Phase change cooling research method of filling body in high-temperature deep well

A filling body and phase change technology, applied in the investigation stage/state change, measuring devices, instruments, etc., can solve the problems of complex mine cooling system, difficult to form structural flow, cooling pipeline, equipment corrosion, etc. The effect of deep well filling slurry transportation and mine cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

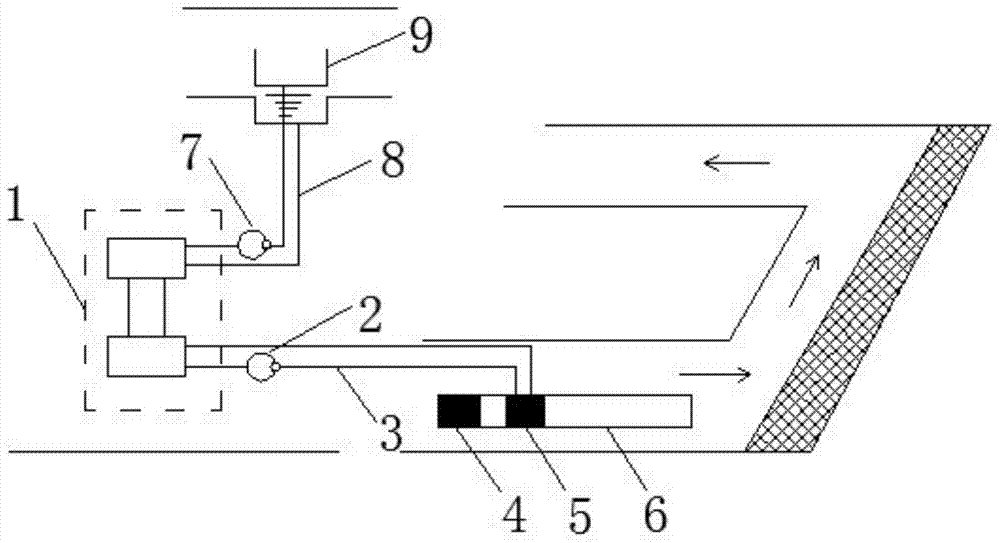

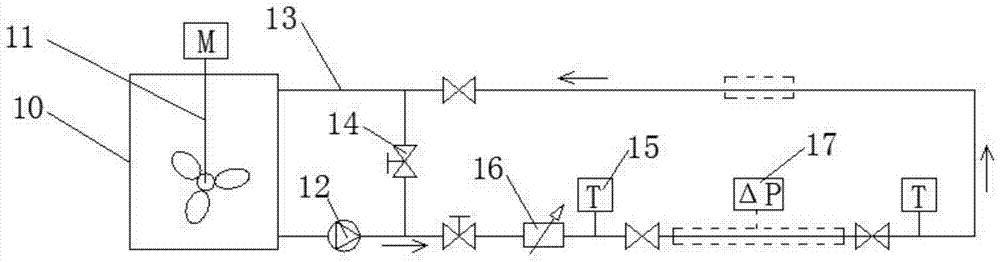

[0027] A research method for phase change cooling of high temperature deep downhole fillings, including the following four stages:

[0028] (1) The first stage

[0029] The research on the optimal particle size gradation of pipeline transportation slurry is completed through a combination of experimental research and numerical analysis. According to the mechanical characteristics of the solid-liquid mixture moving in the pipeline, tailings or rods with particle sizes ranging from millimeters to micrometers are used Scrubs are tested for particle size ratio, and paste / paste-like filler slurry is configured by adding tailings or rod scrubs of different particle sizes, and slump test, sedimentation test, self-flow test, loop test and other conventional filling are performed The experiment, combined with the simulation calculation of PFC particle flow, obtains the particle size gradation of the slurry that is most similar to the structured flow, and then obtains the best particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com