Patents

Literature

181 results about "Standard Template Library" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Standard Template Library (STL) is a software library for the C++ programming language that influenced many parts of the C++ Standard Library. It provides four components called algorithms, containers, functions, and iterators.

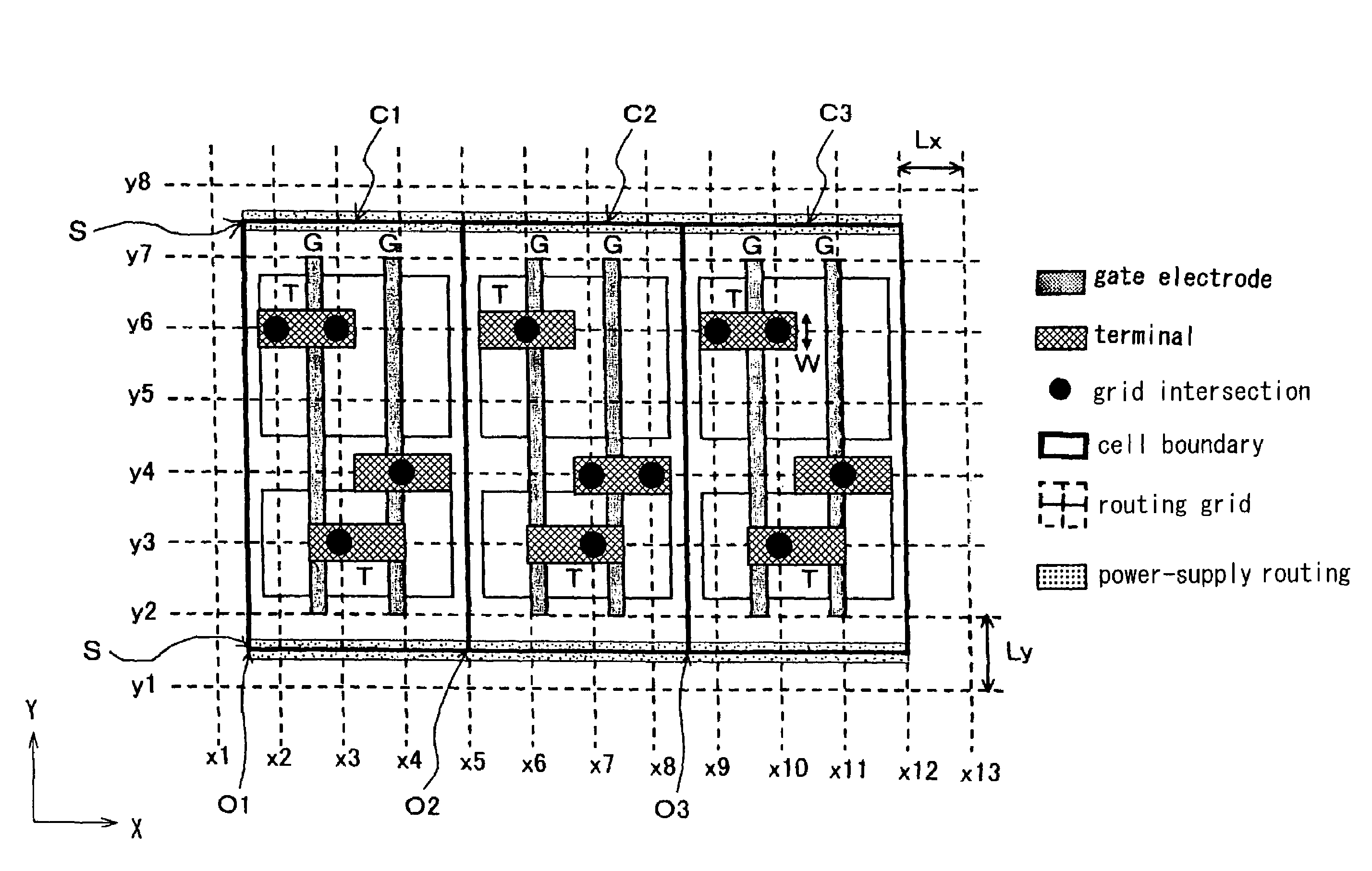

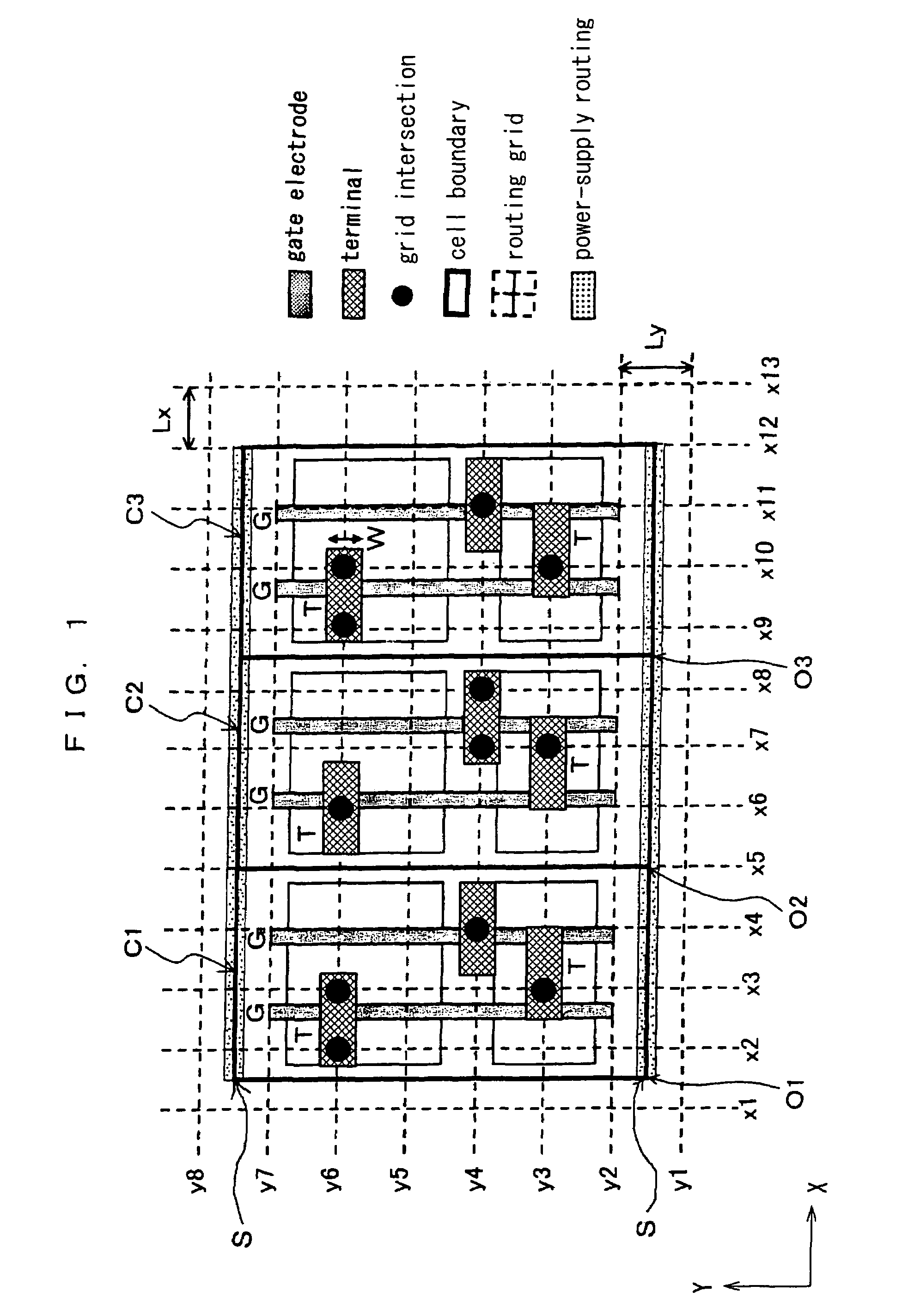

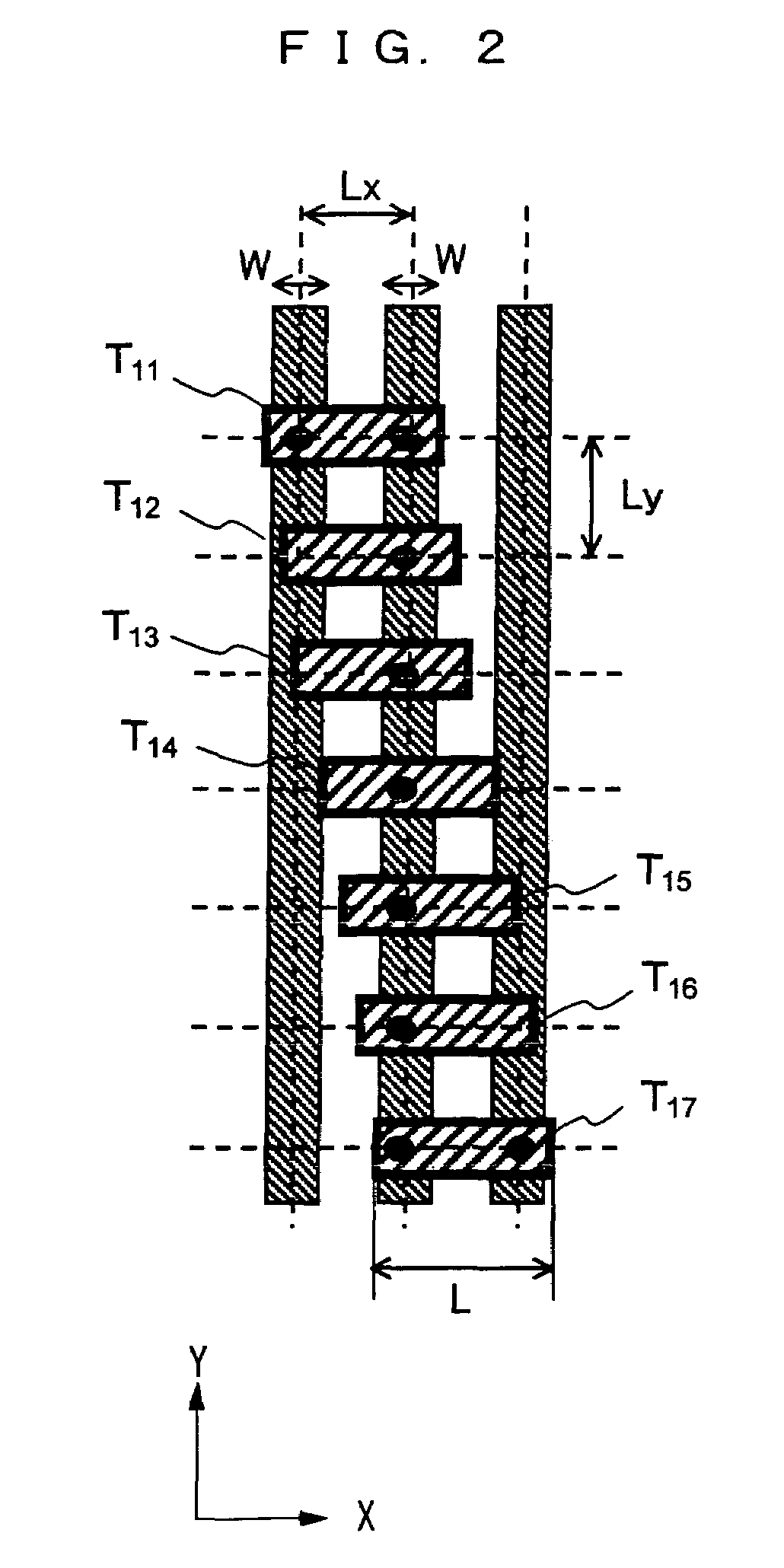

Cell, standard cell, standard cell library, a placement method using standard cell, and a semiconductor integrated circuit

ActiveUS7503026B2Reducing cell area and chip areaHigh precisionSolid-state devicesComputer aided designElectrical batteryEngineering

A cell according to the present invention comprises a plurality of terminals capable of transmitting an input signal or an output signal and serving as a minimum unit in designing a semiconductor integrated circuit, wherein the plurality of terminals is located on routing grids lined in a Y direction which is a direction vertical to a power-supply wiring of the cell used in automatic placement & routing and has a shape extended in an X direction which is a direction in parallel with the power-supply wiring, more specifically such a shape that, for example, a longer-side dimension of the terminal is equal to “a routing grid interval in the X direction+a wiring width. According to the constitution, a cell area is reduced, which advantageously leads to the reduction of a chip area.

Owner:SOCIONEXT INC

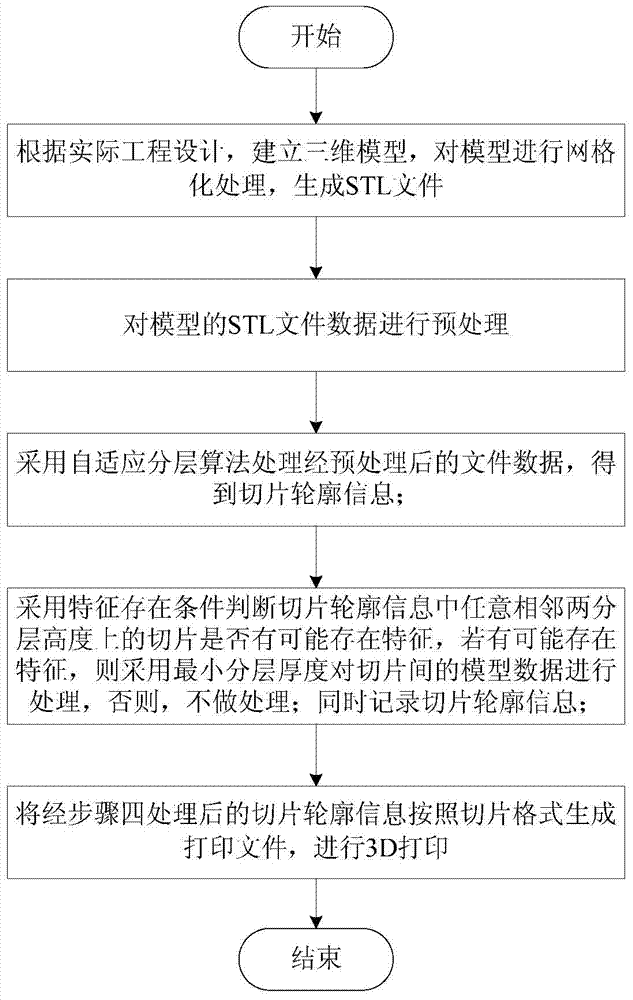

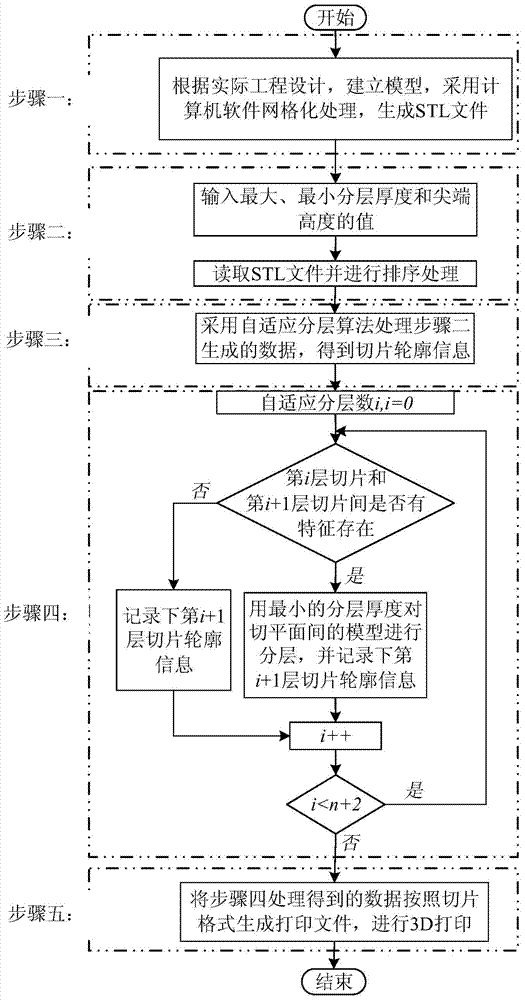

3D (three-dimensional) printing adaptive slicing method capable of reserving model features

ActiveCN104708824ASolve the lossResolve offsetAdditive manufacturing apparatusAlgorithmLayer thickness

The invention relates to a 3D (three-dimensional) printing adaptive slicing method capable of reserving model features, and belongs to the technical field of 3D printing. The method comprises the following steps: (1) according to an actual project design, establishing a 3D model, performing grid processing on the model, and generating STL (standard template library) file data; (2) performing preprocessing on the STL file data of the model; (3) processing the preprocessed file data by adopting an adaptive layer algorithm, and obtaining slice contour information; (4) judging whether the features possibly exist in slices at any two adjacent layer heights in the slice contour information or not by adopting a feature existence condition, if judging that the features possibly exist, performing secondary slicing on the model data of the slices by adopting the minimum layer thickness lmin, or otherwise, not performing processing, and recording the slice contour information; (5) generating a printing file in a slice format by the slice contour information processed in the step 4, and performing 3D printing. The method can effectively shorten printing time and reduce memory usage amount and calculated amount.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

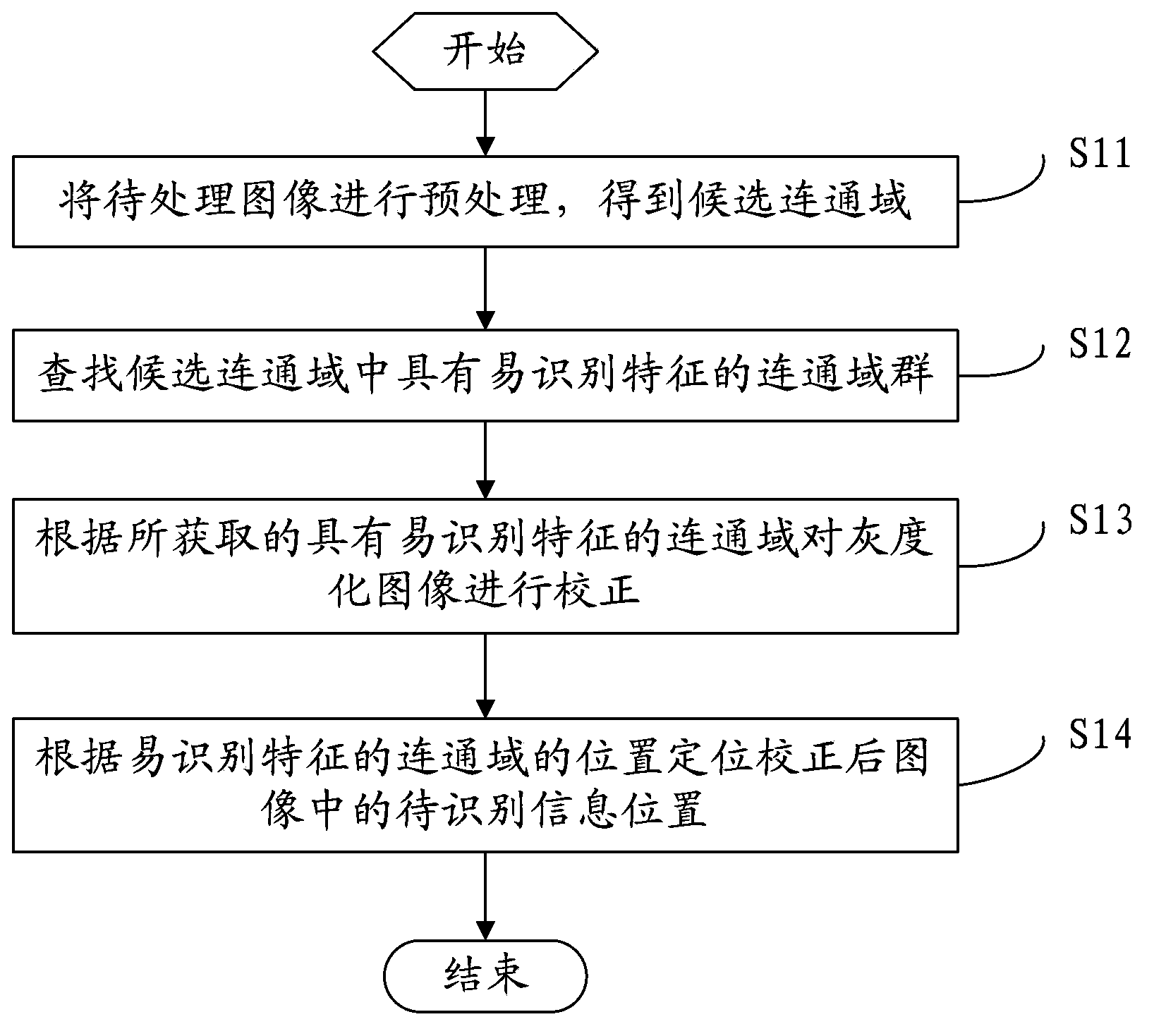

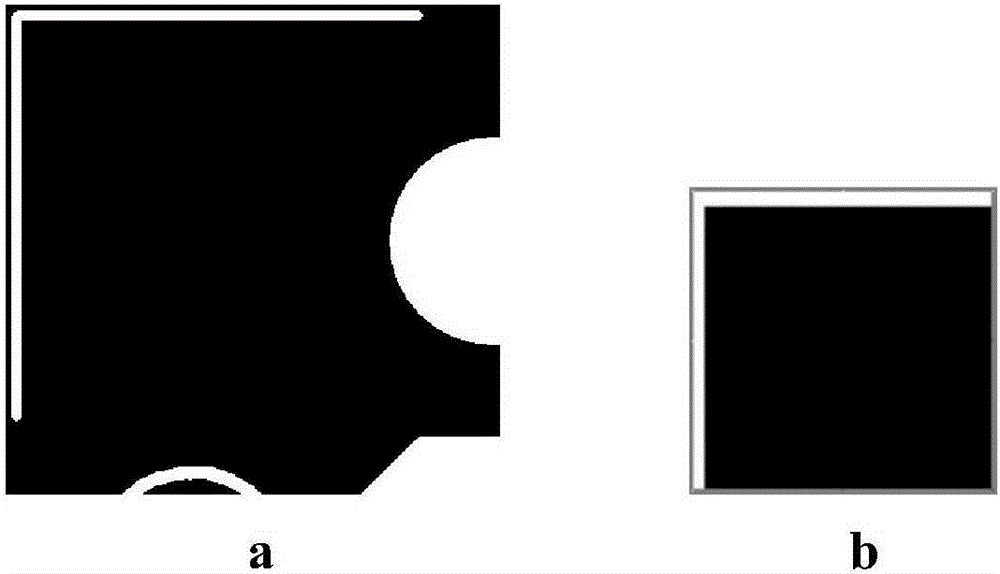

Information locating method for document image based on standard template

InactiveCN103839058ASimplify the collection processDoes not affect layoutCharacter and pattern recognitionRegion analysisStandard Template Library

The invention discloses an information locating method for a document image based on a standard template. The method comprises the following steps: first, binaryzation processing and connected region analysis are performed on an image to be processed to obtain a series of candidate connected domains, and a group of connected domains with the characteristic of easy recognition is searched among the candidate connected domains; then, tilt correction and perspective correction are performed on a gray image of the image to be processed according to the acquired connected domains with the characteristic of easy recognition; and finally, the position of information to be recognized in the corrected image is located according to the positions of the connected domains with the characteristic of easy recognition. According to the invention, a locating method is provided by directly making use of image recognition, the acquisition process is simple and requires neither special equipment nor design of an exclusive bar code, and the method has a wider range of applications.

