Solvent-resistant epoxy modified polyurethane sealant and preparation method thereof

A polyurethane sealant and epoxy modification technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of poor solvent resistance of sealants, failure of bonding and sealing, corrosion of sealants, etc. , to achieve good bonding and sealing effects, improve solvent resistance, and improve softness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

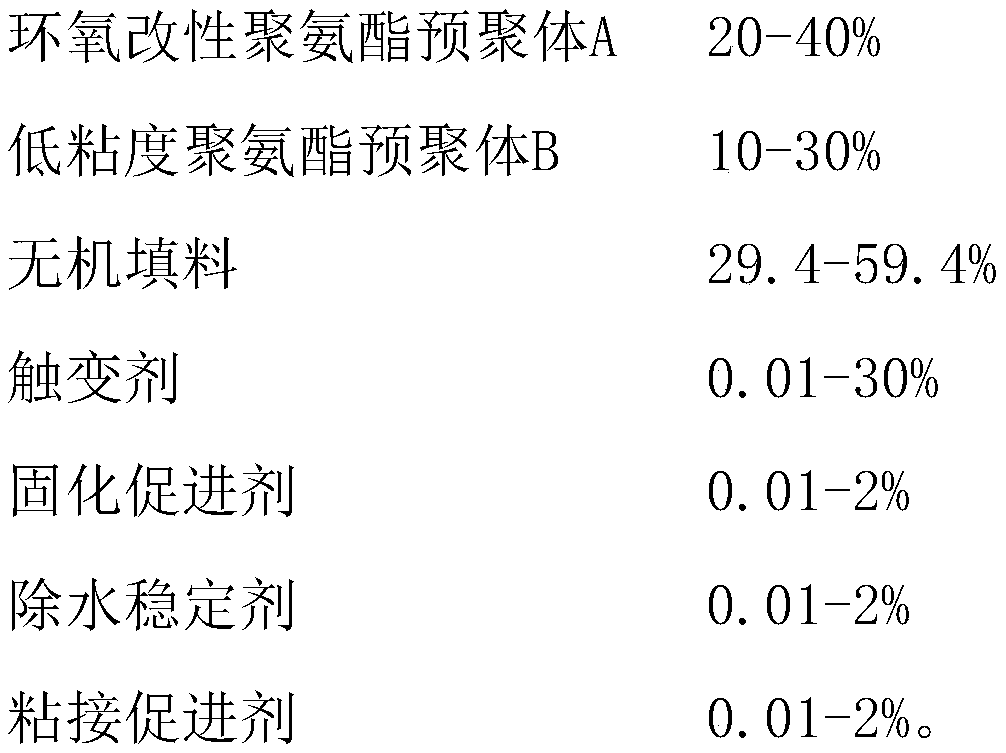

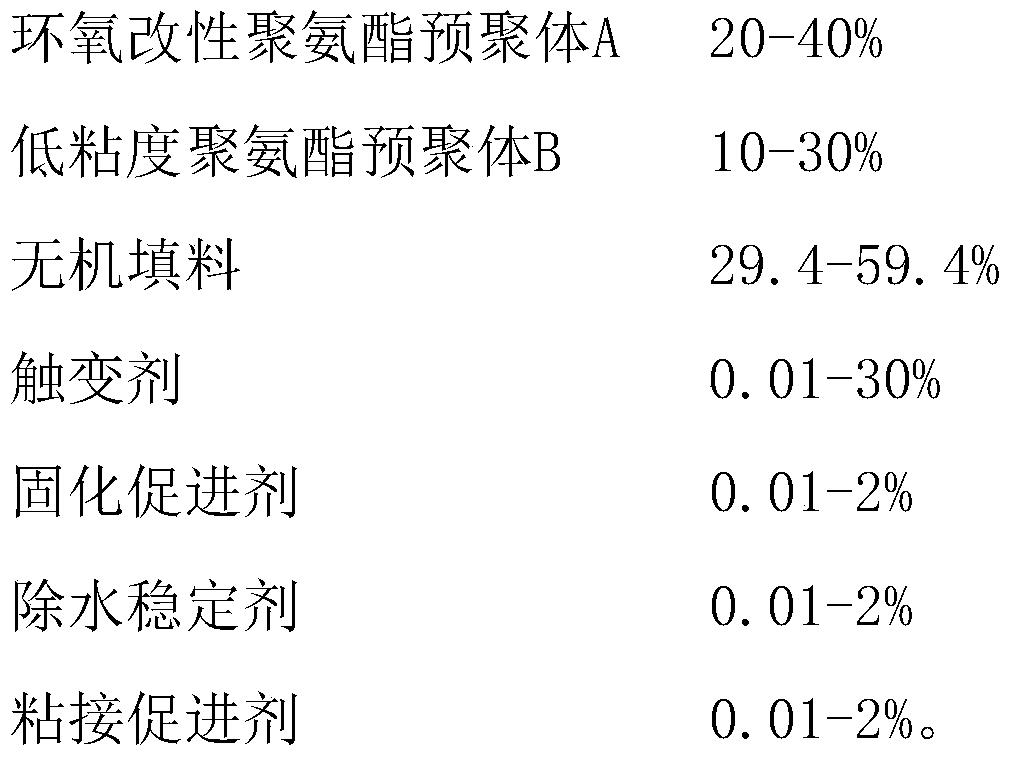

Method used

Image

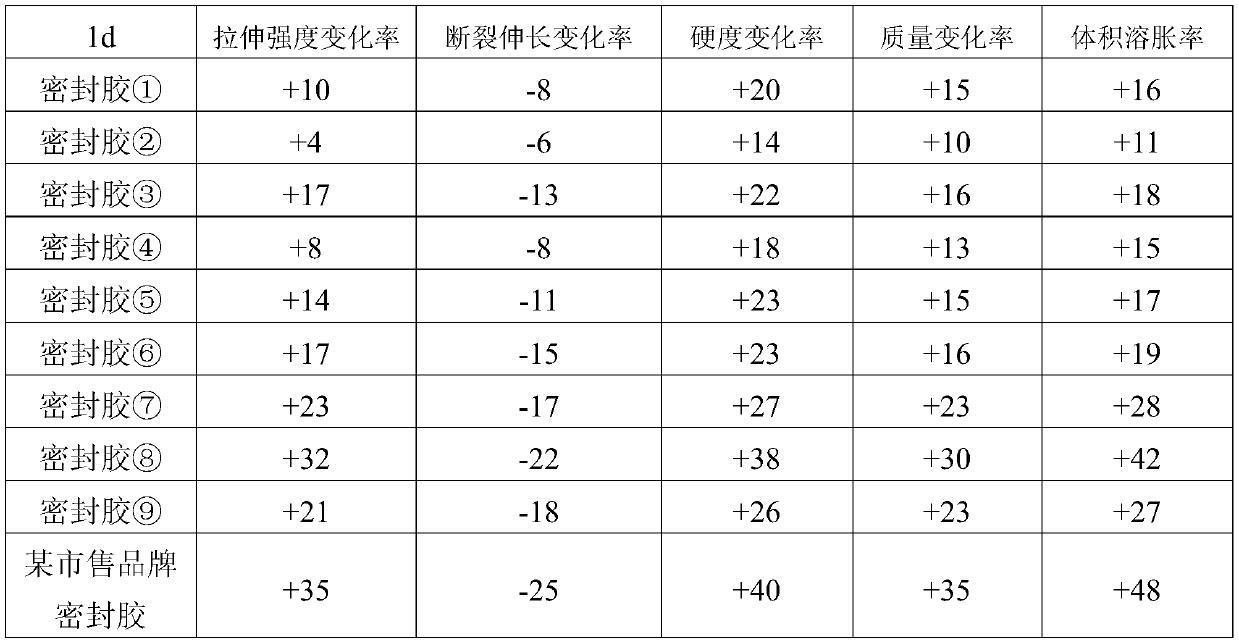

Examples

Embodiment 1

[0046] A preparation method of a solvent-resistant epoxy-modified polyurethane sealant, comprising the steps of:

[0047] Step (1), preparation of epoxy-modified polyurethane prepolymer A: Add 360g of epoxy-modified polyether triol and 480g of polyether triol (relative molecular weight 5000) successively in a dry 2L four-necked bottle, and heat up Vacuum dehydration at 100°C for 2 hours, after detecting that the moisture content of the liquid material is ≤100ppm, cool down to 80°C, add 280g of diphenylmethyl diisocyanate, and keep the reaction for 5 hours under the protection of nitrogen. When the NCO value does not change after the reaction, cool down to room temperature , discharging to obtain the epoxy-modified polyurethane prepolymer A, which is placed in a dry nitrogen airtight container for subsequent use.

[0048] Step (2), preparation of low-viscosity polyurethane prepolymer B: put 800g of polyether diol in a one-mouth bottle, heat up to 100°C, vacuumize and dehydrate,...

Embodiment 2

[0057] A preparation method of a solvent-resistant epoxy-modified polyurethane sealant, comprising the steps of:

