A Method for Mixing Spray Jet and Mainstream Gas

A spray-type, mainstream technology, applied in the direction of fluid mixers, chemical instruments and methods, mixers, etc., can solve the problems of lack of organizational technology and achieve the effect of promoting development and reducing high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

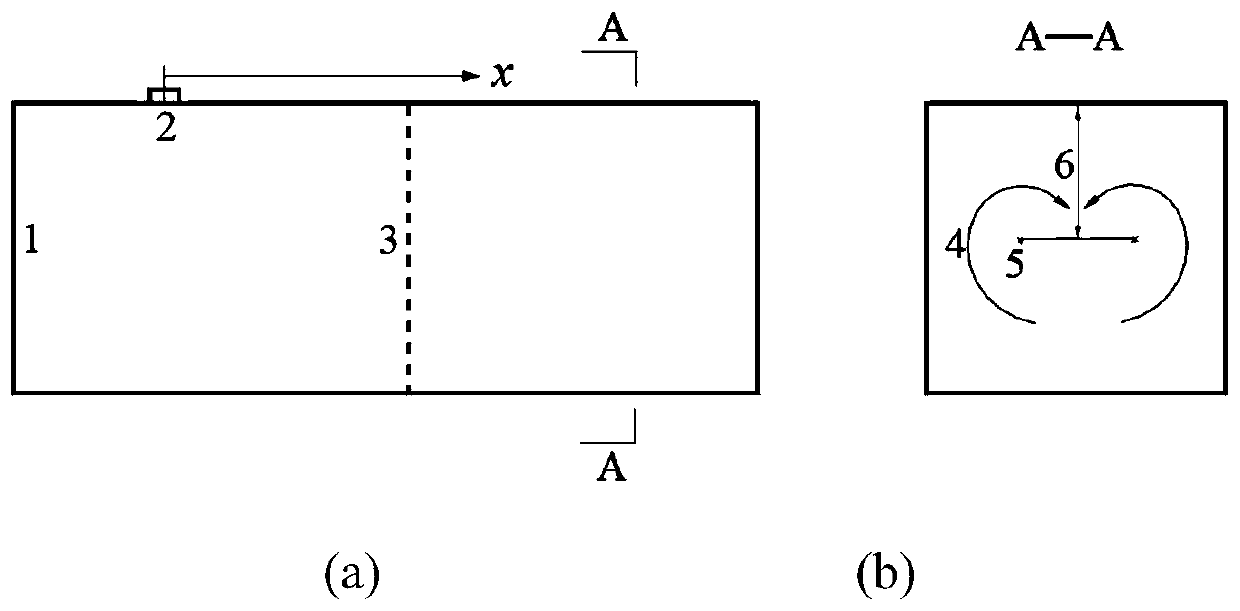

[0049] see figure 1 , figure 1 A structural schematic diagram of a mixing chamber for mixing a spray jet and a mainstream gas provided by the present invention; the mixing chamber of a liquid jet and a mainstream gas is a rectangular pipe structure, and its cross-sectional size is D×D=180mm×180mm, The mainstream gas is air at normal temperature and pressure, and the Reynolds number Re of the airflow g 2.4×10 4 ; The working medium of the jet fluid is water at normal temperature, and the volume flow rate is 6.18×10 -6 m 3 / s.

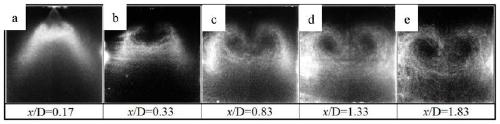

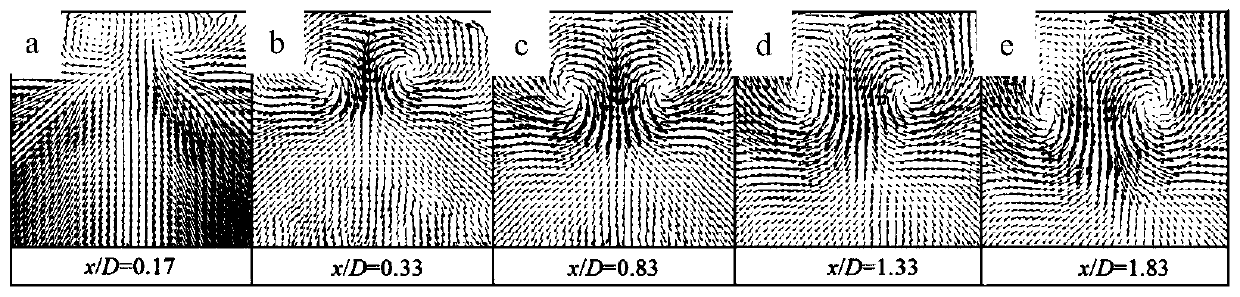

[0050] According to the organization method of a kind of spray jet mixed with mainstream gas of the present invention, the characteristic cross-section of the mixed flow field is selected as 1.33D, and the vortex center depth and vortex center distance of the symmetrical anti-vortex pair on the cross-section are selected as 0.3~0.4D, After calculation, the initial spray droplet size is selected as about 80 μm, and the initial droplet velocity is abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com