Owner:方正国际软件(北京)有限公司 +1

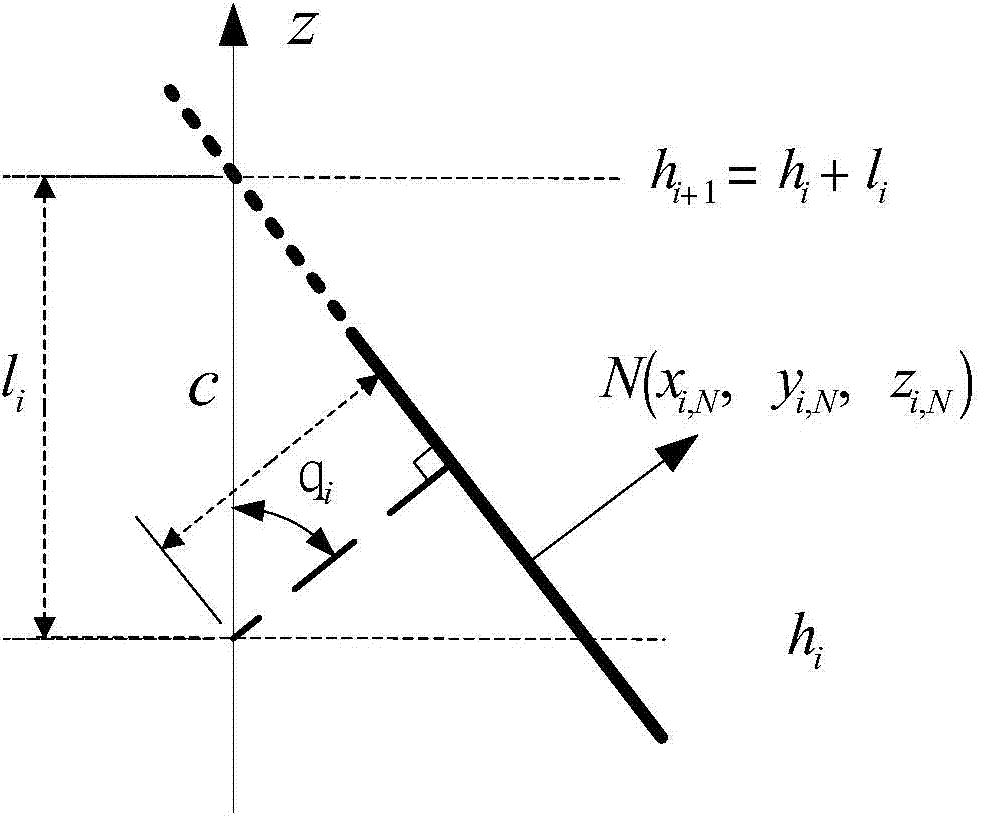

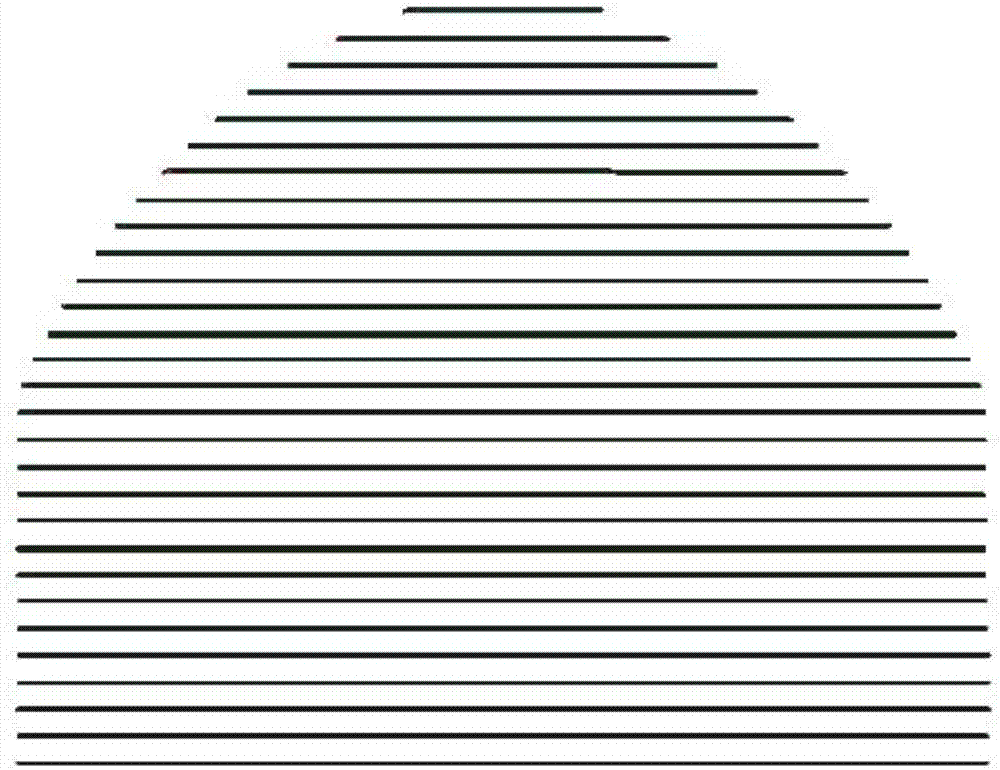

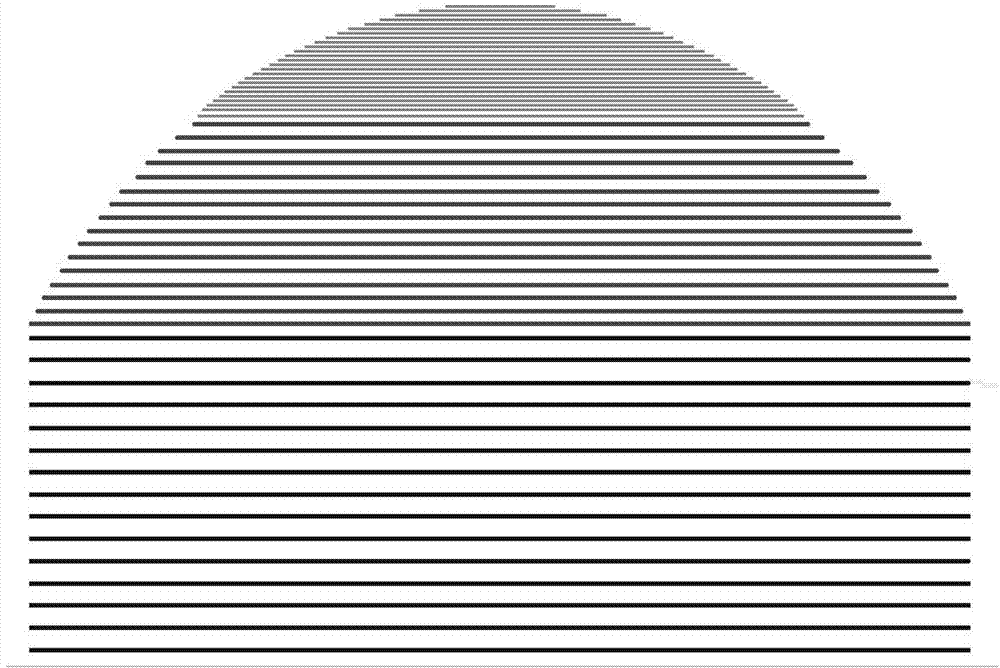

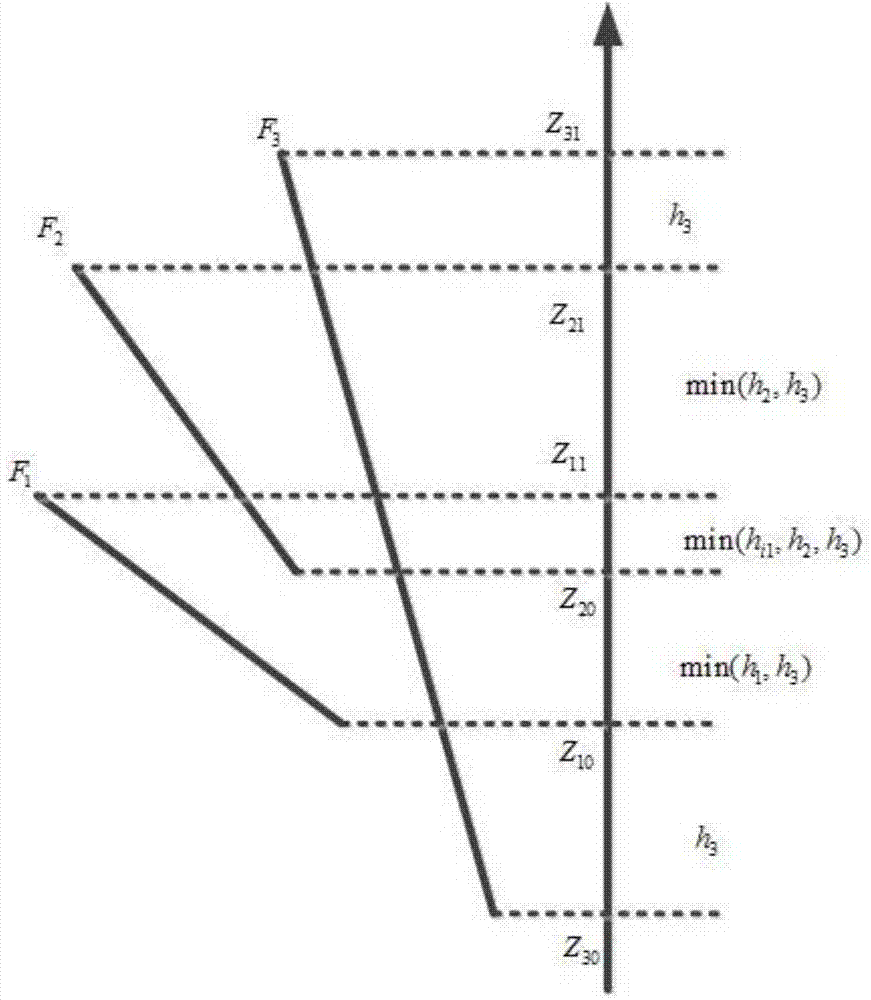

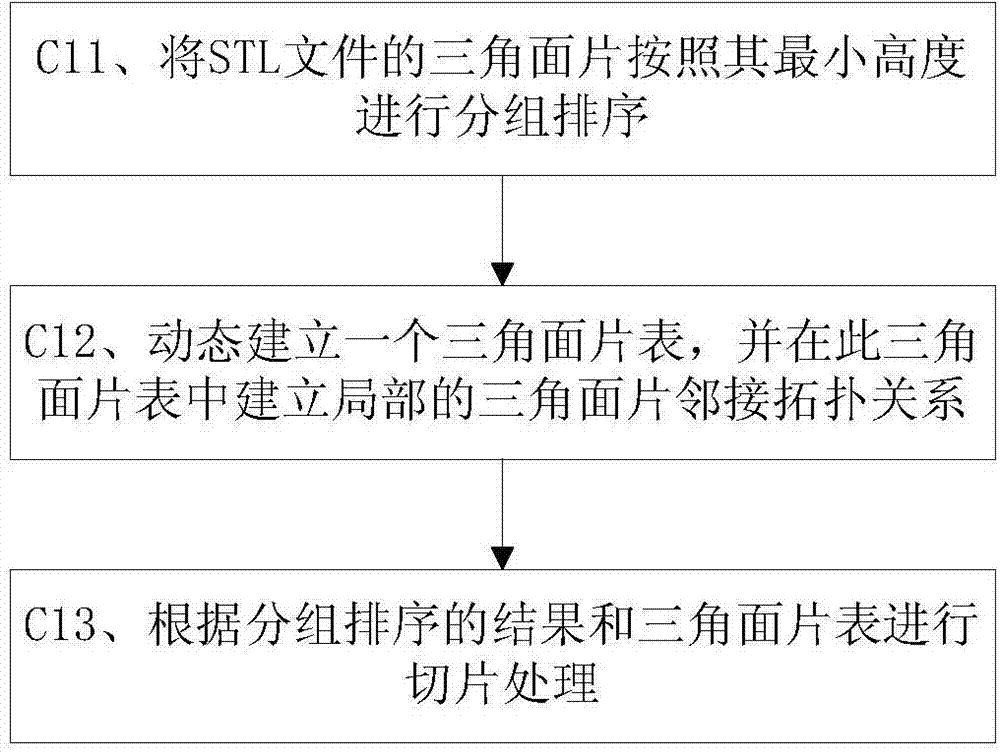

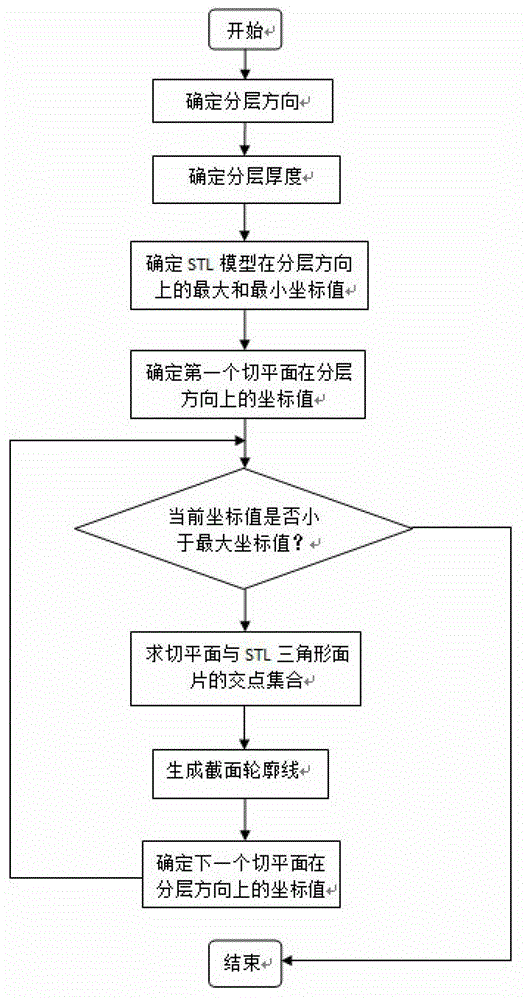

Self-adaption layering method of 3D printing

ActiveCN104503711AHigh precisionImprove Layering Efficiency3D object support structuresImage data processing3d printerSelf adaptive

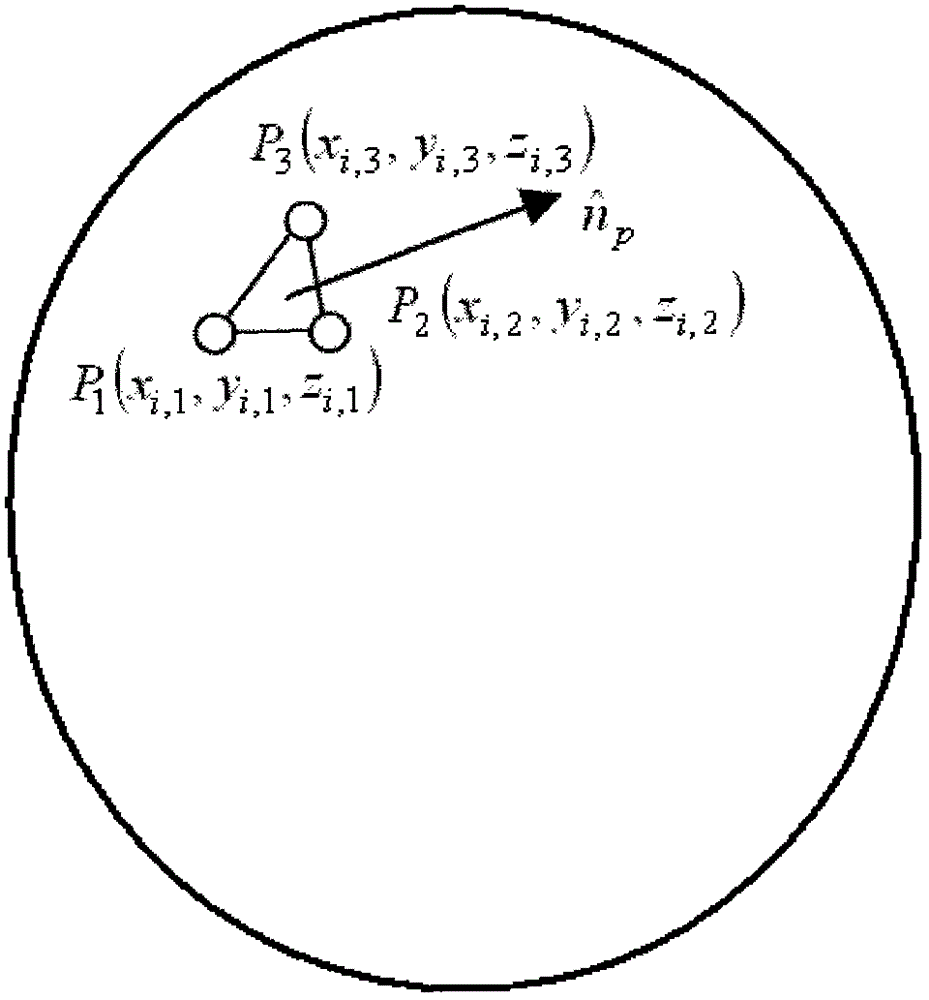

The invention discloses a self-adaption layering method of 3D printing. The self-adaption layering method comprises the following steps: in a process that STL (Standard Template Library) model data is read, calculating layering height corresponding to a triangular patch according to a normal vector of each triangular patch; subsequently, according to the layering height of each triangular patch, calculating optimal layering height within any height range in a vertical direction, and establishing a layering height table (HT); and inquiring the HT to obtain the layering height required for a subsequent layering operation. The self-adaption layering method has the characteristics that layering efficiency is improved, high-precision layering outline data can be obtained, and reliable data support is provided for the high-efficiency and high-precision printing of a 3D printer.

Owner:SHINING 3D TECH CO LTD

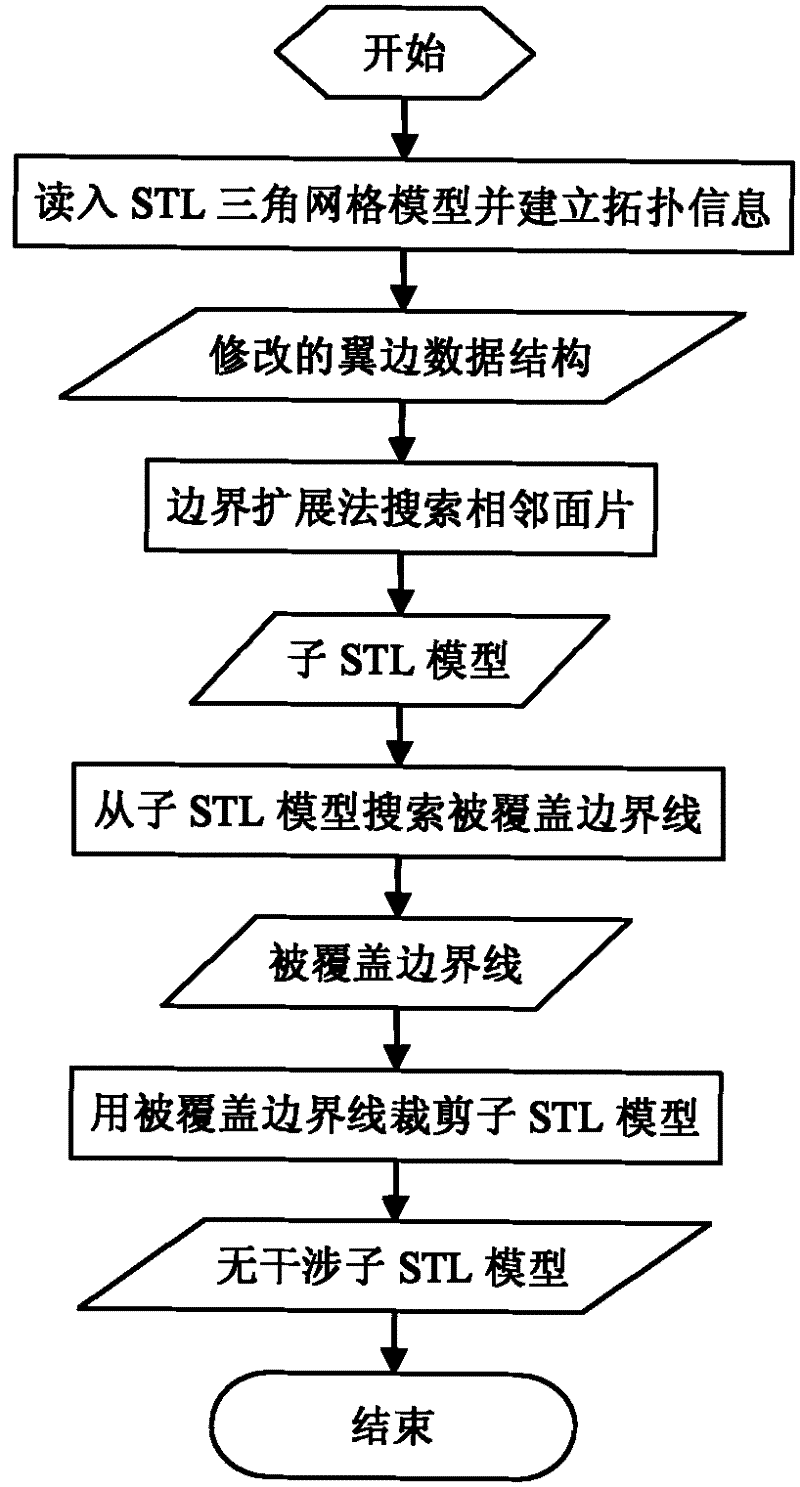

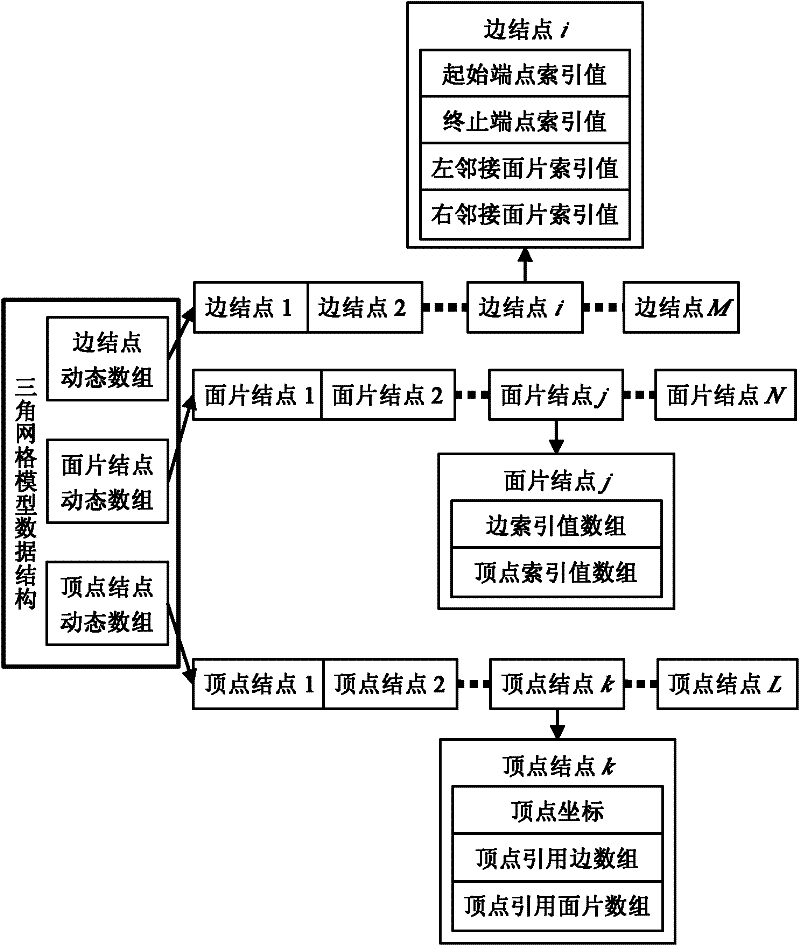

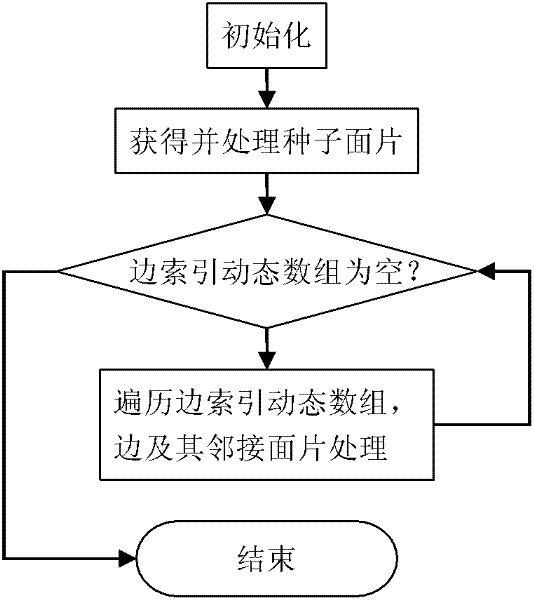

3D segmentation method for stl triangular mesh model

The invention discloses a three-dimensional segmenting method for an STL (Standard Template Library) triangular network model in rapid molding process. The three-dimensional segmenting method comprises the following steps of: firstly, reading the STL triangular network model from an STL file into an internal storage, and establishing complete topological information of a surface patch, a side and a peak in the STL model based on an improved wing-edge structure; secondly, repeatedly searching through information in the internal storage to obtain a highest position surface patch serving as a seed surface patch in an original STL model, and searching an adjacent surface patch having the same normal vector Z-axis component symbol as the seed surface patch with a boundary expansion method on the basis to obtain a plurality of sub-STL models having the same normal vector Z-axis component symbol; and lastly, checking the boundary of each sub-STL model, recognizing and extracting covered boundary lines, and segmenting the sub-STL model by using a vertical plane defined by the covered boundary lines to further generate non-interfered sub-STL models. By adopting the three-dimensional segmenting method, three-dimensional segmentation of the STL triangular network model can be realized effectively; and moreover, the triangular network model has the advantages of high adaptability, high efficiency and low resource consumption.

