cooling research method of filling body in high-temperature deep well

ActiveCN104849303ASolve the pipelineSolve the mechanical propertiesInvestigating phase/state changeParticle dynamicsMulti field

The invention discloses a phase change cooling research method of a filling body in a high-temperature deep well. The phase change cooling research method comprises four stages of screening the best particle size gradation of pipeline transportation slurry through a particle size proportioning test; performing theoretical analysis, model establishment and calculation through computational fluid mechanics, particle dynamics, a two-phase flow theory and the like, and establishing a heterogeneity isothermal flow resistance model of ice containing filling slurry, which is suitable for an engineering design stage; researching the influence of external environment on a solid flow conversion process, and performing cold carrying capability calculation and cooling efficiency test research; modeling and calculating multi-field coupling of phase change slurry by utilizing numerical simulation software, and researching space-time evolution regularities and a non-linear model of a phase change process of the phase change slurry. According to the phase change cooling method, a complete theoretical system of an action mechanism of the phase change cooling filling body in the high-temperature deep well can be formed, obtained test results and formed theories can be directly applied to deep mining, and the problems of difficulties in transportation of the filling slurry of the deep well, mine cooling and the like are solved.

Owner:XIAN UNIV OF SCI & TECH

Video motion object abnormal behavior automatic detection method

InactiveCN103473533AImprove robustnessSimple methodCharacter and pattern recognitionParticle flowParticle dynamics

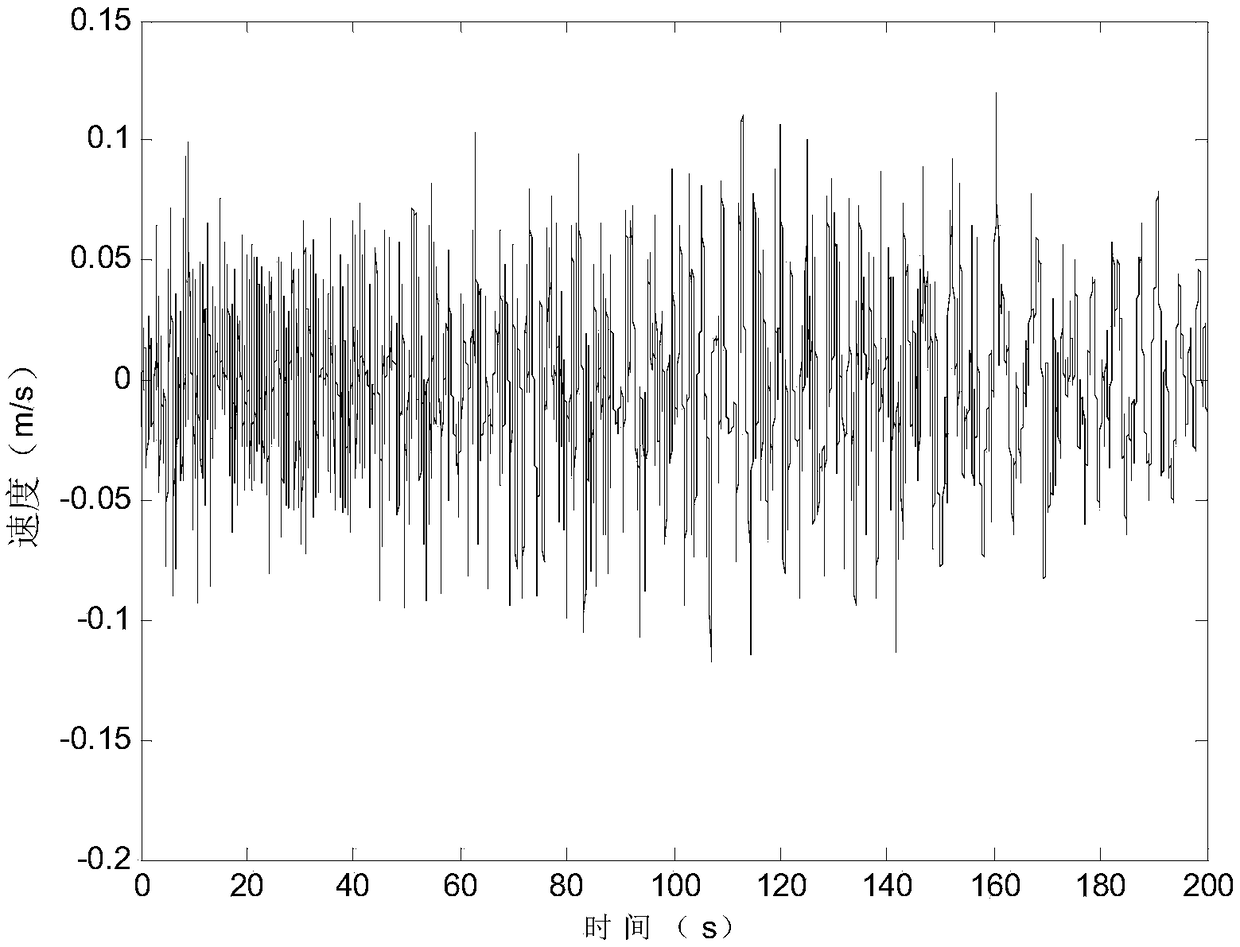

The invention relates to a video motion object abnormal behavior automatic detection method. The motion state of a video motion object is reflected according to particle flow in a Lagrange particle dynamic system, the abnormal behavior of the motion object and the normal behavior of the motion object are different in motion amplitude and motion direction, and by comparing changing of motion amplitude and motion direction in two adjacent frames of video images, automatic detection of the abnormal behavior of the video motion object is achieved. According to the method, the motion object does not need to be tracked, training by collecting a motion object abnormal behavior sample is of no need, and under various situations, automatic detection of the abnormal behavior of the motion object is achieved.

Owner:SHANGHAI UNIV

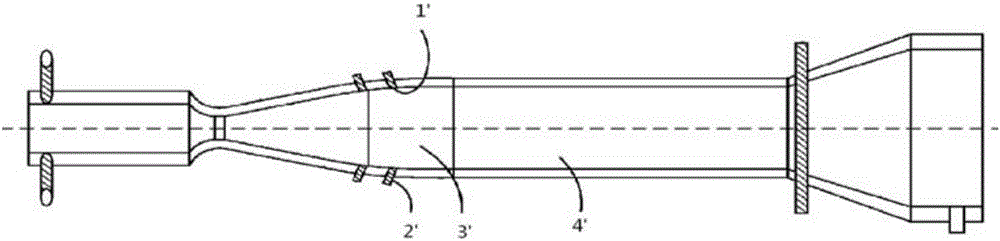

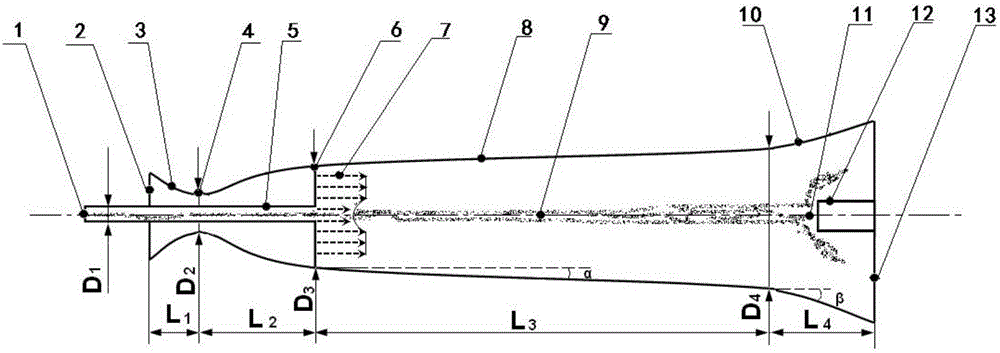

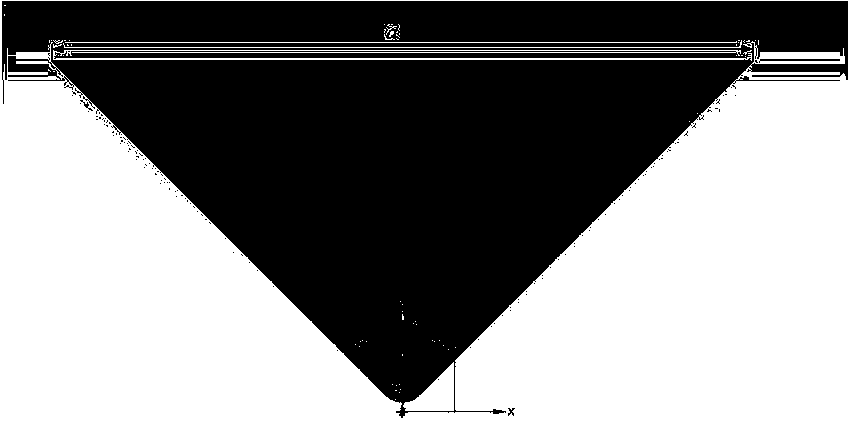

Supersonic nozzle

InactiveCN106693876AUniform flow fieldExact collisionChemical/physical/physico-chemical nozzle-type rreactorsSonic nozzleParticle dynamics

The invention relates to a supersonic nozzle which consists of a ring-shaped shrinking-expanding nozzle, an injected charging pipe, an accelerating pipe and a target head, wherein supersonic gas flow of the ring-shaped shrinking-expanding nozzle is used for injecting and accelerating low-speed gas flow of a central charging circular pipe to an supersonic state, so that material particles obtain enough dynamic energy along with the gas flow, and can be gathered at the gas flow center to crash the fixed target head at the downstream in a focused mode, and therefore, the problems such as difficult charging, low material particle dynamic energy and low collision reaction efficiency in high-speed gas flow solid-phase reaction are solved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

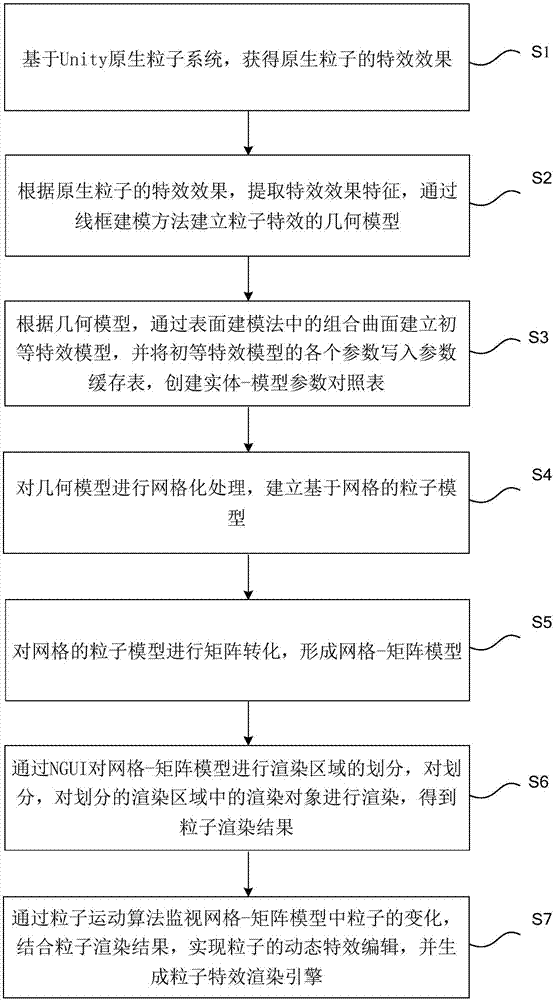

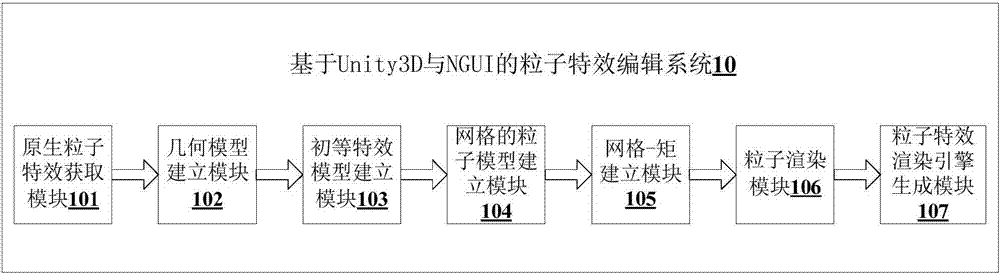

Particle effect editing method and system based on Unity3D and NGUI

PendingCN106952329ARealize dynamic special effects editingReal and diverse special effects3D-image renderingParticle dynamicsGrid based

The invention provides a particle effect editing method and system based on Unity3D and NGUI. The method comprises the steps that the effect of a Unity primary particle is acquired, and the effect characteristics are extracted to establish a particle effect geometric model; an elementary effect model is established according to the geometric model, and parameters are written into a parameter cache table; the geometric model is meshed to establish a particle model based on a mesh, and then matrix transformation is carried out to form a mesh-matrix model; rendering area dividing is carried out on the mesh-matrix model, and a rendered object in a divided rendering area is rendered to acquire a particle rendering result; the change of the particle in the mesh-matrix model is monitored; and the particle rendering result is combined to realize particle dynamic effect editing. According to the invention, meshing, matrix transformation, particle moving and other methods are carried out on the Unity primary particle, so that the particle effect is real and diversified and the change efficiency is high.

