Method for automatically generating support of three-dimensional printing part on basis of scanning biasing

An automatic generation and three-dimensional printing technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of large amount of calculation, low processing efficiency, and difficult peeling of supports, and achieves simple operation, easy realization, and principle clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Figure 6 Shown is an STL model of a part to be supported, and now it needs to be supported to ensure that the part will not collapse during the 3D printing process.

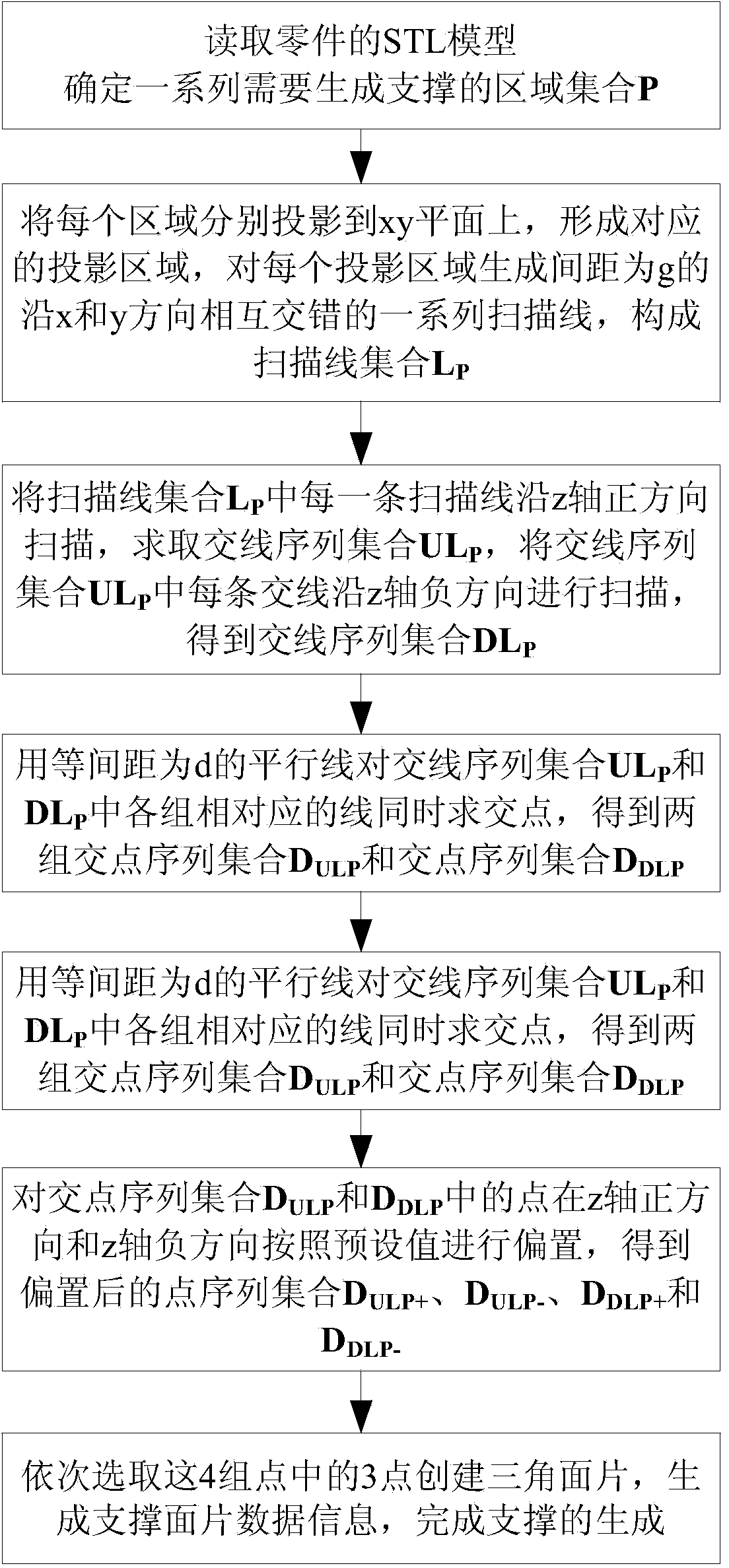

[0042] according to figure 1 The process of identifying the normal vector n of each triangle in the STL model, when the component of n in the z direction is less than Then the triangular face needs to generate support, and the connected triangular faces that need to generate support are combined together to obtain the area to be supported, and multiple areas constitute the area set P={P 1 , P 2 , P 3}, P 1 ,P 2 ,P 3 Respectively for a single region that needs to generate supports, such as Figure 6 shown.