Owner:HUAQIAO UNIVERSITY

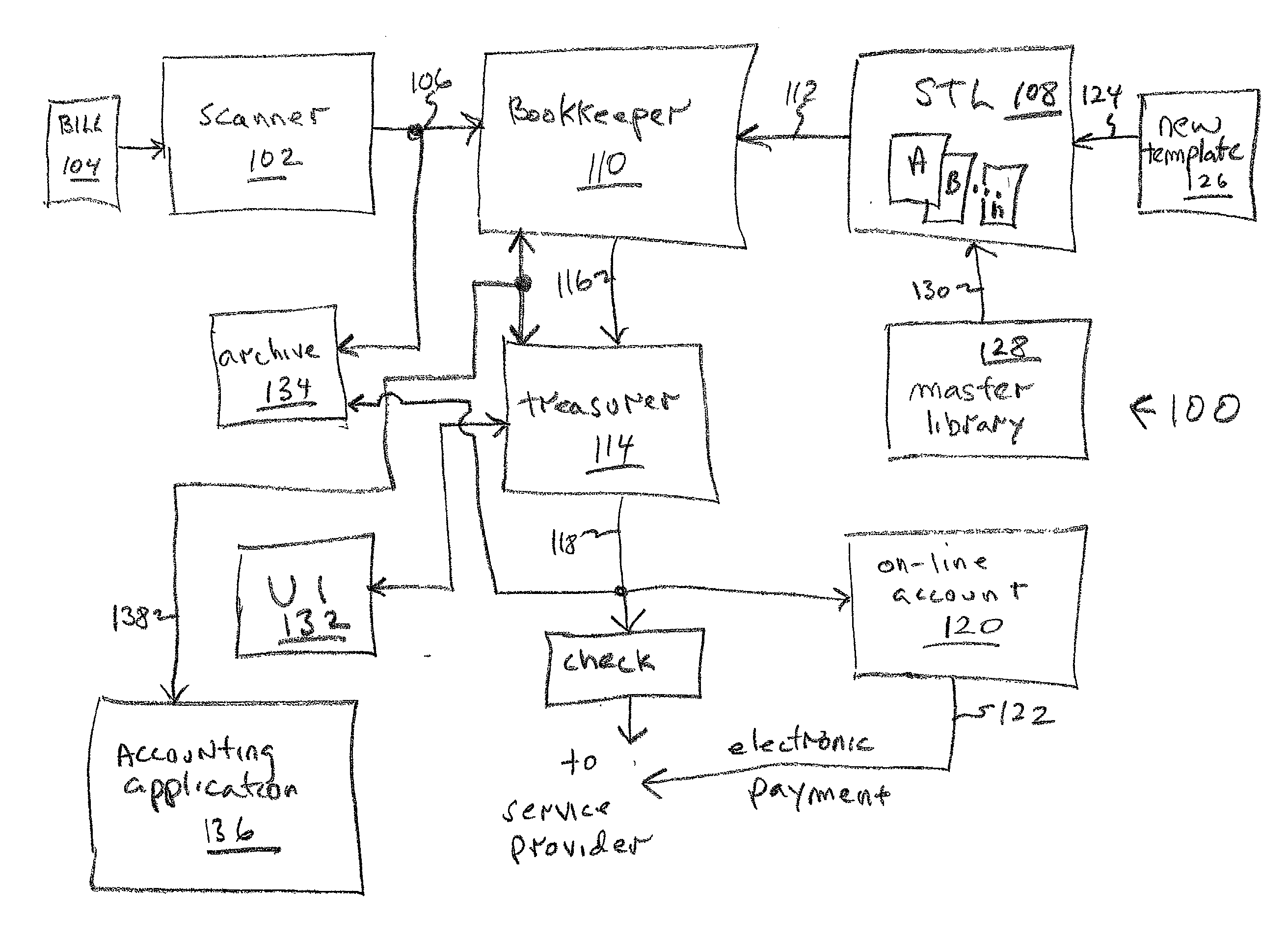

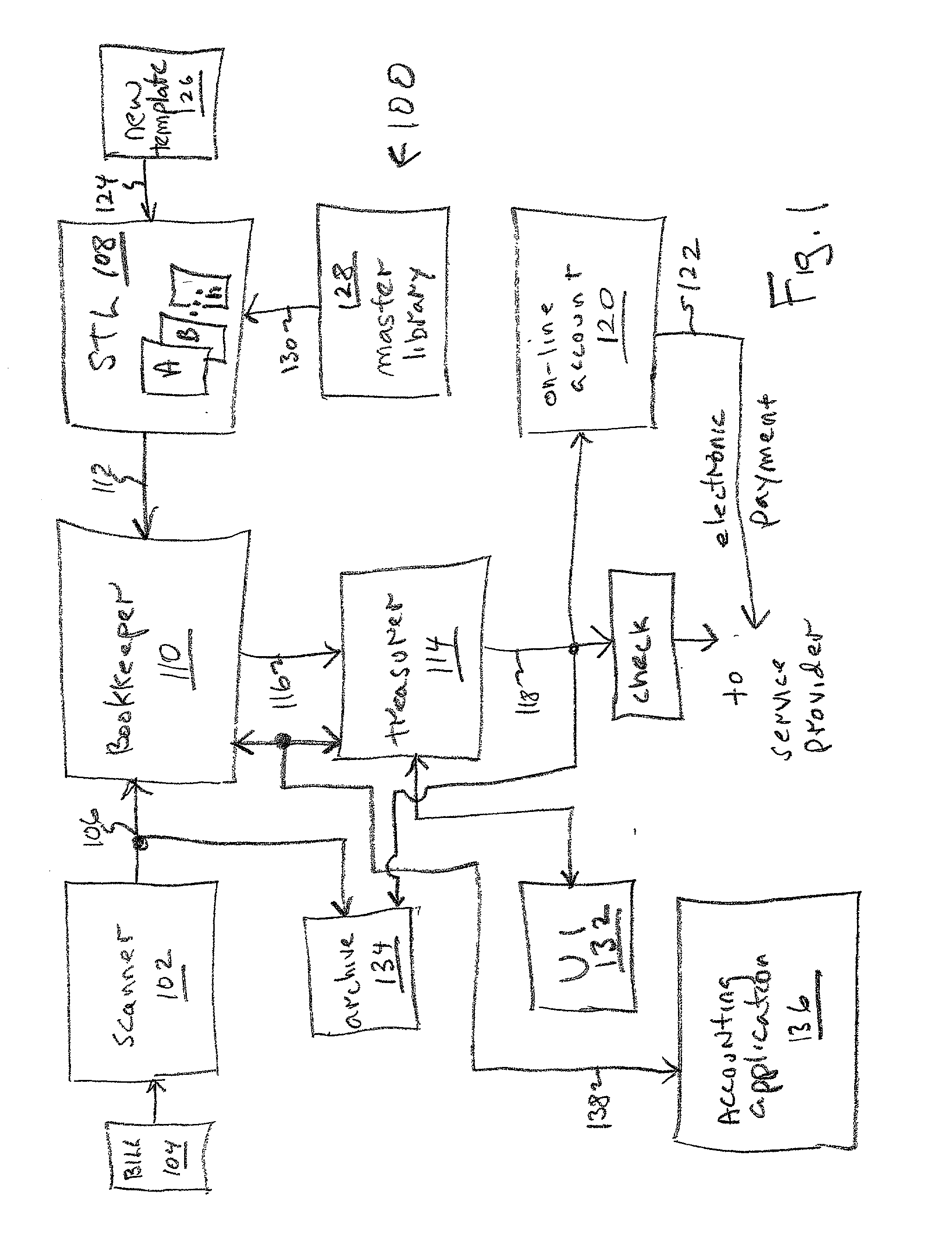

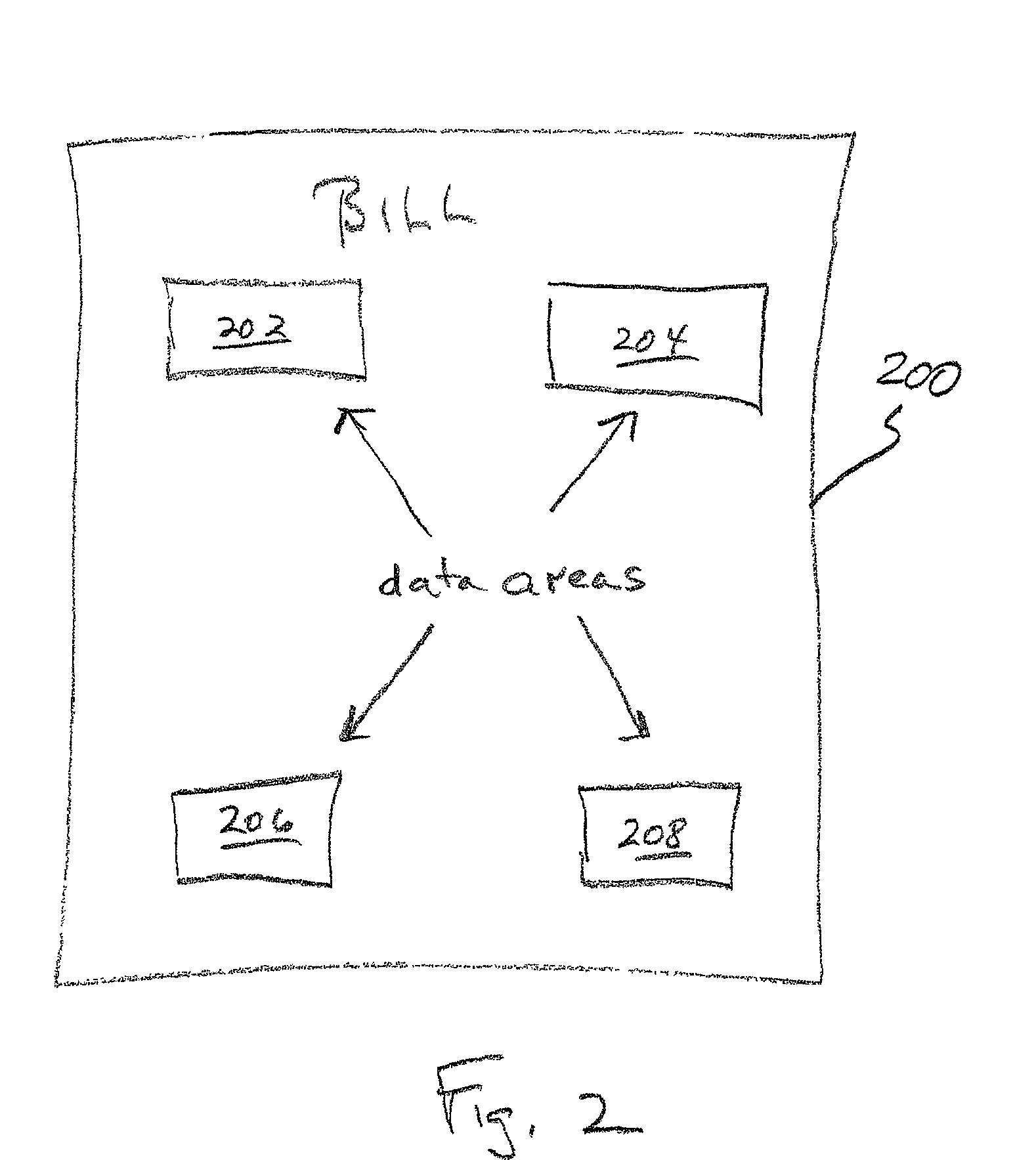

System and method for automatic bill payment

A system and method are provided for automatically paying bills. The method comprises: scanning a received bill; accessing a standard template library (STL); matching the received bill to a bill template from the STL; using the bill template to identify data areas; reading parameters from data areas on the received bill; and, transmitting a payment in response to the parameters. Some common parameters to be read form the data areas of the received bill include the account number, the service provider address, the due date, and the amount owed. Some aspects of the method further comprise establishing an accessible on-line checking account. Then, transmitting a payment includes electronically debiting the checking account and electronically submitting the amount due to the service provider drawn on the checking account. Alternately, a check can be generated for the service provider drawn on the checking account. If a check is generated, it is printed with populated fields such as the payee's name, the amount, the account number, and a signature. Other aspects of the method further comprise: accessing an on-line server master template library; and, downloading templates into a local database standard template library. The on-line server master template library includes templates in a first plurality of languages. Therefore, downloading templates into a local database standard template library includes selecting a language.

Owner:SHARP LAB OF AMERICA INC

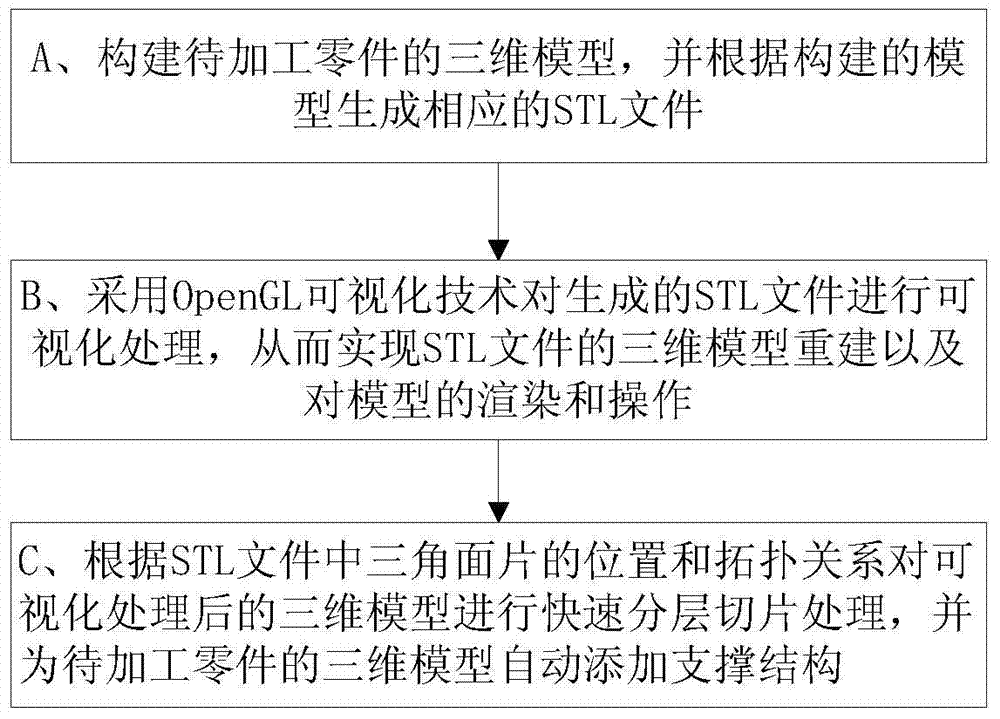

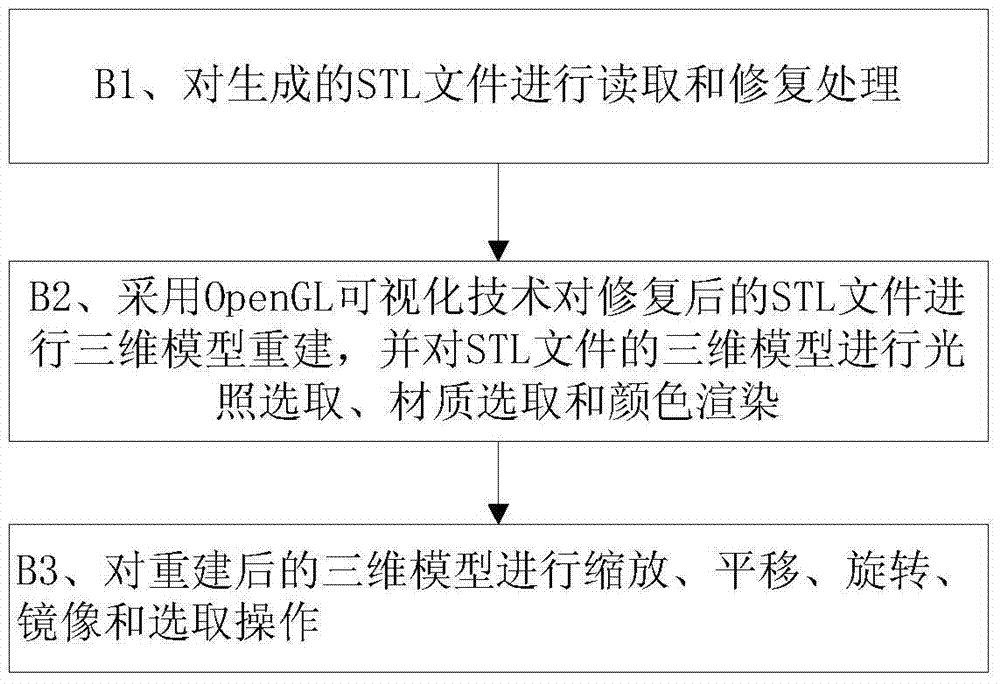

Implementation method based on 3D (Three Dimensional) printing data processing software platform

ActiveCN104504186AOvercome selected deficienciesQuality assuranceSpecial data processing applicationsSelective laser sinteringAutomatic control

The invention discloses an implementation method based on a 3D (Three Dimensional) printing data processing software platform. The implementation method based on the 3D printing data processing software platform comprises the following steps of establishing a 3D model of a part to be processed, and generating a corresponding STL (Standard Template Library) file according to the established model; adopting an OpenGL visualization technology to carry out visualization processing on the generated STL file; carrying out rapid hierarchical slicing processing on a 3D model subjected to the visualization processing according to the position and the topological relationship of a triangular patch in the STL file, and automatically adding a support structure for the 3D model of the part to be processed; according to the result of hierarchical slicing processing and the characteristics of processing materials, adopting a birth-death element method to simulate a processing process based on SLS (Selective Laser Sintering) and SLM (Selective Maping) technology processes for the part to be processed; carrying out parameter selection and model optimization on the part to be processed according to the simulation result, so that optimal printing parameters and an optimal processing model of the part to be processed are obtained. The implementation method based on the 3D printing data processing software platform has the advantages of high efficiency, low cost and good forming quality, and can be widely applied in the field of automatic control.

Owner:广东健齿生物科技有限公司

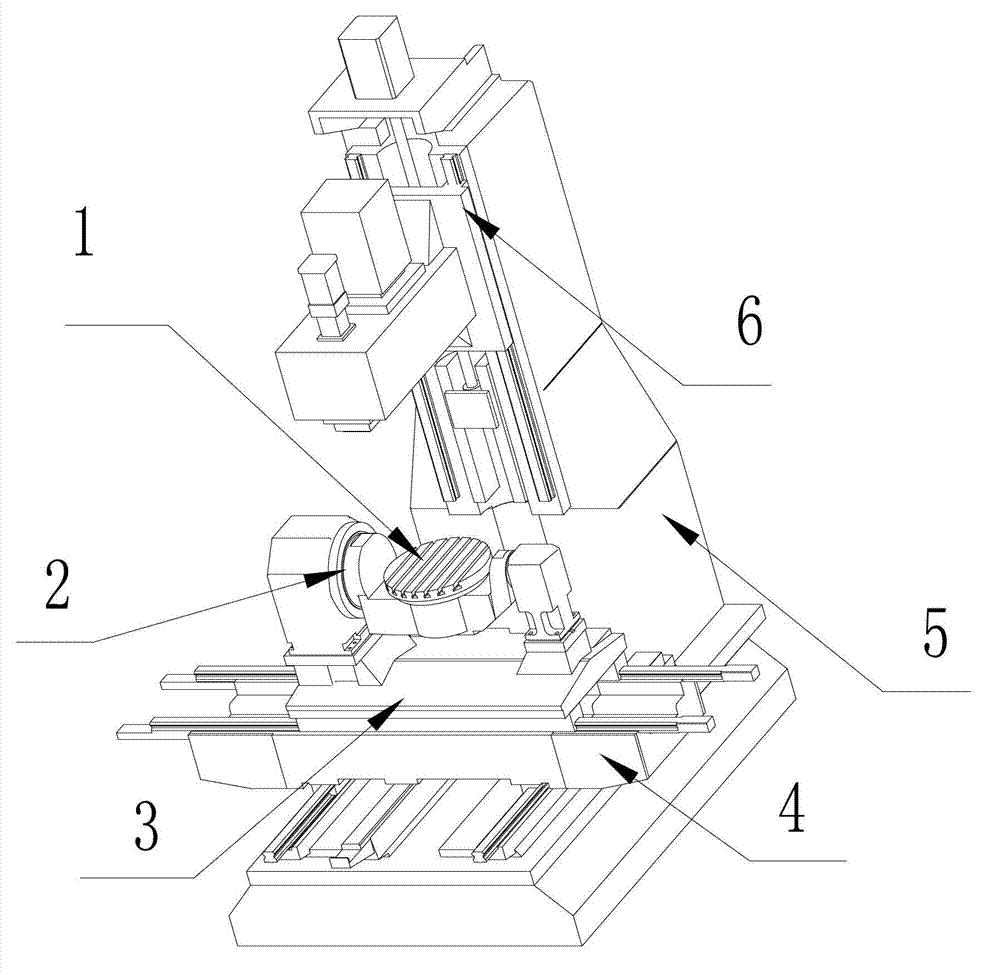

Double-turntable five-axis numerical control machine tool virtual assembling and numerical control machining simulation method

InactiveCN102866638AImprove Simulation EfficiencyImprove manufacturing precisionSimulator controlNumerical controlDimensional modeling

The invention discloses a double-turntable five-axis numerical control machine tool virtual assembling and numerical control machining simulation method and provides a simulation method capable of improving simulation efficiency under the premise of guaranteeing simulation correctness. The method includes: modeling; conducting three-dimensional modeling of blanks and clamps required in all moving components, a machine tool body and numerical control machining; connecting all moving components and the machine tool body to conduct virtual assembling according to a moving relation by using a Pro / E three-dimensional platform; operating a virtual simulating machine tool; outputting models of all components in a standard template library (STL) form on the basis of the same coordinate system; establishing a double-turntable five-axis numerical control machine tool virtual model; establishing a model tree in VERICUT, and the sequence of model components includes two branches: machine tool body Base - Y axis - X axis - A axis - C axis - clamp - blank and machine tool body Base - Z axis - main axis - tool; the STL assembly model output by Pro / E is led into corresponding components in VERICUT directly, namely the double-turntable five-axis numerical control machine tool virtual model is established; and numerical control machining simulation is operated.

Owner:TIANJIN UNIV OF COMMERCE

3D (three-dimensional) printing technology-based preparation method for personalized bionic vertebral column system

InactiveCN103690278AEasy to observeShorten operation timeSpinal implantsData acquisitionHoneycomb like

The invention relates to a technical method for the reconstruction of a stable vertebral column after a vertebral column resection operation. The method comprises the following steps of performing CT (computed topography) and data acquisition on a personalized vertebral column, outputting CT data in a Dicom format, three-dimensionally calculating and establishing a 3D (three-dimensional) vertebral column model, outputting the 3D vertebral column model to a 3D printer in an STL (standard template library) format, and molding a cellular bionic vertebral column by using a titanium printing material with a melting point of 1,668+ / -4 DEG C, wherein the sizes of gaps in the cellular bionic vertebral column are 100 mu m. Compared with the prior art, the method has the advantages that a personalized column body prepared before the operation is directly used for replacing a symptomatic column during the operation, so that the operation time is greatly shortened, bleeding during the operation is reduced, and the incidence rate of various complications during the operation is lowered.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

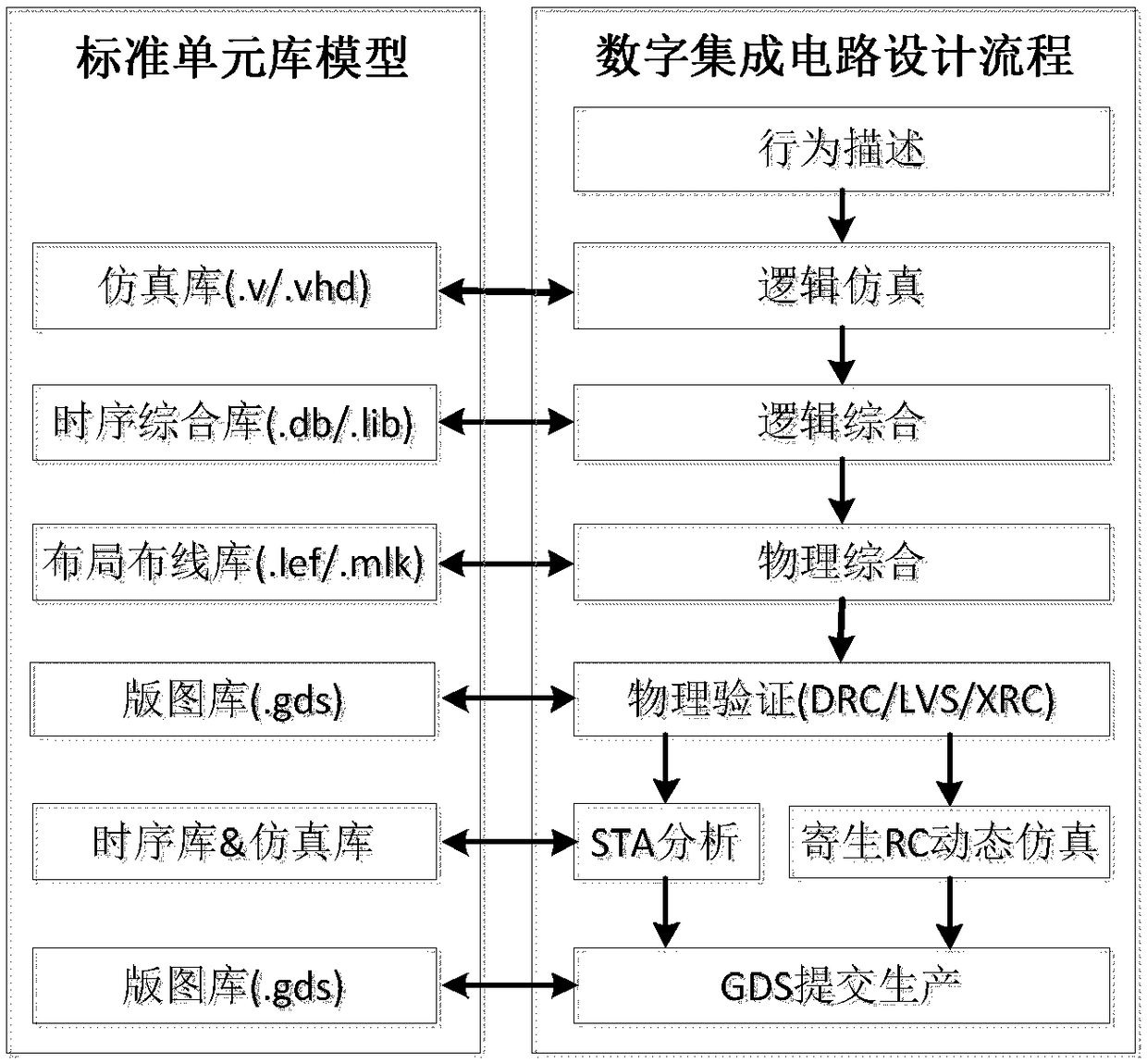

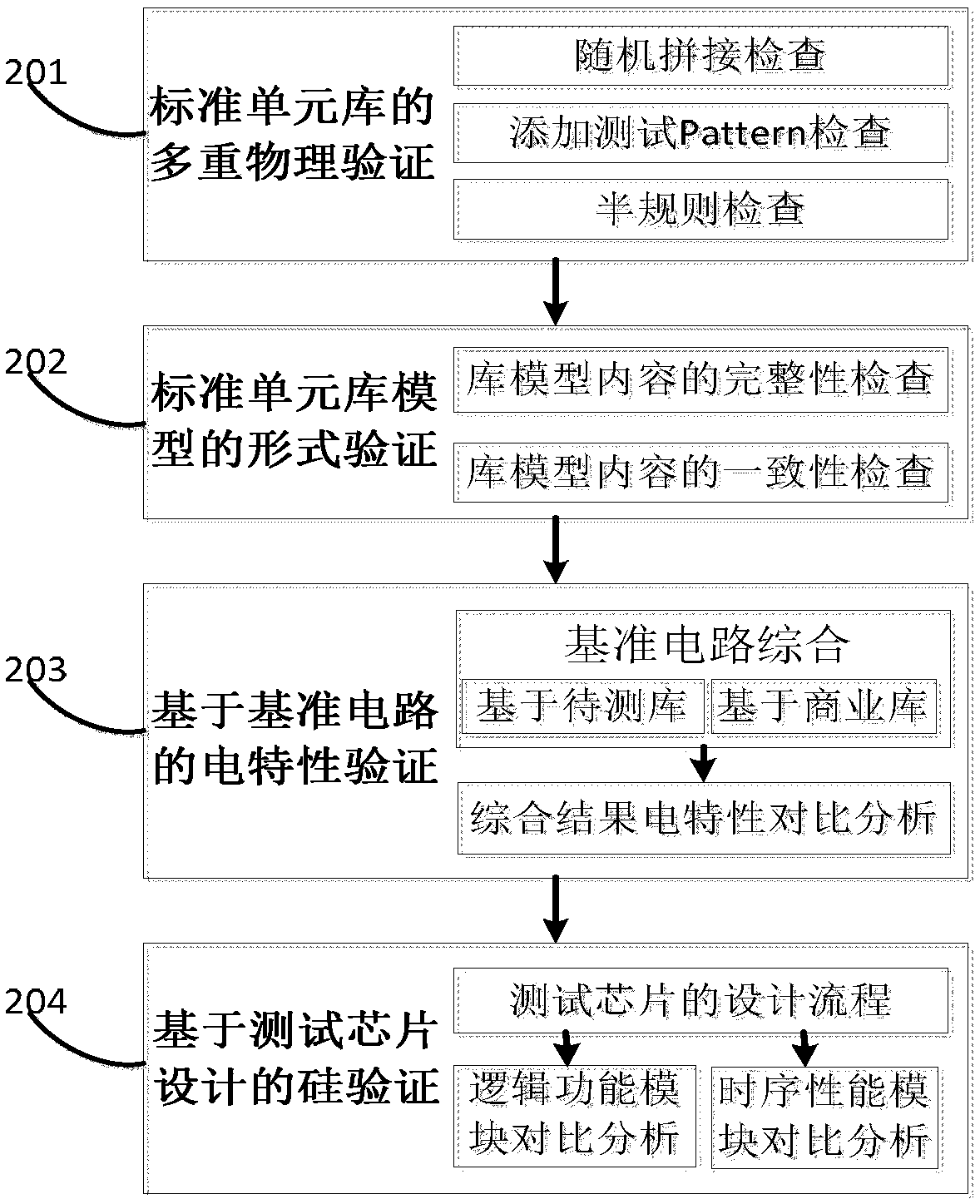

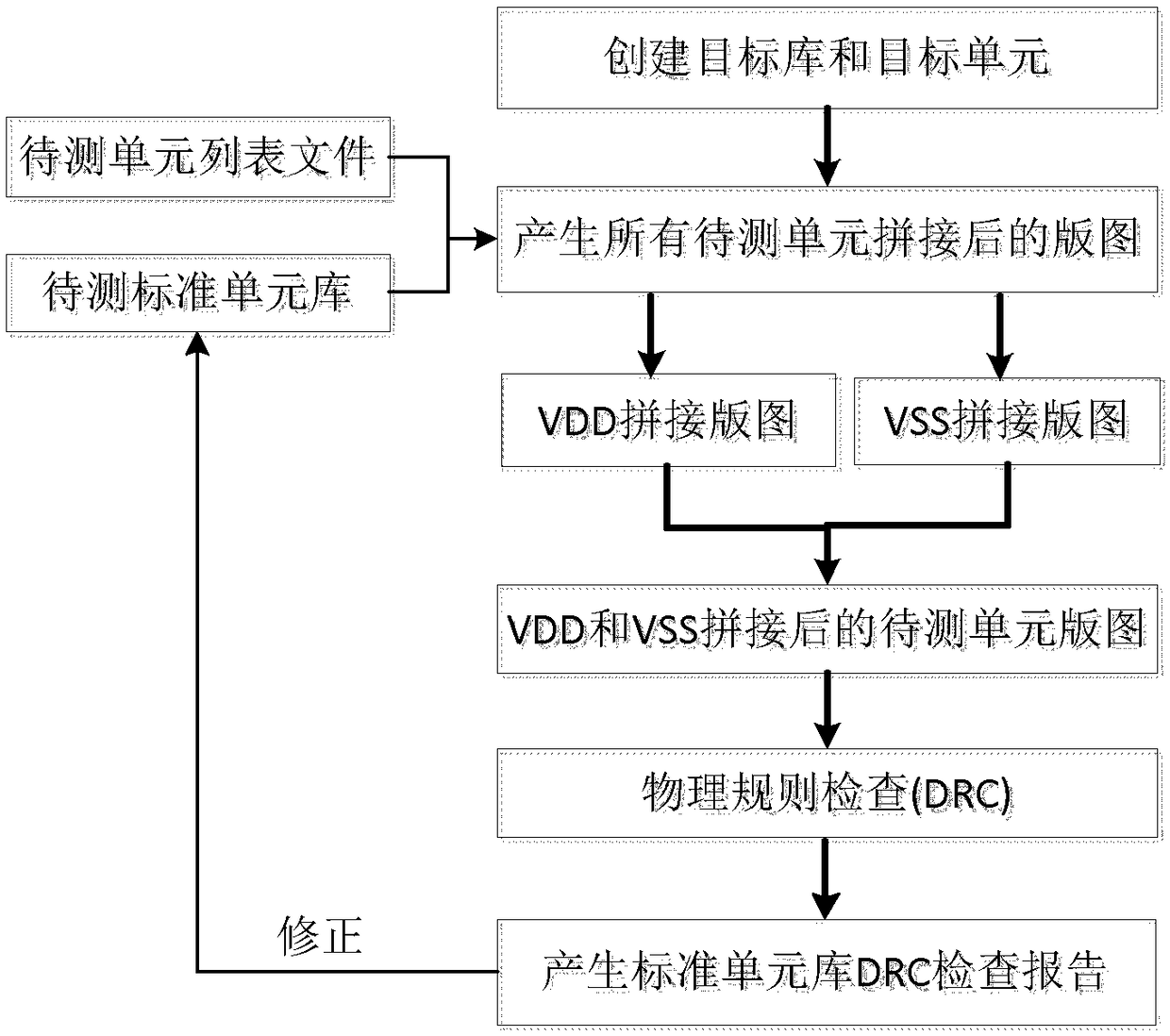

Testing method and system of standard cell library full model

ActiveCN108830008AGuaranteed designGuaranteed successSpecial data processing applicationsComputer architectureFull model

The invention provides a testing method of a standard cell library full model. The testing method comprises the following steps that 201, multiple physical rule checking is conducted on standard celllayout; 202, form verification of a standard cell library model is performed; 203, Benchmark electrical properties of a standard cell library are verified; 204, chip design silicon verification of thestandard cell library is performed. The invention provides a testing system of the standard cell library full model. Testing verification of the standard cell library full model can be quickly completed at high coverage rate.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