Owner:长沙趣动文化科技有限公司

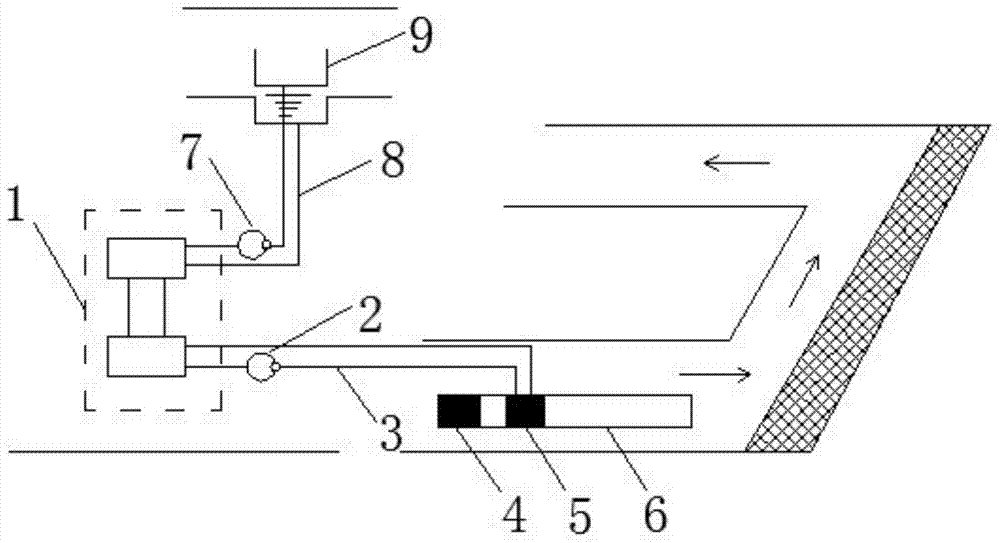

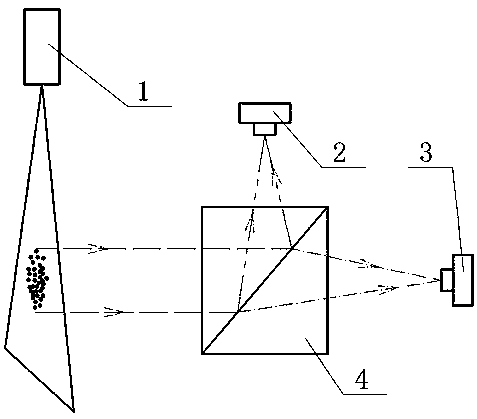

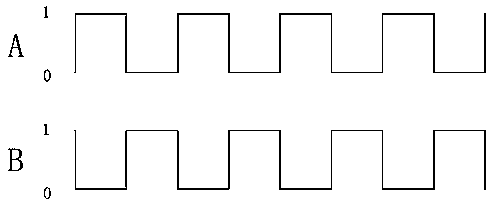

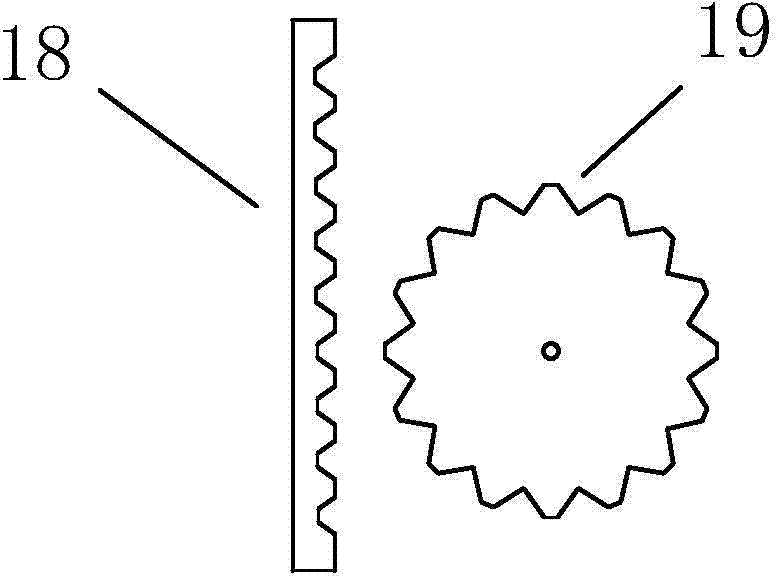

Particle dynamic trajectory measuring system and method based on asynchronous time delay method

The invention provides a particle dynamic trajectory measuring system and a particle dynamic trajectory measuring method based on an asynchronous time delay method, which relate to the technical fieldof measurement. The particle dynamic trajectory measuring method comprises the steps that: a sheet laser light source irradiates tracer particles suspended in a measured plane of a medium solution, light scattered by the tracer particles is projected onto a semi-transparent semi-reflective prism and is decomposed into a reflection image and a transmission image, the reflection image and the transmission image are photographed consecutively and alternately by means of a CCD camera I and a CCD camera II so as form a smearing trajectory diagram of the tracer particles in a time sequence, particle motion trajectories of the sequential tracer particles in the smearing trajectory diagram are extracted by adopting MATLAB software and a dynamic grayscale threshold value based on an Otsu algorithm, and a complete tracer particle dynamic trajectory is obtained through performing additive operation according to the time sequence. The particle dynamic trajectory measuring system and the particledynamic trajectory measuring method solve the technical problems of expensive PIV measurement equipment and complex measurement analysis software in the prior art, and have the beneficial effects of reducing the cost of the PIV measurement technology, decreasing difficulties in system construction and use, being simple in algorithm and ensuring measurement precision.

Owner:CHINA JILIANG UNIV

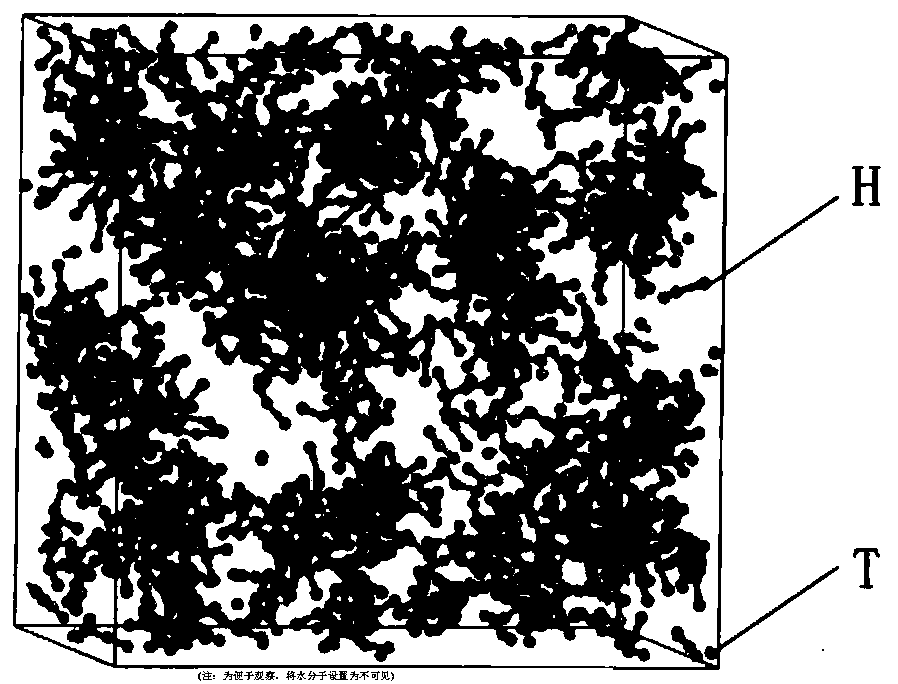

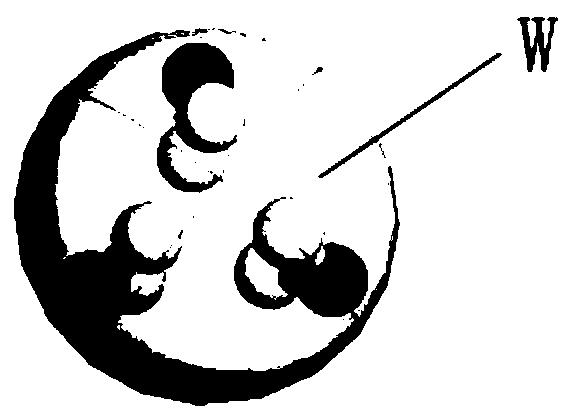

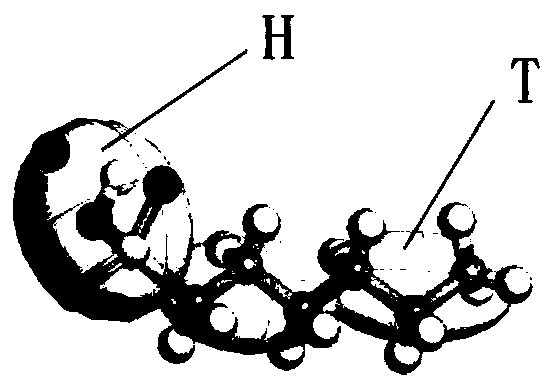

Construction method of surfactant solution dissipative particle dynamic force field

ActiveCN110517733AHigh precisionComputational theoretical chemistrySpecial data processing applicationsParticle dynamicsGrain structure

The invention belongs to the field of environmental pollution treatment meters, and particularly relates to a construction method for simulating a surfactant solution dissipated particle dynamic forcefield by using a computer. The method comprises the following steps: 1) establishing a coarse graining model of a surfactant and water molecules; 2) calculating interaction force parameters among thecoarse grained beads by utilizing a dissipative particle dynamics (DPD) theory; 3) establishing a coarse grained structure model of a solution system composed of a surfactant and water through Materials Studio software; (4) carrying out dissipative particle dynamics simulation on the parameters and models obtained in the step (2) and the step (3) by using a DPD module in Materials Studio softwareto obtain corresponding microstructure property parameters of the surfactant solution; and 5) adjusting interaction parameters among the coarse-grained beads, and optimizing according to experimentaldata of the microstructure property of the surfactant solution to obtain a DPD force field which can match an experimental result. According to the construction method disclosed by the invention, theprecision of the coarse graining force field is improved, the development of the coarse graining force field is promoted, and the construction method is of great guiding significance for researchingthe physical and chemical properties of the surfactant in a solution and at an interface.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI

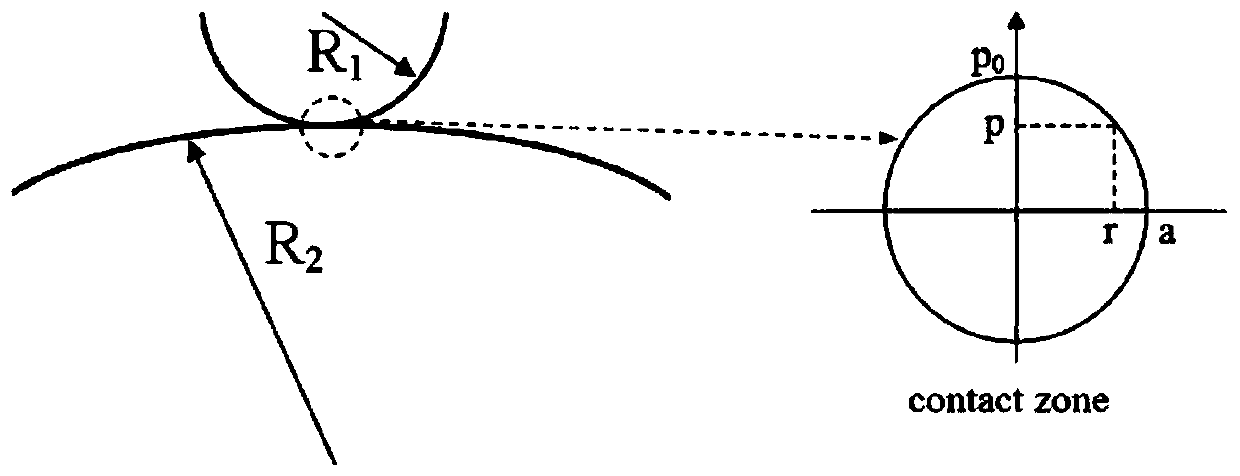

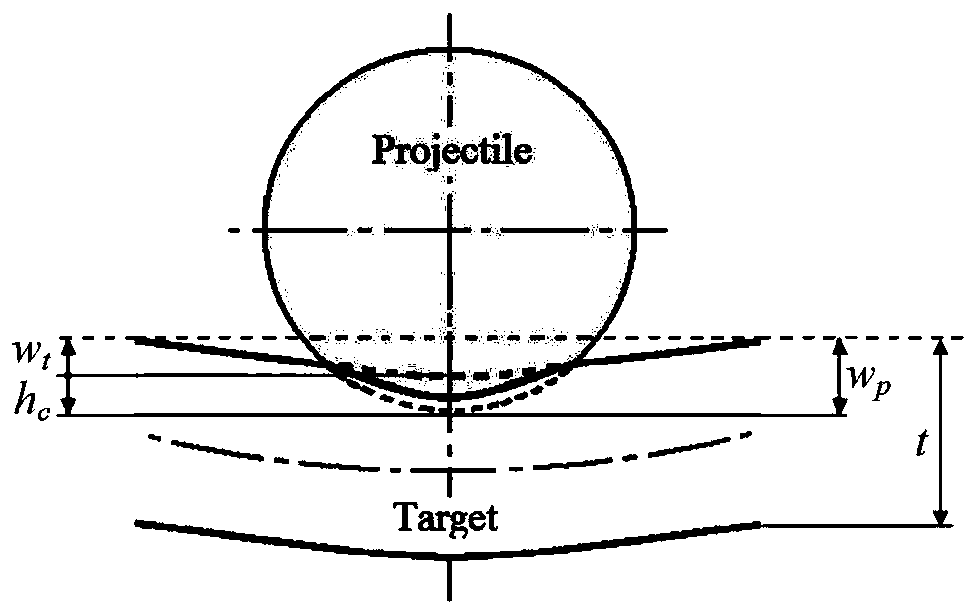

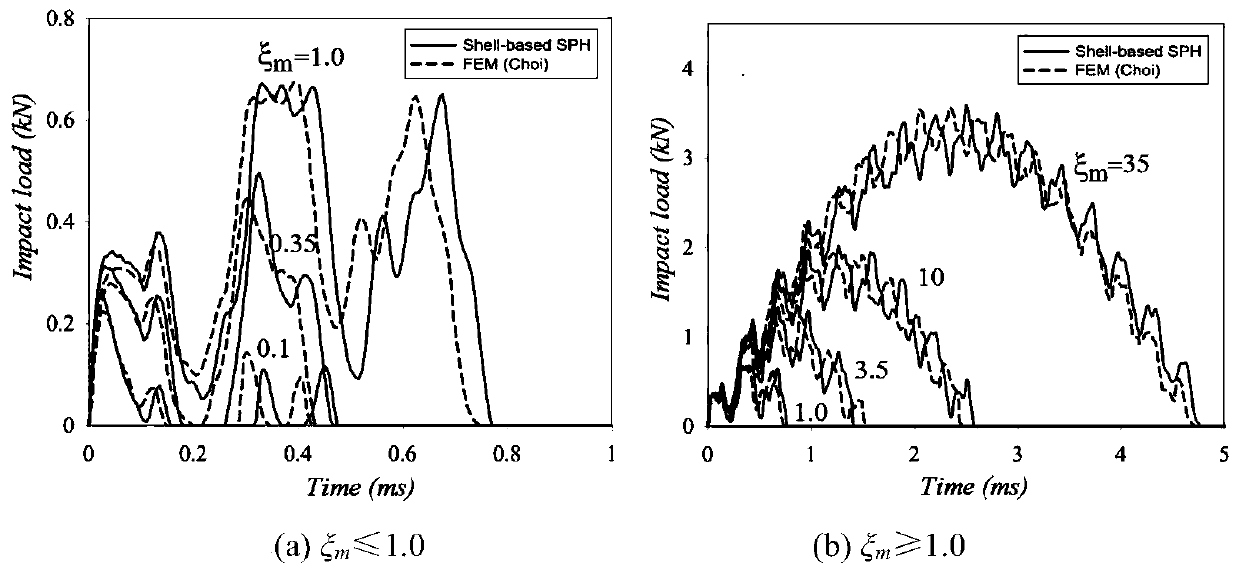

Impact response modeling method for composite laminated plate

InactiveCN111353228ARealize numerical monitoringSolving Dynamic ResponsesDesign optimisation/simulationParticle dynamicsComposite laminates

The invention relates to the field of materials, and provides a composite laminate impact response modeling method. The method comprises the following steps: calculating Hertz contact stiffness kc; acquiring the indentation depth hc of the composite material laminated plate, and calculating the contact load Fimp between the composite material laminated plate and an impacted object; employing a smooth particle dynamics SPH discretization method in a Lagrange form, and calculating the motion of the composite material laminated plate, and calculating the longitudinal acceleration of the punch. According to the relationship between the contact force and the indentation of the composite material laminated structure, the laminated plate impact response SPH model is established, the displacementchange of the laminated plate and the punch is analyzed, the damage form and the expansion mode of the laminated plate when the laminated plate is impacted are established, and the numerical monitoring of the impact response of the composite material layer is realized.