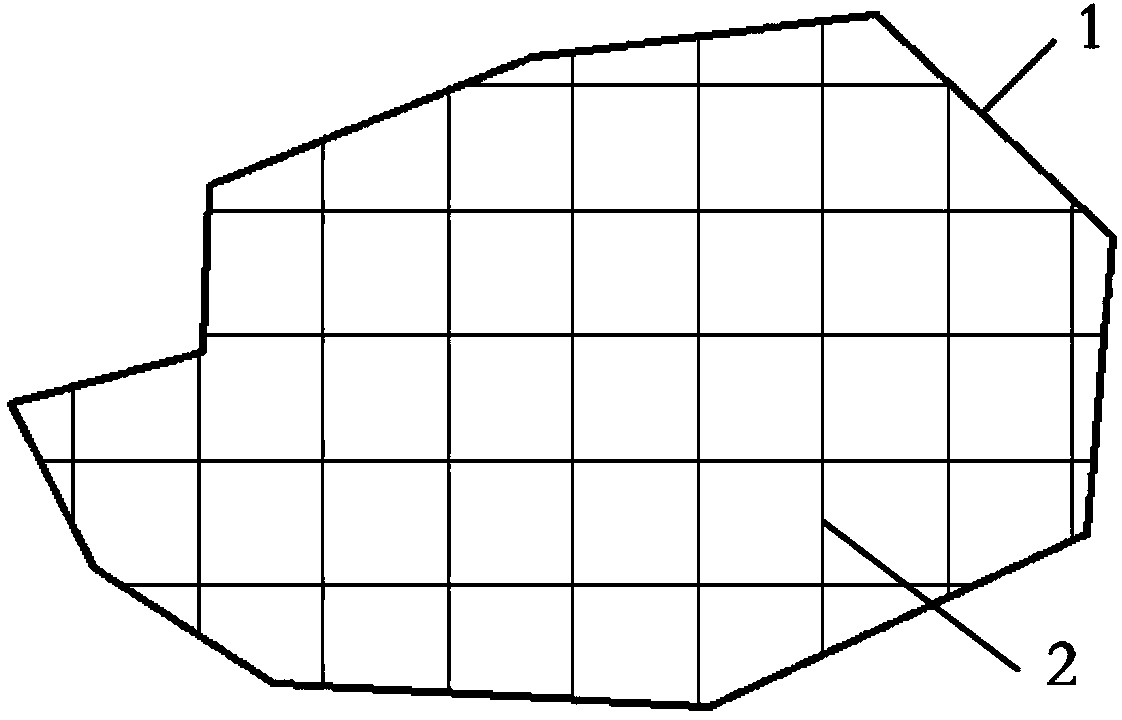

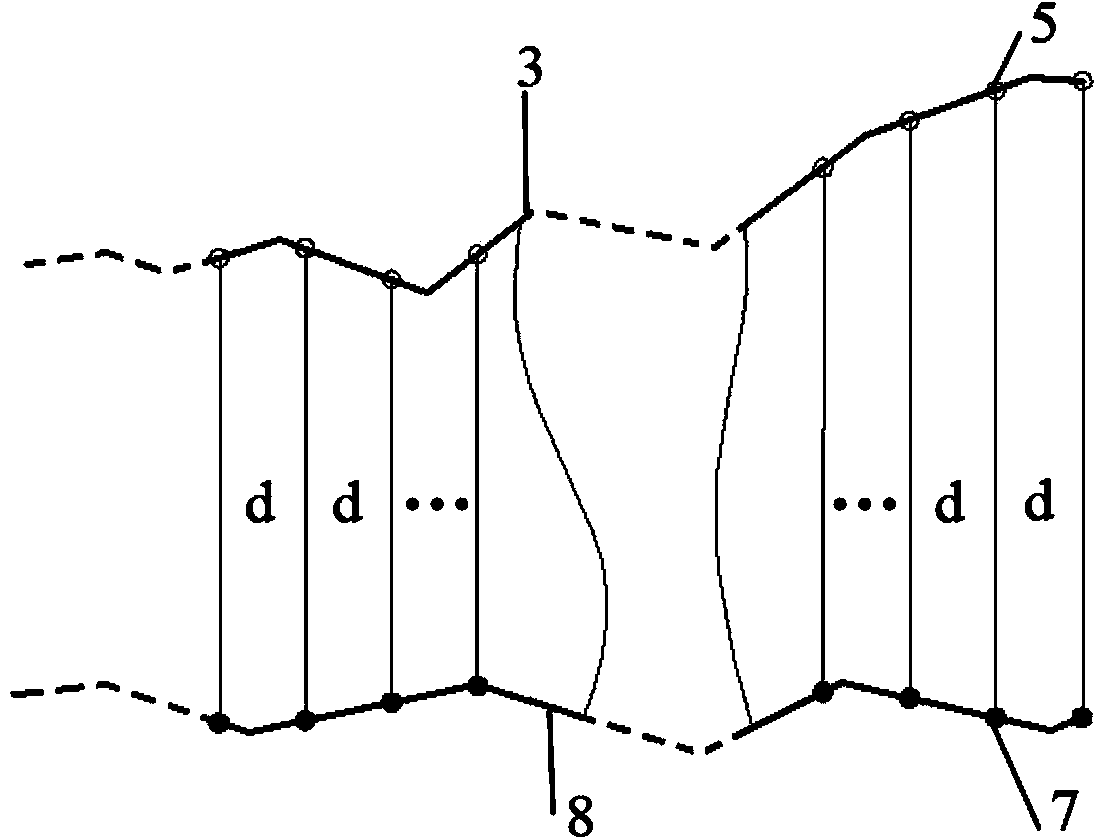

[0043] Such as figure 2 As shown, P 1 ,P 2 ,P 3 Project to the xy plane, and generate a series of scan lines 2 along the x and y directions with a spacing of g=6mm inside each projection area, and the edge projection of the area forms a contour line 1, and P 1 ,P 2 ,P 3 The correspondi...

Embodiment 2

[0055] Figure 9 Shown is a part and its support automatically generated by the present invention, it can be seen from the figure that P E The support in the area is not reasonable enough, too fragile, and the support itself is easy to collapse during the 3D printing process, so this part of the support needs to be manually edited.

[0056] Display P in the visual graphical interface E scanlines within the region, such as Figure 10 As shown in (a), delete the original scan line (automatically generated scan line 13), and manually E Draw the scan line inside to get the manually edited scan line 14, such as Figure 10 As shown in (b), after the editing is completed, P E Regenerate the supports in the area, retain the original supports of other parts, and get the edited supports, such as Figure 11 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com