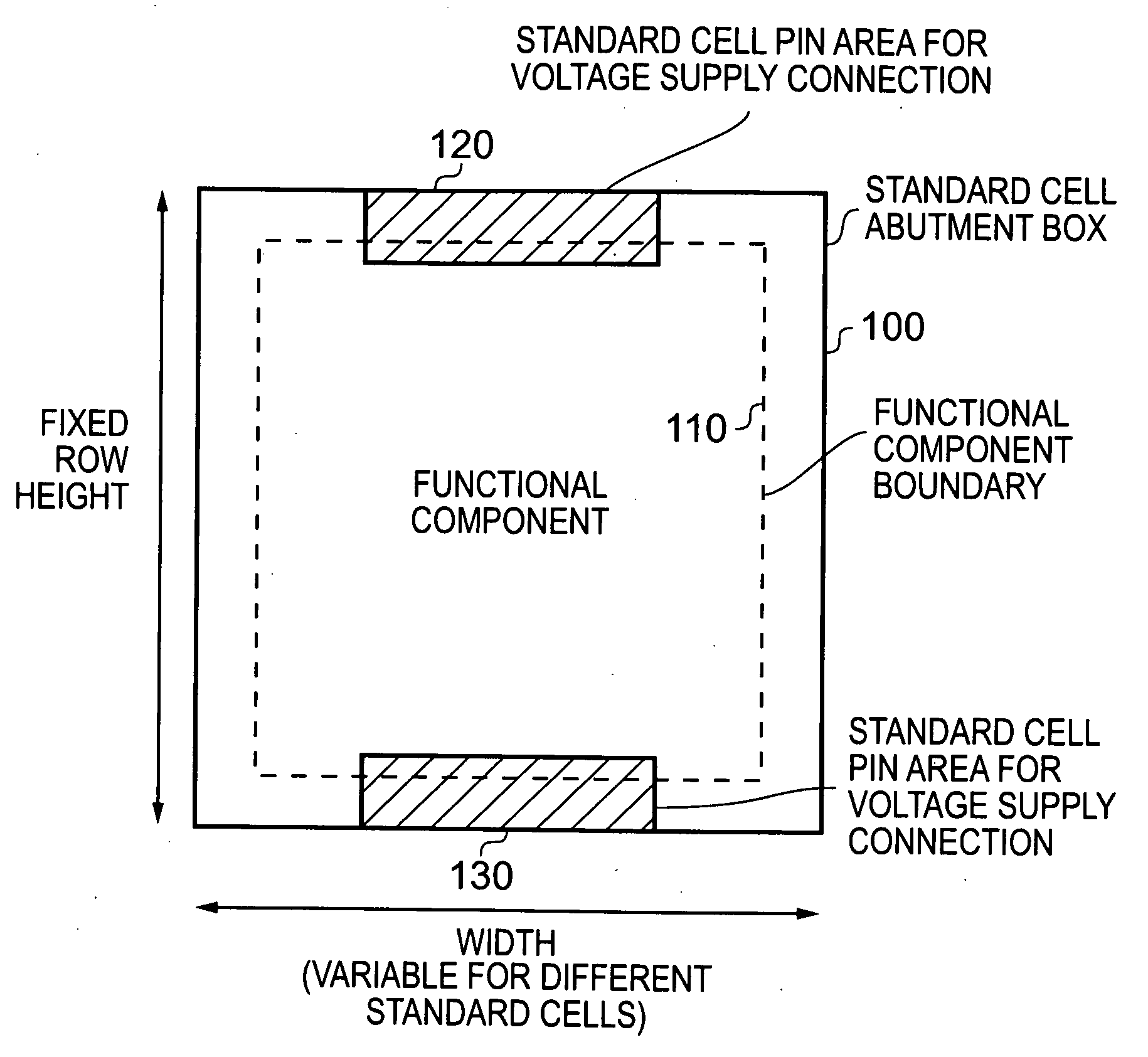

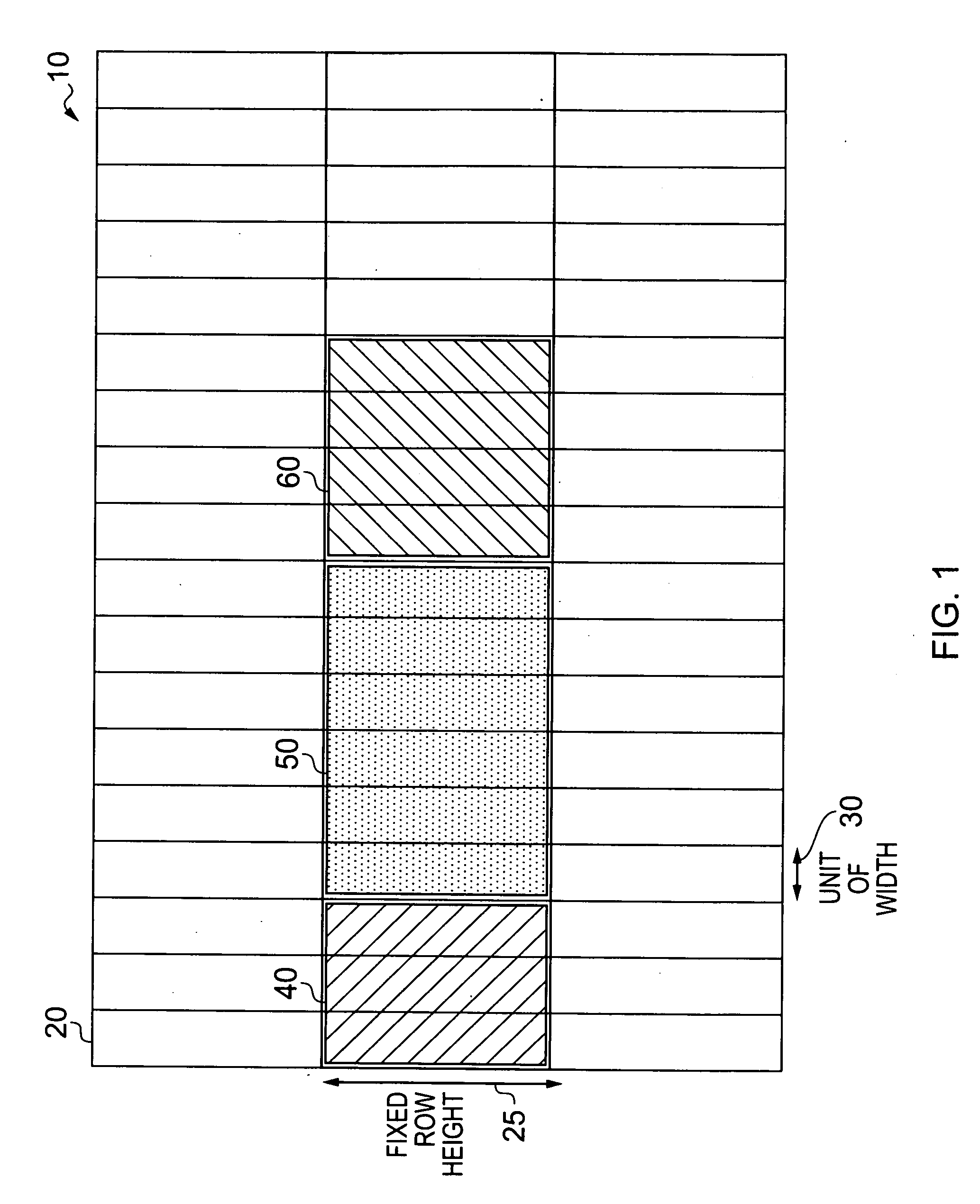

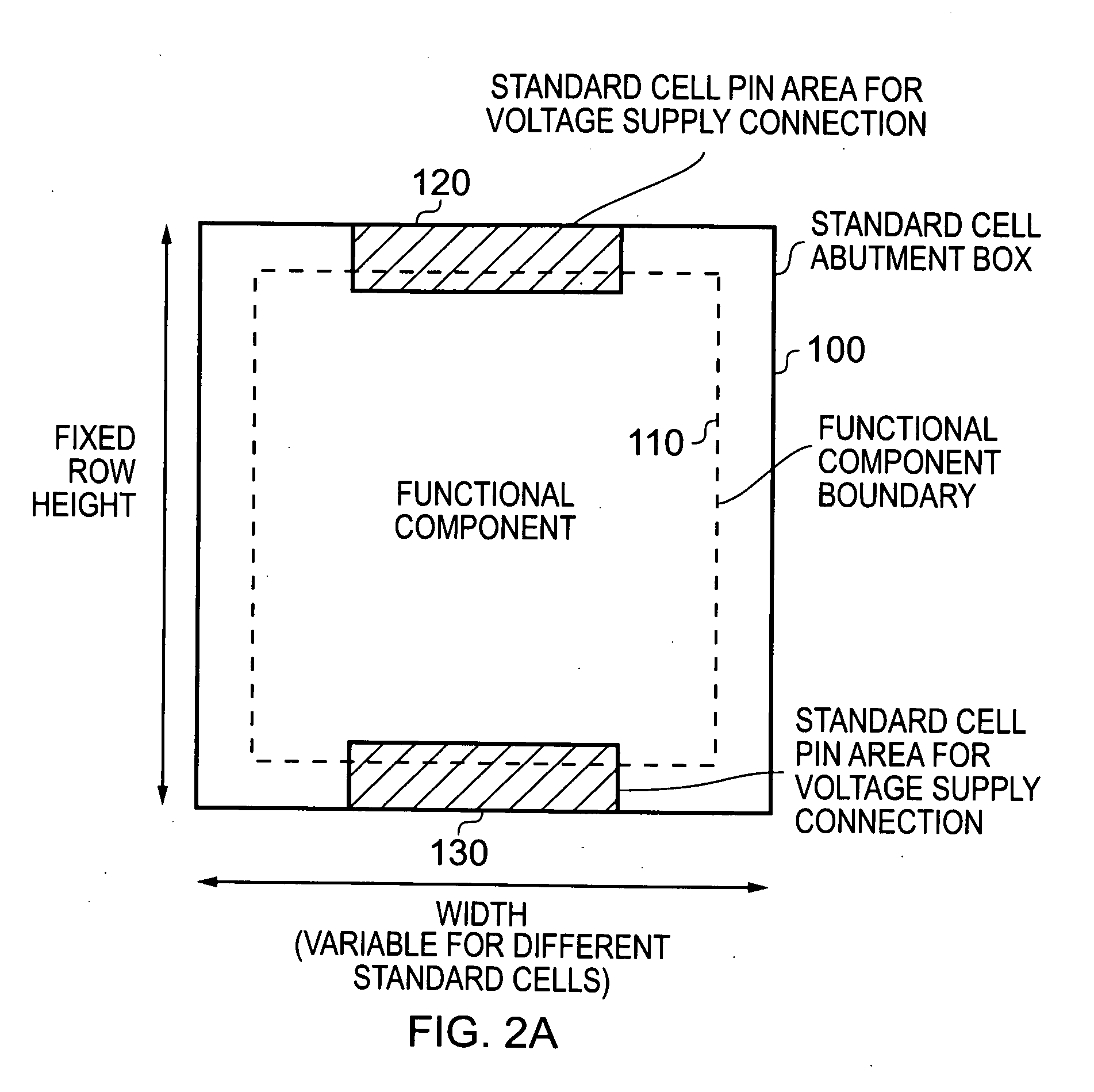

Integrated circuit, method of generating a layout of an integrated circuit using standard cells, and a standard cell library providing such standard cells

ActiveUS20120286858A1Simple and space efficient implementationEfficient implementationSolid-state devicesCAD circuit designFlexible MechanismsEngineering

An integrated circuit, a method of generating a layout of such an integrated circuit using standard cells, and a standard cell library providing such standard cells, are disclosed. The method of generating the layout comprises forming a plurality of rows, and populating each row with a plurality of standard cells chosen in dependence on the functional components required by the integrated circuit, each standard cell having its abutment area abutting the abutment area of at least one adjacent standard cell in the row. Within each row, each standard cell in that row is arranged to have a voltage connection area that is aligned with a common routing track, but with each standard cell having its voltage connection area configured so as not to extend across the entire width of the standard cell. Within each row, for each standard cell in the row, the voltage connection area of that standard cell is then connected to one of a plurality of voltage supplies having regards to a voltage requirement of the corresponding functional component defined by the standard cell, and independent of the voltage supply to which each adjacent cell in the row is connected. This provides a particularly flexible mechanism for placing standard cells during the layout operation, since standard cells that are required to run off the same voltage supply no longer need to be placed together.

Owner:ARM LTD

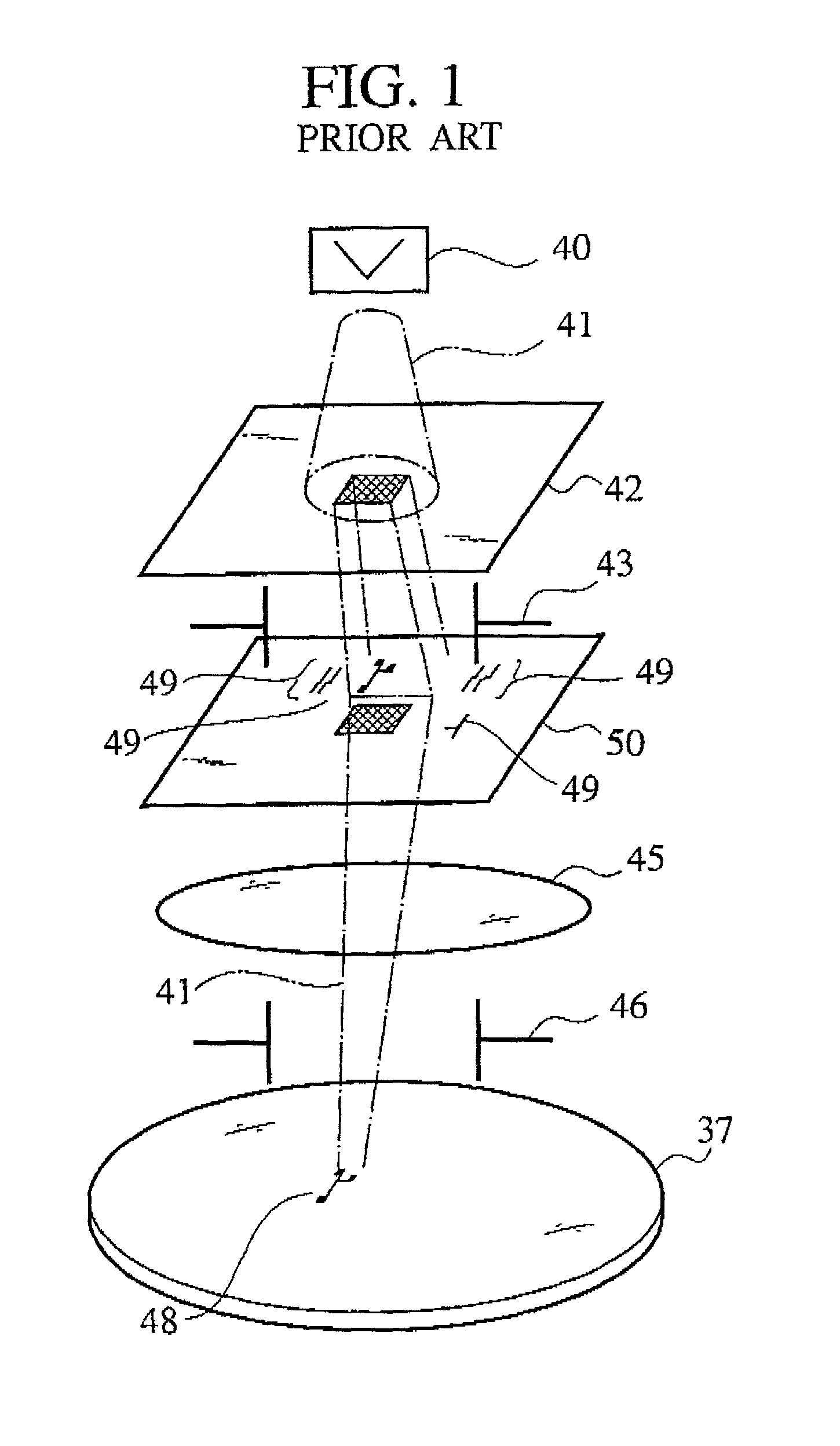

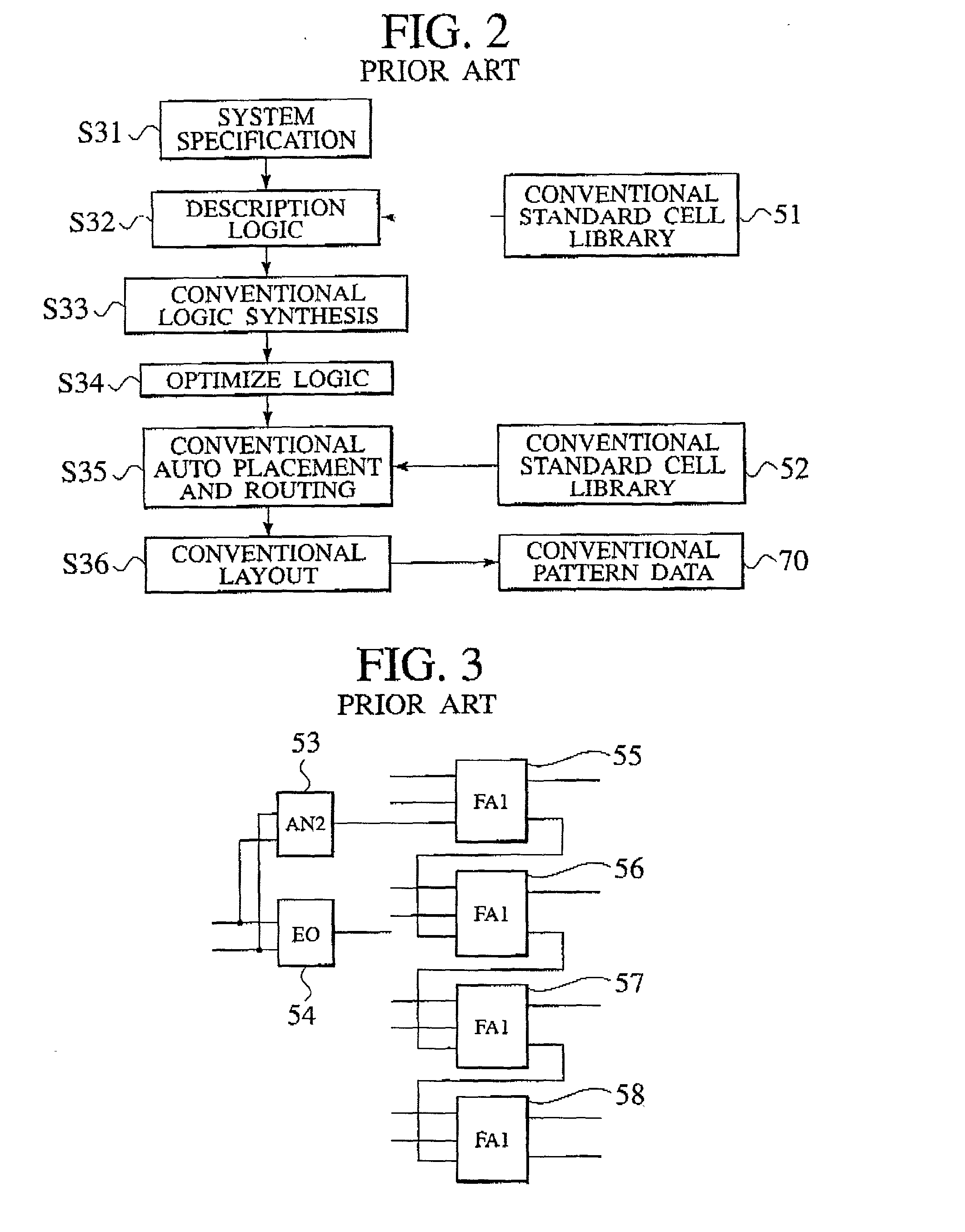

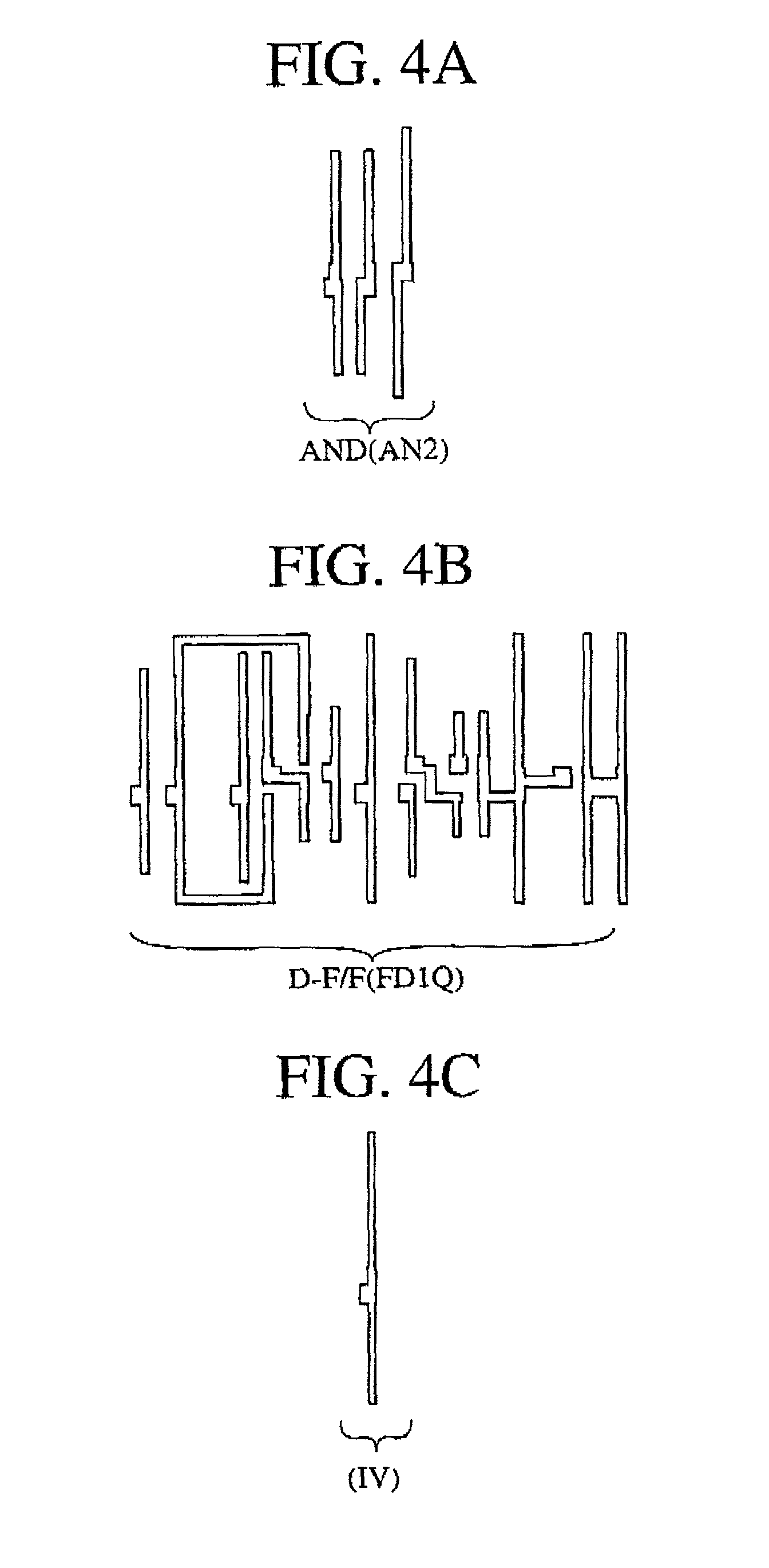

Exposure pattern data generation apparatus associated with standard cell library and charged beam exposure

Logic synthesis is conducted for CP apertures 44 using standard cells corresponding to shaping holes 4 used in logic design of a system and placed at first placement positions on the respective CP apertures 44. A CP aperture 44 used for exposure is selected from among the CP apertures for which logic synthesis has been conducted. Second placement positions of the standard cells on a substrate which standard cells correspond to the shaping holes 4 provided on the selected CP aperture 44 and wiring routes the standard cells are calculated.

Owner:KK TOSHIBA

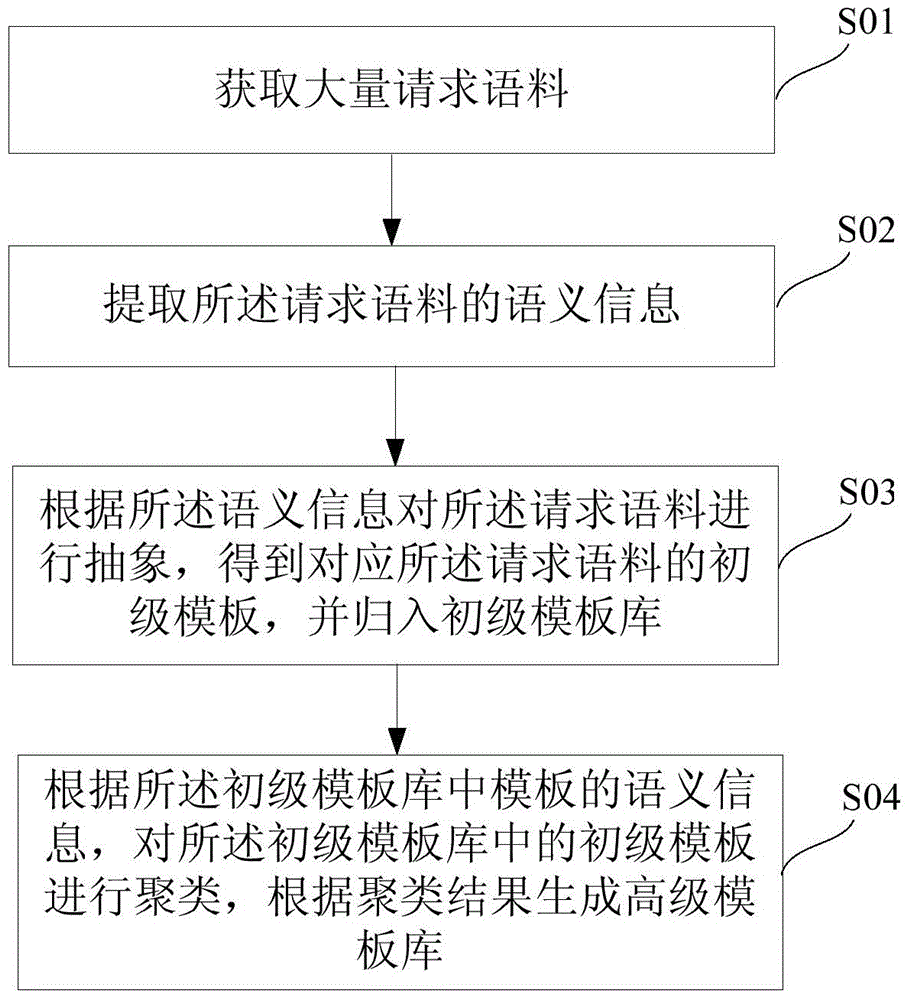

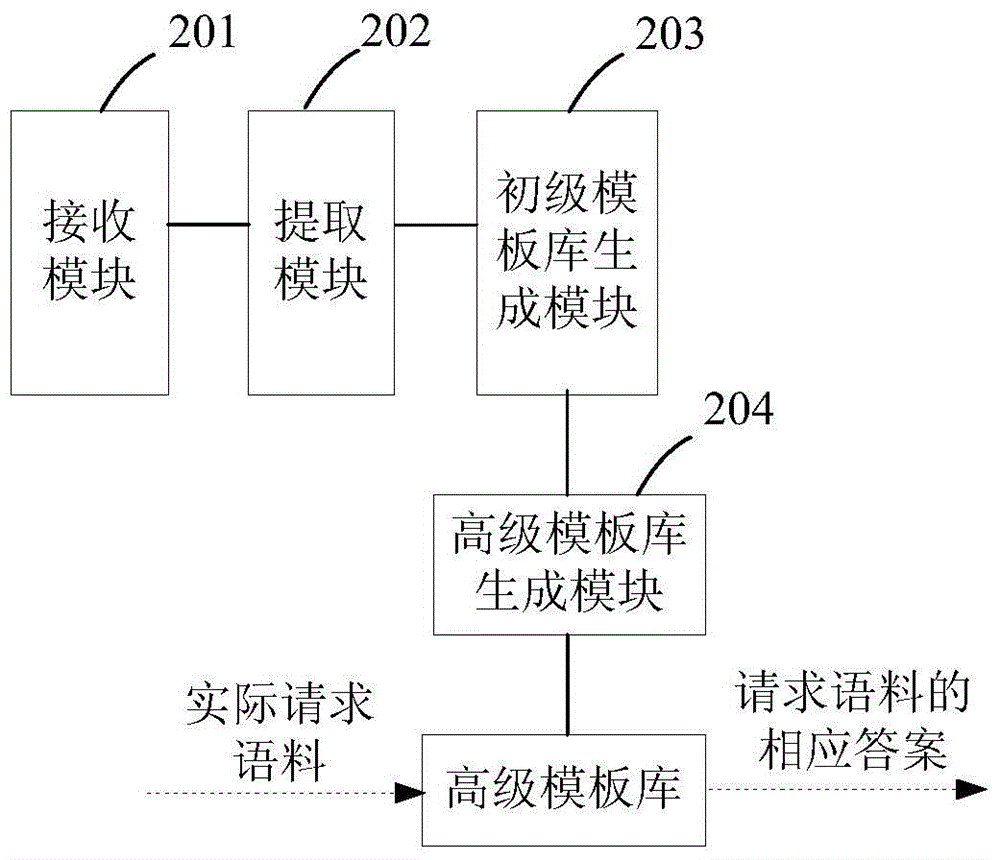

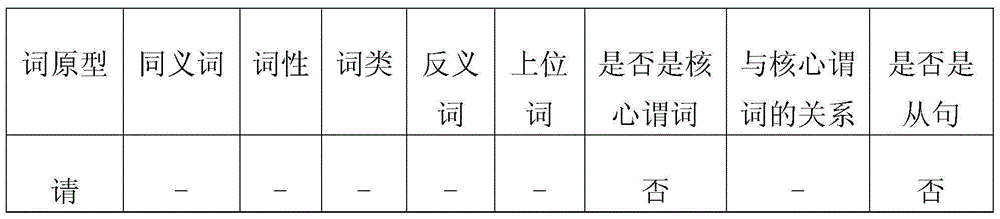

Method and system for automatically constructing template library

ActiveCN104991955AImprove search efficiencyReduce redundant templatesSemantic analysisCharacter and pattern recognitionComputer scienceStandard Template Library

The invention discloses a method and a system for automatically constructing a template library. The method comprises: acquiring a lot of request linguistic data; extracting semantic information of the request linguistic data; abstracting the request linguistic data according to the semantic information to obtain a primary template of the request linguistic data and collecting the primary template into a primary template library; and clustering the primary template in the primary template library according to the semantic information of the template in the primary template library, and generating a high-grade template library according to a clustering result. By virtue of the method disclosed by the invention, the request linguistic data is abstracted according to the semantic information to obtain the primary template library, and the primary template library is clustered to obtain the high-grade template library so that a template construction process can automatically construct the template library by uniform criteria; and a redundancy template can be effectively reduced so that the finding efficiency of the template library is improved.

