Construction method of surfactant solution dissipative particle dynamic force field

A technology of surfactant and construction method, applied in the field of environmental pollution treatment meter, can solve problems such as blindness, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

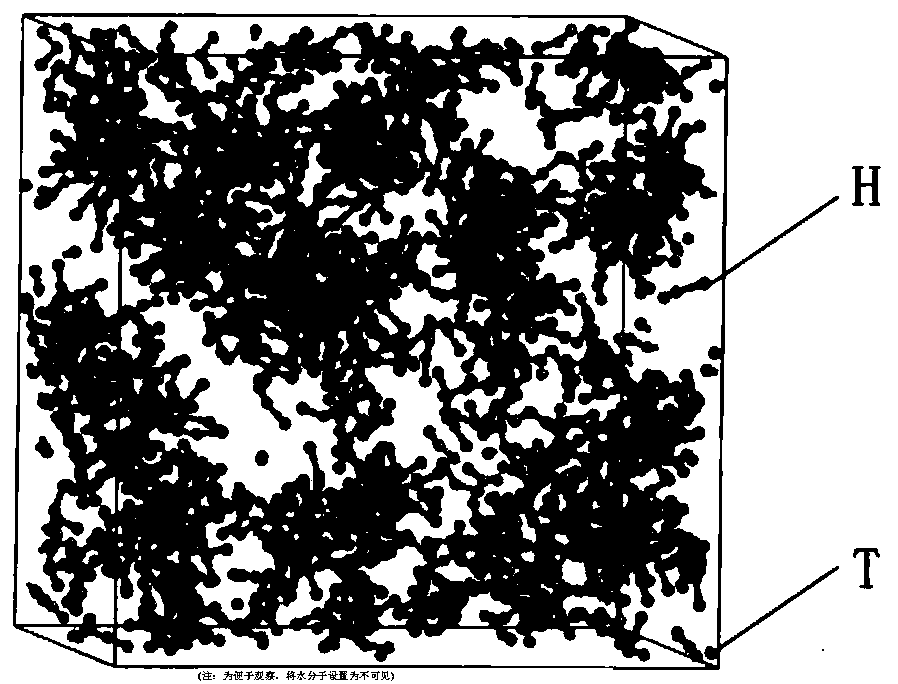

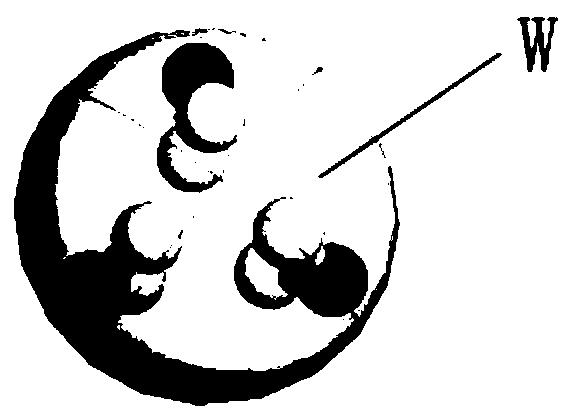

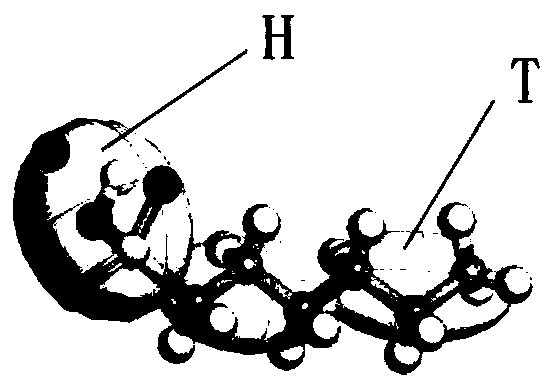

[0036] (1) The present embodiment selects the surfactant molecule represented by sodium alkyl sulfonate, first establishes the coarse-grained model of surfactant molecule and water molecule, promptly defines coarse-grained DPD beads, as follows: water beads W( 3H 2 O) coarse-grained model such as figure 1 Shown; According to the structure of sodium alkylsulfonate, the surfactant molecule consists of n hydrophilic beads H(-OSO 3 Na) and m hydrophobic beads T (terminal CH 3 -CH 2 -CH 2 - or middle - CH 2 -CH 2 -CH 2 -) Composition (the DPD coarse-grained models of sodium hexaalkylsulfonate, sodium nonalkanesulfonate, sodium dodecylsulfonate, and sodium pentadecylsulfonate are represented as H1T2, H1T3, H1T4, H1T5, respectively) , its DPD coarse-grained structure model is as follows Figure 2 to Figure 5 shown.

[0037] (2) Calculate the interaction force parameters between the coarse-grained beads in the coarse-grained model of step (1), obtain the corresponding interac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com