Owner:SHANDONG UNIV

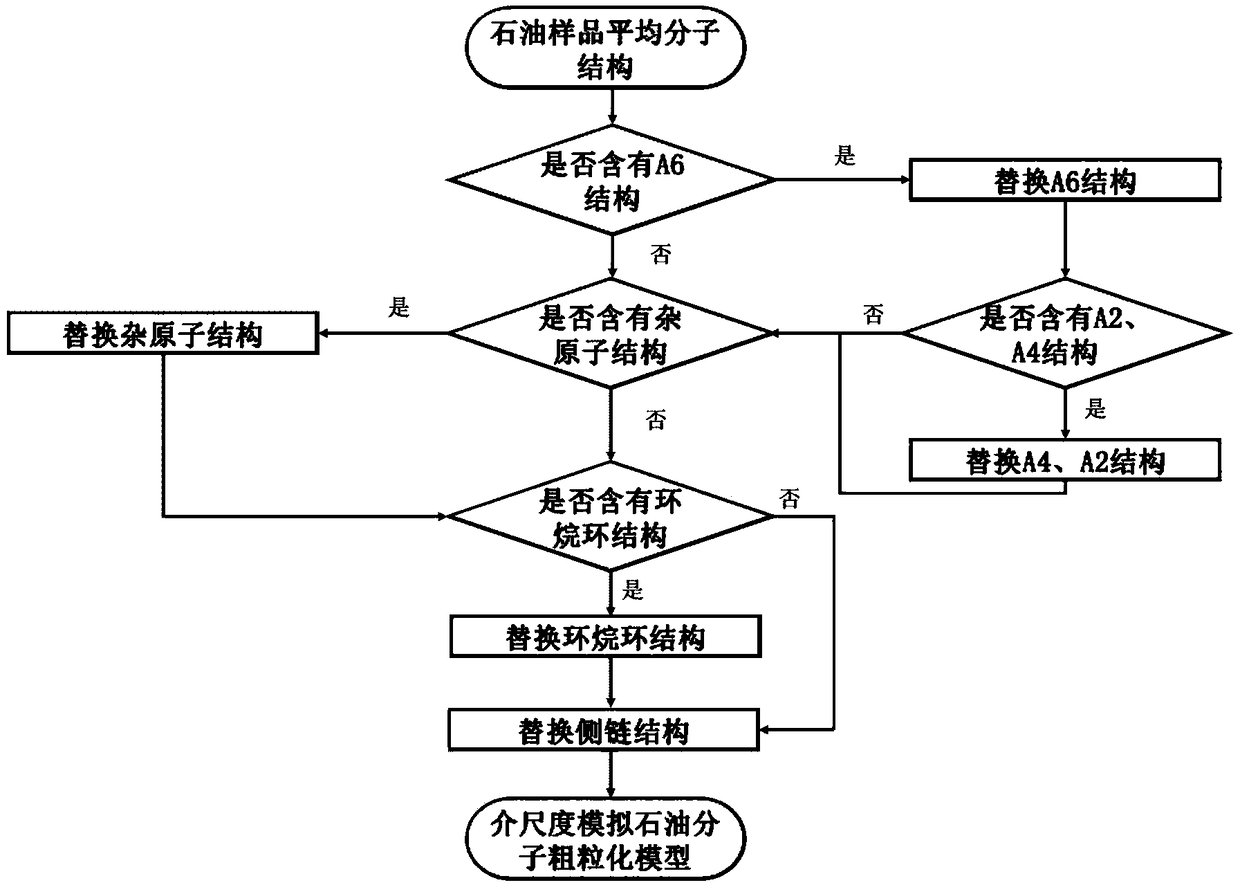

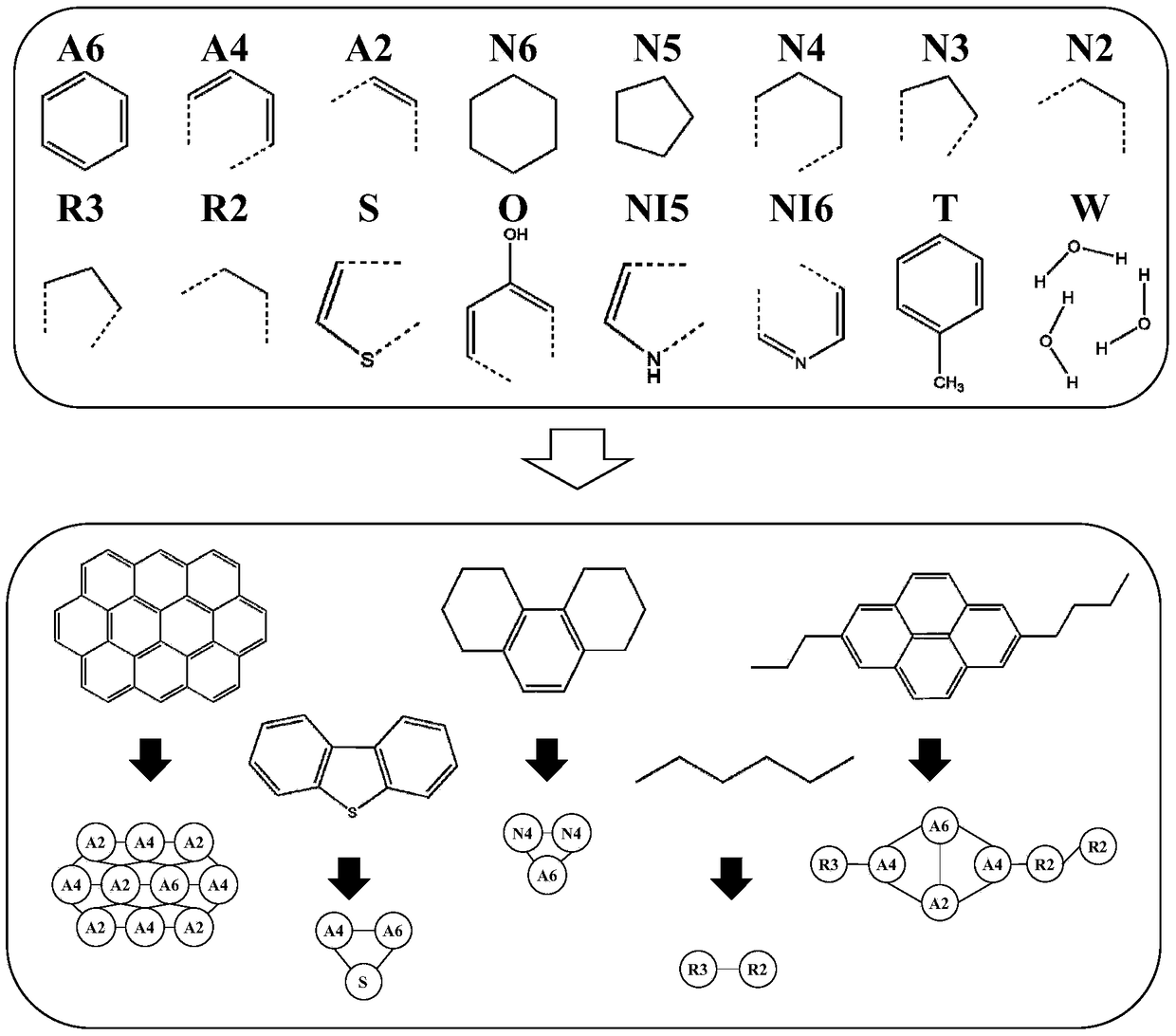

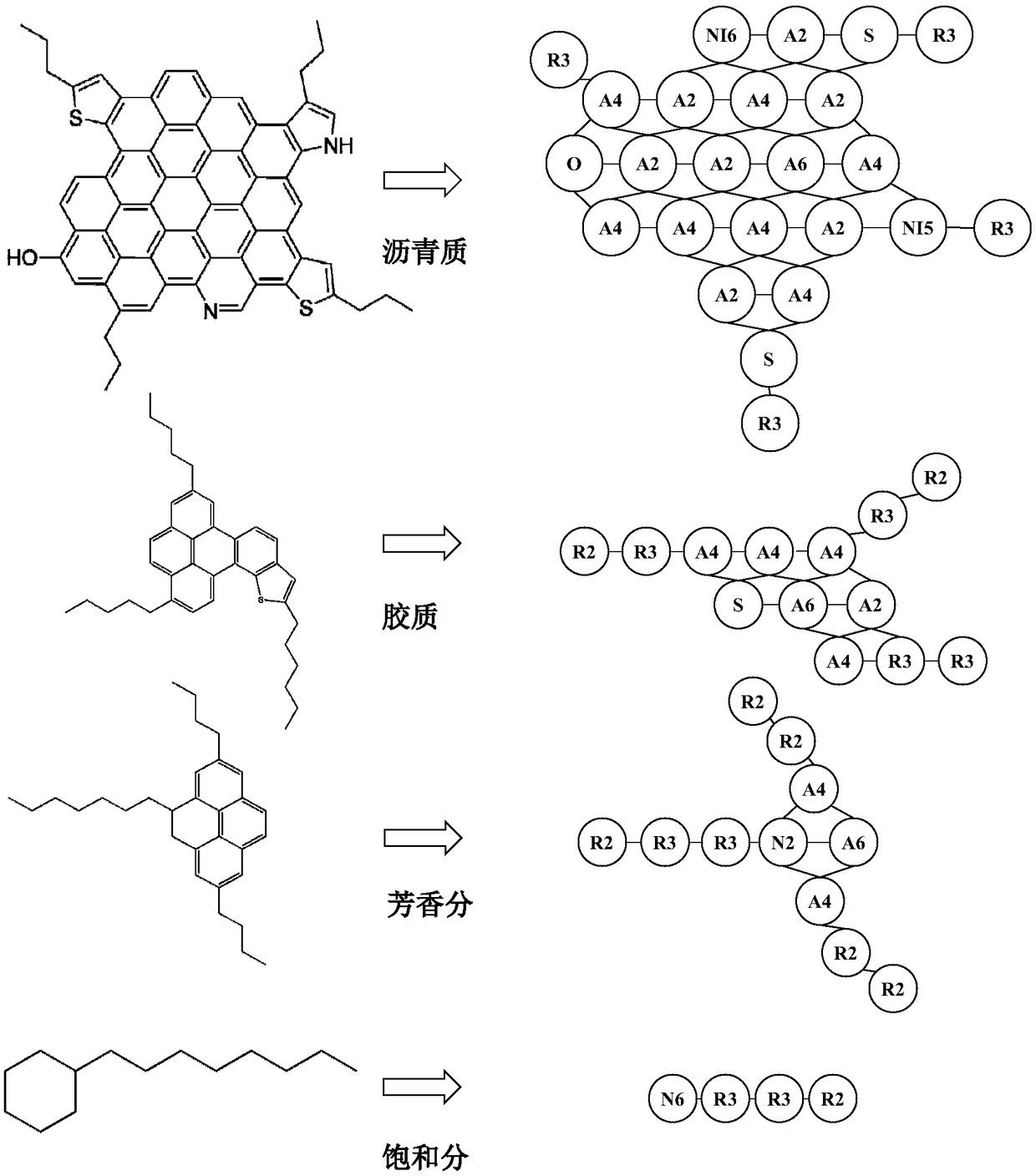

Model for mesoscale simulation of petroleum molecular coarse granulation and construction method and prediction method of model

ActiveCN109378041AAvoid direct cuttingPredicting Microstructural PropertiesComputational theoretical chemistryComputational materials scienceSolubilityConservative force

The invention provides a model for mesoscale simulation of petroleum molecular coarse granulation and a construction method and a prediction method of the model. The construction method comprises thesteps: average molecular structures of petroleum samples of different component types are obtained firstly, whether the average molecular structures of the petroleum samples of the different componenttypes contain structures such as condensed aromatic ring atoms, heteroatomic ring atoms, naphthenic ring atoms and side chain atoms or not is judged sequentially, equivalent replacement beads are adopted for replacement, and finally the model for mesoscale simulation of petroleum molecular coarse granulation is constructed. The prediction method comprises the steps: solubility parameters of the replacement beads are obtained through molecular dynamics simulation, and a Flory-Huggins theory and a dissipative particle dynamics theory are interrelated to obtain conservative force parameters; byutilizing the model for mesoscale simulation of petroleum molecular coarse granulation and combining a dissipative particle dynamics method, a stable equilibrium molecule disperse system structure issimulated; and microstructure properties of the oil samples are predicted through statistic analysis, and the good prediction effect is achieved especially for structure properties difficult to observe.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

