Cohered rubber particle dynamic screening and smashing device and smashing and conveying method

A technology for bonding rubber and granules, which is applied in the direction of grain processing, etc., can solve the problems of prolonging the processing time of rubber granules, increasing the labor intensity of workers, and increasing the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

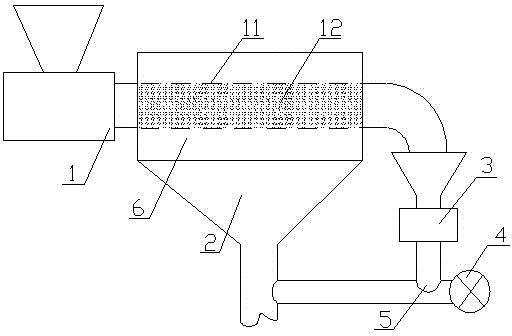

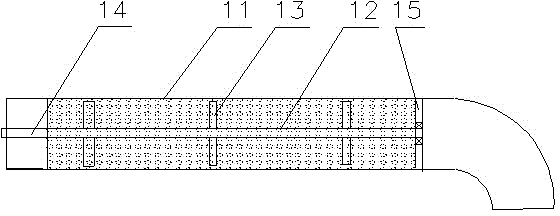

[0010] Embodiment 1: with reference to attached figure 1 and 2 . A dynamic screening and crushing device for bonded rubber particles, comprising a screw extruder 1, a collecting hopper 2, a pulverizer 3 and a blower 4, the outlet of the screw extruder 1 is located directly above the feed hopper of the pulverizer 3, and the screw extruder The discharge port of the discharge machine 1 is connected to the feed end of the sieve conveying pipe 11, the discharge port of the sieve conveying pipe 11 is directly facing the feed hopper of the pulverizer 3, and the discharge port of the pulverizer 3 is connected with one of the tee 5 , the other two links in the tee 5 are communicated with the air outlet of the blower 4 and the discharge pipe of the collecting hopper 2 through the air duct respectively. The wall of the sieve feed pipe 11 is a sieve-like structure 12, and the diameter of the sieve holes in the sieve-like structure 12 is a circular hole of 4mm. The sieve feeding pipe 11...

Embodiment 2

[0011] Embodiment 2: On the basis of Example 1, a method for dynamically screening and crushing bonded rubber particles, the screw extruder 1 extrudes the bonded rubber particles into the sieve feed pipe 11, and the sieve feed The spiral stirring rack 13 in the material pipe 11 breaks up the bonded rubber particles while driving the broken rubber particles to leak into the hopper 2 from the sieve holes on the wall of the sieve delivery pipe 11, but not into the hopper The bonded rubber of 2 is pulverized by pushing pulverizer 3, and the pulverized rubber particles are blown into the collecting hopper 2 by the wind blown out by blower 4. The wind speed of the wind blown by the blower 4 is greater than 3.5 m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com