Owner:讯飞医疗科技股份有限公司

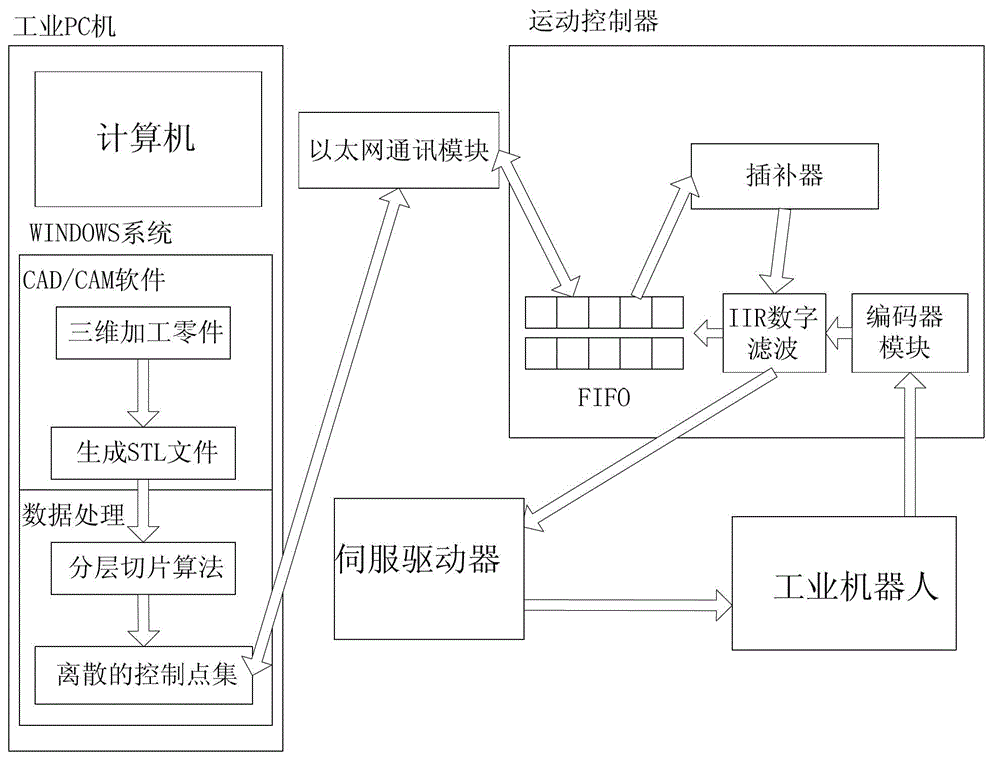

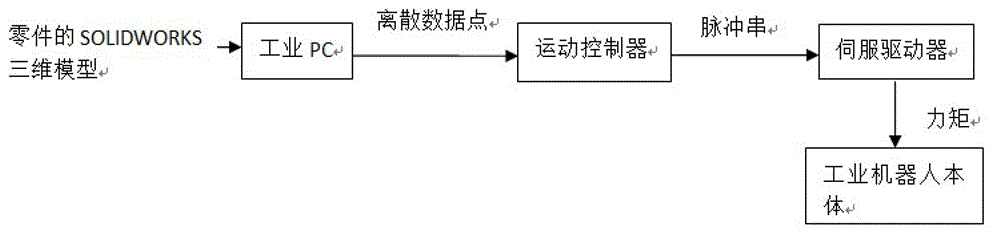

Track generating method facing toward complex curved surface processing and track generating system thereof

InactiveCN103064343AOvercoming the inability to resolve model voidsReduce the number of timesProgramme controlComputer controlIntersection of a polyhedron with a lineMotion controller

The invention discloses a track generating method facing toward complex curved surface processing and a track generating system thereof. The track generating method includes that a to-be-processed complex curved surface is chosen and a standard template library (STL) file is generated; layer dividing direction and layer dividing thickness are determined; group dividing is conducted on a triangular patch; the point of intersection is obtained by an incremental method; a coordinate minimum value point of each section point of intersection gather in the direction of being vertical to the layer dividing direction is found out, another point of intersection of the same triangular patch is searched and connected with the minimum value point, and the process continues until the outline of each tangent plane is obtained and eventually the generating route track is obtained. The track generating system comprises an industrial personal computer (PC), a motion controller, a servo driver and an industrial robot body. The industrial PC generates three-dimensional to-be-processed components into a scattered control point set and transmits the control point set to the motion controller. The motion controller conducts an interpolation calculation on the control point set and outputs pulse trains to the servo driver, and drives the industrial robot body to conduct coordinated movement in a torque control mode. The track generating method facing toward complex curved surface processing and the track generating system thereof have the advantages of small calculation quantity, short calculation time, and high calculation efficiency.

Owner:SOUTH CHINA UNIV OF TECH

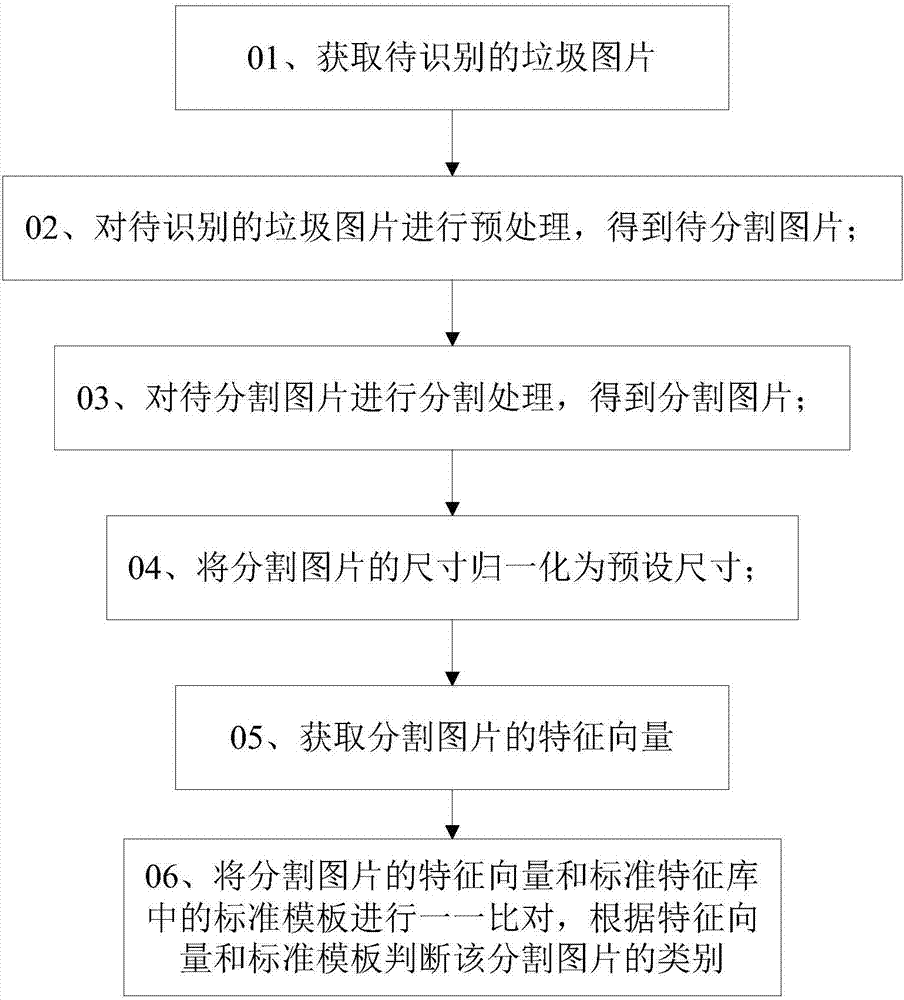

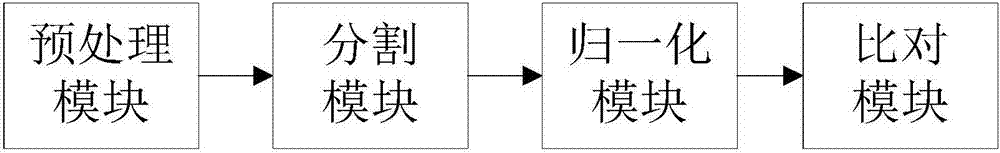

Garbage classification method, device and system based on image identification

ActiveCN107092914AEasy to classifyReduce workloadImage analysisCharacter and pattern recognitionFeature vectorClassification methods

The invention discloses a garbage classification method, device and system based on image identification. The method includes the steps of S1, pre-processing a garbage picture to be identified to obtain a picture to be segmented; S21, segmenting the picture to be segmented to obtain a plurality of sub pictures; S22, acquiring feature information of each sub picture, judging whether the feature information belongs to a preset threshold range, if so, judging the corresponding sub picture as a segmented picture, and if not, performing S23; S23, further segmenting the segmented picture for each sub picture; S3, normalizing the size of each segmented picture into a preset size; and S4, acquiring feature vectors of the segmented pictures, and judging the category of the segmented pictures according to the feature vectors and standard templates in a standard template library. The invention is advantageous in that garbage identification can be quickly performed through the image identification technique, people are assisted in quick garbage classification in daily life, and the workload for secondary garbage sorting is reduced.

Owner:GUANGDONG MATVIEW INTELLIGENT SCI & TECH CO LTD

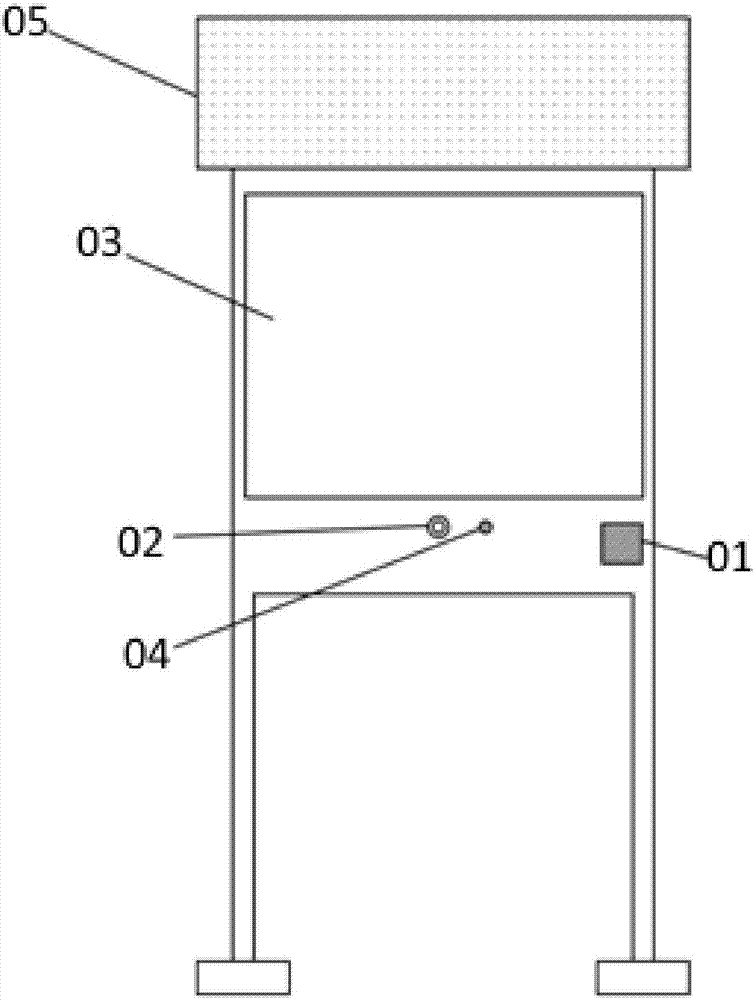

Garbage classification prompting device and system based on image recognition

The invention discloses a garbage classification prompting device and system based on image recognition. The device comprises a garbage classification prompting screen which comprises a camera, an information processor, a display module and a power supply module. The camera is used for sending taken garbage pictures to the information processor. The information processor is used for classifying garbage according the garbage pictures and prestored standard templates in a standard template library, generating classification result information and sending the classification result information to the display module to be displayed. The power supply module is used for supplying power to the camera, the information processor and the display module. The garbage classification prompting device has the advantages of rapidly recognizing garbage through the image recognition technology, helping people to rapidly classify garbage in daily life and reducing the workload of secondary garbage sorting.

Owner:GUANGDONG MATVIEW INTELLIGENT SCI & TECH CO LTD

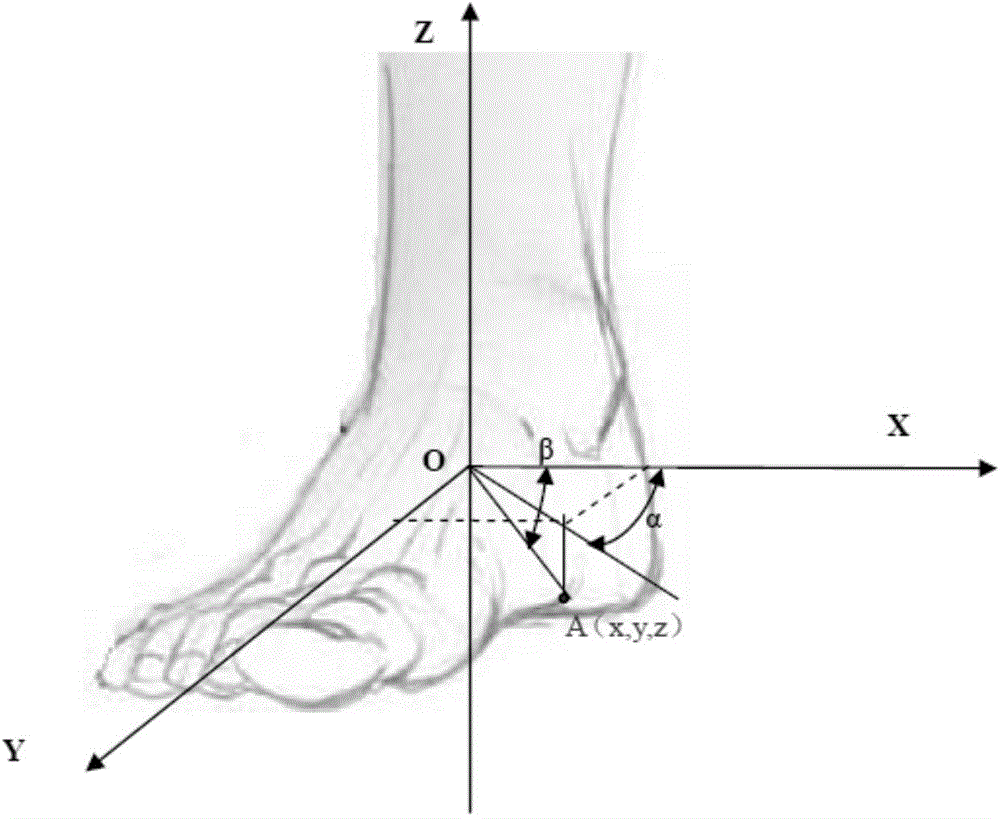

Real-person shoe type copying device and shoe tree manufacturing method based on single-eye multi-angle-of-view robot vision

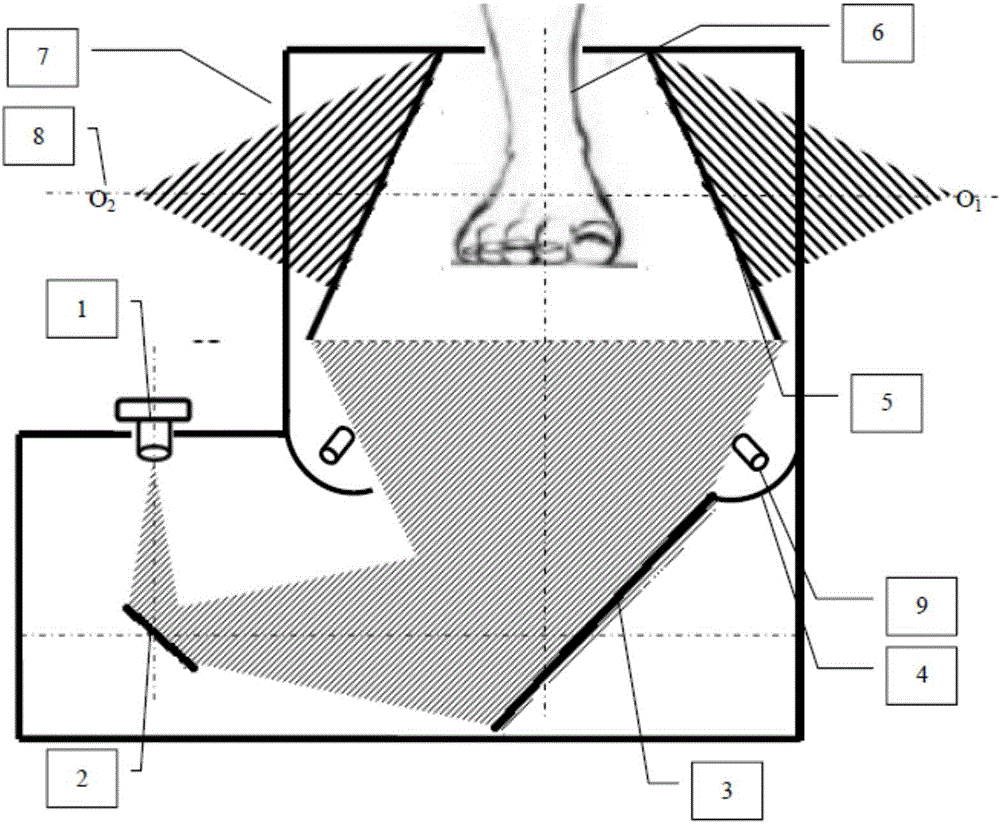

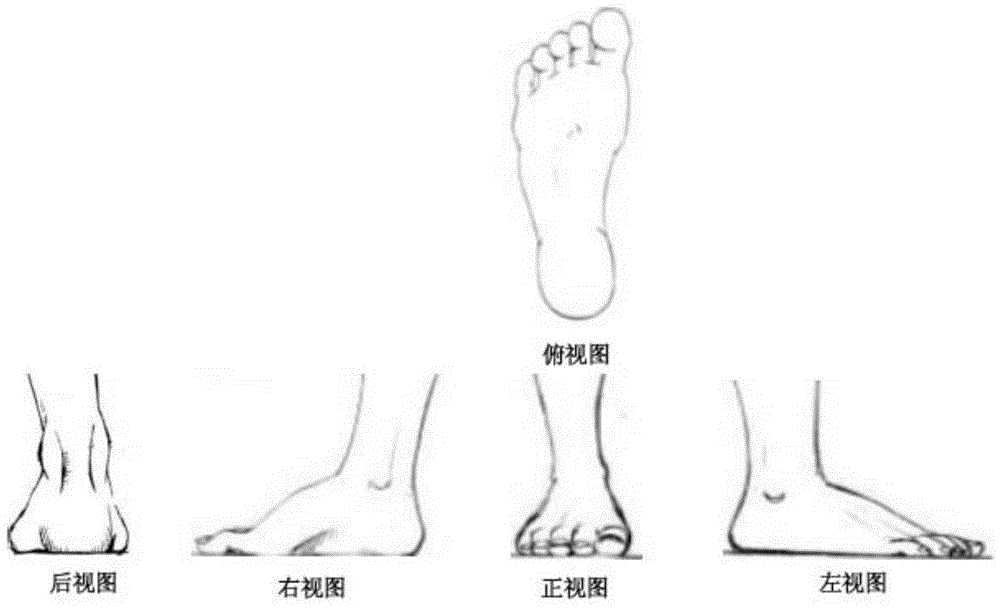

InactiveCN104573180AIncrease silhouetteConstraints for adding silhouettesSpecial data processing applications3D modellingPlane mirrorImage segmentation

The invention discloses a real-person shoe type copying device based on single-eye multi-angle-of-view robot vision. The device comprises a single-eye multi-angle-of-view 3D (Three-dimensional) vision box and a computer, wherein the single-eye multi-angle-of-view 3D vision box is used for shooting images of a foot of a real person at five different angles of view; the computer is used for achieving the 3D reconstruction of the foot of the real person and automatically generating a 3D printing file; a plane mirror rectangular bucket-type cavity is formed inside the single-eye multi-angle-of-view 3D vision box and consists of four trapezoidal mirror planes; the upper part of a mirror body is large, and the lower part of the mirror body is small; the mirror planes face the inner side of a cavity body; a light source used for providing uniform soft lighting for the foot of the real person is arranged at the lower part of the plane mirror rectangular bucket-type cavity; cameras used for obtaining the images of the foot of the real person at multiple angles of view according to the refraction and reflection principle of the mirror planes are further arranged in the single-eye multi-angle-of-view 3D vision box; the computer comprises a single-eye multi-angle-of-view 3D vision calibrating unit, an image division, conversion and correction unit, a real person foot surface shape measurement unit and an automatic STL (Standard Template Library) file generation unit. The invention further discloses a shoe tree manufacturing method based on the single-eye multi-angle-of-view robot vision.

Owner:ZHEJIANG UNIV OF TECH

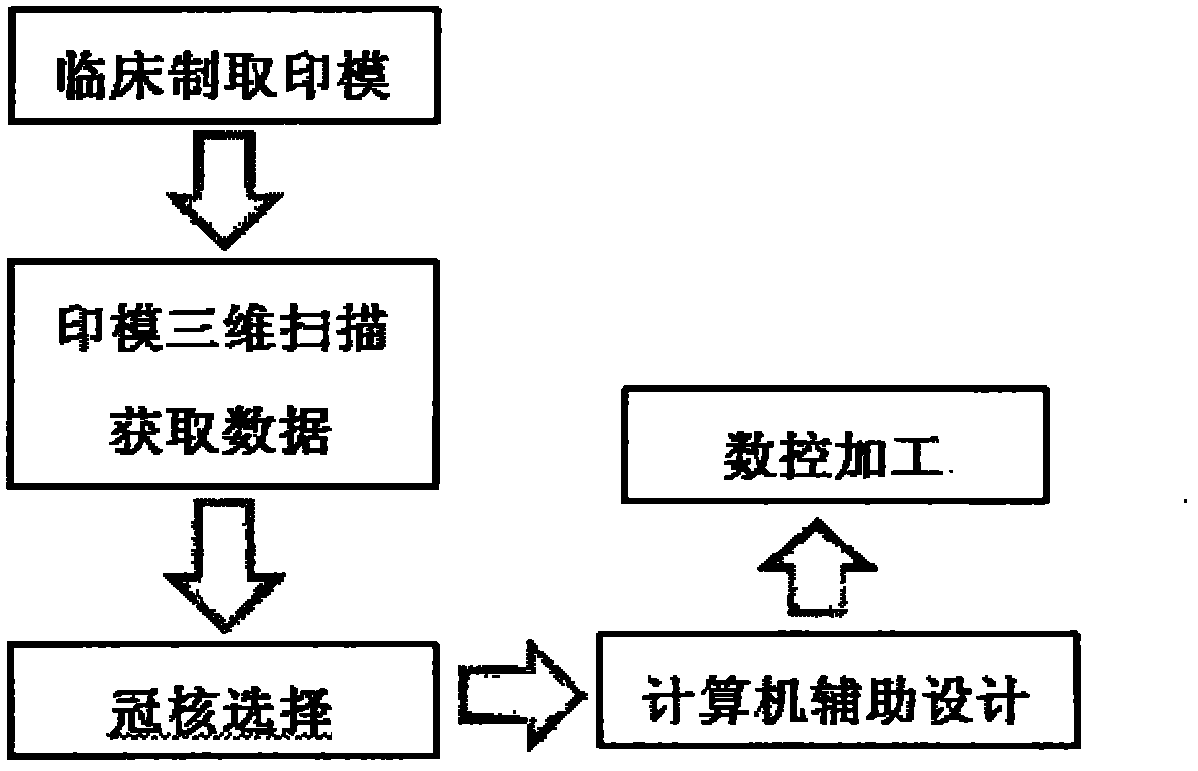

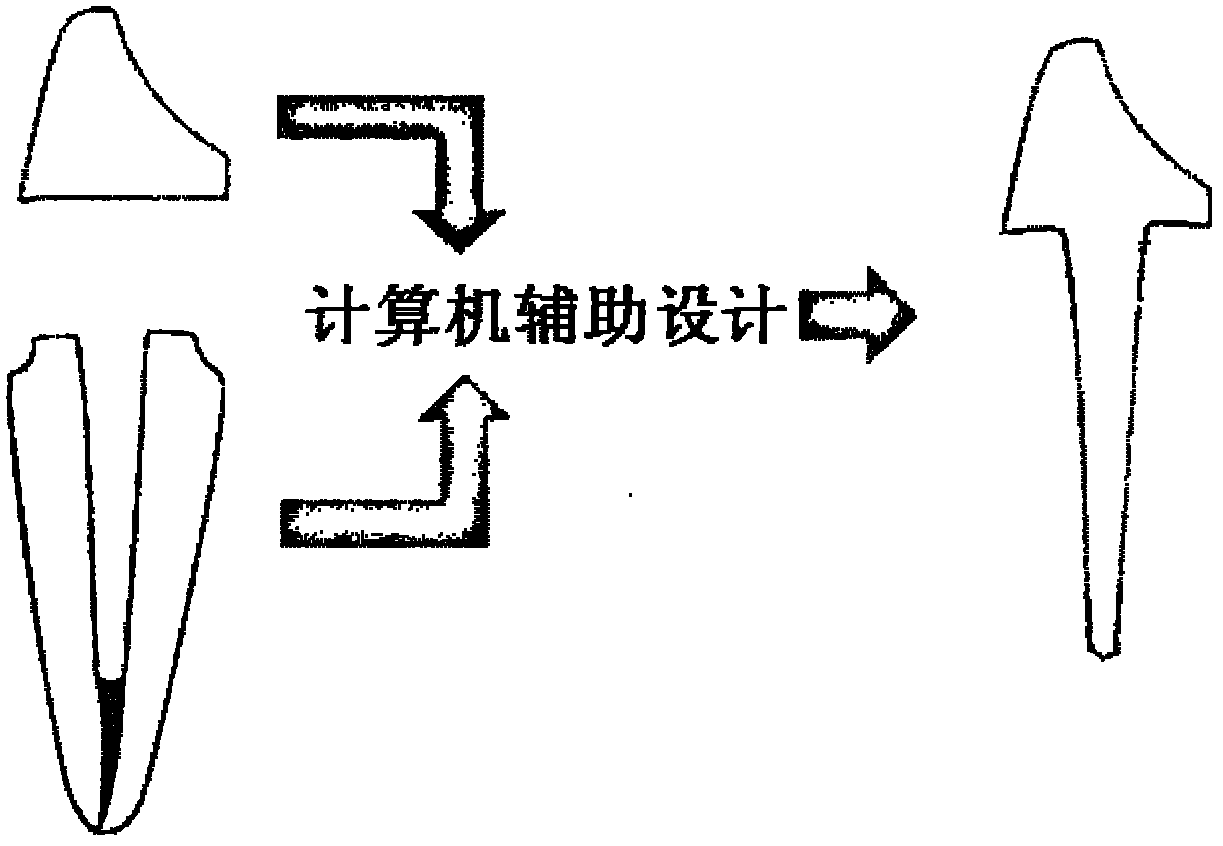

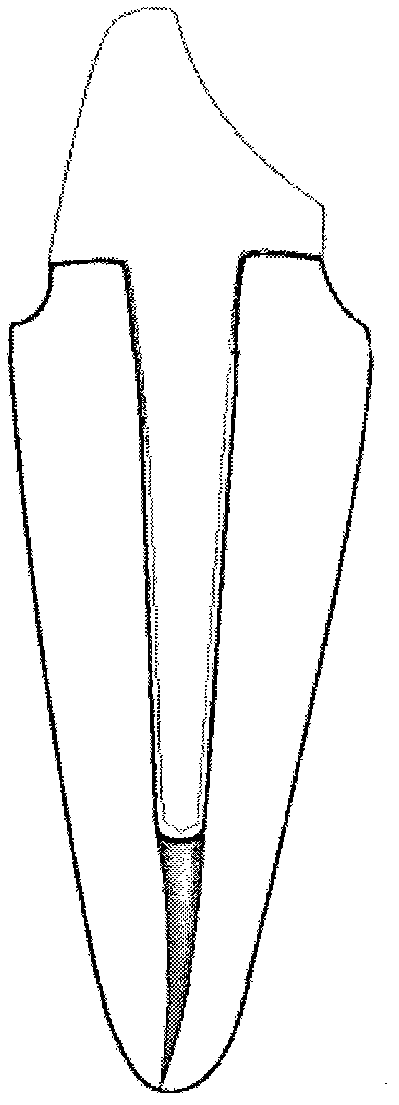

Computer-aided design making method for dental personalized integrated non-metal post core