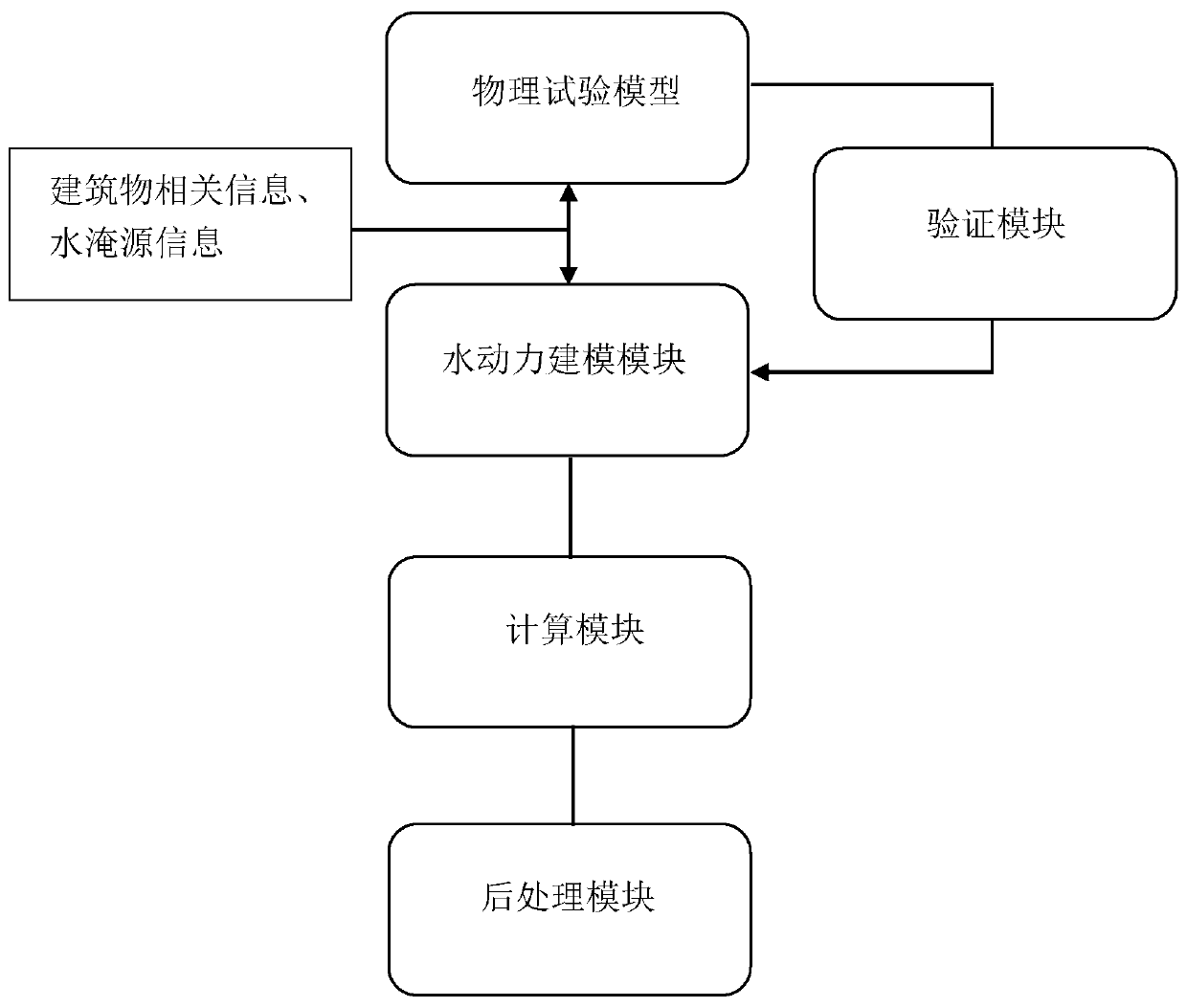

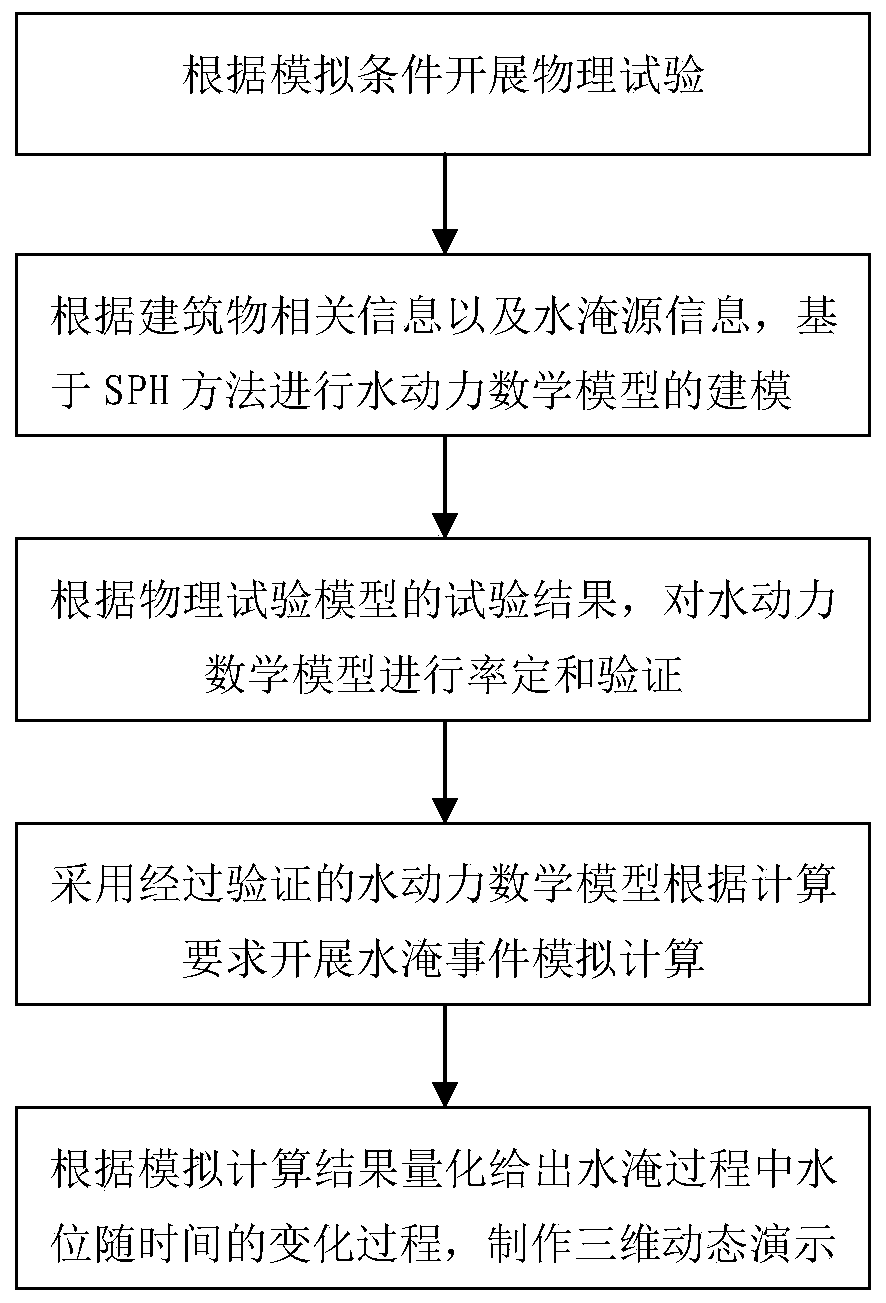

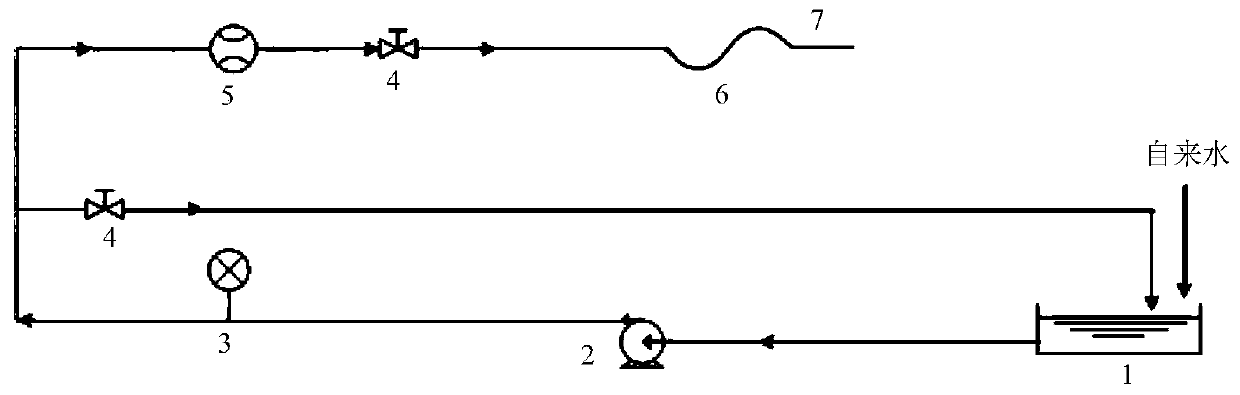

Simulation system and method for water logging in building

PendingCN110083866ARealize accurate calculationAvoid deficiencies that are prone to distortionGeometric CADClimate change adaptationDynamic methodParticle dynamics

The invention provides a simulation system and method for water logging in a building. The method comprises the following steps: firstly, carrying out a typical situation physical model test accordingto research conditions; modeling a hydrodynamic mathematical model based on an SPH method, and carrying out calibration and verification on the hydrodynamic mathematical model by adopting a physicalmodel test result; carrying out water logging event numerical simulation calculation by adopting the verified mathematical model; and analyzing and processing a numerical calculation result to obtaina water logging characteristic and a water body movement process three-dimensional demonstration animation. The water logging three-dimensional dynamic process is simulated through the gridless smoothparticle dynamics method, the method is suitable for calculating the large deformation problem of the liquid level, and the defect that distortion is likely to be generated when the gridding method tracks the free liquid level under the complex conditions of water overturning, crushing and the like is overcome. The nuclear island plant building is complex in structure and large in calculation amount, the method solves the problem of calculation efficiency through parallel calculation, and accurate calculation of water logging in the nuclear island plant building is achieved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

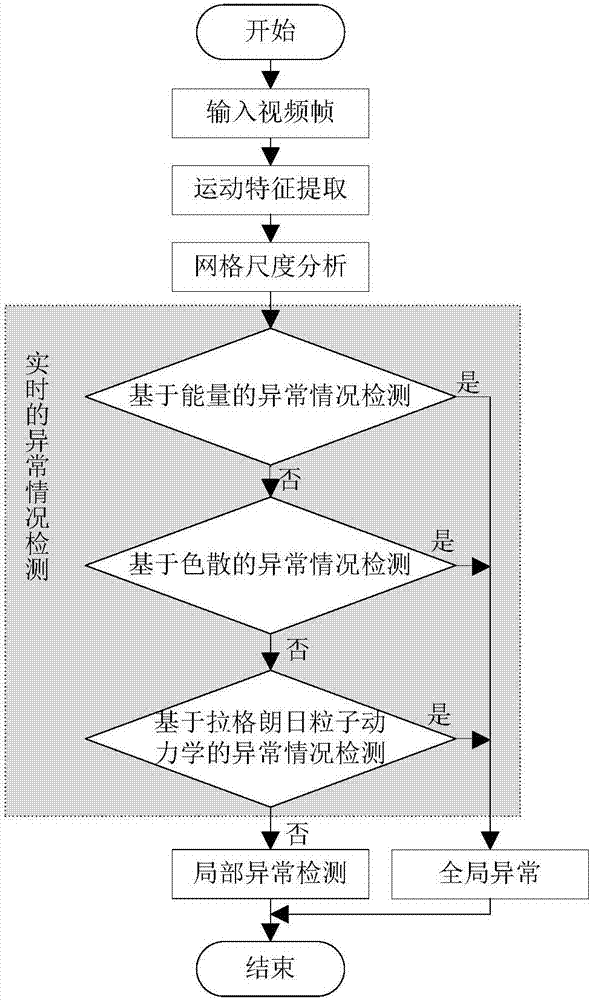

Global abnormal behavior detecting method based on target motion characteristic

InactiveCN106951827AImprove accuracyImprove detection efficiencyCharacter and pattern recognitionPattern recognitionParticle dynamics

The invention discloses a global abnormal behavior detecting method based on a target motion characteristic, which belongs to the technical field of video behavior detection. The method comprises the steps that the motion characteristic of a motion target in a video is extracted; according to the extracted motion characteristic, learning and establishing of abnormal behavior models based on energy, dispersion and Lagrangian particle dynamics are carried out on the motion target; according to the established abnormal behavior models based on energy, dispersion and Lagrangian particle dynamics, global abnormal behavior detecting is carried out on the motion target; and an abnormal area is determined and marked. According to the invention, based on the inherent characteristic of a video abnormal behavior, the global abnormal behavior detecting accuracy and efficiency can be effectively improved; three models are used to detect the abnormal behavior; and the detection precision is further improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

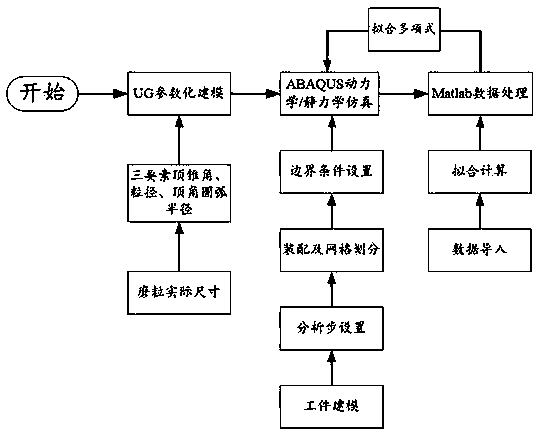

Diamond abrasive particle wear prediction method based on finite element dynamic scribing simulation

ActiveCN110263476AThe result is easy to convergeDesign optimisation/simulationSpecial data processing applicationsMaterials scienceModelling software

The invention provides a diamond abrasive particle abrasion prediction method based on finite element dynamic scribing simulation. According to the method, stress data and temperature data obtained in the abrasive particle dynamic scribing process are fitted and loaded to abrasive particles for calculation and prediction of abrasive particle abrasion. The method comprises the steps that the geometric size of abrasive particles is defined according to actual machining conditions, and modeling software is used for conducting parametric modeling; a workpiece model is established in finite element simulation software, and workpiece and abrasive particle material attribute endowing, assembling work, analysis step setting, grid division, contact setting and the like are sequentially completed; single diamond abrasive particle scribing simulation is finished, and stress data, abrasive particle temperature distribution data and the like are obtained in the scribing process through post-processing; mathematical software is used to fit scribing time-stress data and scribe time-temperature data into a polynomial; and the obtained stress and temperature data are loaded on the abrasive particles in the form of an equation to predict the wear area and the wear amount of the abrasive particles. Combined dynamic simulation of single abrasive particle scribing and abrasion evolution and abrasion loss prediction of the diamond abrasive particle scribing process are carried out by combining modeling software, a finite element simulation analysis technology and mathematical software.