[0058] Step (1), preparation of epoxy-modified polyurethane prepolymer A: Add 522g of epoxy-modified polyether triol and 174g of polyether triol (relative molecular weight 5000) successively in a dry 2L four-necked bottle, and heat up Vacuum dehydration at 100°C for 2 hours, after detecting that the moisture content of the liquid material is ≤100ppm, cool down to 85°C, add 464g of toluene diisocyanate, keep it under nitrogen protection for 5 hours, and wait until the NCO value does not change, cool down to room temperature, and discharge , to prepare epoxy-modified polyurethane prepolymer A, and place it in a dry nitrogen-airtight container for subsequent use.

[0059] Step (2), preparation of low-viscosity polyurethane prepolymer B: put 800g of polyether diol in a single-mouth bottle, heat up to 105°C, vacuumize and dehydrate, and when the moisture content is les...

Embodiment 3

[0068] A preparation method of a solvent-resistant epoxy-modified polyurethane sealant, comprising the steps of:

[0069] Step (1), preparation of epoxy-modified polyurethane prepolymer A: Add 232g of epoxy-modified polyether triol and 464g of polyether triol (relative molecular weight 5000) successively in a dry 2L four-necked bottle, and heat up Vacuum dehydration at 110°C for 2 hours. After detecting that the moisture content of the liquid material is ≤100ppm, cool down to 90°C, add 464g of p-phenylene diisocyanate, and keep it under nitrogen protection for 5 hours. When the NCO value does not change after the reaction, cool down to room temperature. Material, prepared epoxy-modified polyurethane prepolymer A, placed in a dry nitrogen airtight container for subsequent use.

[0070] Step (2), preparation of low-viscosity polyurethane prepolymer B: put 400g of polyether diol in a single-mouth bottle, heat up to 110°C, vacuumize and dehydrate, and when the moisture content is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com