InactiveCN102426614AShort consultation cycleOmit stepsTeeth fillingSpecial data processing applicationsPersonalizationNumerical control

The invention discloses a computer-aided design making method for a dental personalized integrated non-metal post core. The method comprises the following steps of: 1, performing tooth preparation to make a silicon rubber impression duplication defect tooth form; 2, acquiring impression three-dimensional data by using a high-accuracy optical scanner; 3, selecting a proper crown core from a database; 4, finishing stitching and processing of defect root canal and section data and crown core data through three-dimensional design software, and establishing a virtual model for the personalized integrated post core; and 5, importing post core data in an STL (Standard Template Library) format into a computer-aided making numerical control center, and selecting a proper non-metal blank to process into a personalized integrated post core entity. Through the computer-aided design making method for the dental personalized integrated non-metal post core, the processes of perfusion of a plaster model, making of a wax pattern and the like are saved, a processing period is shortened, a making error is reduced, higher accuracy can be achieved, the post core entity and the remaining tooth tissue have better fitness, the fracture resistance of a post core prosthesis can also be enhanced, and the risk of repair failure is reduced.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Method and device for designing standard cell library and integrated circuit

InactiveCN101539958AIncrease profitReduce dynamic power consumptionSpecial data processing applicationsDesign standardStandard Template Library

The invention discloses a method and a device for designing a standard cell library. The method comprises a step of designing a common standard cell, and also comprises a step of designing a double-edge flip-flop cell, and the step of designing the double-edge flip-flop cell comprises: when determining the type of the standard cell, adding the double-edge flip-flop cell to the standard cell type; designing a schematic diagram of the double-edge flip-flop cell; and designing a diagram of the double-edge flip-flop cell. A mold of the double-edge flip-flop cell is established, and the method for establishing the mold comprises the following steps of: establishing a rising edge comprehensive library and a falling edge comprehensive library for the double-edge flip-flop; and establishing a double-edge flip-flop simulated library for the double-edge flip-flop. The invention also discloses a method and a device for designing an integrated circuit. Due to the method and the device, the rising edge and the falling edge for each jump of the clock signal can serve the logical function of a chip, so that the jumping frequency of the clock, needed to complete the same logical function, is reduced, and the dynamic energy consumption of the circuit is also lowered.

Owner:北京芯汇中秀电子技术有限公司

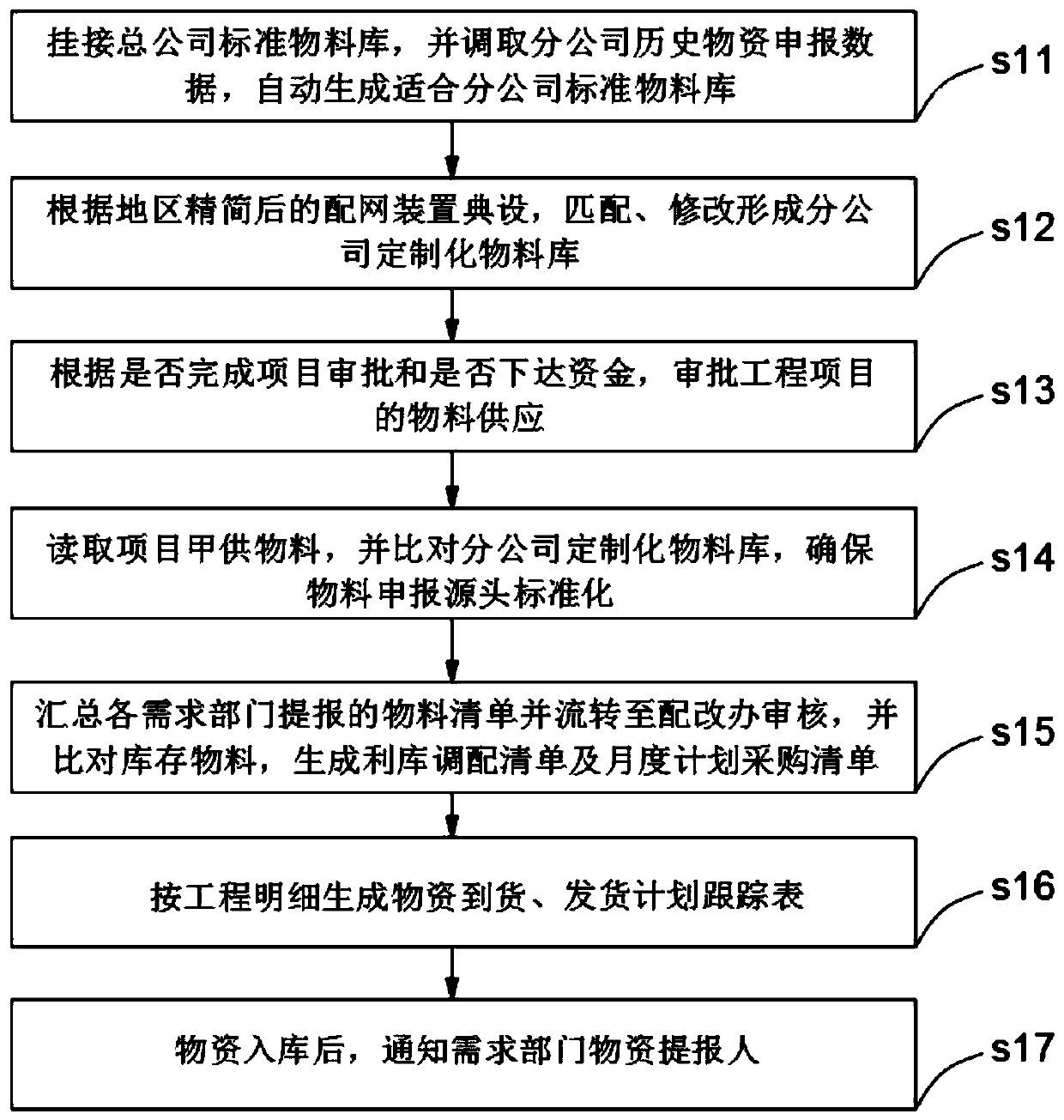

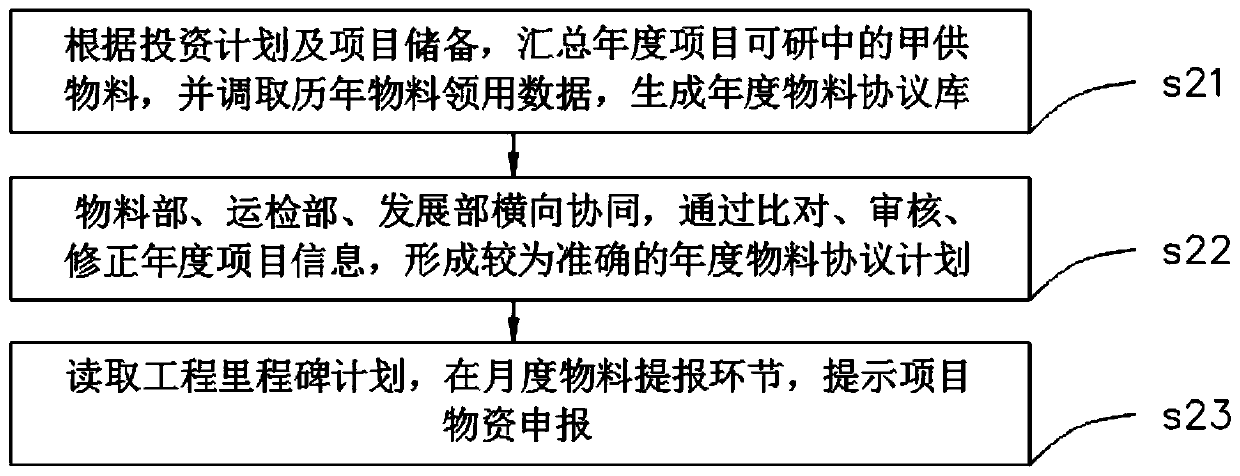

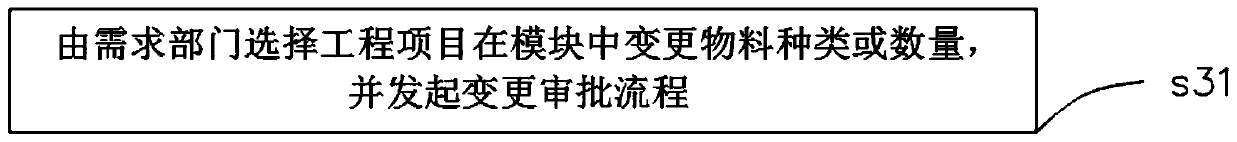

A distribution network material plan management method and system

ActiveCN109697550AA wide variety of solutionsSolve complexityResourcesLogisticsDesign standardProgram planning

The invention provides a distribution network material plan management method and system, and the method comprises the steps: carrying out the matching of a network province company standard materiallibrary according to the simplified distribution network device typesetting of a region, and forming a branch company customized standard material library; predicting an annual material demand plan according to materials such as an annual comprehensive plan, a project feasibility plan and the like; determining a monthly object demand plan according to the engineering project comprehensive plan, the implementation progress of the engineering and the determined engineering construction scheme and the supply period of the unified purchase and distribution materials; according to the final matching result of the province company, an order is created in time, and the matching result is imported to form a material arrival and delivery tracking table; material change caused by engineering designchange and the like is coordinated in time by tracking the actual performance condition of unified purchased materials in time; and the design standard is reversely improved by comparing the difference between the material utilization and the plan in the project. The invention provides a distribution network material plan management method and system which can improve the material plan managementlevel of a unit and improve the professional operation capability of materials.

Owner:STATE GRID ZHEJIANG HANGZHOU CITY FUYANG DISTRICT POWER SUPPLY CO LTD +2

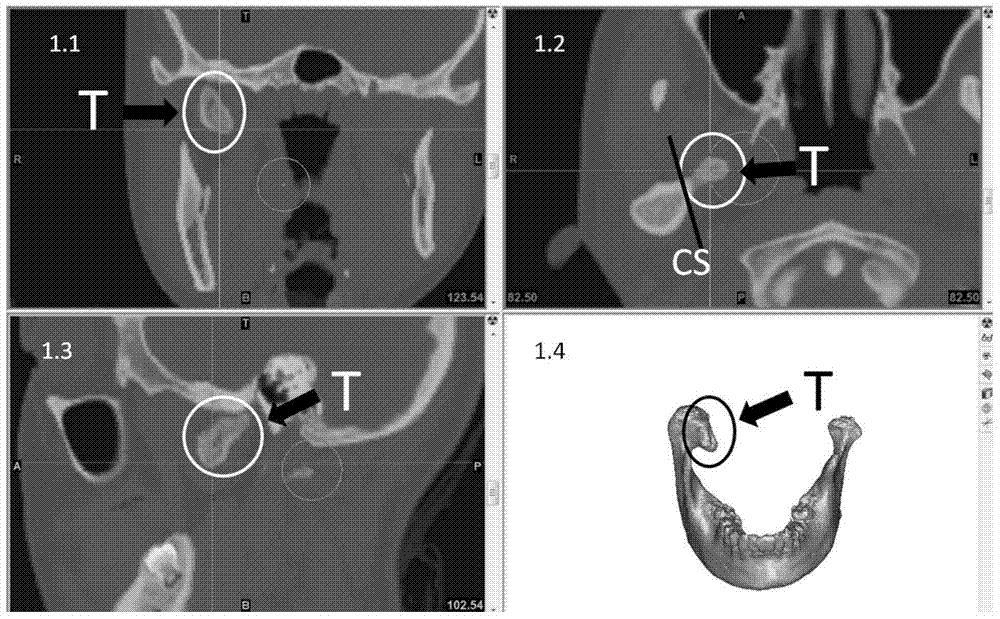

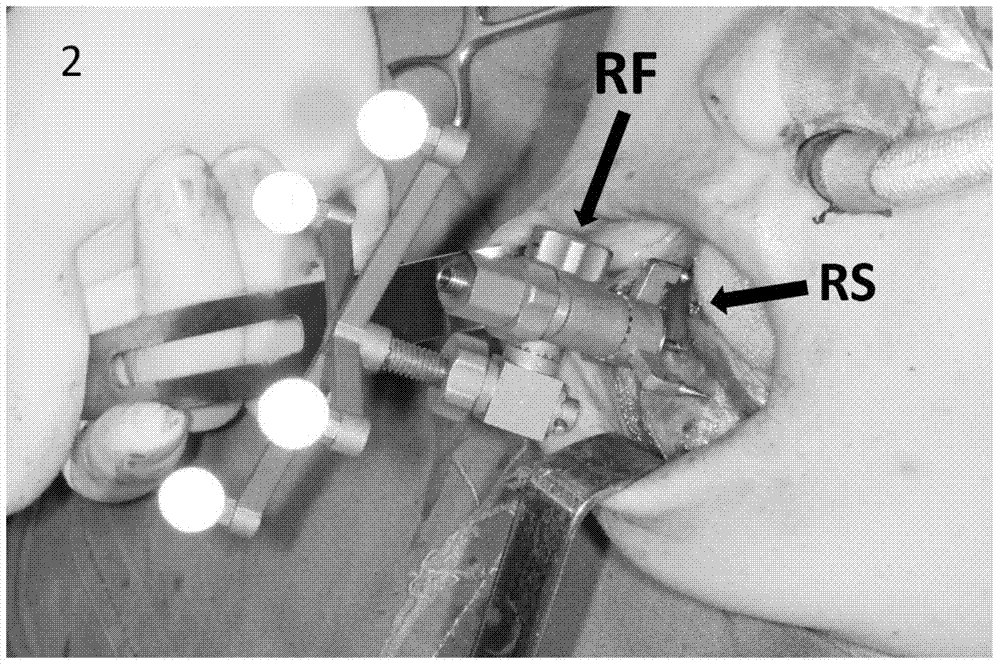

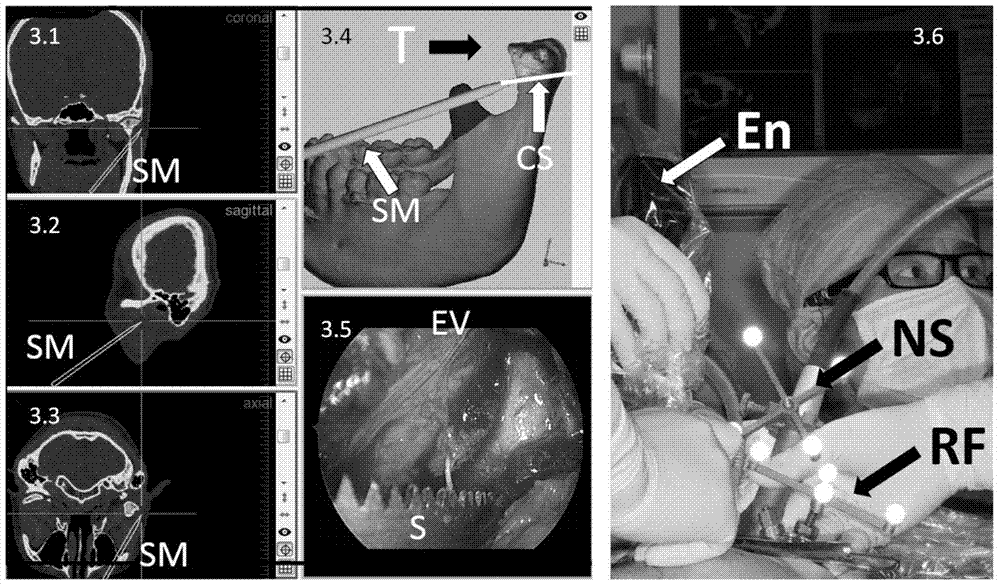

Application of digitization technology to oral approach mandibular condylar lesion surgical excision

InactiveCN104720877APostoperative cosmetic effectMinimally invasiveSpecial data processing applicationsSurgical sawsDigital imagingNavigation system

The invention relates to application of a digitization technology to oral approach mandibular condylar lesion surgical excision. The application comprises the following steps: planting five self-tapping titanium screws into a mandible of a patient to be used as registration mark points of a navigation system in a surgery; photographing maxillofacial region CT (Computed Tomography) scanning and storing in a DICOM (Digital Imaging and Communications in Medicine) format; establishing a patient lesion three-dimension pattern; designing an osteotomy face and an osteotomy range according to a lesion boundary; introducing navigation software in an STL (Standard Template Library) format to reestablish a three-dimensional geometrical model; mounting a navigation reference frame, and registering by using a navigation positioning probe and the mark points; setting an incision and dissecting and separating a joint capsule under an endoscope view to expose a condylar process; searching an osteotomy face position by using the positioning probe and calibrating a coordinate of a bone saw; adjusting the bone saw to the position of the osteotomy face and the cutting angle; and under the guidance of the incision stretched endoscope probe and a navigation positioning image, carrying out condylar osteotomy by holding the bone saw via a surgery doctor. By the aid of the application, the surgery doctor can accurately cut off condylar tumors according to preoperative plans, so the ideals of minimally invasive surgery and accurate surgery are uniformed.

Owner:王旭东 +1

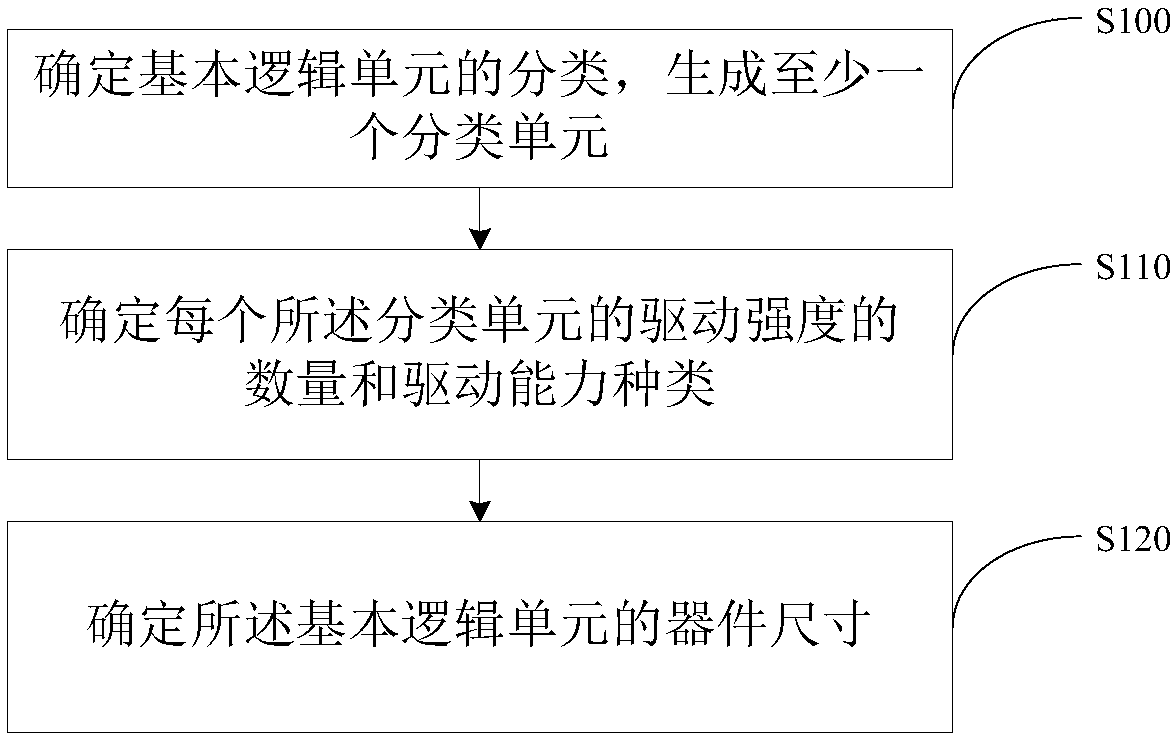

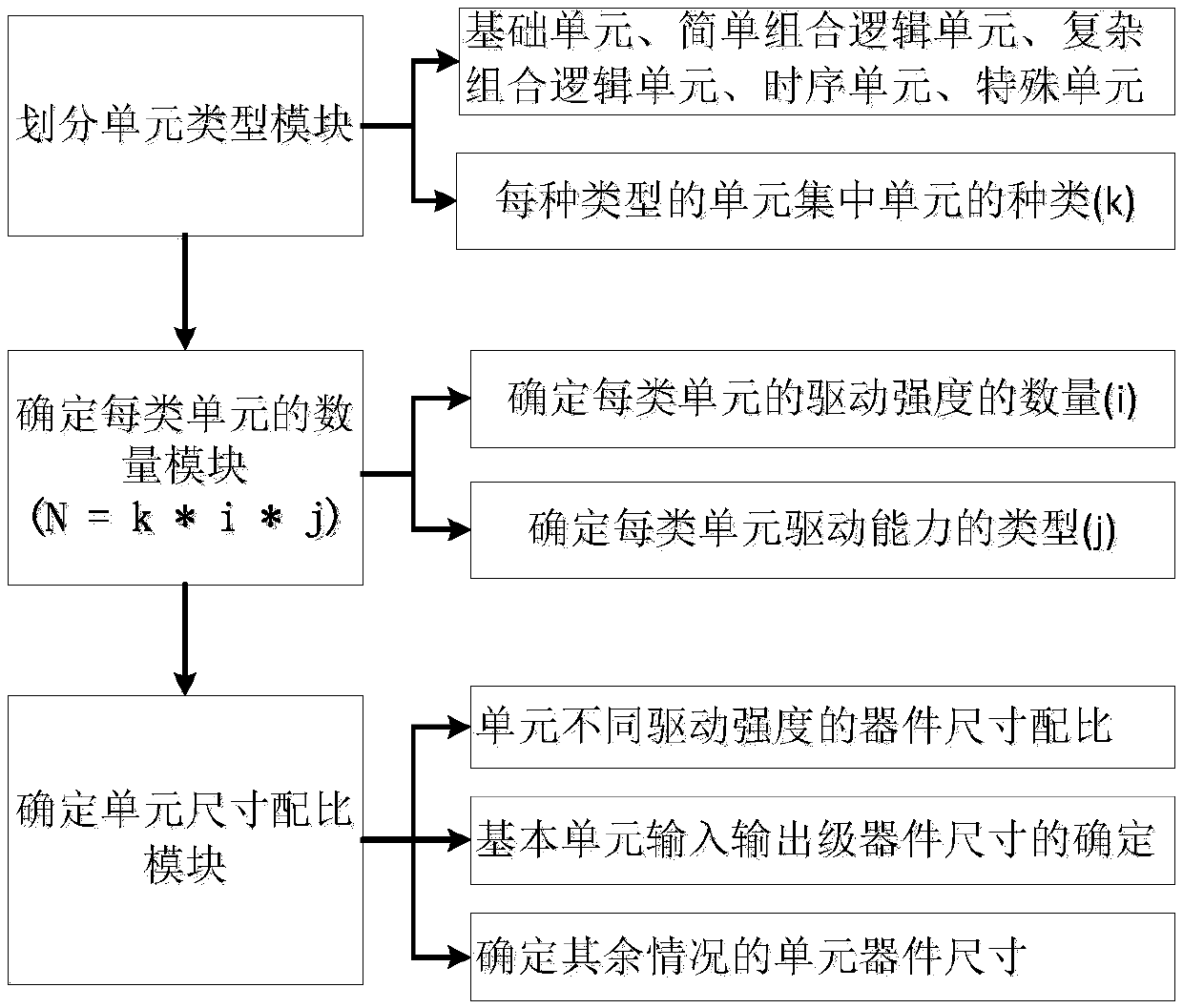

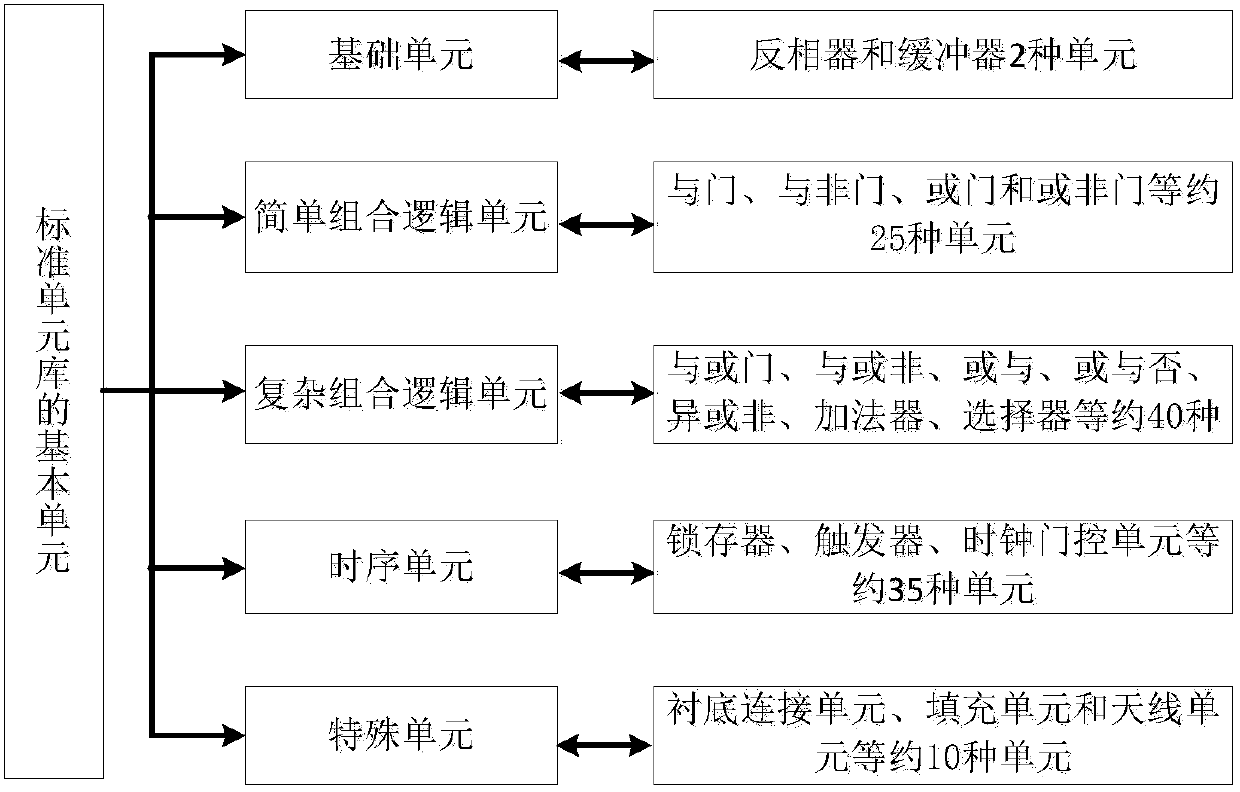

Creating method and system for standard cell library

ActiveCN107784136AImprove consistencyConfiguration CADCAD circuit designComputer architectureLogic cell