Owner:CHONGQING UNIV OF TECH

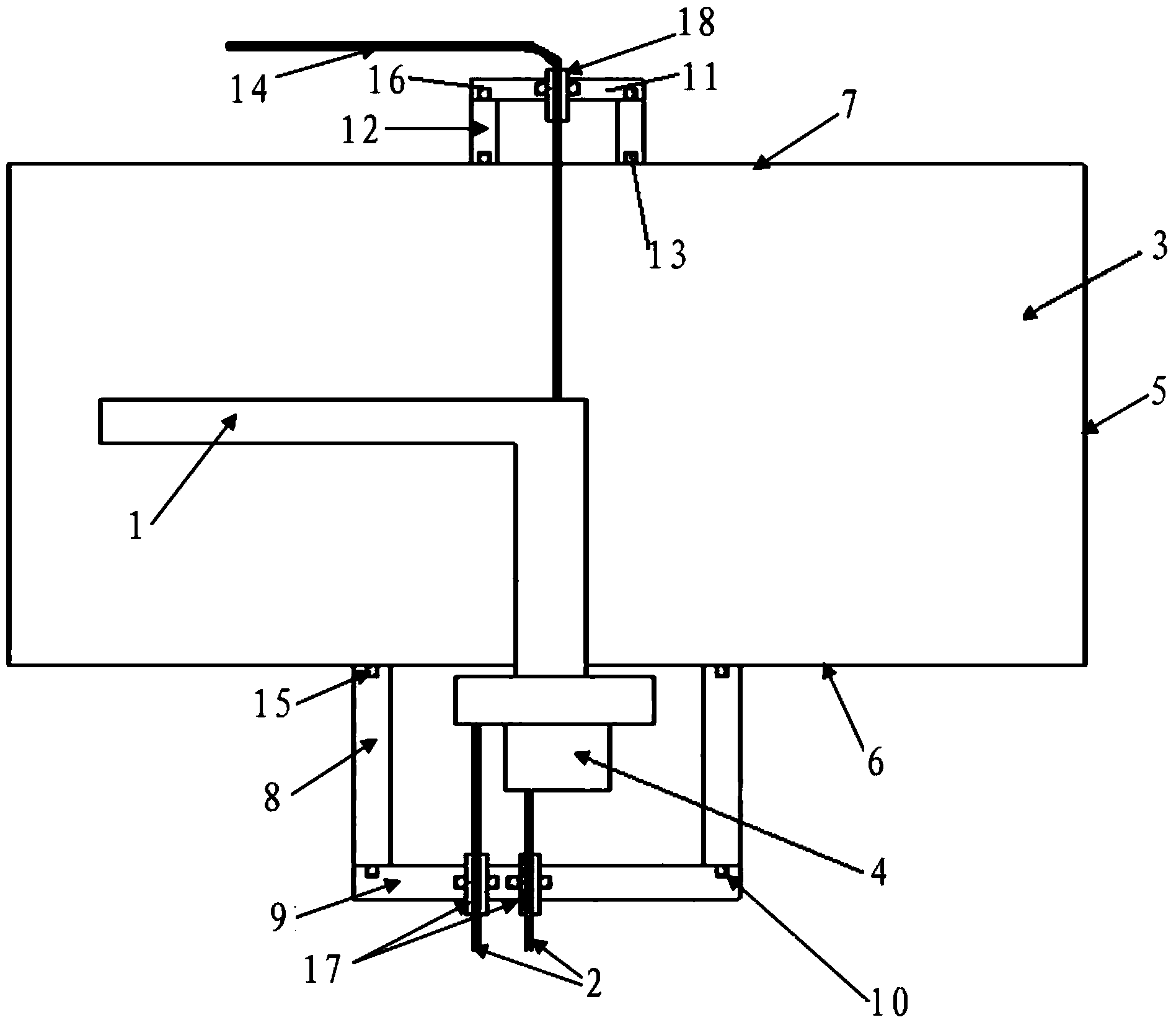

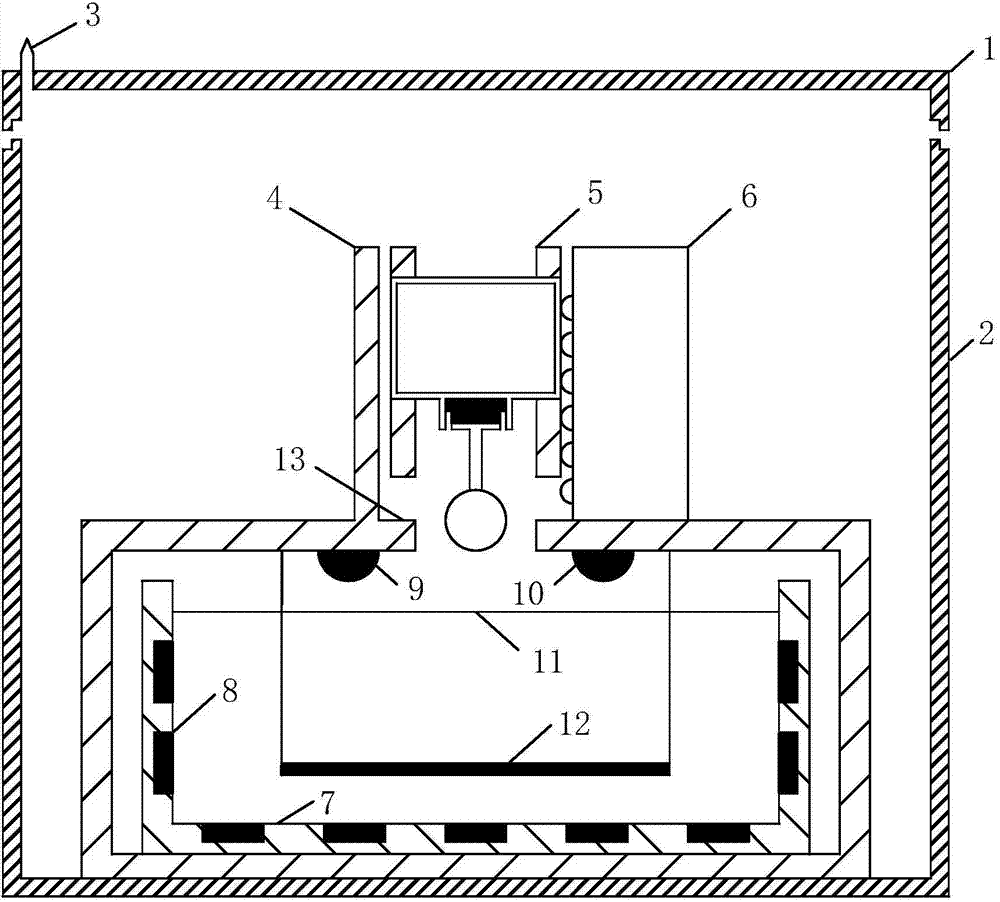

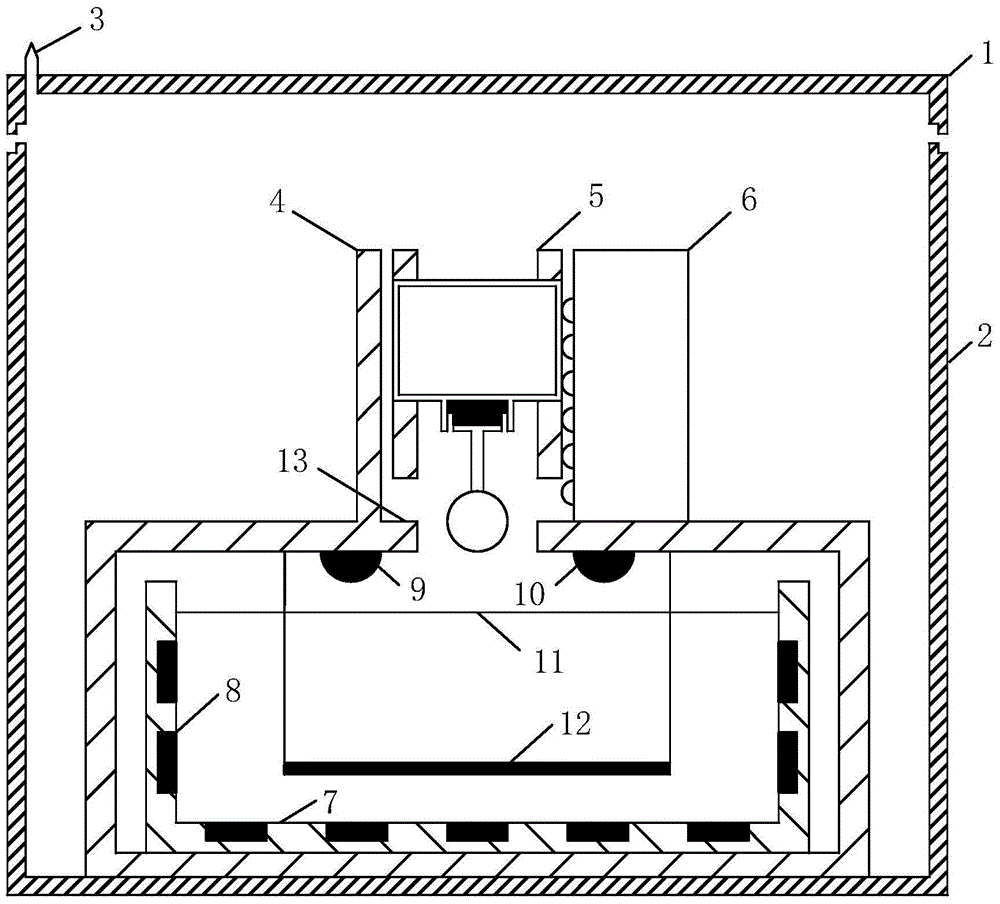

Circular accelerator magnetic field measuring device

ActiveCN103675720AAccurate dataMagnitude/direction of magnetic fieldsParticle dynamicsMeasurement device

The invention discloses a circular accelerator magnetic field measuring device. The device comprises a movement mechanism (1), a motor (4) and data lines (2, 14), wherein the movement mechanism (1) is arranged inside a main magnet (3) and can measure a magnetic field, the motor (4) is arranged outside the main magnet (3) and connected with the movement mechanism (1), and the data lines (2, 14) are connected with the movement mechanism (1) and the motor (4). The movement mechanism, the motor and the data lines connected with the movement mechanism and the motor are all arranged in closed space. According to the technical scheme, it is ensured that the measuring device can operate under the vacuum conditions, the accuracy of a measuring result is ensured, and data which are more accurate are provided for magnetic field shimming and particle dynamics computation.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

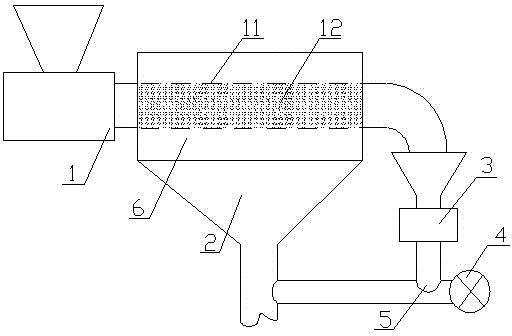

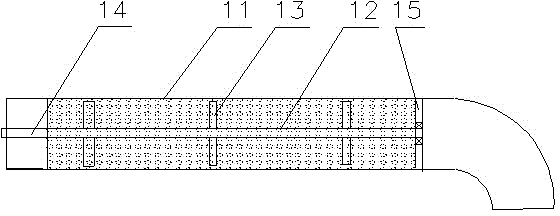

Cohered rubber particle dynamic screening and smashing device and smashing and conveying method

The invention relates to a cohered rubber particle dynamic screening and smashing device with the functions of material conveying, cohered rubber particle scattering and material leakage, and a smashing and conveying method. The cohered rubber particle dynamic screening and smashing device comprises a spiral extruding machine, a material collecting hopper, a pulverizer and an air blower, wherein the discharging hole of the spiral extruding machine is located right above the feeding hopper of the pulverizer, the discharging hole of the spiral extruding machine is connected with the feeding end of a screening hole conveying pipe, the discharging hole of the screening hole conveying pipe directly faces the feeding hopper of the pulverizer, the discharging hole of the pulverizer is communicated with one way of a tee joint, and another two ways of the tee joint are communicated with an air pipe and the air blower respectively and are communicated with a discharging pipe of the material collecting hopper. The cohered rubber particle dynamic screening and smashing device has the advantages that the screening hole conveying pipe has a function of scattering cohered rubber particles, a function of a filter screen and a function of conveying the cohered rubber particles to the pulverizer due to the design of the screening hole conveying pipe, and besides, the air blower is adopted for conveying the rubber particles pulverized by the pulverizer, the manual operation is not required and pulverized rubber particles can be conveyed automatically.

Owner:HANGZHOU GAOXIN RUBBER & PLASTIC MATERIALS CO LTD

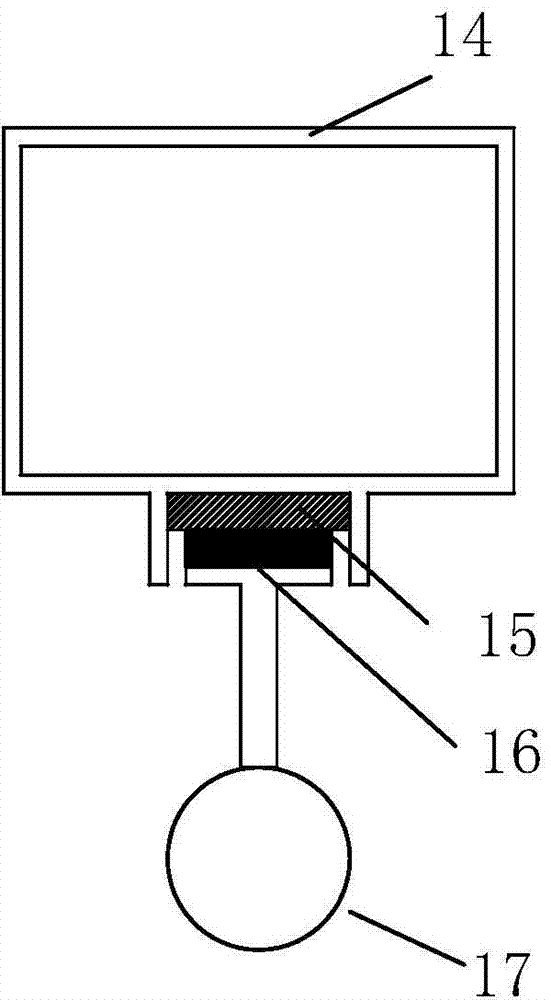

Device and method for measuring liquid flow-solid conversion mechanism in impact process

InactiveCN104515721AControl speedPrecise speed controlMaterial analysisParticle dynamicsElectric machinery

The invention discloses a device and method for measuring the liquid flow-solid conversion mechanism in an impact process. The device comprises a pressure box body and a loading tank arranged in the pressure box body, wherein an air valve is arranged on the pressure box body; a loading rack is also arranged in the pressure box body; the loading tank is arranged in the loading rack; an impact device connected with a motor power device and ascending and descending on the loading rack is arranged at the upper end of the loading rack; the lower end of the impact device is connected with an impact object which can acts on the loading tank; a speed measuring sensor is arranged on the impact object; pressure sensors are arranged at the bottom and on the side surfaces of the loading tank; a video capture instrument and a particle dynamics scanner are arranged on the loading rack; a stop block is further arranged on the loading rack and positioned right below the impact device. According to the invention, the liquid flow-solid conversion critical speed in the impact process can be well measured, different formulas can be evaluated and the matching can be optimized.

Owner:HOHAI UNIV

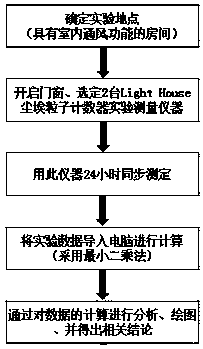

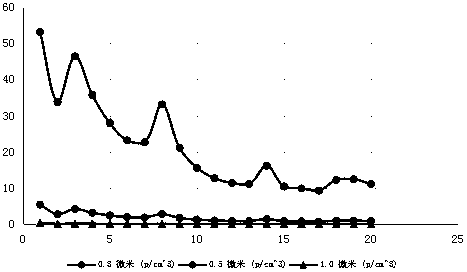

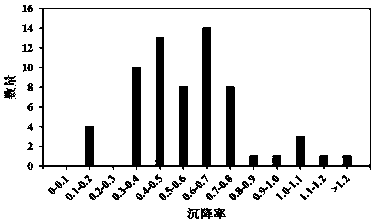

Determination method of indoor particle sedimentation parameters based on dynamic mass balance

The invention discloses a determination method of indoor particle sedimentation parameters based on dynamic mass balance, and belongs to the field of environmental science. The method includes the following steps: firstly, selecting a to-be-measured room, and arranging dust particle counters inside and outside the to-be-measured room as measuring instruments for indoor and outdoor particles; secondly, starting the measuring instruments for synchronous determination; thirdly, obtaining the parameters of indoor and outdoor particle concentration ratios, ventilation times, sedimentation rates andpermeability factors through the dust particle counters and data analysis; and finally, establishing a mass balance equation based on the dynamic balance of particles and calculating to obtain a sedimentation rate Kcomp and permeability P of the to-be-measured room by using a least square method. The determination method of the indoor particle sedimentation parameters based on the dynamic mass balance determines the permeability and the sedimentation rate by using the mass balance equation, which can better understand indoor particle dynamics and behavior under natural ventilation conditionsand helps to analyze the particle size distribution of the indoor particles.

Owner:SHANDONG UNIV OF SCI & TECH

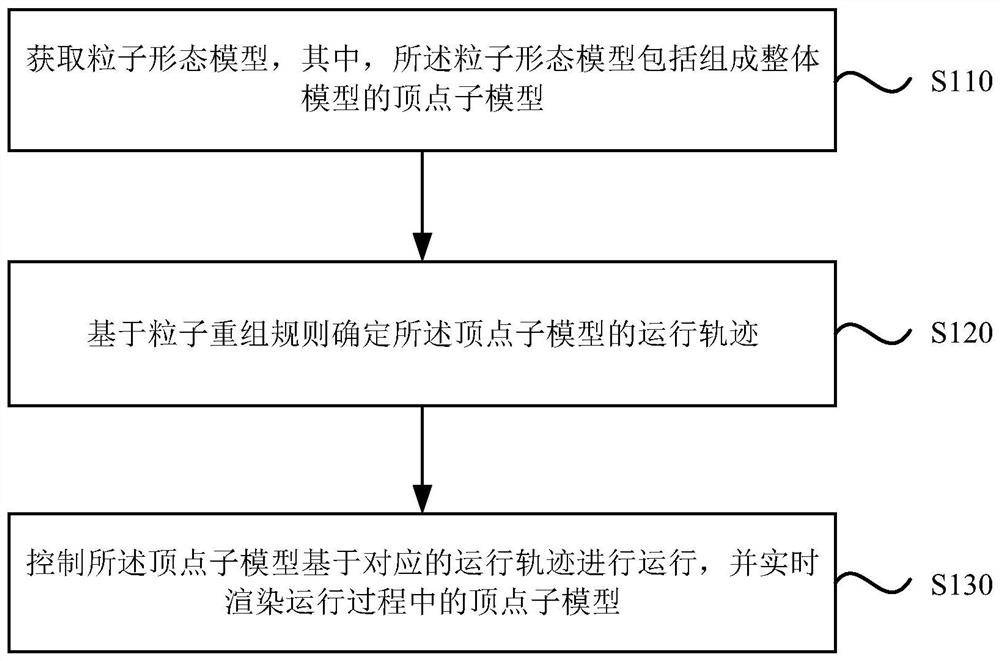

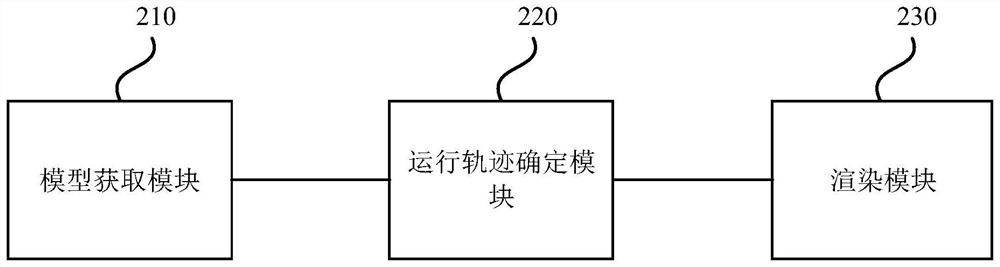

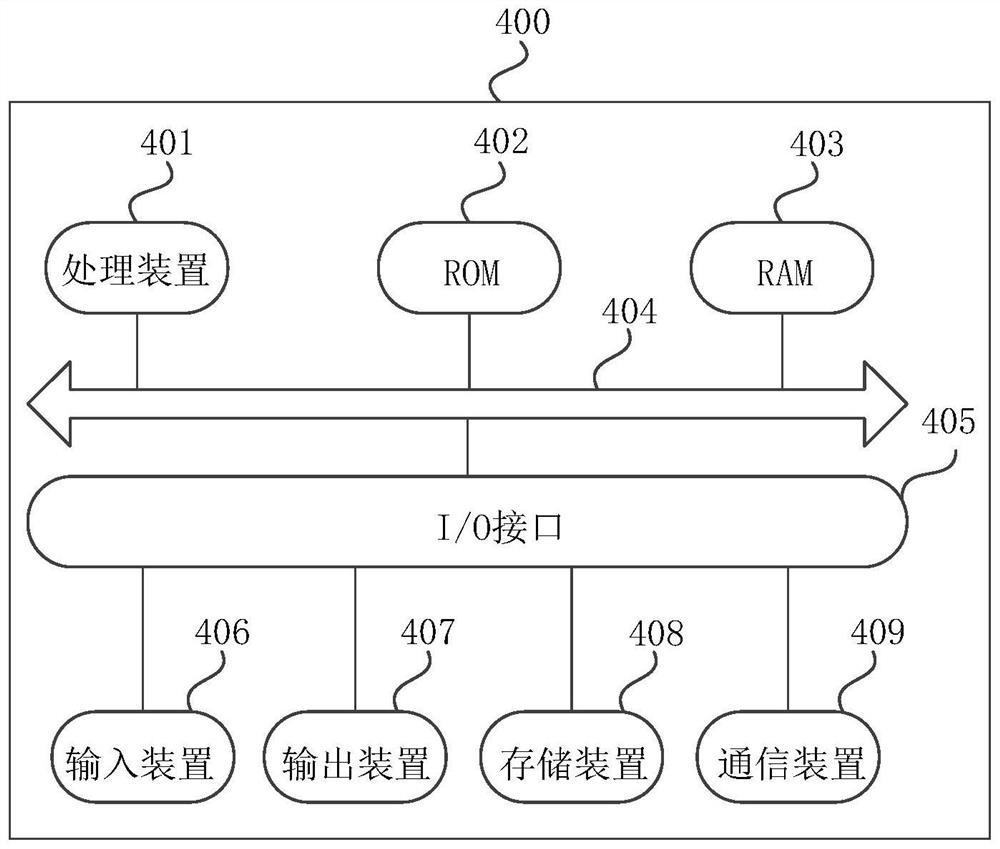

Particle effect rendering method and device, equipment and medium

PendingCN114332323AReal-time renderingRealize the rendering effect3D-image rendering3D modellingParticle dynamicsEngineering

The embodiment of the invention discloses a particle effect rendering method and device, equipment and a medium. The method comprises the steps that a particle morphology model is obtained, and the particle morphology model comprises vertex sub-models forming an overall model; determining the moving trajectory of each vertex sub-model based on a particle recombination rule; and controlling each vertex sub-model to run based on the corresponding running track, and rendering each vertex sub-model in the running process in real time. The method comprises the following steps: simulating particles forming a model through vertex sub-models, determining a moving trajectory of each vertex sub-model based on a particle recombination rule, controlling each vertex sub-model to operate based on the corresponding moving trajectory, and rendering each vertex sub-model in the operating process in real time to simulate the operating process of the particle recombination model. And the operation process is rendered, so that simulation rendering of the particle dynamic operation process of the model is realized.