The embodiment of the invention provides a creating method and system for a standard cell library. By determining the classification of a basic logical unit, at least one classification unit is generated, and then the amount of driving strength of each classification unit is determined, and finally the component size of the basic logical unit is determined. Each basic logical unit of the standardcell library is reasonably allocated by the creating method and system, effectively achieving the balance of timing sequence and area of a chip during an ASIC design process can be guaranteed, and chip area waste caused by adopting multiple units combinations which is due to the lack of corresponding drive can be prevented. In addition, a matching ratio of the basic logical unit is defined, a schematic diagram of a unit circuit is convenient to quickly achieve, the time of design and development of the standard cell library is effectively shorten, a good drive consistency is provided, the rapid convergence of critical path timing sequence of the chip is facilitated, the number of invalid iterations of repairing timing sequence violations in the processes of logic synthesis and locating andwiring is obviously reduced, and the efficiency of designing a large scale integrated circuit is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

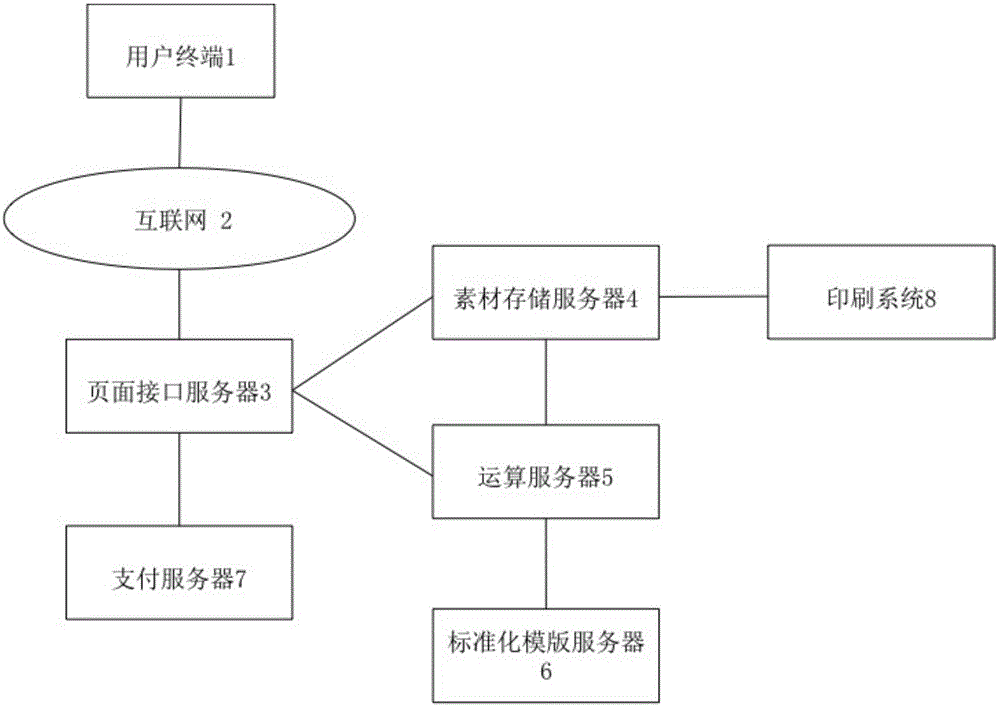

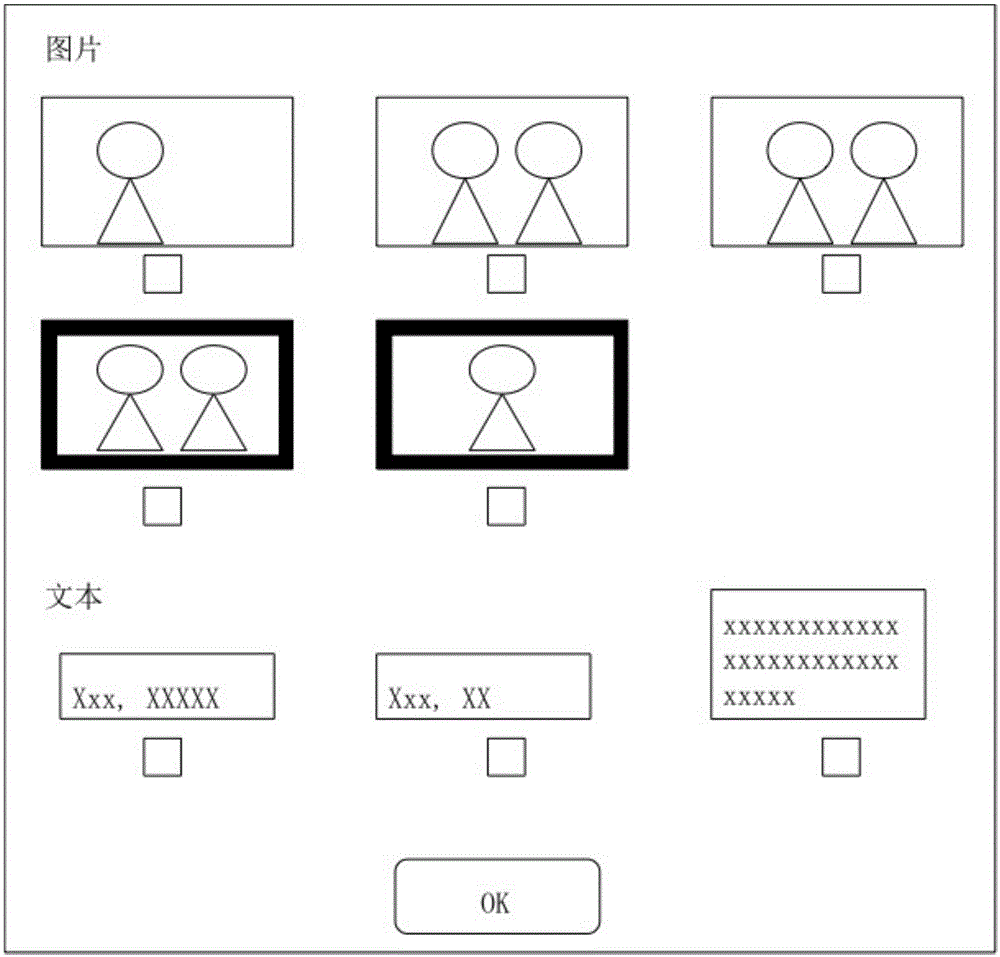

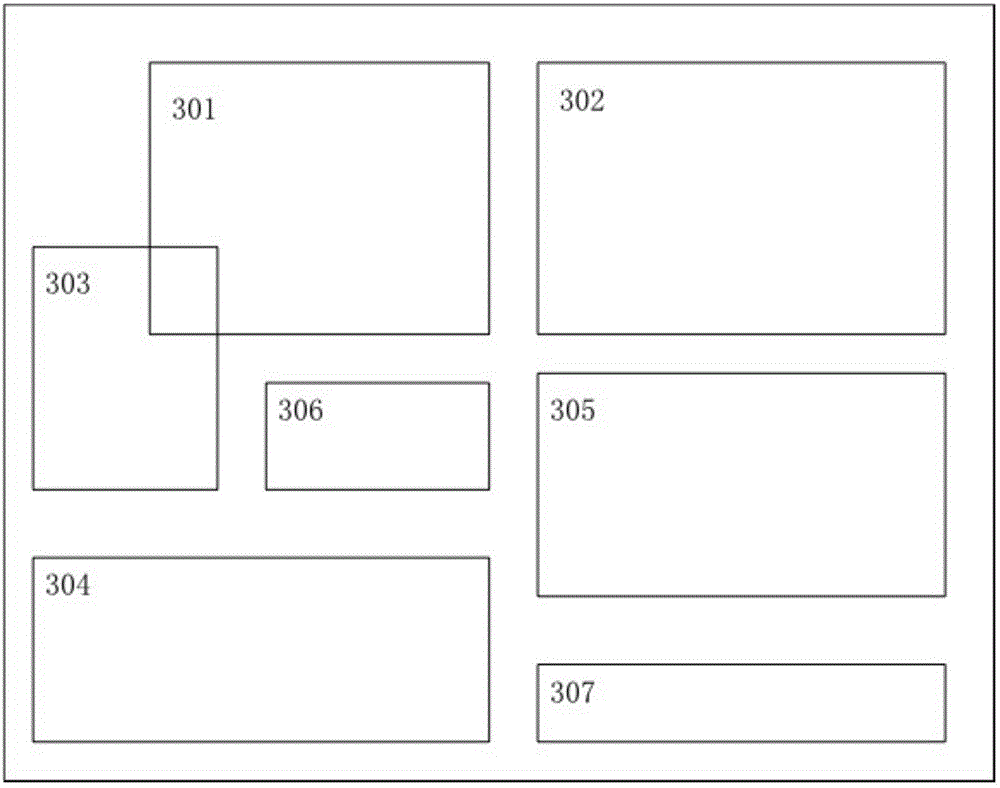

Printed matter on-line design service cloud platform and on-line design method thereof

The invention provides a printed matter on-line design service cloud platform and an on-line design method thereof. On one hand, mass standardized templates are aggregated, and analysis is conducted on the standardized templates to form adaptability condition parameters; on the other hand, the mode that a user selects a template and then fills the template with materials during printed matter layout on-line design is changed into the mode that the user provides the materials, material description information is generated according to the materials, the standardized templates with the adaptability condition parameters meeting the requirements are screened out through template retrieval operation with the material description information as the condition, the matching degree sequence is generated, and the standard templates are recommended to the user according to the sequence. By means of the printed matter on-line design service cloud platform and the on-line design method, the templates satisfying the requirements and materials of the user are pushed to the user from mass-grade standardized template resources of a template library, time consumed when the user browses a large amount of template resources is saved, and difficulty caused to the printed matter layout design when the matching degree of the selected templates and the materials is not high is avoided.

Owner:武汉改图网技术有限公司

Near-net-shape forming method of refractory metal part

InactiveCN102773479APromote absorptionImprove bindingAdditive manufacturingIncreasing energy efficiencySelective laser meltingSoftware design

The invention discloses a near-net-shape forming method of a refractory metal part, aiming at solving the complexity and the time consumption of a PM (power metallurgy) molding mode, and compensating the technical defect that the comprehensive property of an alloy cannot brought into play completely due to the fact that an SLM (selective laser melting) method liquid phase quantity cannot achieve the technical index of 30-35Vol / % of the densification. The method provided by the invention is as follows: 1, three-dimensional modeling software is adopted to design a CAD (computer-aided design) of a part, subsequently multiple layer slicing information is generated by slicing processing software, and an STL (Standard Template Library) file is stored, and the data of the STL file is transmitted to an SLM rapid molding system; 2, a layer of metal powder to be machined (the thickness ranges from 0.02-0.2mm, and the particle diameter is about 10-100 micrometer) is paved on a working platform by a powder conveying mechanism; 3, an optical fiber laser is adopted to scan the slicing, and the metal powder to be machined paved in the step 2 is completely melted, wherein the scanning speed is 50-1000mm / s; and 4, the steps (2) and (3) are repeated till the whole part machining is ended. The method has the beneficial effects that the powder is subjected to alloying, the bonding property of the alloy is improved, thereby being beneficial for the filling and the molding densification of the liquid, and improving the comprehensive property of the alloy.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

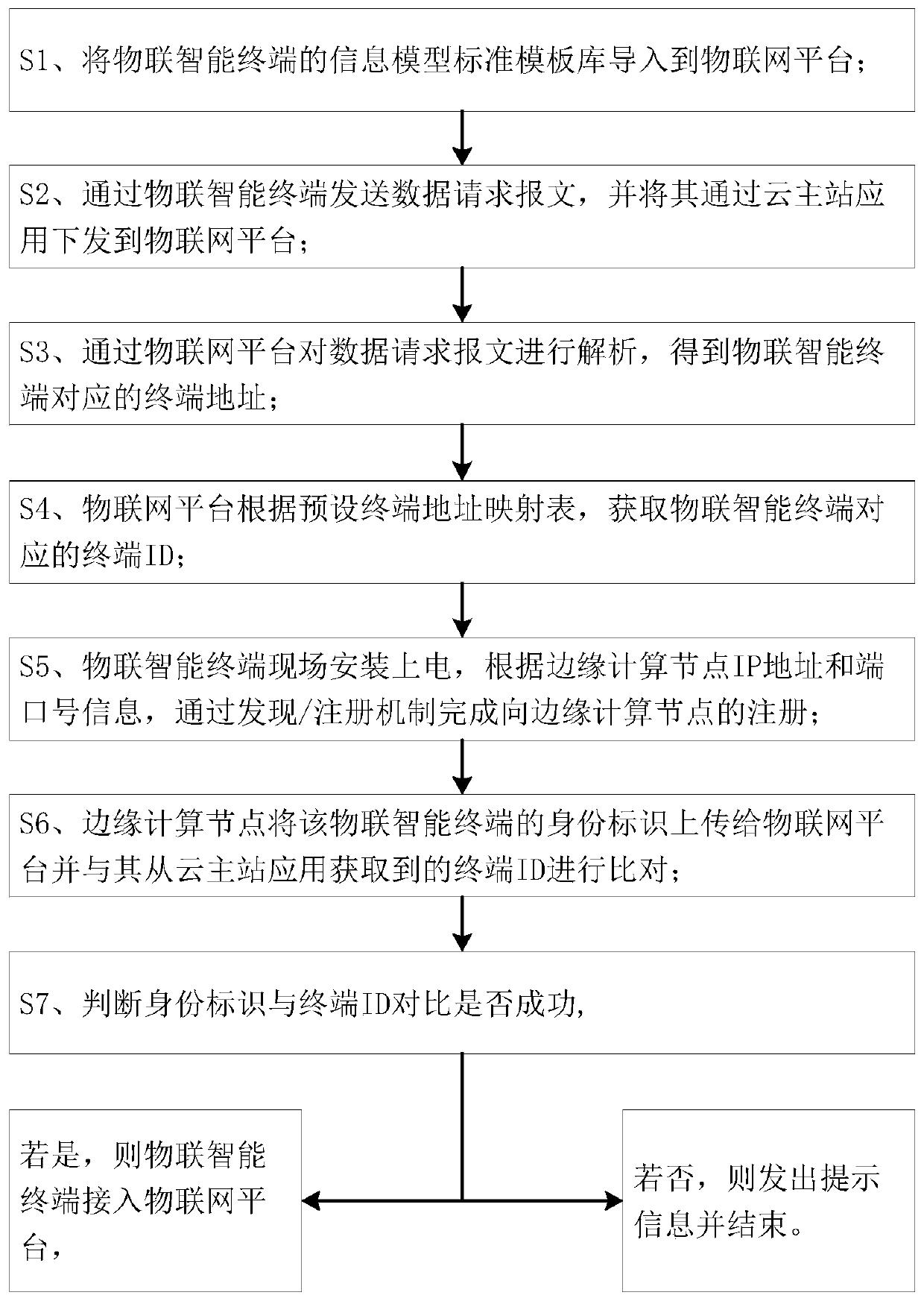

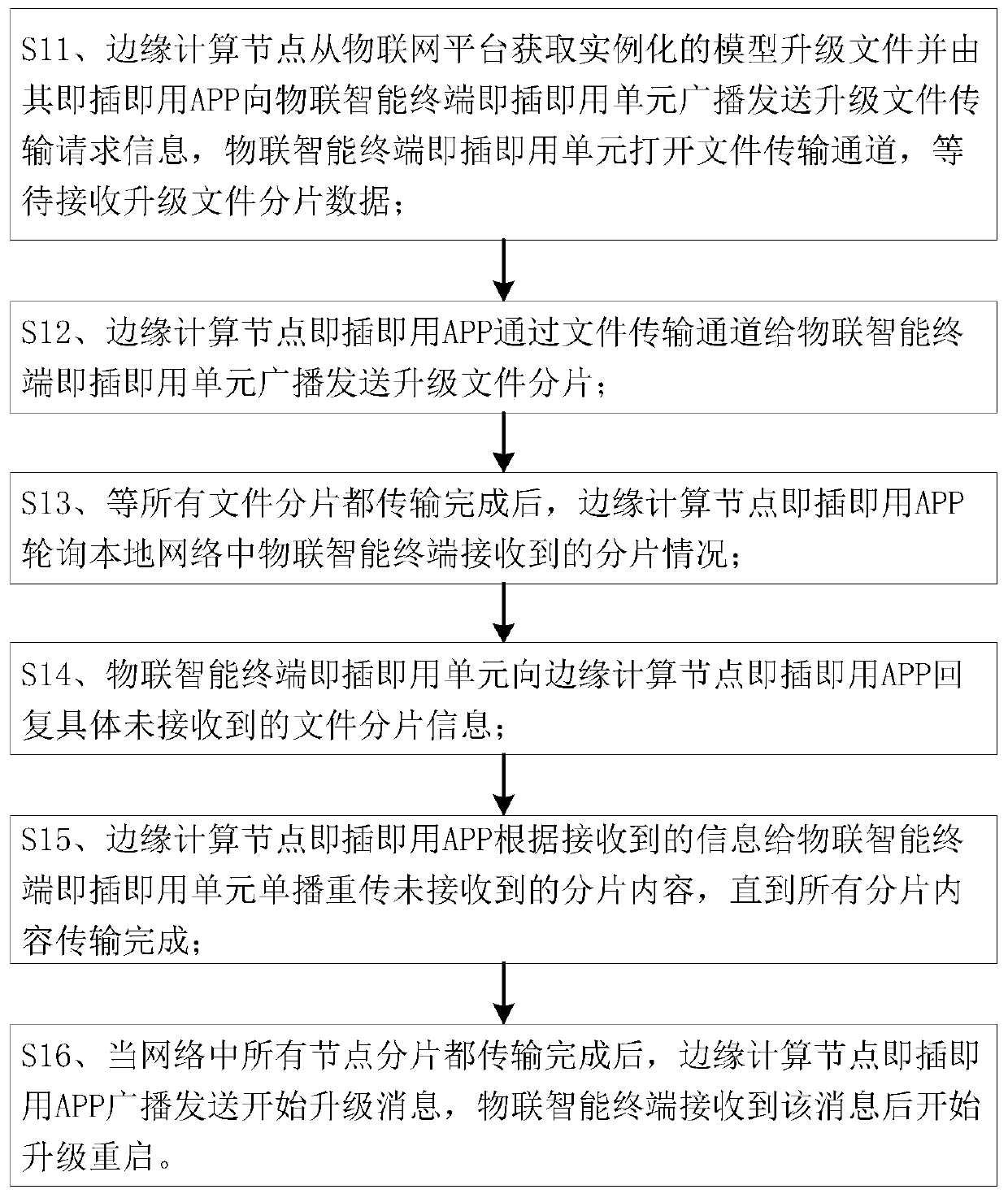

Method for adaptively accessing Internet of Things intelligent terminal to ubiquitous power Internet of Things

ActiveCN111262859AEasy accessAlleviate distribution network growthUser identity/authority verificationEdge computingThe Internet

The invention provides a method for adaptively accessing an Internet of Things intelligent terminal to a ubiquitous power Internet of Things. The method comprises the steps of S1 importing an information model standard template library of the Internet of Things intelligent terminal into an Internet of Things platform; S2 sending a data request message through the Internet of Things intelligent terminal; S3 analyzing the data request message through the Internet of Things platform to obtain a terminal address corresponding to the Internet of Things intelligent terminal; S4 acquiring a terminalID corresponding to the Internet of Things intelligent terminal; S5 installing the Internet of Things intelligent terminal and powering on on site, and completing registration through a discovery / registration mechanism; S6 enabling the edge computing node to upload the identity identifier of the Internet of Things intelligent terminal to an Internet of Things platform and compares the identity identifier with a terminal ID obtained from a cloud master station application; and S7 judging whether the identity identifier is successfully compared with the terminal ID or not, if so, accessing the Internet of Things platform by the Internet of Things intelligent terminal, and if not, sending out prompt information and ending. The problem that a large number of Internet of Things intelligent terminals have access to the ubiquitous power Internet of Things is solved.

Owner:NANJING NENGDI ELECTRICAL TECH

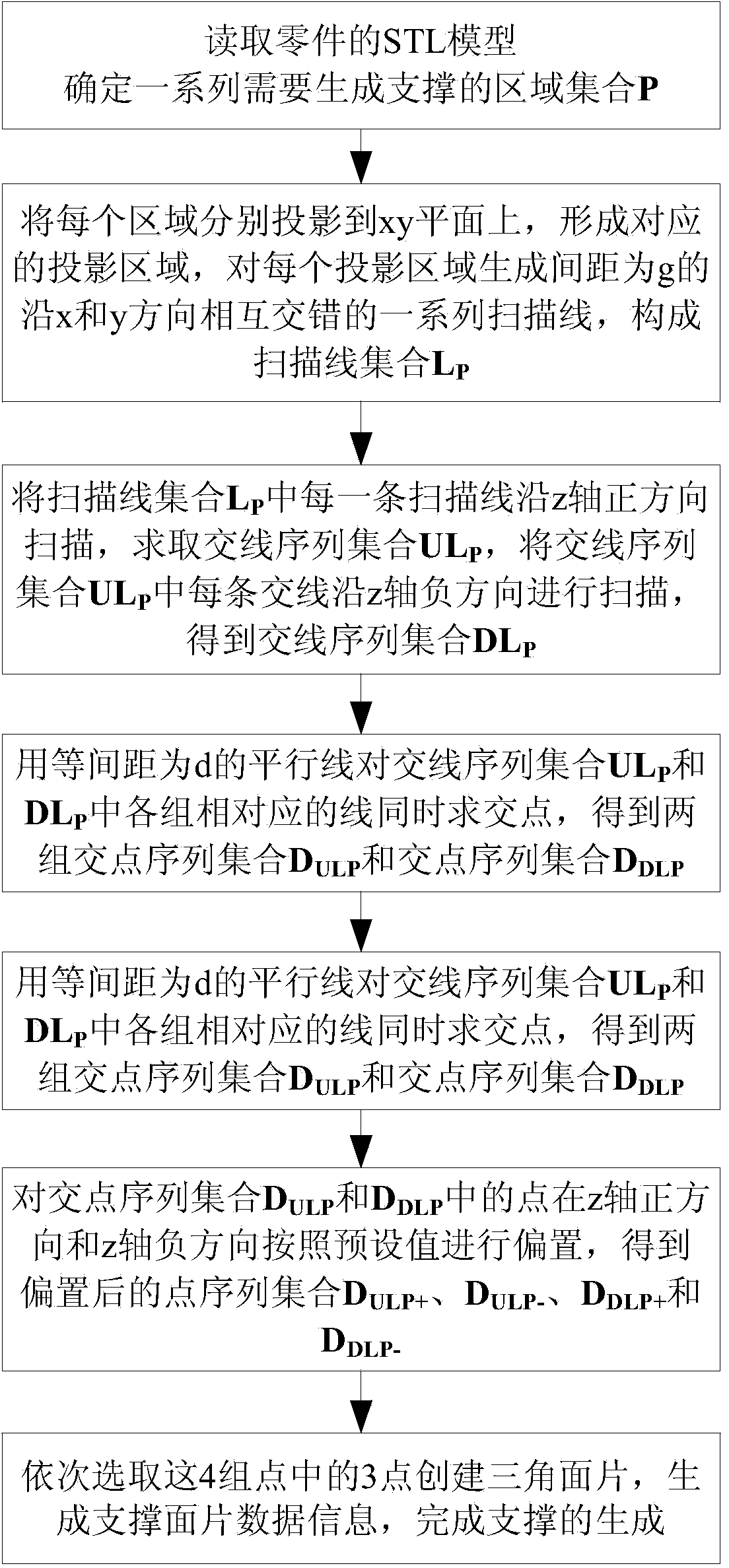

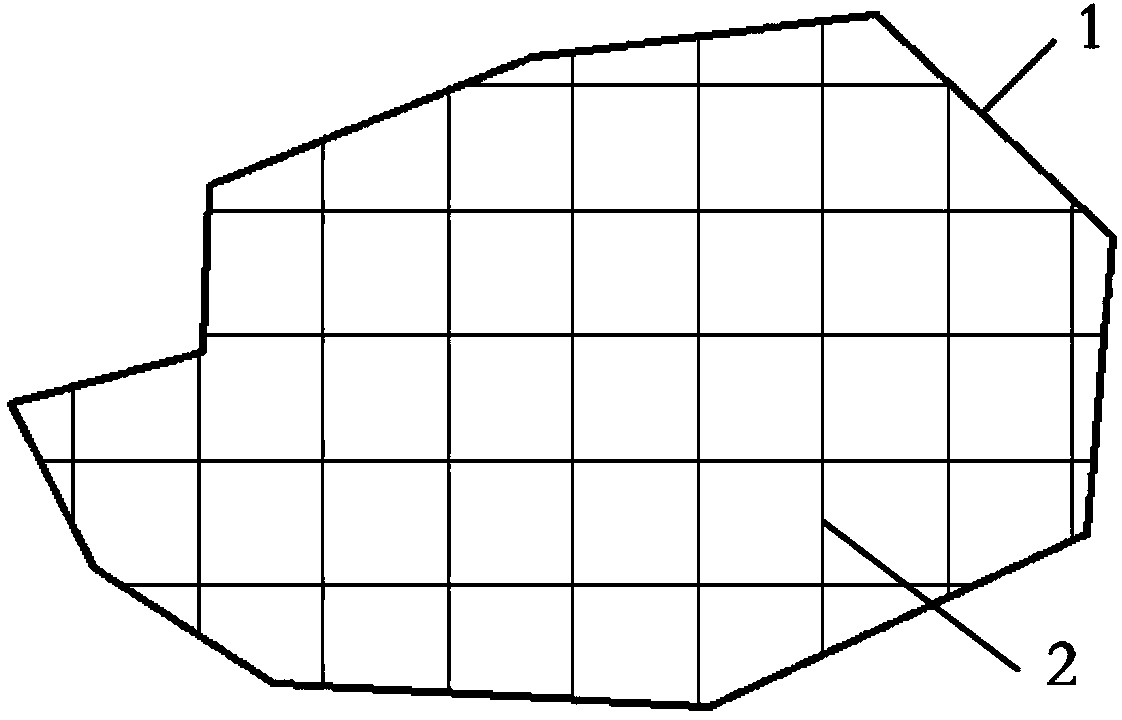

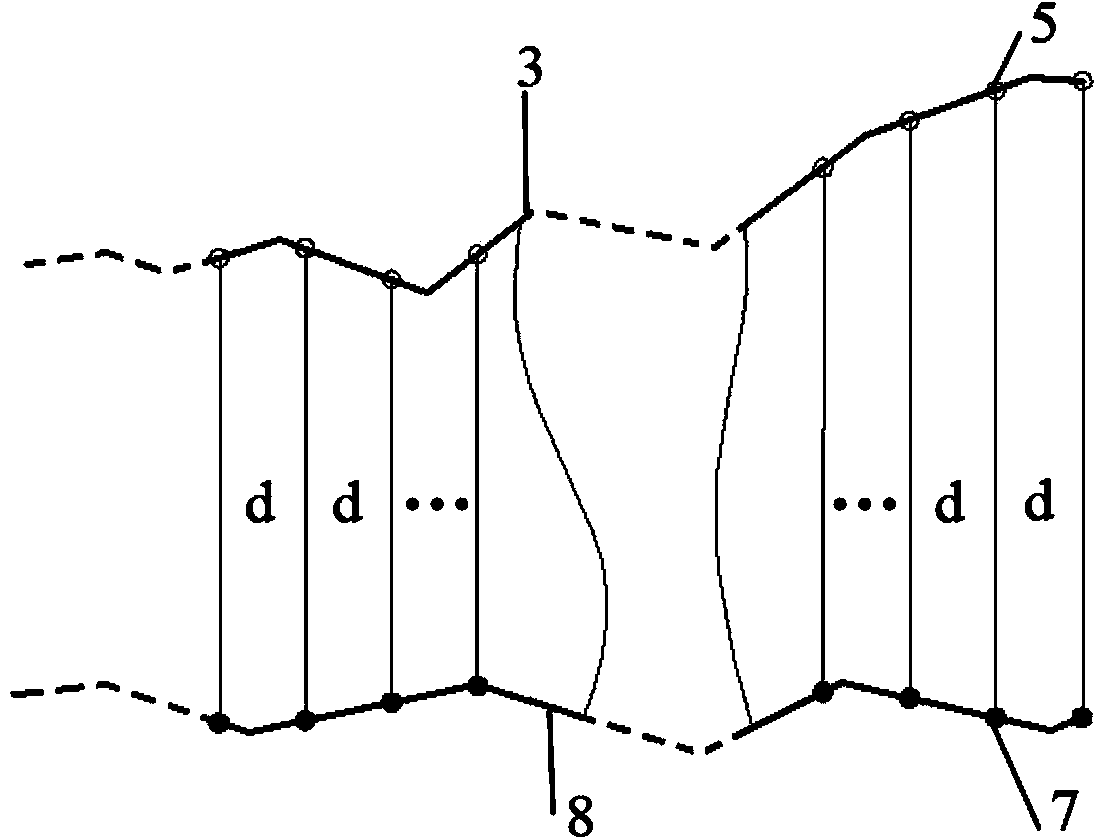

Method for automatically generating support of three-dimensional printing part on basis of scanning biasing

ActiveCN103823928AQuality improvementEasy to operateSpecial data processing applicationsPoint sequenceProject area

The invention discloses a method for automatically generating a support of a three-dimensional printing part on the basis of scanning biasing. The method comprises the following steps of determining an area gather requiring a support in an STL (standard template library); respectively projecting areas in the area gather on an xy plane to form projection areas; generating a series of scanning lines which are mutually staggered along the x direction and the y direction on each projection area so as to form a scanning line gather; scanning the scanning lines in the scanning line gather along the z-axis direction; solving two intersection line sequence gathers; solving an intersection point of the two intersection sequence gathers by using parallel lines of which the spacing distances are (d) so as to obtain two groups of intersection point sequence gathers; classifying the two groups of intersection point sequence gathers and biasing the two groups of intersection point sequence gathers in the z-axis direction so as to obtain four groups of corresponding biased point sequence gathers; sequentially selecting three groups of biased point sequence gathers from the four groups of corresponding biased point sequence gathers to create a triangular patch; generating data information of the supporting patch; and generating the support. By using the method, the support of the three-dimensional printing part is generated automatically. The method is clear in principle and easy to operate.