Owner:BEIJING ZITIAO NETWORK TECH CO LTD

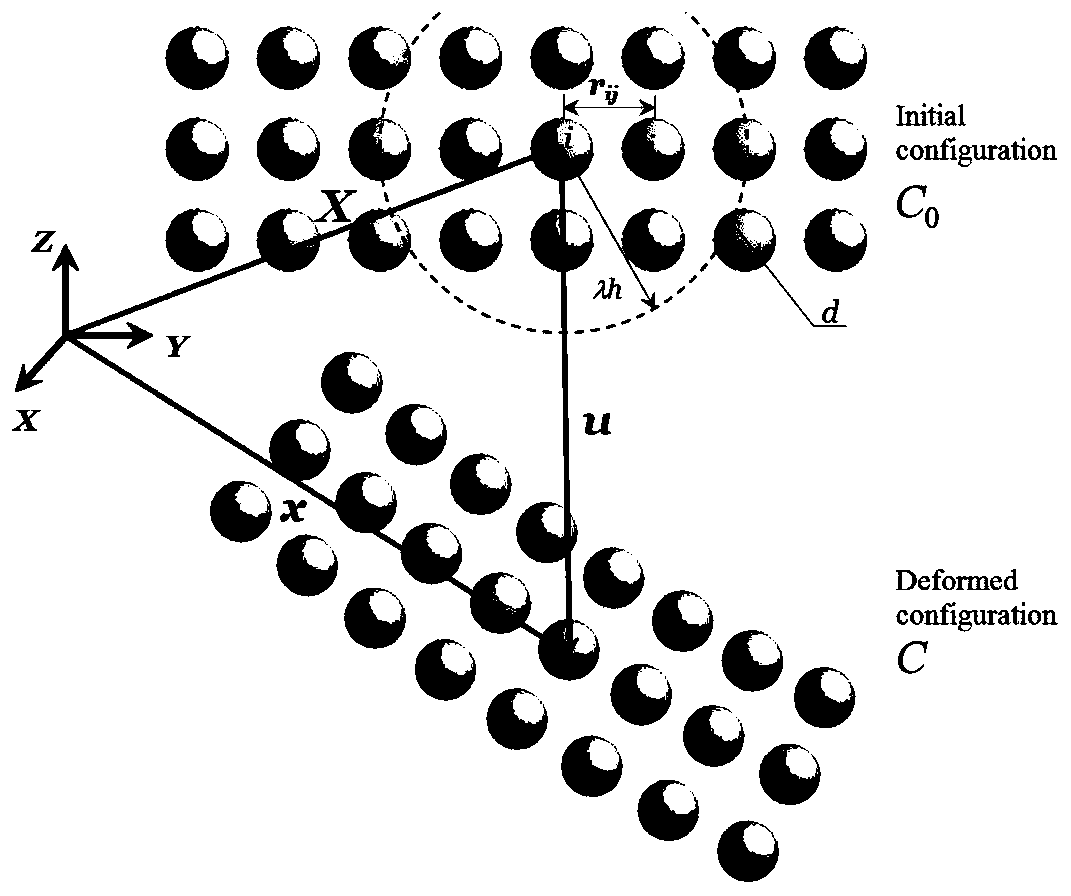

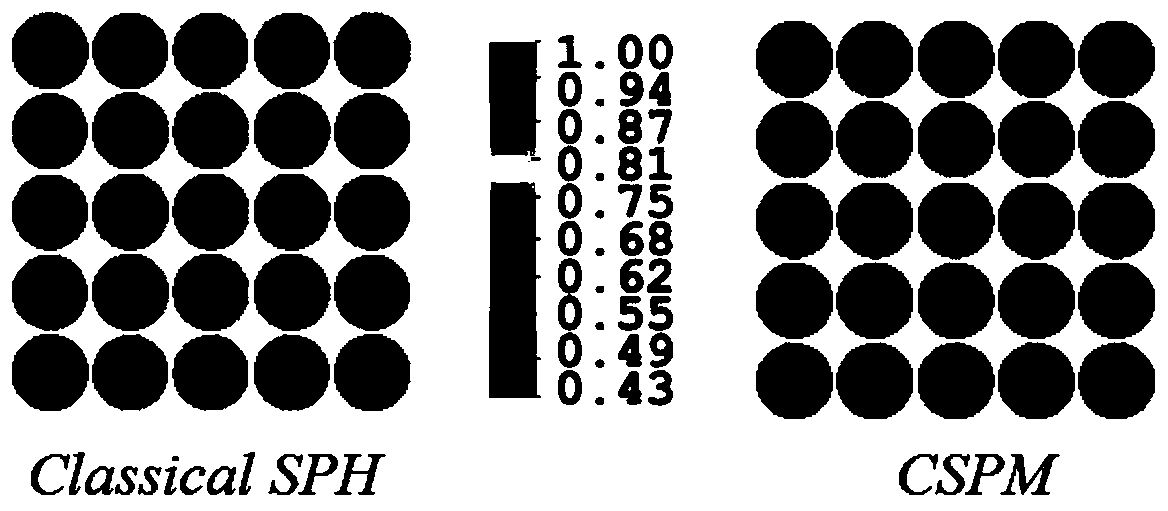

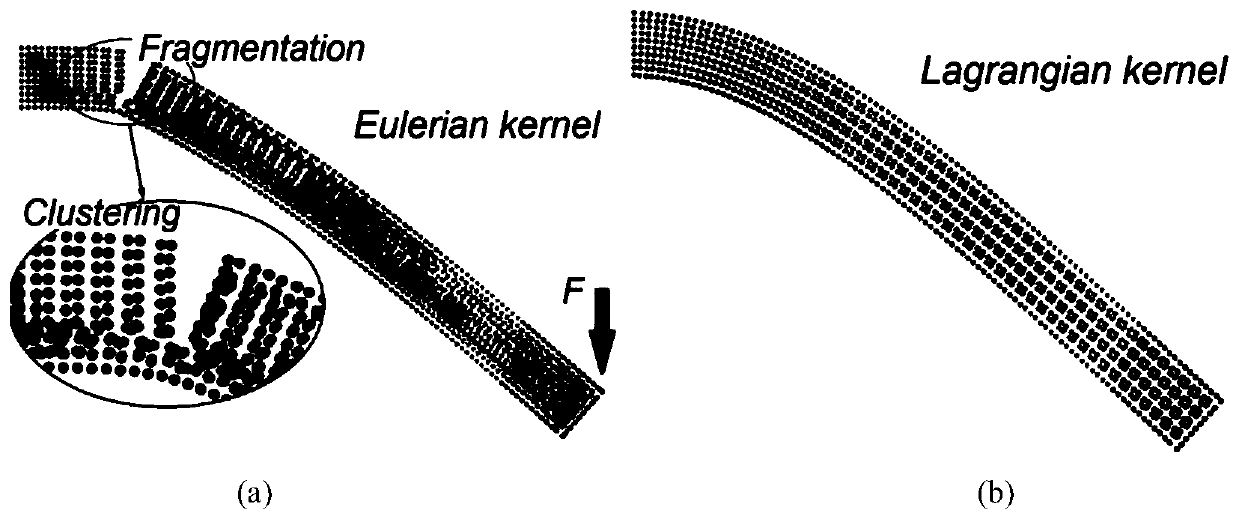

Smooth particle dynamics modeling method for solid structure

ActiveCN111353229AGuaranteed first-order completenessHigh precisionDesign optimisation/simulationNumerical methodologyParticle dynamics

The invention relates to the field of materials, and provides a solid structure smooth particle dynamics modeling method. The method comprises the steps: discretizing a planar solid structure into SPHparticles, wherein each particle carries at least one kind of same physical information; deformation occurs at a spatial point xi, and calculating a correction mode of a smooth function derivative atthe spatial point xi; then calculating the deformation of the spatial point xi; and finally, in a deformation state, calculating the deformation gradient at the spatial point xi. According to the invention, a smooth function correction method and a complete Lagrange SPH method are combined to obtain the correction mode of the smooth function derivative as an integral kernel, so the first-order completeness of the numerical method is ensured, the boundary calculation accuracy is improved, the stretching instability phenomenon is eliminated, the calculation time is greatly saved, and the boundary defects and instability of the traditional SPH are overcome.

Owner:SHANDONG UNIV

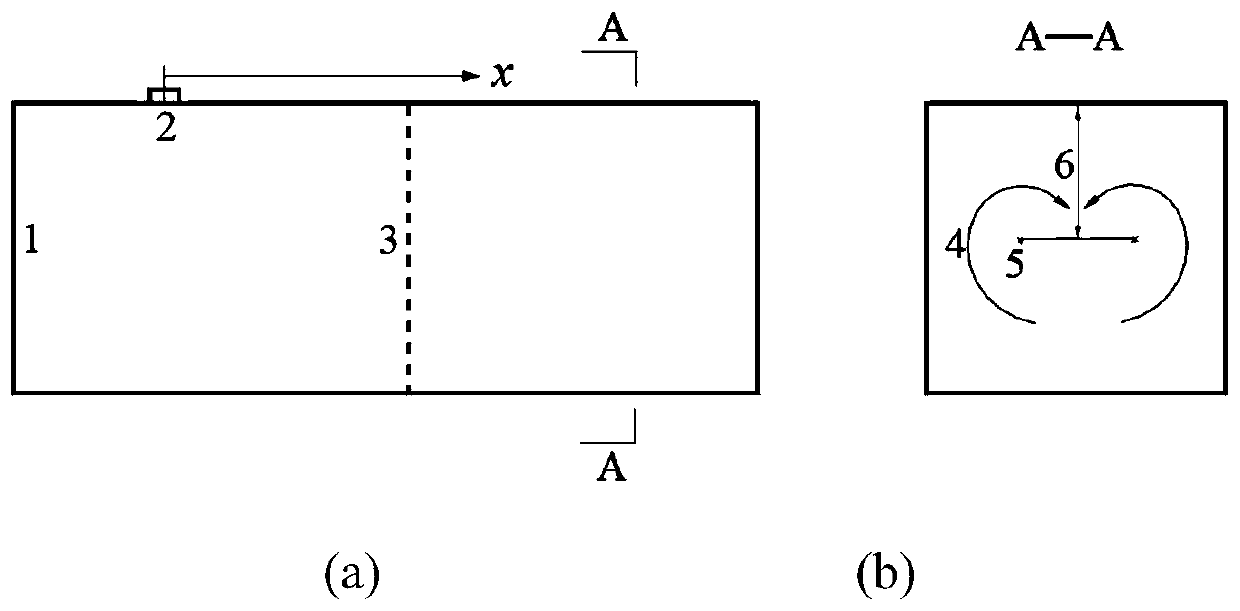

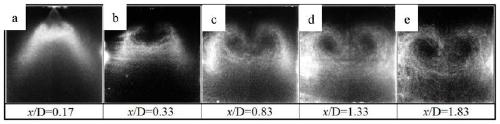

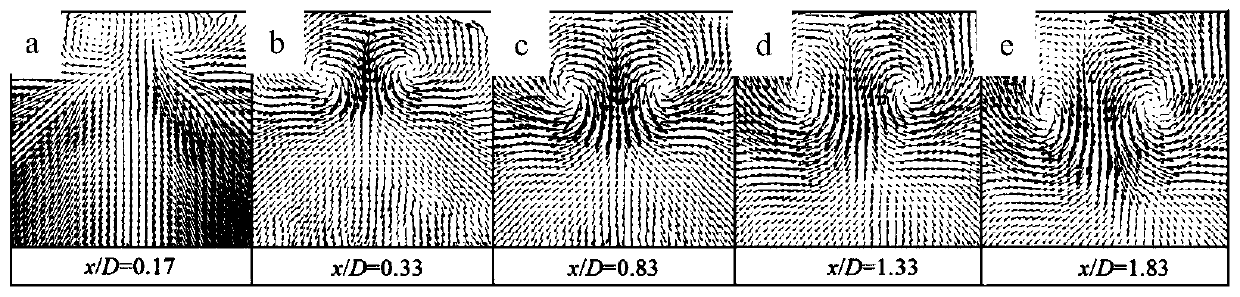

A Method for Mixing Spray Jet and Mainstream Gas

ActiveCN109647240BSolve the problem of lackFlow mixersTransportation and packagingParticle dynamicsMixed flow

The invention discloses a method for organizing the mixing of spray jet and mainstream gas. By analyzing the mixing mechanism and law of spray jet and mainstream gas, combined with particle dynamics, vortex dynamics and other theories, a blending method based on regulation and control is proposed. The large-scale vortex structure-symmetric anti-vortex pair that dominates the diffusion characteristics of spray droplets in the flow field is used to realize a new idea of rationally organizing the mixing process of the spray jet and the mainstream gas, and according to the characteristics of the symmetrical anti-vortex pair in the mixing flow field The internal relationship between the size and the parameters of the flow field, the determination method of the spray jet atomization characteristic parameters and the nozzle selection method based on the mainstream gas state are given, which solves the problem of mixing the spray jet with the mainstream gas in the current industrial process. The problem of lack of organizational skills in the mixed process.

Owner:XI AN JIAOTONG UNIV

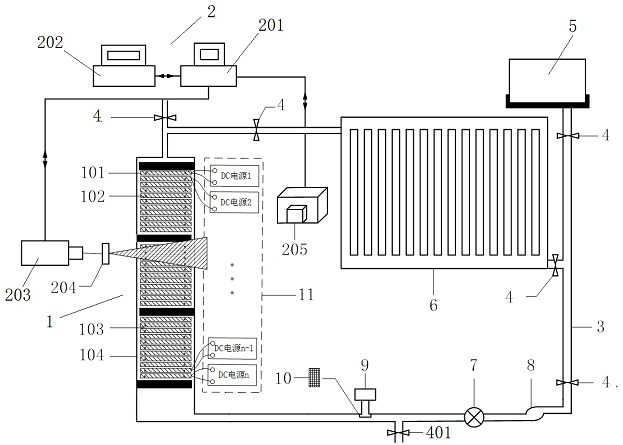

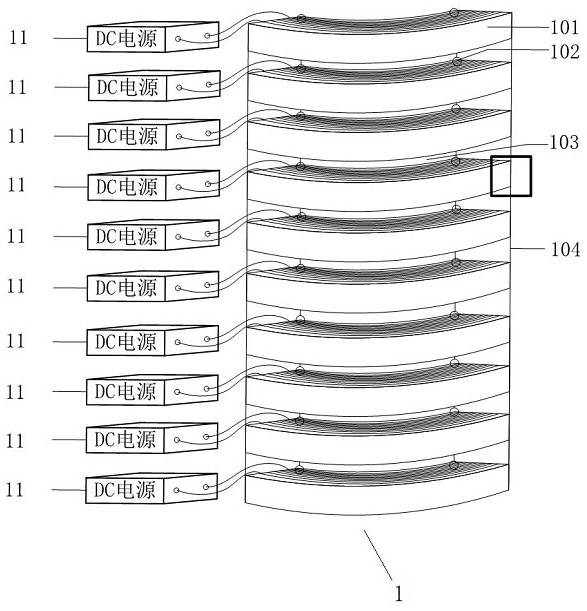

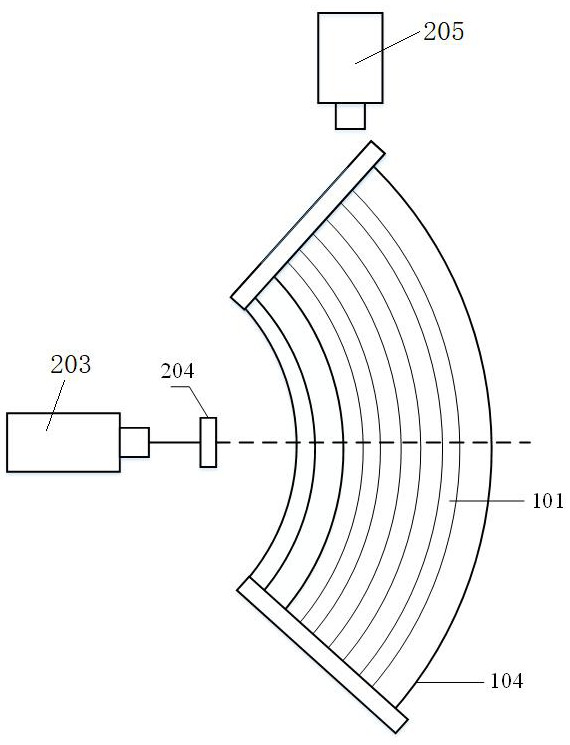

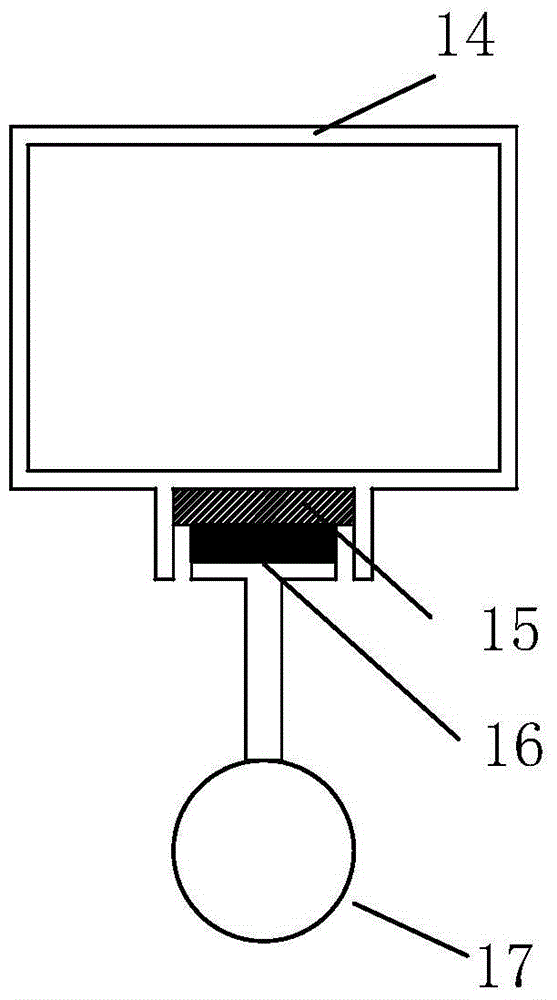

Device and method for observing dynamic behaviors of impurities with different particle sizes in oil duct of transformer

ActiveCN112923977AHelps explore the relationship between partial discharge and particle motionTransformers/inductances coolingMeasurement devicesOil canParticle dynamics

The invention relates to a device and a method for observing dynamic behaviors of impurities with different particle sizes in an oil duct of a transformer, and the device comprises a winding model, a particle dynamic observation system, an oil tank, a cooling fin, a particle emitter, a fixed-mesh screen and a direct-current power supply module. The output power of the direct-current power supply module for heating the winding cake is defined. Parameters of a winding cake are defined, the aperture of a fixed-mesh screen is adjusted, and the power of a double-head laser source corresponding to the aperture of the fixed-mesh screen is defined. The dynamic behaviors of the impurities with different particle sizes in the oil duct of the transformer under the actual working condition can be effectively observed, the relationship between the dynamic behaviors of the impurities with different particle sizes and the partial discharge of the transformer insulating oil can be researched, and the insulating performance of the transformer can be further researched.

Owner:CHINA UNIV OF MINING & TECH

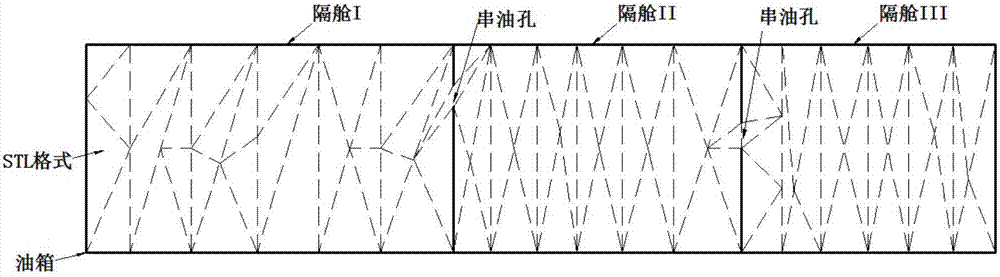

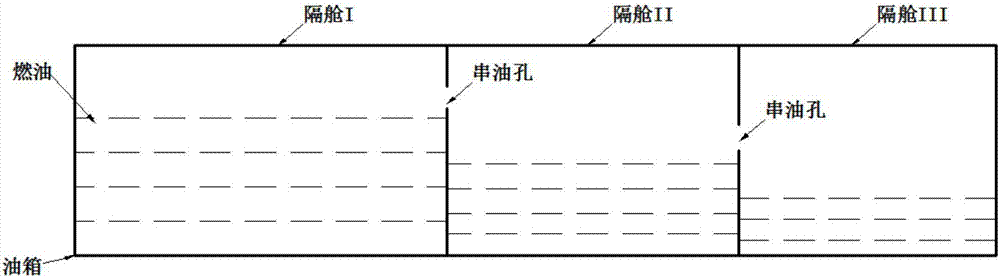

High-accuracy analysis method for oil intermingling characteristic in aircraft fuel tank

ActiveCN107256283AQuick solveAccurate solutionGeometric CADSustainable transportationSmoothed-particle hydrodynamicsParticle dynamics

The invention discloses a high-accuracy analysis method for an oil intermingling characteristic in an aircraft fuel tank. The method comprises the following steps that: through an STL (Standard Template Library) geometry file format, the digital model of a fuel tank structure is represented, and reading and storage are carried out by a method based on a balanced binary tree; and a smoothed particles hydrodynamics model is adopted to discretize continuous fuel into one series of fuel particles which have independent quality and mutually act, and the discretized fuel particles are subjected to analysis calculation to obtain the shaking and intermingling information, including the flowing law, the oil consumption sequence information and the like of the fuel in each compartment, of the fuel in each compartment in an aircraft movement process. By use of the method, the analysis accuracy of the shaking and the intermingling of the aircraft fuel can be improved.

Owner:XI AN JIAOTONG UNIV

Method and device for realizing dynamic interface

ActiveCN104850389BWith particle dynamic effectImprove realismAnimationExecution for user interfacesParticle dynamicsAnimation

The embodiment of the invention provides a method and apparatus for implementing a dynamic interface. The method comprises steps of generating interface elements and a corresponding animation effect, wherein the interface element includes a background, objects in the background and particle images corresponding to the objects; establishing a particle emitter and setting the attribute of the particle emitter; generating one or more particle sources, and defining particle parameters of the particle sources, wherein the particle parameters includes contents which are particle images of the particles; adding the one or more particle sources in the particle emitter; and implementing the background and the animation effect corresponding to the objects in the background, and displaying a dynamic particle effect of the objects using the particle emitter. According to the method and apparatus for implementing the dynamic interface provided by the embodiment of the invention, a particle dynamic effect can be displayed on the interface, tracks and special effects of motions of the true-life objects can be simulated at high order, and the third dimension effect and the interest of the interface can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

A device and method for measuring liquid fluid-solid transformation mechanism during impact

The invention discloses a device and method for measuring the liquid flow-solid conversion mechanism in an impact process. The device comprises a pressure box body and a loading tank arranged in the pressure box body, wherein an air valve is arranged on the pressure box body; a loading rack is also arranged in the pressure box body; the loading tank is arranged in the loading rack; an impact device connected with a motor power device and ascending and descending on the loading rack is arranged at the upper end of the loading rack; the lower end of the impact device is connected with an impact object which can acts on the loading tank; a speed measuring sensor is arranged on the impact object; pressure sensors are arranged at the bottom and on the side surfaces of the loading tank; a video capture instrument and a particle dynamics scanner are arranged on the loading rack; a stop block is further arranged on the loading rack and positioned right below the impact device. According to the invention, the liquid flow-solid conversion critical speed in the impact process can be well measured, different formulas can be evaluated and the matching can be optimized.

Owner:HOHAI UNIV

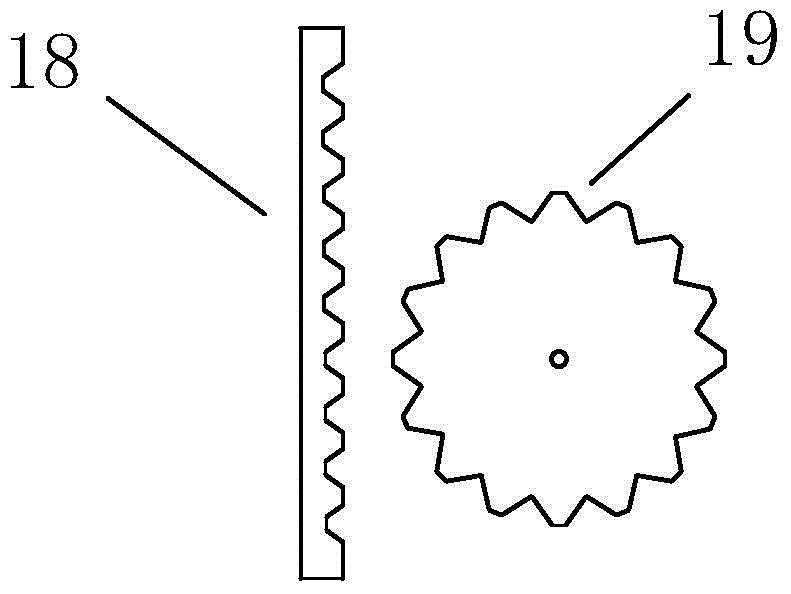

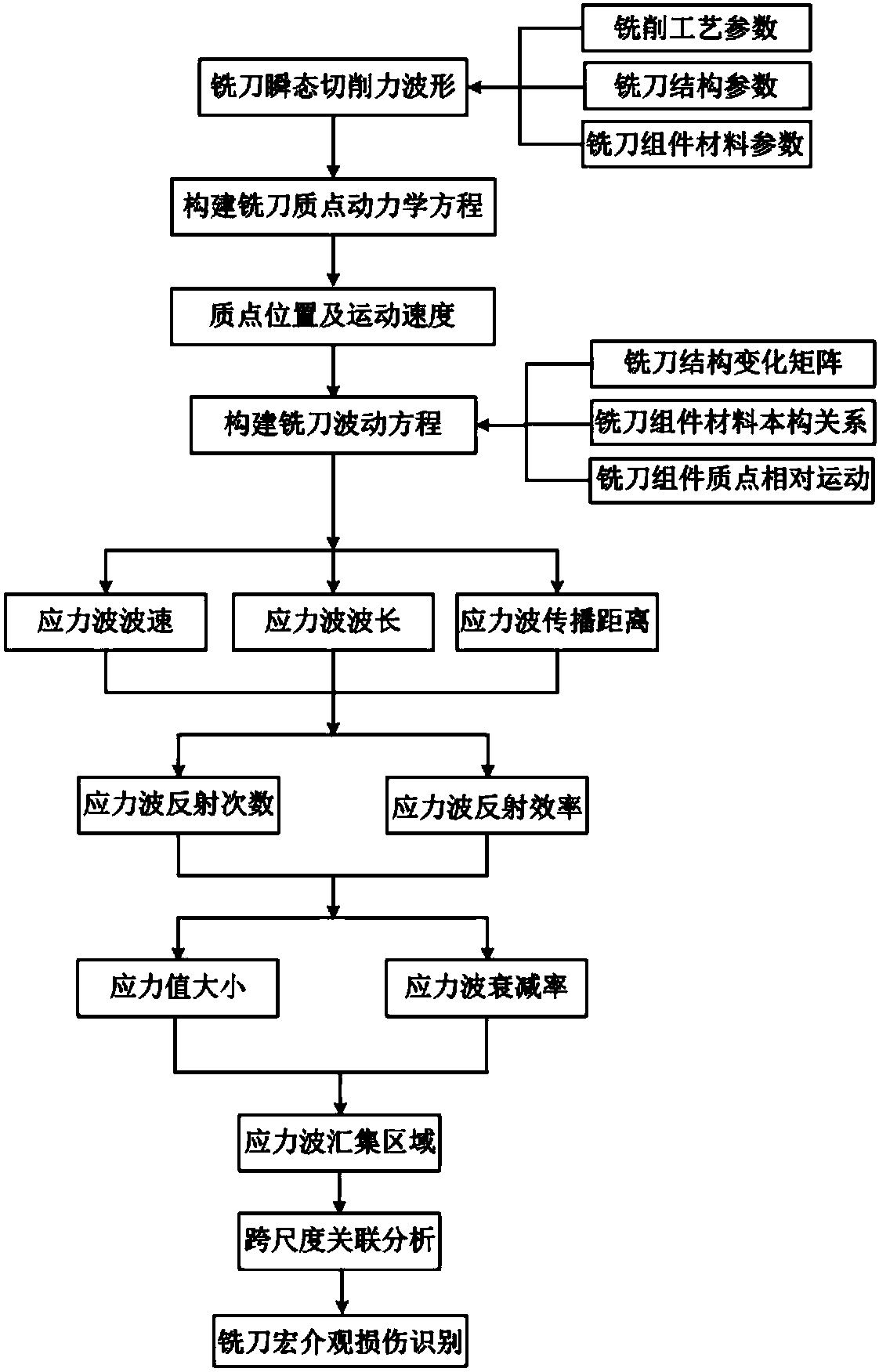

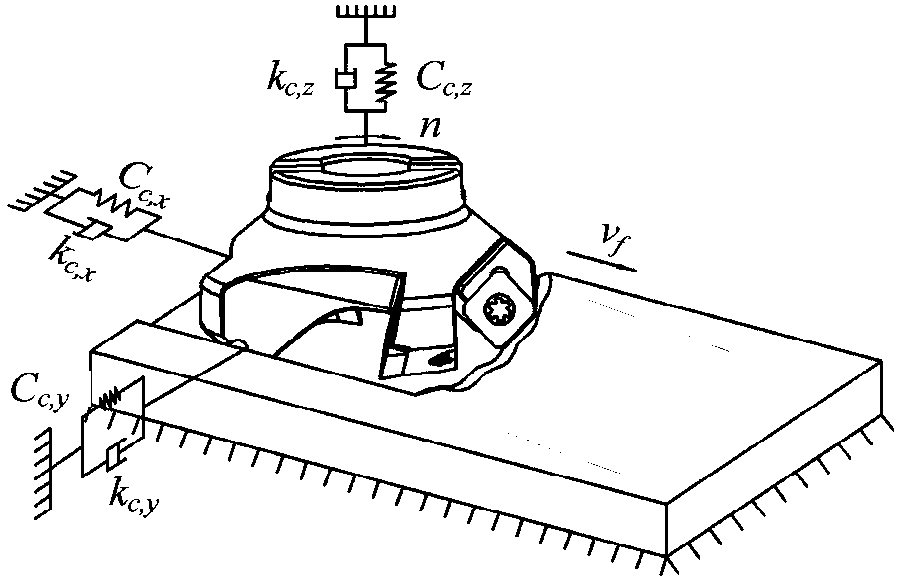

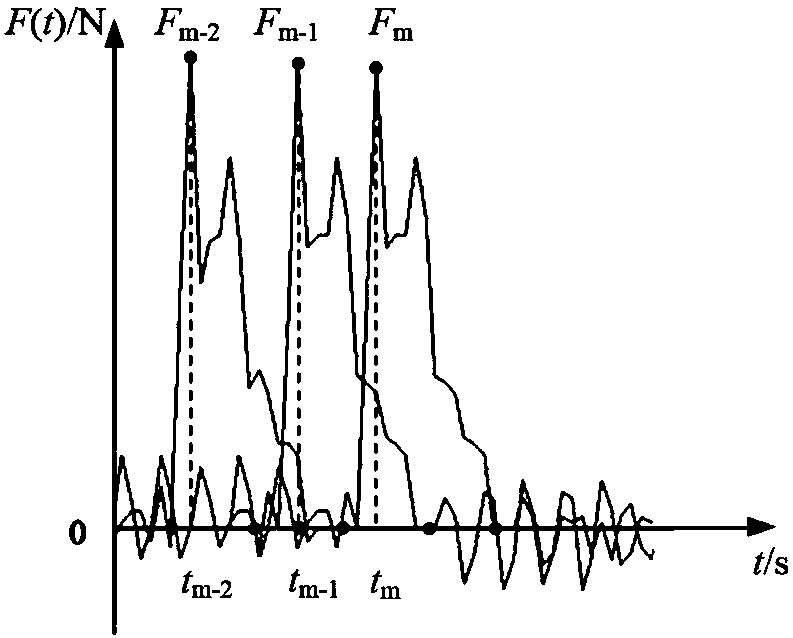

A wave dynamics damage identification method for high-speed milling cutters under intermittent impact loads

ActiveCN106334970BSolving the problem of multi-scale evolution of wave mechanics damageMeasurement/indication equipmentsMetal working apparatusUltrasound attenuationParticle dynamics

The invention discloses a method for identifying wave mechanical damage of a high-speed milling cutter under the intermittent impact load effect. The method is technically characterized by comprising steps as follows: I, a transient cutting force model and an equation of particle dynamics of the high-speed milling cutter are established; II, a wave equation of a stress wave of the high-speed milling cutter is established; III, an attenuating stress value and an attenuation rate of the stress wave of the high-speed milling cutter are solved; IV, the wave mechanical damage of the high-speed milling cutter is identified. With the method, the internal relation of macroscopic and mesoscopic structure domains of the high-speed milling cutter can be disclosed, local macroscopic and mesoscopic damage of the milling cutter is identified, a high-frequency stress wave collecting area of the high-speed milling cutter can be determined, trans-scale association analysis can be performed, in combination with molecular dynamic simulation, the part, prone to damage, of the high-speed milling cutter and the type of the damage in the mesoscale can be identified, the problem of identification of potential damage positions and damage types of a milling cutter assembly under the high-speed intermittent impact load effect is solved in an emphasized manner, and meanwhile, the problem of multi-scale evolution of the wave mechanical damage of the high-speed milling cutter is also solved.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com