Owner:ZHEJIANG UNIV

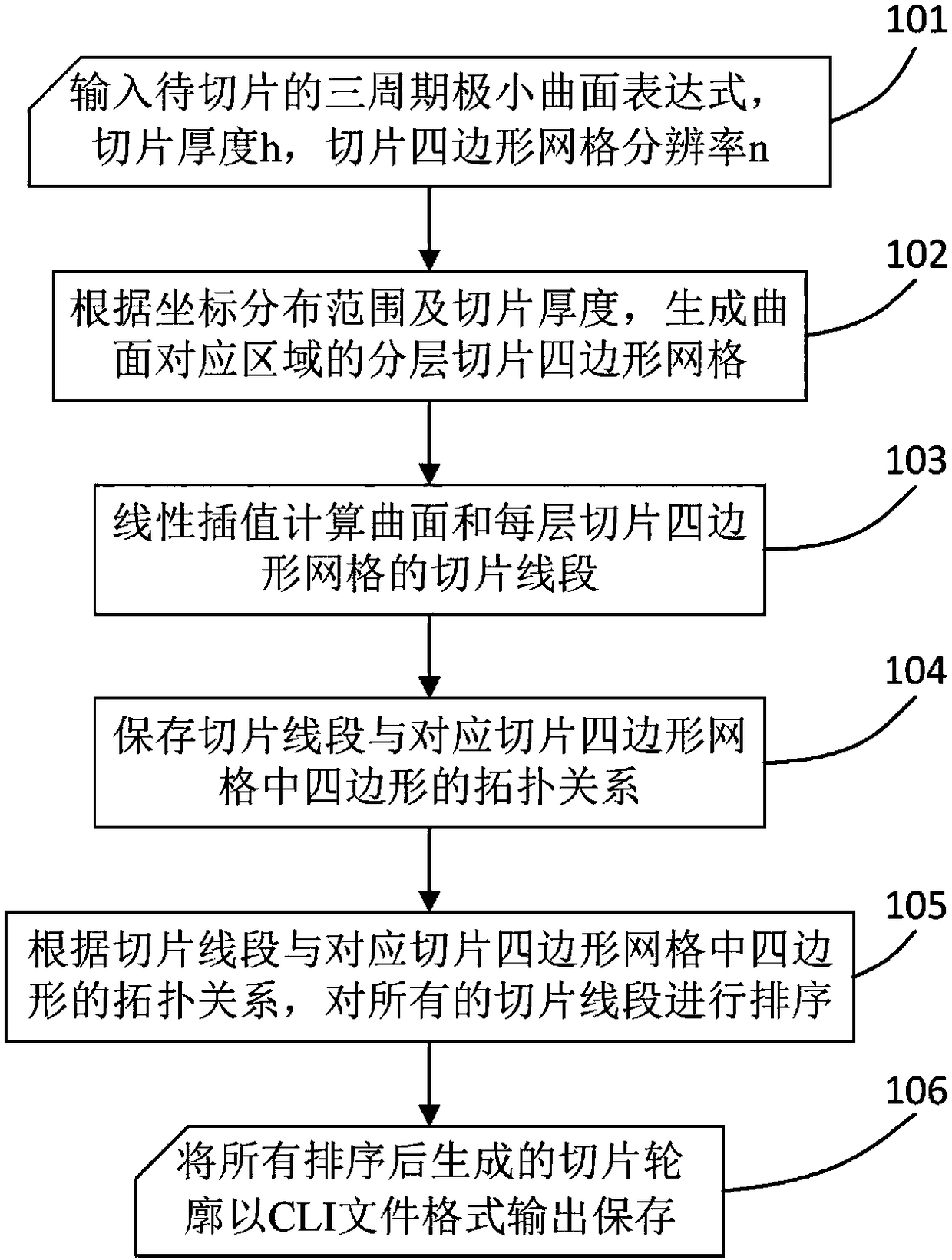

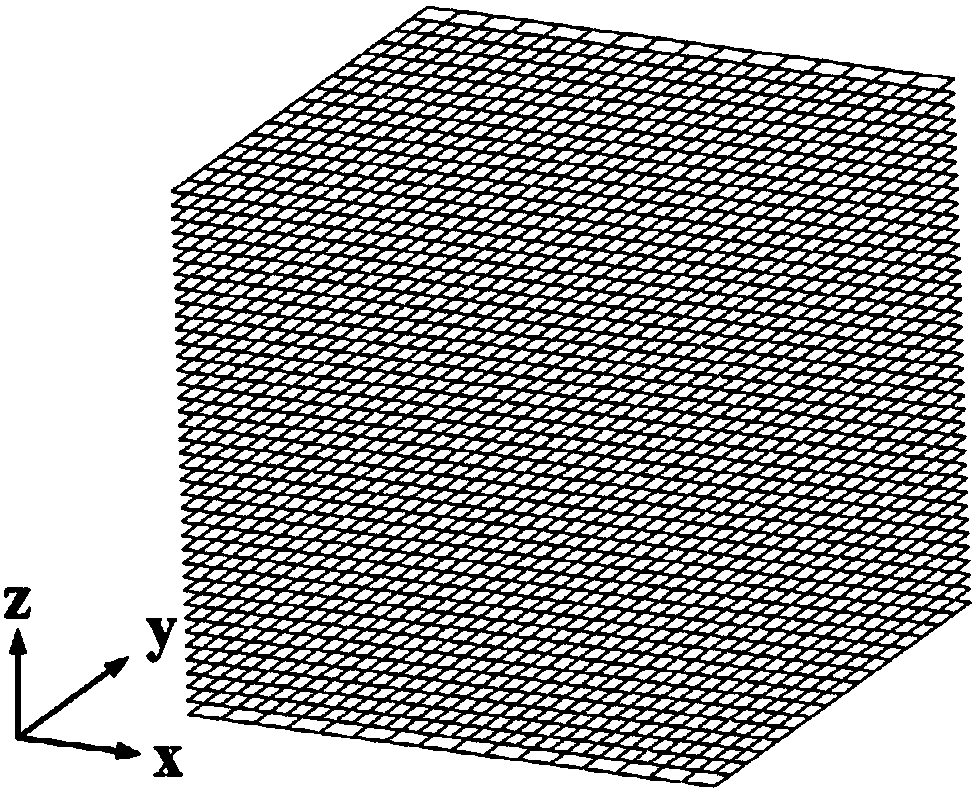

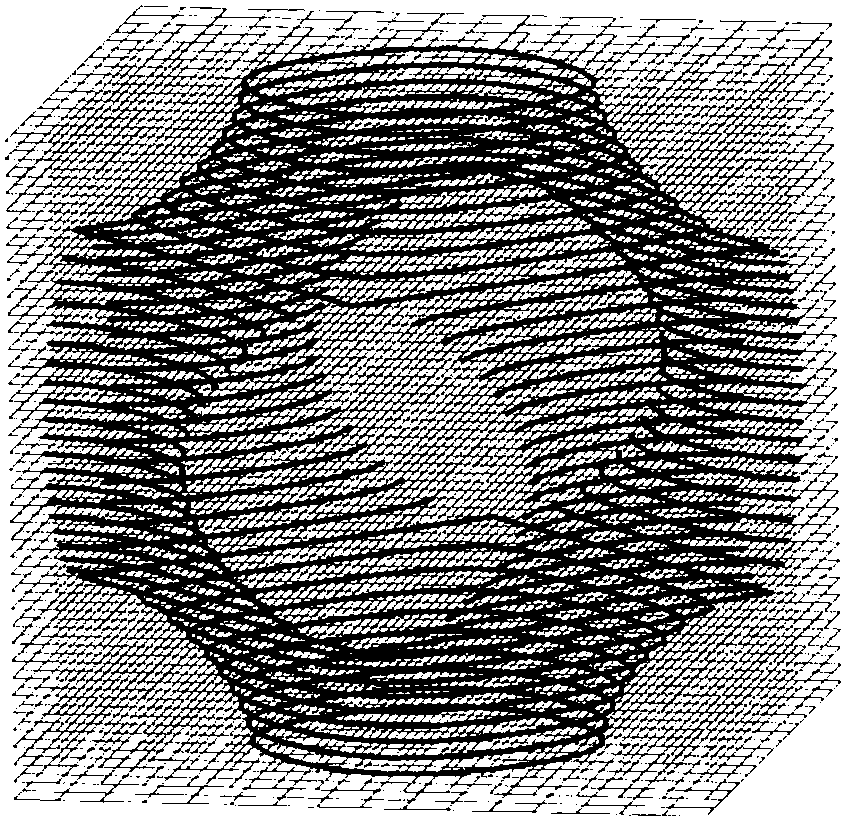

Quick generation method of three-dimensional printing slice contour of triply periodic minimal surface

ActiveCN108327287AGenerate efficientlySave processing timeAdditive manufacturing apparatusManufacturing data aquisition/processingSlice thicknessLayer interface

The invention discloses a quick generation method of a three-dimensional printing slice contour of a triply periodic minimal surface. The method comprises the steps of inputting an expression of the triply periodic minimal surface to be sliced, slice thickness and a slice quadrilateral mesh resolution, generating slice quadrilateral meshes of an area corresponding to the surface according to a co-ordinate distribution range of the triply periodic minimal surface and the slice thickness, calculating slice line segments of the surface and each slice quadrilateral mesh by linear interpolation according to the expression of the surface, storing a topological relationship between the slice line segments and quadrangles in the corresponding slice quadrilateral meshes, sorting all the slice linesegments, and at last, outputting the slice contour generated after sorting in a CLI (common layer interface) file format for storage. The method achieves quick slicing of the triply periodic minimalsurface and quick sorting of scattered slice line segments by using the slice quadrilateral meshes, quickly generates the three-dimensional printing slice contour, and avoids the disadvantages of consumption of much time and a large memory space due to generation of an STL (standard template library) model in the traditional method.

Owner:ZHEJIANG UNIV

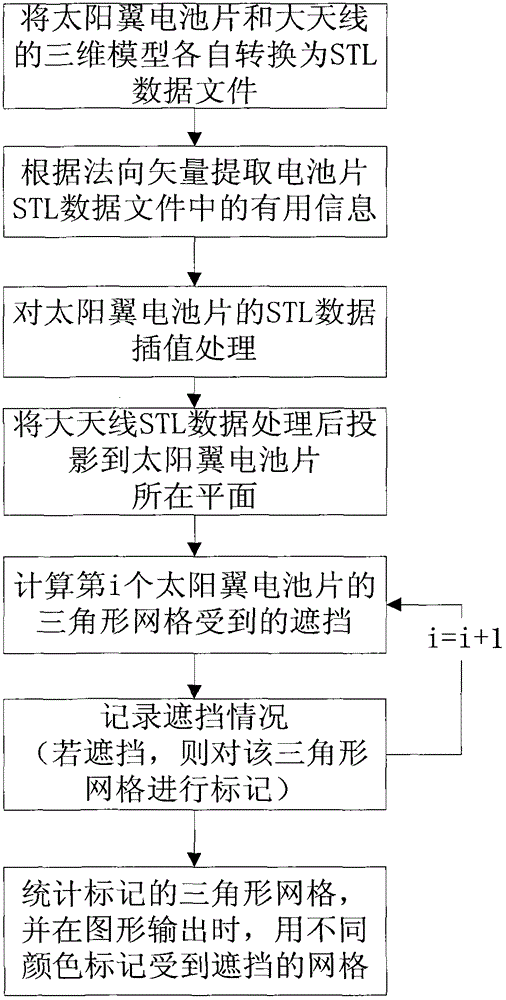

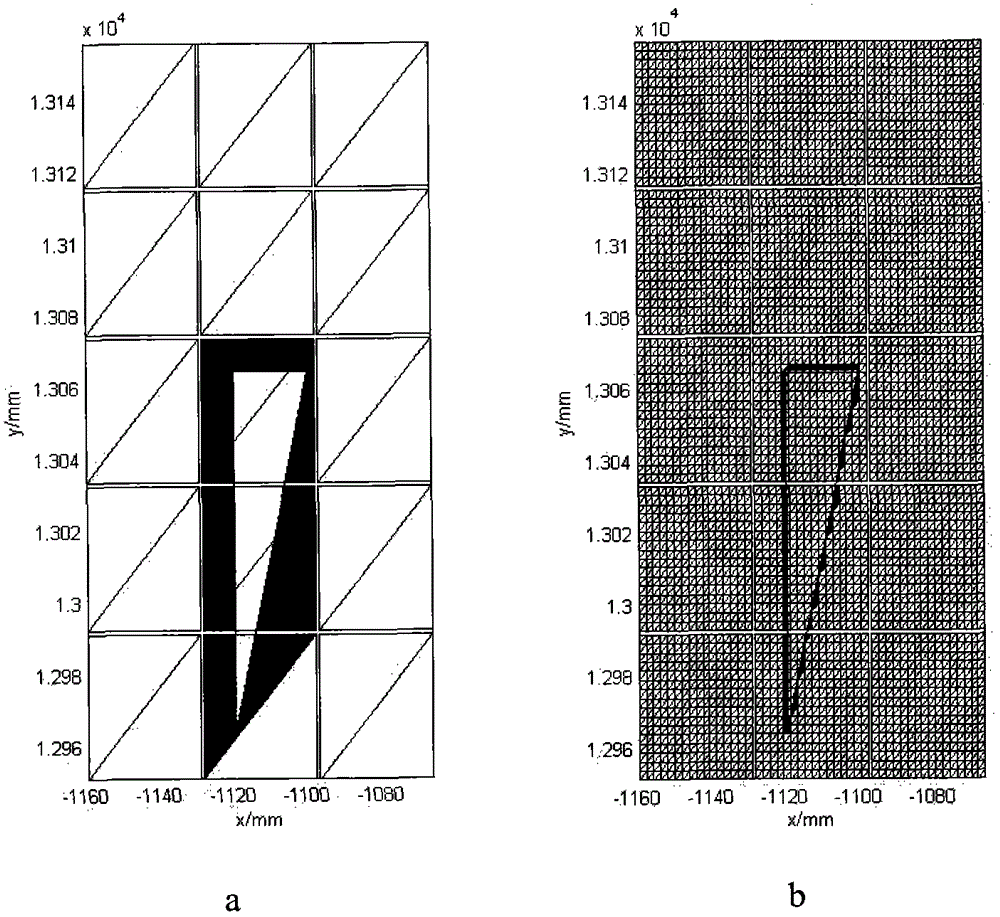

STL (standard template library)-based analysis method on sheltering to solar wing by communications satellite large antenna

The invention relates to an STL (standard template library)-based analysis method on the sheltering to a solar wing by a communications satellite large antenna, and belongs to the technical field of satellite design. The invention provides a method which can effectively analyze the sheltering to the solar wing by the large antenna according to a satellite orbit dip angle and attitude offset, and comprises the steps of firstly, converting a three-dimensional model of an object to be analyzed into an STL data file, secondly, extracting an effective triangular net in solar wing battery piece STL data, thirdly, performing interpolation processing on the triangular net of a solar wing battery piece, fourthly, processing large antenna STL data and then projecting the large antenna STL data to a plane where the solar wing battery piece exists, fifthly, judging the sheltering condition of the battery piece and the triangular net of the large antenna in a two-dimensional plane, and sixthly, computing the sheltering area according to the sheltering condition and generating an analysis graph. The method can obtain the sheltering condition of the large antenna to the solar wing at any moment, is convenient for a power supply and distribution designer to perform intuitive analysis, simplifies the computing process, and is convenient for project implementation.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

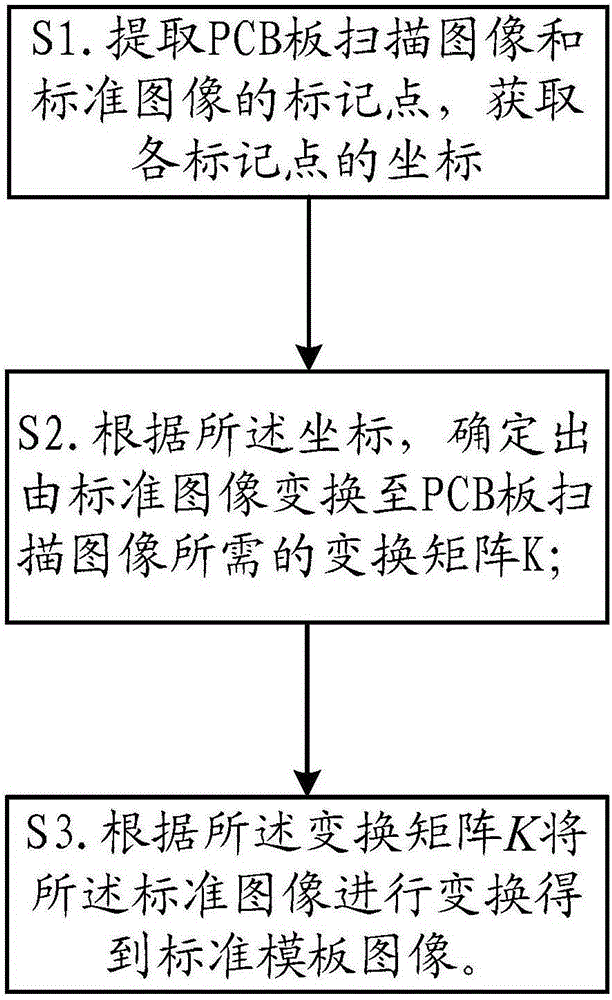

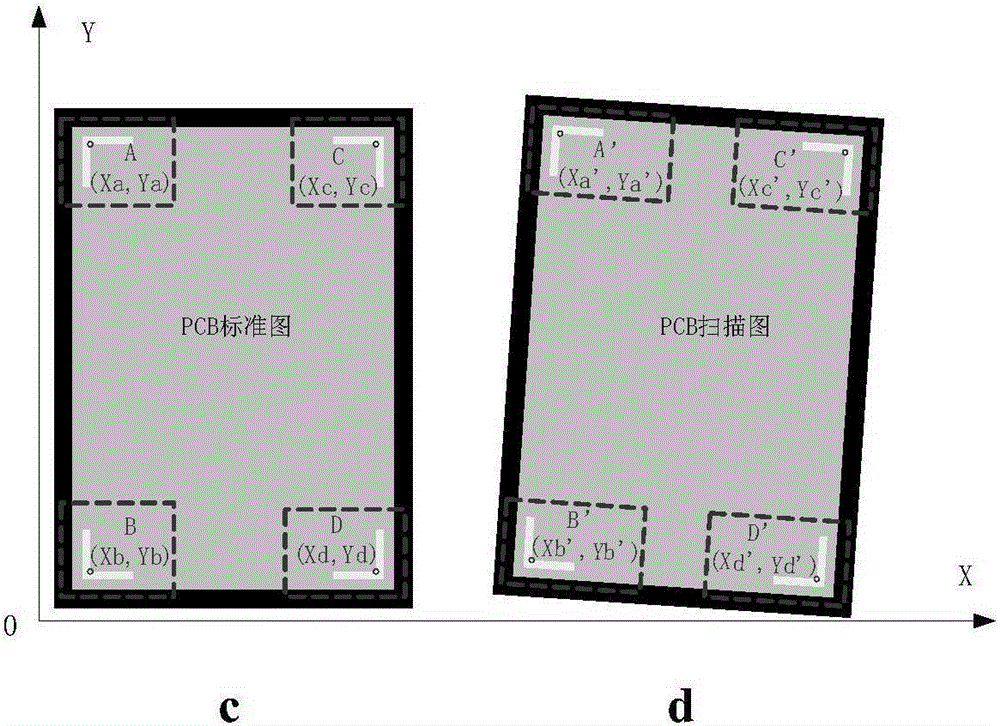

automatic PCB (Printed Circuit Board) scan image matching method and system

The present invention is applicable to the field of image scanning and provides an automatic PCB scan image matching method. The method comprises: step A, extracting marking points of a PCB scan image and a standard image, and acquiring coordinates of the marking points; step B, according to the coordinates of the marking points on the standard image and the coordinates of the marking points in the same positions of the PCB scan image, determining a transform matrix K for transforming the standard image into the PCB scan image; and step C, transforming the standard image according to the transform matrix K to obtain a standard template image. According to the automatic matching method and system provided by the present invention, a space transformation relationship between two images is found out by adopting a bilinear transform algorithm according to corresponding relationships among the coordinates of the similar feature points of the PCB scan image and the corresponding standard image, thereby acquiring a standard image with the same size as the scan image for subsequent defect comparison; and no manual interference is required, matching points can be automatically found out and calculated, the obtained scan image is substantially not distorted, and the matching is relatively precise, so that a foundation is laid for subsequent defect identification.

Owner:SHENZHEN UNIV

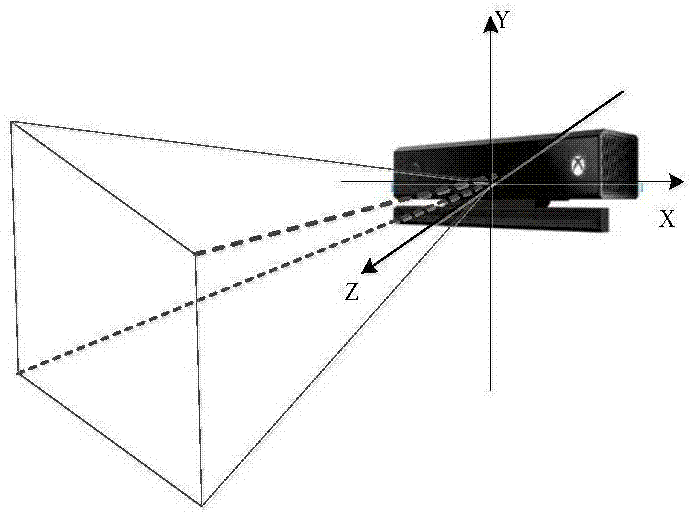

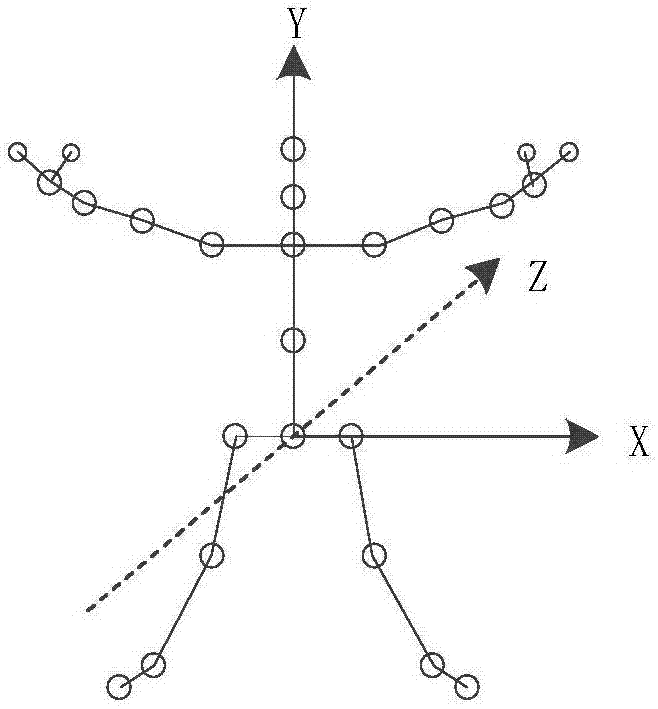

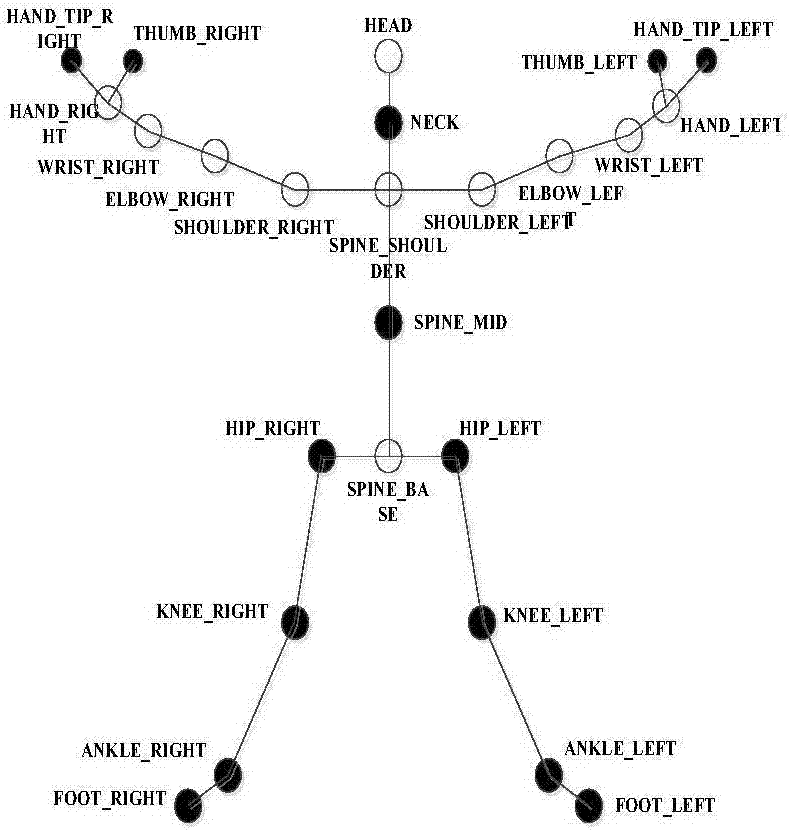

Locomotive hand signal operation training method based on body feeling technology

InactiveCN107293175AImprove interactivityLow costCosmonautic condition simulationsCharacter and pattern recognitionTemplate matchingVirtual training

The invention discloses a locomotive hand signal operation training method based on a body feeling technology and belongs to a virtual training category of virtual reality. In existing hand signal teaching training, a training result can not be fed back in real time, and manual cost is increased and there are many other disadvantages. By using the method of the invention, the above disadvantages are overcome. Based on the body feeling technology, through data acquisition and standard template library establishment, a template matching algorithm is used to carry out real-time assessment on training and a hand signal work training system with good interactivity is established. The method mainly comprises two portions of standard signal library establishment and real-time signal matching training. The invention provides an effective method for railway hand signal training to some extent.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com